文章编号:1004-0609(2016)-05-0988-07

Cu-Mn-Ni-Ag钎料高频感应钎焊2Cr13不锈钢接头的显微组织与性能

郑 义,颜家振,李 宁,曹永同,帅 帆

(四川大学 制造科学与工程学院,成都 610065)

摘 要:采用新型的Cu-Mn-Ni-Ag中温铜基钎料高频感应钎焊2Cr13不锈钢,并对钎料的工艺特性、钎焊接头的显微组织以及测试温度对钎焊接头力学性能的影响进行研究。结果表明:Cu-Mn-Ni-Ag钎料的熔点约为880 ℃,由富Ag相、Cu-Mn-Ni固溶体以及少量的Ni-Mn-Si化合物组成;钎料与2Cr13不锈钢产生良好的冶金结合,且钎焊接头组织致密;界面反应区的组织为Fe-Mn-Ni-Cr-Cu固溶体,钎缝区组织由富Ag相、Cu-Mn-Ni固溶体和少量的Ni-Mn-Si化合物组成;钎焊接头断裂于钎缝中间的富Ag相和CuMnNi固溶体上,为以剪切韧窝为主的韧性断裂,室温剪切强度最大可达369 MPa,在400 ℃、500 ℃和600 ℃下接头的剪切强度分别为251 MPa、208 MPa和84 MPa。

关键词:铜基钎料;Cu-Mn-Ni-Ag;高频感应钎焊;2Cr13;显微组织;剪切强度

中图分类号:TG425;TG454 文献标志码:A

钎焊技术是一门精密且可靠的连接技术,广泛应用于不锈钢构件的连接,比如压气体涡轮、燃气轮机换热器以及发动机燃油总管等零部件[1-3],这些不锈钢钎焊构件多应用于比较恶劣的工况环境,要求具有良好的强度、耐蚀性以及一定的耐热性。镍基钎料是目前用于钎焊不锈钢的主要钎料,具有较好的热强性、耐腐蚀性以及抗氧化性[4]。但是大部分镍基钎料的熔点比较高,钎焊温度多在1050~1200 ℃之间[5-8],过高的钎焊温度易导致不锈钢晶粒粗大,使母材的性能变差;其次,镍基钎料中含有大量易形成脆性金属间化合物的B、Si、P等降熔点元素[9],这会使钎缝中形成难以消除的连续脆性金属间化合物,降低接头力学性能。

针对镍基钎料的不足,近年来发展了一系列Cu-Mn-Ni体系为基的铜基钎料。柴静等[10]制备了34Cu-16Mn-44Ni-4B-2Si钎料合金,在1200 ℃下真空钎焊304不锈钢,粘接强度达到386 MPa。但上述钎料因Ni含量过高,导致钎焊温度很高。王鼎钟[11]研制一种用于钎焊1Cr13不锈钢的Cu-Mn-Ni-Zn钎料,该钎料熔点≤920 ℃,500 ℃的钎料强度≥127 MPa。马向阳等[12]研制了Cu-33Mn-8Ni-5Sn-1Zn-0.2Si-0.1La钎料,该钎料熔点的较低(872.3℃),具有良好润湿性和较高的抗拉强度,可以用于碳钢钎焊。杨光等[13]设计了一种熔点为890 ℃的Cu-Mn-Ni-Si钎料(36.5%~ 38.5%Mn(质量分数,下同),4.5%~5.5%Ni,1.5%~ 2.0%Si,余量为Cu)用于2Cr13不锈钢的钎焊,研究发现,当钎焊温度为1050 ℃时,接头剪切强度达到321 MPa。以上研究表明:Cu-Mn-Ni基钎料在适当的成分配比下,可以获得较低的熔点,并能取得较高的接头强度,但这些研究仅侧重于钎料制备或室温性能的研究,对接头的组织形成以及高温性能研究较少,因此有必要进一步深入研究。

在Cu-Mn-Ni体系中加入合金元素Ag有利于进一步降低钎料的熔点、提高钎料的塑形和钎焊工艺性,但是Cu-Mn-Ni-Ag钎料在相关文献中鲜有报道,因此本文作者制备了一种新型的Cu-Mn-Ni-Ag中温铜基钎料,以期能获得综合性能良好的不锈钢钎焊接头。研究Cu-Mn-Ni-Ag钎料的显微组织和熔化特性、2Cr13不锈钢钎焊接头的显微组织以及测试温度对力学性能的影响,对接头组织和力学性能进行分析,为这种钎料的工程应用进行前期探索以及提供实验基础。

1 实验

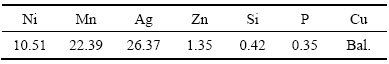

Cu-Mn-Ni-Ag钎料的化学成分如表1所列,采用真空感应熔炼,浇注成铸锭后,轧制成厚度为0.2 mm的片材。采用的母材为2Cr13 马氏体不锈钢,化学成分如表2所列。

表1 Cu-Mn-Ni-Ag钎料的化学成分

Table 1 Chemical composition of Cu-Mn-Ni-Ag filler alloy (mass fraction, %)

表2 2Cr13的化学成分

Table 2 Chemical composition of 2Cr13 (mass fraction, %)

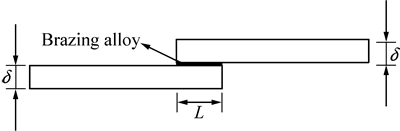

2Cr13马氏体不锈钢线切割成50 mm×12 mm×2mm片材,依次使用320号、600号及1000号SiC砂纸将不锈钢和钎料打磨光亮,放入丙酮中超声清洗15 min待用。钎焊试样采用搭接接头,如图1所示,搭接长度为3 mm。钎焊设备为高频感应真空钎焊炉,采用CX2015A型感应加热电源,最大输出功率为15 kW。将装配好的试样置于炉内,当炉内真空度优于8×10-3 Pa后充氩气至250 Pa,然后通电加热,钎焊电流为530 A,通过窗口观察到钎料明显熔化并填缝时保持加热5 s后断电,从开始加热到加热结束的钎焊总时间约为70~90 s。钎焊结束后,采用RGX-M300型电子万能试验机测试钎焊接头室温和400 ℃、500 ℃、600 ℃的剪切强度。测试高温强度前,先将试样加热到测试温度并保温10 min。

将钎焊接头制作成金相试样,经打磨抛光后使用腐蚀液(5 g FeCl3+5 mL HCl+95 mL无水乙醇)进行腐蚀,以便对显微组织的进行分析。使用NETZSCH STA 449F3型差示扫描量热仪和X射线衍射仪(XRD)分析钎料的熔化特性和物相;采用装配有X射线能谱仪(EDS)的HITACHI S-4800型扫描电子显微镜(SEM)对钎料和焊缝的显微组织和化学成分进行分析;利用HVS-1000型数显显微硬度计测量钎料不同相的硬度。

图1 2Cr13/2Cr13钎焊搭接示意图

Fig. 1 Schematic diagram of 2Cr13/2Cr13 brazing joint

2 结果与分析

2.1 钎料的分析

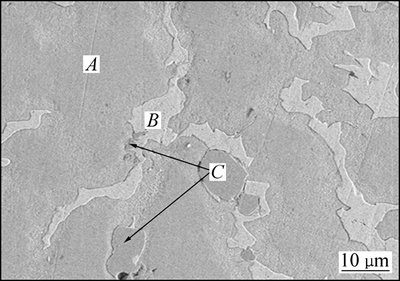

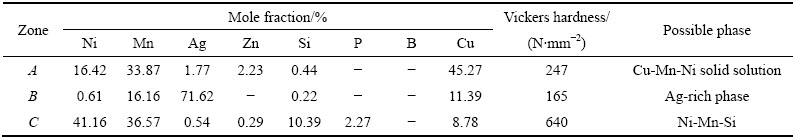

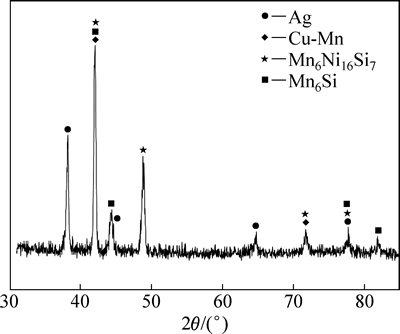

Cu-Mn-Ni-Ag钎料的显微组织(见图2)表明钎料由3个不同的区域组成:基体区域A、带状区域B以及独立的颗粒状区域C。表3所列为钎料中不同区域的EDS分析结果及维氏硬度大小。根据维氏硬度的测试结果,C区的平均硬度(640HV)是最高的,远大于A区(247HV)和B区(165HV)的平均硬度,由此推断C区可能为一种化合物,A区和B区可能是具有较好塑性的固溶相。根据化学成分的分析结果,区域A的主要元素成分为45.27%Cu、33.87%Mn和16.42%Ni(质量分数),根据CuMn、CuNi以及NiMn的二元相图[14],该区域形成固溶了少量Ag、Zn、Si的Cu-Mn-Ni固溶体;区域B含有大量的Ag,是一种富Ag相;区域C含有41.16%Ni、36.57%Mn和10.39%Si,结合C区的高硬度来判断,区域C是一种含有Cu和P的Ni-Mn-Si化合物。XRD分析的结果(见图3)也证实了钎料由富Ag相、CuMn固溶体相以及Ni-Mn-Si之间形成的化合物组成。

图2 Cu-Mn-Ni-Ag钎料的显微组织

Fig. 2 Microstructures of Cu-Mn-Ni-Ag filler alloy

表3 图2中钎料各区EDS分析结果和维氏硬度

Table 3 EDS analysis and Vickers hardness of different zone of filler alloy in Fig. 2

图4所示为钎料的DSC曲线,图4中曲线有3个不同的吸热峰(在图4中标为Ⅰ,Ⅱ,Ⅲ),这表明钎料中存在着3种不同熔点的相。峰Ⅰ的峰值温度为786 ℃,代表富Ag相的液相线温度;峰Ⅱ的峰值温度为880 ℃,代表Cu-Mn-Ni固溶体的液相线温度;峰值温度为1024 ℃的峰Ⅲ代表Ni-Mn-Si化合物的液相线温度。不过从图4中可看出,峰Ⅲ强度远弱于峰Ⅰ和峰Ⅱ强度,可以忽略,故可认为钎料的熔点约为880 ℃。

图3 Cu-Mn-Ni-Ag钎料的XRD谱

Fig. 3 XRD pattern of Cu-Mn-Ni-Ag filler alloy

图4 Cu-Mn-Ni-Ag钎料的DSC曲线

Fig. 4 DSC curve of Cu-Mn-Ni-Ag filler alloy

2.2 钎焊接头的显微组织分析

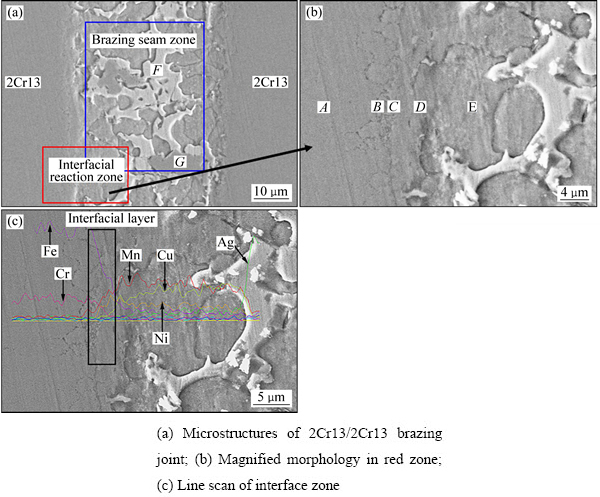

图5(a)所示为钎焊接头的显微组织,钎焊接头由3个区域组成:母材、界面反应区和钎缝区。其中钎缝区组织致密,根据E、F和G的化学成分(见表4),钎缝区也是由3种相组成:Cu-Mn-Ni固溶体(E)、富Ag相(F)和少量的Ni-Mn-Si化合物(G)。界面反应区是钎料与母材冶金结合的区域(见图5(b)),更确切地说,从图5(b)中可以看出界面反应区是钎料中的Cu-Mn-Ni固溶体与母材的结合区域,可以观察到界面反应区没有形成任何空洞、裂纹或第二相,说明母材与钎料形成良好的冶金结合。图5(c)所示为界面处的线扫图,结合表4中点A到点E的成分分析结果,界面区域从点A到点E元素成分的变化趋势为:Fe、Cr元素的含量逐渐减少,Cu、Mn、Ni元素的含量逐渐增加,界面反应区几乎不含Ag。母材中Fe和Cr元素含量的减少(点B)是因为母材向钎料中发生了溶解扩散。根据FeMn、FeNi以及FeCu的二元相图[14],Mn、Ni可以完全固溶于Fe中,而Cu在Fe中的最大固溶度只有13%,因而Mn、Ni元素扩散到母材的距离大于Cu扩散到母材的距离,这与线扫图中的元素分布结果相吻合。Ag与界面处各元素之间的固溶度都很小,因此在界面处含量非常少。根据图5(c)中曲线的变化情况,可以算出界面反应区大约只有4 μm厚,说明钎料与母材中各元素的扩散距离都很短,这是由于感应钎焊时间很短而限制了钎料与母材进一步的冶金反应和元素的溶解扩散。

根据钎焊接头的元素分布特点,接头的形成过程可解释为:在钎焊过程中,当钎料熔化后,母材开始被液相的钎料溶解,Mn、Ni与Fe在液相时无限固溶,并且Cu在Fe中具有一定的溶解度,导致界面处的液相中Fe、Cr元素浓度变高,使得界面处的液相线升高,当液相线高于钎焊温度后,这些高熔点液相在母材表面形核并长大[15],很快就在母材表面形成一层很薄的固溶体相,这层先凝固的固溶体可表示为Fe-Mn-Ni-Cr-Cu固溶体,当Fe-Mn-Ni-Cr-Cu固溶体完全覆盖母材表面后,由于钎料与母材之间元素的扩散由原来的溶解扩散变成固相扩散,使得Fe-Mn-Ni-Cr- Cu固溶体的长大速度变得很慢,加上钎焊时间短,最后在母材表面就形成了很窄的界面反应区;待钎焊加热结束后,Cu-Mn-Ni固溶体紧挨着Fe-Mn-Ni-Cr-Cu固溶体形核、长大并向钎缝区扩展,这符合线扫图(见图5(c))中界面区域的元素分布特点。因为Ag在Cu-Mn-Ni固溶体中的固溶度很小,致使残余的液相富银,当温度进一步降低,残余的液相凝固并形成富Ag相,即钎缝区中的带状组织;由于钎料中的Ni-Mn-Si化合物熔点高于钎焊加热过程中的钎焊温度,加上钎焊过程的热循环很短,所以钎焊时Ni-Mn-Si化合物只是被少量溶解而并未完全熔化,被溶解部分中的Si元素扩散到界面区,这与界面区分布的Si元素相吻合(见表4中B、C、D)。

图5 2Cr13/2Cr13钎焊接头的显微组织及界面区的元素成分线扫图

Fig. 5 Microstructures of 2Cr13/2Cr13 brazing joint and line scan of interface zone

表4 图5中钎焊接头不同区域的EDS分析结果

Table 4 EDS analysis of different zones of brazing joint in Fig. 5

2.3 接头力学性能分析

表5所列为10组钎焊接头室温剪切强度,接头剪切强度最高可达369 MPa,平均剪切强度为328 MPa。图6所示为测试温度对钎焊接头力学性能的影响,钎焊接头剪切强度随着测试温度的升高而降低,当测试温度为400 ℃和500 ℃时仍然保持较高的剪切强度,分别达到251 MPa与208 MPa,当测试温度为600 ℃时接头强度明显降低,只有84 MPa。

表5 钎焊接头的室温剪切强度

Table 5 Room temperature shear strength of brazing joints

图6 测试温度对钎焊接头力学性能的影响

Fig. 6 Effect of testing temperature on mechanical properties of brazing joints

图7 钎焊接头室温剪切测试后的断口横截面显微照片及断口形貌

Fig. 7 Cross sectional micrographs (a) and fracture surface morphologies (b) of brazing joint after room temperature shear test

图7(a)所示为钎焊接头在室温拉断后的断口横截面显微照片,钎焊接头的断口平整,断裂的位置位于钎料中间的富Ag相和Cu-Mn-Ni固溶体上,而界面处没有产生任何裂纹,这也说明钎料与母材之间形成了良好的冶金结合。图7(b)所示为钎焊接头拉断后的断口表面形貌,断口主要由大而浅的剪切韧窝组成,可以判断该钎焊接头的断裂方式是韧性断裂。

根据前面的分析可知,钎焊接头中富Ag相的硬度低、塑形好,有利于缓解接头在冷却过程中由于母材收缩而产生的残余应力。而作为基体的Cu-Mn-Ni固溶体具有适中的硬度,具有良好的强度和塑性,保证了接头的强度。从图5(a)中可以看出,钎缝中富Ag相和Cu-Mn-Ni固溶体是混合分布的,这种混合分布的结构进一步增加了接头的强度。此外,钎焊接头中少量的Ni-Mn-Si化合物并没有明显的损害接头的力学性能,反而可能提高了钎焊接头的强度,但也可能在一定程度上降低了接头的塑性。因此,以富Ag相和Cu-Mn-Ni固溶体混合分布的结构保证了钎焊接头取得较高的力学性能。

3 结论

1) Cu-Mn-Ni-Ag中温铜基钎料由富Ag相、 Cu-Mn-Ni固溶体以及少量的Ni-Mn-Si化合物组成,熔点约为880 ℃,成功用于高频感应真空钎焊2Cr13不锈钢,接头的显微组织表明钎料与母材之间形成了良好的冶金结合,钎缝组织致密。钎焊接头组织由界面反应区的Fe-Mn-Ni-Cr-Cu固溶体和钎缝区的富Ag相、Cu-Mn-Ni固溶体以及少量的Ni-Mn-Si化合物组成。

2) 2Cr13不锈钢钎焊接头室温剪切强度最高可达369 MPa,随着测试温度升高,钎焊接头的剪切强度降低,当测试温度为500 ℃时,剪切强度仍达到208 MPa。剪切强度测试后的接头显微组织表明接头断裂于钎缝中间的富Ag相和Cu-Mn-Ni固溶体上,接头的断裂方式为以剪切韧窝为主的韧性断裂。以富Ag相和Cu-Mn-Ni固溶体混合分布的结构保证了钎焊接头取得较高的力学性能。

REFERENCES

[1] 张启运, 庄鸿寿. 钎焊手册[M].北京: 机械工业出版社, 1998: 187, 205, 461-481.

ZHANG Qi-yun, ZHUANG Hong-shou. Brazing directory[M]. Beijing: China Machine Press, 1998: 187, 205, 461-481.

[2] 孙 磊, 秦优琼. 合金元素Cu对不锈钢钎焊接头组织及性能影响的研究[J]. 热加工工艺, 2014, 43(23): 68-71.

SUN Lei, QIN You-qiong. Effect of alloy element Cu on microstructure and mechanical properties of stainless steel brazed joints[J]. Hot Working Technology, 2014, 43(23): 68-71.

[3] JIANG Wen-chun, GONG Jian-ming, TU Shan-dong, CHEN Hu. Modelling of temperature field and residual stress of vacuum brazing for stainless steel plate-fin structure[J]. Journal of Materials Processing Technology, 2009, 209(2): 1105-1110.

[4] 周辰琳, 高磊, 张莹莹, 齐洪洋. 316L不锈钢钎焊工艺试验[J]. 热加工工艺, 2012, 41(19): 196-196.

ZHOU Chen-lin, GAO Lei, ZHANG Ying-ying, QI Hong-yang. Welding process of 316 stainless steel[J]. Hot Working Technology, 2012, 41(19): 196-196.

[5] YUAN X, KIM M B, KANG C Y. Microstructural evolution and bonding behavior during transient liquid-phase bonding of a duplex stainless steel using two different Ni-B-based filler materials[J]. Metallurgical & Materials Transactions A, 2011, 42(5): 1310-1324.

[6] PHILIPS N R, LEVI C G, EVANS A G. Mechanisms of microstructure evolution in an austenitic stainless steel bond generated using a quaternary braze alloy[J]. Metallurgical & Materials Transactions A, 2008, 39(1): 142-149.

[7] 刘文胜, 刘书华, 马运柱, 蔡青山, 刘昊阳, 余 强, 伍 镭. 基于镍基微晶钎料的钨/钢真空焊接接头的组织及性能[J]. 中国有色金属学报, 2014, 24(12): 3051-3058.

LIU Wen-sheng, LIU Shu-hua, MA Yun-zhu, CAI Qing-shan, LIU Hao-yang, YU Qiang, WU Lei. Microstructure and properties of tungsten/steel joint brazed with Ni-based foil-type filler[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(12): 3051-3058.

[8] CHUNG T, KIM J, BANG J, RHEE B, NAM D. Microstructures of brazing zone between titanium alloy and stainless steel using various filler metals[J]. Transactions of Nonferrous Metals Society of China, 2012, 22(S3): s639-s644.

[9] 经敬楠, 于治水, 苌文龙, 秦优琼. BNi7镍基钎料真空钎焊316L不锈钢接头钎缝的显微组织和显微硬度[J]. 机械工程材料, 2013, 37(1): 10-13.

JING Jing-nan, YU Zhi-shui, CHANG Wen-long, QIN You-qiong. Microstructure and microhardness of 316L stainless steel joint seam vacuum brazed by BNi7 Ni-based filler metal[J]. Materials for Mechanical Engineering, 2013, 37(1): 10-13.

[10] 柴 静, 严 彪. Cu-Mn-Ni基钎焊料性能研究[J]. 金属功能材料, 2013, 20(6): 15-17.

CHAI Jing, YAN Biao. Study of properties of Cu-Mn-Ni based brazing material[J]. Metallic Functional Materials, 2013, 20(6): 15-17.

[11] 王鼎钟. 一种新型Cu-Mn-Ni-Zn钎料的研制[J]. 材料开发与应用, 2000, 15(4): 5-9.

WANG Ding-zhong. Development of a new Cu-Mn-Ni-Zn brazing[J]. Development and Application of Materials, 2000, 15(4): 5-9.

[12] 马向阳, 俞伟元, 路文江, 王有良, 邓有忠. 高强度低熔点铜基钎料的研制[J]. 热加工工艺, 2012, 41(11): 133-135.

MA Xiang-yang, YU Wei-yuan, LU Wen-jiang, WANG You-liang, DENG You-zhong. Development of a new copper-base brazing metal with high strength and low melting temperature[J]. Hot Working Technology, 2012, 41(11): 133-135.

[13] 杨 光, 李 宁, 颜家振, 苑 博. CuMnNiSi钎料钎焊不锈钢接头组织性能研究[J]. 热加工工艺, 2011, 40(9): 165-167.

YANG Guang, LI Ning, YAN Jia-zhen, YUAN Bo. Structure and property of stainless steel brazed joint with CuMnNiSi filler metal[J]. Hot Working Technology, 2011, 40(9): 165-167.

[14] 刘安生译. 二元合金状态图集[M]. 北京: 冶金工业出版社, 2004: 6-288.

LIU An-sheng, translation. Binary alloy phase diagrams[M]. Beijing: Metallurgical Industry Press, 2004: 6-288.

[15] SAIZ E, TOMSIA A P. Kinetics of high-temperature spreading[J]. Current Opinion in Solid State & Materials Science, 2006, 9(4): 167-173.

Microstructure and performance of 2Cr13 stainless steel joint by high frequency induction brazing using Cu-Mn-Ni-Ag filler alloy

ZHENG Yi, YAN Jia-zhen, LI Ning, CAO Yong-tong, SHUAI Fan

(School of Manufacturing Science and Engineering, Sichuan University, Chengdu 610065, China)

Abstract: The characteristic of Cu-Mn-Ni-Ag filler alloy and the microstructure and mechanical properties of the 2Cr13 stainless steel joint brazed by high frequency induction brazing using Cu-Mn-Ni-Ag filler alloy were studied. The results show that the melting point of the Cu-Mn-Ni-Ag filler alloy is 880 ℃ and it is composed of Ag-rich phase, Cu-Mn-Ni solid solution and a little Ni-Mn-Si compound; a layer of Fe-Mn-Ni-Cr-Cu solid solution forms at the interface between the filler alloy and base metal, and the brazing seam zone is composed of Ag-rich phase, Cu-Mn-Ni solid solution and a little Ni-Mn-Si compound. The brazing joints fails in the inside Cu-Mn-Ni solid solution and Ag-rich phase, and the fracture mode of the joints is mainly ductile dimple fracture, the best shear strength of the brazing joint at room temperature is 369 MPa, the high temperature shear strength of the brazing joints at 400 ℃, 500 ℃ and 600 ℃ are 251 MPa, 208 MPa and 84 MPa, respectively.

Key words: copper-based filler alloy; Cu-Mn-Ni-Ag; high frequency induction brazing; 2Cr13; microstructure; shear strength

Foundation item: Project (2014GZ0008) supported by Sichuan Province Science and Technology Support Program, China

Received date: 2015-08-25; Accepted date: 2015-12-12

Corresponding author: YAN Jia-zhen; Tel: +86-28-85405320;E-mail:yanjiazhen@scu.edu.cn

(编辑 王 超)

基金项目:四川省科技支撑计划项目(2014GZ0008)

收稿日期:2015-08-25;修订日期:2015-12-12

通信作者:颜家振,讲师,博士;电话:028-85405320;E-mail:yanjiazhen@scu.edu.cn