文章编号:1004-0609(2007)08-1367-06

300 kA铝电解槽中焦粒焙烧过程温度场的仿真优化

李 劼, 伍玉云, 刘 伟, 赖延清, 王志刚, 刘 杰

(中南大学 冶金科学与工程学院, 长沙 410083)

摘 要:使用有限元法建立了300 kA铝电解槽的焦粒焙烧三维1/4整槽模型,针对目前普遍采用焦粒均匀铺设方式,对其焦粒焙烧过程的温度分布与变化特征进行了瞬态数值仿真研究。当前的焦粒焙烧启动方式存在阴极表面温差过大、各阴极炭块随空间位置不同温度分布差异过大、端部第1至第3块阴极炭块平均温度低于900 ℃、阴极炭块和捣固糊升温速度过快等缺陷。提出在阴极表面从电解槽边缘向中心依次铺设电阻率递增的焦粒层的优化焙烧方案,并进行温度场仿真计算。结果表明:该优化方案可以使阴极表面温度分布更加均匀,端部第1至第3块阴极炭块表面温差比优化前降低8%以上,中间第4至第13块阴极炭块表面温差降低30%以上,阴极炭块和阴极缝糊平均升温速度降低12%,该优化方案更有利于减少电解槽的早期破损。

关键词:铝电解;电热场;焦粒焙烧;仿真;优化

中图分类号:TF 821 文献标识码:A

Simulation and optimization of thermal field during coke

preheating process in 300 kA aluminum reduction cell

LI Jie, WU Yu-yun, LIU Wei, LAI Yan-qing, WANG Zhi-gang, LIU Jie

(School of Metallurgical Science and Engineering, Central South University, Changsha 410083, China)

Abstract: A three-dimensional transient thermo-electric finite element model of 300 kA quarter aluminum reduction cell was developed to study the thermal field of carbon cathode during the heating-up process by using the same resistivity coke bed. Many defects such as high difference in temperature in the cathode, non-uniform temperature among the cathode surface, non-uniform temperature among the cathodes at different positions, the arerage temperature in the end cathode carbon block 1 to 3 lower than 900 ℃ and too fast heating-up rate during the process were found. In order to solve this problem, an optimization using increasing resistivity coke bed from the side of the cell to the center to preheat the cell was carried out. The results show that the temperature difference is decreased by more than 8% at the end cathode carbon block 1 to 3 and that in the center cathode carbon block 4 to13 more than 30%. The heating-up rate is decreased by 12% in cathodes. The risk of early failure of the cell lining can be reduced by this optimum scheme.

Key words: aluminum reduction; thermo-electric field; coke bed preheating; simulation; optimization

自筑砌完成以后电解槽必须经历焙烧启动这一过程。电解槽的焙烧过程与槽寿命密切相关,为保证较长的槽寿命,在焙烧时阴极内衬中必须有均衡的热分布和低的热梯度,这样才不致于产生过大的应力而导致阴极破损。焙烧与启动这一过程在电解槽的整个使用寿命内时间很短,但对电解槽的寿命起决定性的作用[1?2]。研究表明,焙烧启动对电解槽寿命的影响程度可达25%[3]。焦粒焙烧具有焙烧时间短,温度上升快、对阴极内衬的热冲击小、能有效弥补施工缺陷等优点,因此成为现代大型预焙槽普遍采用的焙烧技术。但焦粒焙烧温度梯度大,存在局部过热或欠烧的问题[4?6]。因此,研究开发安全、经济、可行的铝电解槽焦粒焙烧方案非常必要。理想的焙烧启动工艺要保证热冲击小、温度梯度小、膨胀应力小、阴极内衬无破损。由于焙烧过程工艺非常复杂而且很难进行分析,工业槽上的实验测试又很困难并且耗时耗资,因此随着计算机技术和数值模拟方法的发展,通过数学模型和数值计算对铝电解槽焙烧过程进行仿真研究是一种经济有效的方法。

Dupuis等[7?10]使用有限元法对电解槽焦粒焙烧过程电?热?应力进行了研究,比较了采用条形和环形两种不同的焦粒层的铺设方式对阴极内衬焙烧启动热应力的影响。李劼等[11]使用有限元方法研究了不同的起始电流和分流制度以及不同电流加载时间间隔对160 kA铝电解槽焦粒焙烧启动升温速度的影响,指出如何保证阴极碳块内温度分布相对均匀、温度梯度最小,是工程实践上急需解决的问题。本文作者从数值仿真的角度,运用有限元分析软件ANSYS 对焦粒焙烧启动过程中铝电解槽内的温度场进行瞬态仿真,并对其温度分布进行分析,从而提出焙烧启动的优化方案。

1 焦粒焙烧的数学模型

1.1 控制方程和边界条件

数学模型是对原型某种性质的抽象、定量描述,是根据过程的内在联系而建立起来的各变量之间的数学关系。数学模型的基本方程、初始条件和边界条件构成了控制方程。

1.1.1 导电控制方程

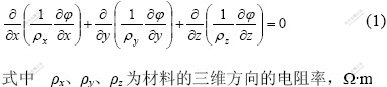

导电过程微分方程为[12]

其值随温度而变,数据来源可参考文献以及测试报告;φ为电位。

1.1.2 导热控制方程

根据传热学的原理,电解槽各组成内的热传导分别服从带有内热源的瞬态热传导控制方程。对三维空间来说,控制方程为[13]

1.1.3 初始边界条件

初始边界条件如下:

1) 电解槽的初始温度为25 ℃;

2) 指定阴极钢棒端部电位为零,阳极母线加载电流;

3) 电解槽槽壳外表面加对流传热和辐射传热边界。

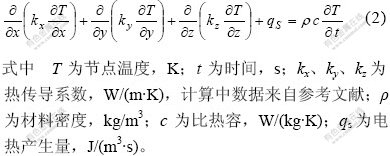

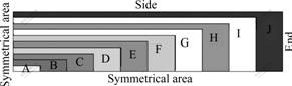

1.2 300 kA铝电解槽三维有限元模型的建立

电解槽模型参照某厂300 kA大型预焙铝电解槽的设计施工图纸建立,电解槽整槽包括40个阳极,26块阴极炭块,104个阴极钢棒。为了方便研究,针对电解槽的对称性,建立了300 kA铝电解槽三维1/4整槽模型(见图1)。模型包括铝导杆、钢爪、阳极、焦粒层、阴极缝糊、阴极、阴极钢棒、内衬、保温材料、耐火材料以及槽壳部分。电解槽内导电部分采用solid69单元划分网格,非导电部分采用solid70单元划分网格,模型全部为六面体网格划分。

图1 300 kA电解槽1/4有限元模型

Fig.1 1/4 finite element model of 300 kA aluminum reduction cell

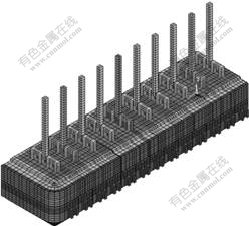

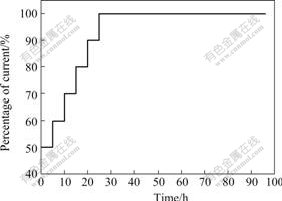

1.3 焦粒焙烧过程电流的加载

电流加载方案示意图如图2所示。在模型中没有分流片,需要通过控制分流阶段加载的电流量来等效分流片的作用。流入阳极母线的电流值如下:整槽的全电流为300 kA,1/4槽电流为300/4=75 kA,按照铝电解槽焙烧启动的分流方案,电流分5步加载,起始电流为总电流的50%,此后每隔5 h增加10%,25 h后加至全电流焙烧。

图2 电流加载方案示意图

Fig.2 Diagrammatic sketch of current uploading

2 模型验证和算例分析

2.1 模型验证

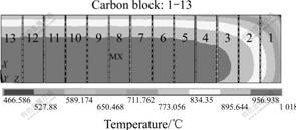

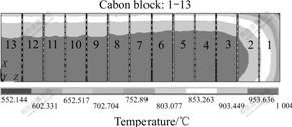

工业应用上焙烧过程采用均匀一致的焦粒铺设方式,模型焙烧96 h后的阴极炭块的温度分布如图3所示,焙烧结束后电解槽最高温度位于电解槽中心区域,最高温度达到1 018 ℃,最低温度位于端部阴极炭块1的角部,其值为466 ℃,阴极表面平均温度为921 ℃。本文计算结果和实测结果[14]吻合很好,说明模型具有可靠性。

图3 焦粒均匀铺设条件下焙烧96 h后阴炭块的温度分布

Fig.3 Isotherms of cathode carbon block preheated by homogeneous resistivity coke bed for 96 h

2.2 算例结果分析

角部炭块1位于电解槽的低温区,其温度位于466~866 ℃之间,温度差高达400 ℃,平均温度仅为746 ℃,温度明显偏低。炭块8在焙烧结束时处于高温区,其表面平均温度为951 ℃,符合启动要求。

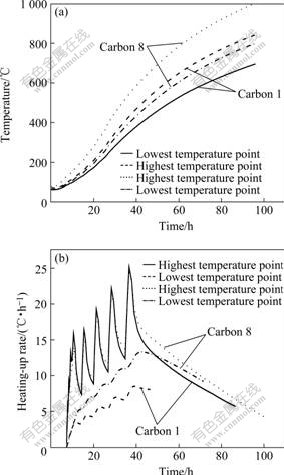

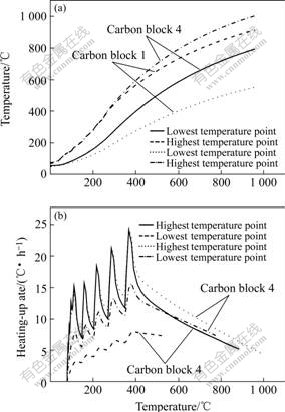

图4所示为电解槽阴极炭块的升温曲线,该升温速度曲线和Mohmmed[10]计算出的升温曲线分布趋势一致。由图4(b)可知,图4(a)开温曲线与炭块8中温度最高点的升温速度最大,最大升温速度为25.01 ℃/h,位于400 ℃左右,在200~600 ℃之间的升温速度平均值为16.53 ℃/h。当温度低于435 ℃时,炭块1中温度最高点升温速度和炭块8中温度最高点的升温速度相接近,当温度高于435 ℃后二者的升温速度都有所下降,但炭块1中温度最高点的升温速度低于炭块8中温度最高点的升温速度。炭块1温度最高点在200~600 ℃之间的平均升温速度为13.51 ℃/h。

图4 典型阴极炭块升温曲线和升温速度曲线

Fig.4 Heating-up curves (a) and heating-up rate curves in typical cathode blocks

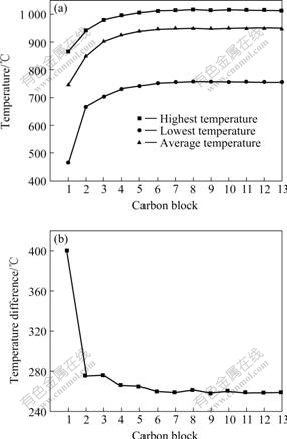

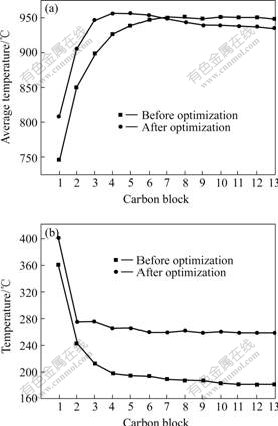

图5(a)所示为不同炭块表面最高温度、最低温度以及平均温度的分布情况,炭块1至炭块3的表面温度较低,平均表面温度在900 ℃以下,且温差较大。图5(b)显示端部炭块1的最高温度和最低温度之差高达400 ℃,其余炭块的温差介于258~275 ℃之间。温差大导致温度梯度也大。电解槽的早期破损主要原因就是由于焙烧过程电解槽阴极和内衬中温度梯度过大而引起的热应力过大,从而导致电解槽阴极内衬的早期开裂和阴极炭块上抬。

图5 不同位置阴极炭块温度对比

Fig.5 Comparison of temperatures of different cathode blocks: (a) Highest, lowest and average temperatures; (b) Temperature difference

3 焙烧工艺的温度场优化

3.1 优化方案

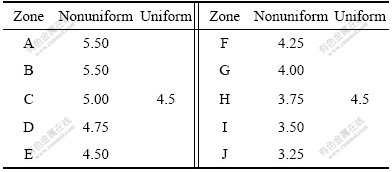

为使阴极表面温度分布更均匀,实验中考虑采用不同电阻率的焦粒层铺设方式。在阴极表面从电解槽边缘向中心依次铺设电阻率递增的焦粒层,从而改善电流密度的分布以达到改善温度场的目的。不同电阻率的焦粒可以是煅后石油焦或者石墨粉或者二者的混合物,因为煅后石油焦电阻率大,石墨粉电阻率小,二者通过不同的比例混和,即可以得到不同电阻率的焦粒层。焦粒层电阻率如表1所示。铺设方式如图6所示,不同区域焦粒层电阻率由大到小的顺序如下:ρA>ρB>ρC>ρD>ρE>ρF>ρG>ρH>ρI>ρJ。

表1 焦粒层电阻率

Table 1 Resistivty of coke layer in different zones(10?3 Ω?m)

图6 非均匀焦粒层铺设方式示意图

Fig.6 Sketch map of different resistivity coke beds covered on cathode blocks

3.2 优化结果分析

焙烧时间仍然是96 h,计算结果如图7所示,最高温度为1 004 ℃,比优化前降低1.37%,最低温度为552 ℃,比优化前升高了18.5%,整个阴极表面的平均温度为931 ℃,比优化前表面温度升高1.11%。

图7 采用非均匀焦粒层焙烧96 h后阴极炭块的温度分布

Fig.7 Isotherms of cathode carbon block preheated by different resistivity coke beds for 96 h

为方便比较,选取阴极高温区的阴极炭块4和低温区的炭块1作为研究对象。端部炭块1的表面温度差为361 ℃,温差比优化前降低9.6%。炭块4温度介于786~1 004 ℃之间,表面平均温度为956 ℃,完全符合电解槽启动要求。

图8所示为优化前后炭块温度对比。从图8(a)可以看出,优化后阴极表面平均温度和优化前相比,端部炭块1至炭块6温度有所升高,而中间炭块7至炭块13温度有所下降。从图8(b)看出,优化后各阴极炭块表面温差明显降低,端部炭块1和炭块2的温差降低8%以上;中间炭块3至炭块13的表面温差降低 30%以上,这也说明优化后电解槽阴极内部温度梯度明显降低,从而可以降低电解槽的早期破损的风险。

图8 优化前后炭块温度对比

Fig.8 Comparison of temperatures of different cathode blocks between after and before optimization: (a)—Average temperature; (b)—Temperature difference

优化后炭块温度的升温曲线如图9(a)所示,在进行全电流焙烧以前端部炭块1温度最高点的升温曲线和阴极炭块4温度最高点的升温曲线基本重合,全电流焙烧以后,炭块4的温度最高点的温度始终高于炭块1的,而炭块4温度最低点的温度在焙烧过程中低于炭块1中温度最高点的温度,炭块1中温度最低点的温度始终最低。升温速度曲线如图9(b)所示。由图可知,炭块1和炭块4中温度最高点的升温速度在418 ℃之前基本一致,当温度高于418 ℃以后,炭块4中温度最高点的升温速度大于炭块1中温度最高点的升温速度。炭块4温度最高点的最大升温速度出现在385 ℃左右,其值为23.89 ℃/h,比优化前降低4.48%,在200~600 ℃之间的平均升温速度为14.46 ℃/h,比优化前降低12.52%,即无论是最大升温速度还是平均升温速度都比优化前有所降低。200~600 ℃是捣固糊内挥发分排出的温度范围,在此范围内升温速度的降低有利于挥发分的缓慢排出,降低了挥发分排出过快引起捣固糊开裂的风险,对降低铝电解槽早期破损有很大帮助。

图9 优化后典型炭块的升温曲线和升温速度曲线

Fig.9 Heating-up curves and heating-up rate curves in typical cathode blocks after optimization: (a)—Heating-up curves; (b)—Heating-up rate curves

4 结论

1) 建立了300 kA铝电解槽三维1/4整槽模型,对现行电解槽焦粒焙烧的阴极温度场进行仿真研究,研究发现采用均匀一致的焦粒层焙烧时阴极炭块表面温差较大,最高温差达到400 ℃;端部炭块1、炭块2和炭块3表面的平均温度低于900 ℃,未达到启动要求。阴极炭块在200~600 ℃范围内平均升温速度偏大,不利于捣固糊的焙烧。

2) 提出一个焦粒焙烧优化方案,采用非均匀一致的焦粒层焙烧后,阴极炭块表面温度趋于均匀,平均温度为931 ℃,比优化前温度有所提高,更有利于电解槽的启动;阴极表面温差明显降低,端部炭块1和炭块2在优化后的温差比优化前温差降低8%以上;优化后中间炭块3至炭块13的表面温差比优化前降低30%以上,这也说明优化后电解槽阴极内部温度梯度也明显降低,这更有利于减少电解槽的早期破损的风险。

3) 优化后炭块4中温度最高点的最大升温速度出现在385 ℃左右,其值为23.89 ℃/h,比优化前降低4.48%,在200~600 ℃之间的平均升温速度为14.46 ℃/h,比优化前降低12.52%。无论是最大升温速度还是平均升温速度都比优化前有所降低,200~600 ℃是捣固糊内挥发分排出的温度范围,在此范围内升温速度的降低有利于挥发分的缓慢排出,降低了挥发分排出过快引起捣固糊开裂的风险。

REFERENCES

[1] 张 力, 伍成波, 潘良明, 冉景煜, 辛明道. 铝电解质预焙槽气体焙烧流场与温度场数值模拟[J]. 烧料科学与技术, 2002, 8(4): 377?380.

ZHANG Li, WU Cheng-bo, PAN Liang-ming, RAN Jing-yu, XIN Ming-dao. Numerical simulation of the temperature and flow fields of the gas baking method for heating aluminum electrolgtic cells[J]. Journal of Combustion Science and Technology, 2002, 8(4): 377?380.

[2] 游 旺, 王前普, 李欣峰, 梅 炽. 铝电解槽槽膛内形在线动态仿真理论研究[J]. 中国有色金属学报, 1998, 8(4): 695?699.

YOU Wang, WANG Qian-pu, LI Xin-feng, MEI Zhi. Online dynamic simulation of freeze profile in aluminum reduction cells[J]. The Chinese Journal of Nonferrous Metals, 1998, 8(4): 695?699.

[3] Arkhipov G, Pingin V. Investigating cathode strained-stressed state in the aluminum electrolysis cell[C]//Wolfgang Schneider Light Metals 2002. Seattle, Washlogton, USA: TMS, 2002: 347?354.

[4] 刘永刚, 唐 骞, 梁 韬. 铝电解大型预焙槽四种焙烧方法的比较[J]. 轻金属, 2000(4): 32?35.

LIU Yong-gang, TANG Qian, LIANG Tao. The comparison of four methods used to preheat large aluminum reduction cell[J]. Light Metals, 2000(4): 32?35.

[5] Bentzen H. Gas preheat and start of soderberg cells[C]//Elwin rooy. Light Metals 1991. New Orleans, Louisiana, USA: TMS, 1991: 741?747.

[6] Rolofs B. Thermal bake-out of aluminum reduction cells[C]//A technology for the future. Seattle, Washlogton, USA: TMS, 2002: 343?346.

[7] Dupuis M, Géni S. Usage of a full 3D transient thermo-electric FE model to study the thermal gradient generated in the lining during a coke preheat[C]//Joseph Anjier. Light Metals 2001. New Orleans, Louisiana, USA: TMS, 2001: 757?761.

[8] Dupuis M, Asadi G, Read C. Thermal study of the coke preheating for hall-Héroult cell[C]//CIM Conference. Québec, Canada: TMS, 1993: 93?100.

[9] Dupuis M, Tabsh I. Evaluation of thermal stresses due to coke preheat of a hall-Héroult cell[C]//Ansys Conference, 1994: 15?23.

[10] Goulet P, Laberge C, Lacroix R, Perron K L. Modeling of the coke bed used in the electrical preheat of an aluminum reduction cell[C]// Wolfgang Schneider Light Metals 2002. San Diego, USA: TMS, 2003: 263?268.

[11] LI Jie, LIU Wei, ZHANG Qin-song, LAI Yan-qing, LIU Ye-xiang, HU Guo-rong. Simulation study on the heating-up rate for coke bed preheating of aluminum reduction cell[C]//Travis J. Galloway Light Metals 2006. San Antonio, USA: TMS, 2006: 681?685.

[12] 郭宽良. 计算传热学[M]. 合肥: 中国科学技术大学出版社, 1988.

GUO Kuan-liang. Theory of calculating heat transfer[M]. Hefei: China Science and Technology University Press, 1998.

[13] 陶文铨. 数值传热学[M]. 西安: 西安交通大学出版社, 1988.

TAO Wen-quan. Theory of numerical heat transfer[M]. Xi’an: Xi’an Jiaotong University Press, 1988.

[14] 赵无畏, 赵 群, 谢雁丽, 邱竹贤, 田 强. 现代预焙铝电解槽预热焦粒焙烧启动研究[J]. 轻金属, 2003(2): 34?39.

ZHAO Wu-wei, ZHAO Qun, XIE Yan-li, QIU Zhu-xian, TIAN Qiang. Study on coke powder bake preheat start-up of modern prebaked pot[J]. Light Metals, 2003(2): 34?37.

基金项目:国家自然科学基金资助项目(50374081)

收稿日期:2006-10-12;修订日期:2007-05-10

通讯作者:李 劼,教授,博士;电话:0731-8830474;E-mail: wuyuyun8182@163.com

(编辑 龙怀中)