文章编号:1004-0609(2009)05-0881-06

纯铝粉末多孔烧结材料等通道转角挤压

李 萍,黄科帅,薛克敏,周明智,韩国民

(合肥工业大学 材料科学与工程学院,合肥 230009)

摘 要:以纯铝粉末多孔烧结材料为研究对象,在200 ℃下采用粉末包套-等通道转角挤压工艺制备了完全致密的块体超细晶材料,研究在挤压过程中3种路径(A、BC、C)对其组织和性能的影响。结果表明:在3种路径挤压下均实现了材料的晶粒细化与致密,其中路径BC和路径A的细化效果优于路径C的;以细化效果最佳的路径BC为例,初始平均粒径为46.8 ?m,相对密度为0.88的粗大等轴晶组织经过4道次挤压后得到平均粒径为1.5 ?m完全致密的超细晶组织,且屈服强度比初始时提高了两倍左右;3种路径下显微硬度与挤压道次的关系基本一致,即一次挤压后硬度比初始值提高了75%,之后随着挤压道次的增加,硬度增加趋于缓慢。

关键词:粉末烧结材料;组织;性能;包套-等通道转角挤压

中图分类号:TG 376 文献标识码:A

Equal channel angular pressing of pure Al powder sintered material

LI Ping, HUANG Ke-shuai, XUE Ke-min, ZHOU Ming-zhi, HAN Guo-min

(School of Materials Science and Engineering, Hefei University of Technology, Hefei 230009, China)

Abstract: Pure aluminium sintered material was successfully consolidated into fully dense bulk material by powder in tubes-equal channel angular pressing at 200 ℃. During the pressing, the effects of three routes (A, BC, C) on the structure and properties were studied. The results show that the materials are refined and compacted after pressing through three kinds of routes. The refining effect of routes BC and A are better than that of route C. Using route BC as example, the initial coarse equiax-grained microstructure with relative density of 0.88 and mean grain size of 46.8 ?m becomes fully dense ultra-fine grained microstructure with mean grain size about 1.5 ?m after four pressing passes. The yield strength is two times higher than that of sample before ECAP processed. The relationship between the microhardness and pressing passes under three routes is the same, that is to say the microhardness increases 75% after one pressing, while increases slightly where after.

Key words:powder sintered material; microstructure; properties; tubes-equal channel angular pressing

等通道转角挤压[1](Equal channel angular pressing,ECAP)作为一种独特的制备块体超细晶材料的新型塑性加工技术,受到了材料科学领域内研究者日益广泛的关注。近年来,针对ECAP开展了大量的研究,并成功地制备出Al、Cu、Mg、Ni和Ti等多种致密金属及其合金的块体超细晶材料[2-3]。

随着制粉技术的发展,粉末冶金材料在新材料研究中的优势越来越突出。传统的粉末烧结材料及其制品由于其内部存在大量的孔隙,使其强度和韧性大大降低难以在高负荷下使用。因此,为了获得所要求的力学性能,常需对粉末烧结材料进行后续塑性加工,如挤压、锻造和轧制等方法。然而,传统的塑性加工方法由于受到各种条件的限制,很难制备出高致密度和性能优越的材料。

等通道转角挤压作为一种新型的塑性加工工艺,利用其独特的变形特点,可以使粉末材料的基体组织在较低的温度下发生大剪切变形,同时变形过程所产生的高静水压力可以使材料内部的孔隙有效地收缩,从而为以粉末材料为原材料,制备出高致密度、组织结构均匀、力学性能优良的块体超细晶材料提供一种可能而有效的新途径。近年来,针对致密材料的等通道转角挤压变形已经进行了大量的研究报道[4-10],但对粉末类多孔材料的相关研究尚处于起步阶段[11-14]。本文作者通过实验方法系统地研究了ECAP对纯铝粉末多孔烧结材料组织及性能的影响。

1 实验

1.1 挤压毛坯的制备

实验材料采用工业纯铝粉末,主要成分如表1所列。利用激光粒度测试仪测算出其初始粒度为46.8 ?m。挤压毛坯制备过程如下:将粉末压坯,进行冷等静压处理,再在400 ℃真空条件下烧结,时间为4 h,最后通过线切割加工成d 7 mm×45mm的圆柱形试样以备用。

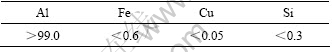

表1 纯铝粉末的主要化学成分

Table 1 Main chemical compositions of pure Al powder (mass fraction, %)

1.2 粉末烧结材料包套-等通道转角挤压

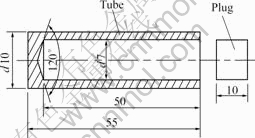

考虑到挤压材料塑性较差,为确保挤压件获得满意的变形累积,本研究采用粉末包套-等通道转角挤压工艺(Powder in tubes-equal channel angular pressing,PITS-ECAP)。包套材料为纯铝,几何形状与尺寸示意图如图1所示。PITS-ECAP原理示意图如图2所示。实验中,模具内角为90?、外角为37?,根据文献[15],每道次挤压后等效剪切应变量的增加值约为1,两通道横截面积都为10 mm×10 mm。实验中,挤压温度为200 ℃,挤压速度约为1 mm/s。采用3种路径进行挤压,路径A:两次连续挤压之间试样方向不旋转;路径BC:两次连续挤压之间试样方向绕挤压轴沿同一方向旋转90?;路径C:两次连续挤压之间试样方向绕挤压轴沿同一方向旋转180?。挤压过程中采用石墨进行润滑。

图1 包套几何尺寸的示意图

Fig.1 Schematic diagram of tube dimension (unit: mm)

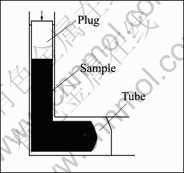

图2 PITS-ECAP的工艺原理示意图

Fig.2 Schematic diagram of PITS-ECAP technique

1.3 性能检测

将挤压试样线切割去包套并加工成各种规格的检测样品。切割后的试样断面经磨制、清洗、抛光和干燥后,采用3%HF(体积分数)水溶液的腐蚀剂进行表面腐蚀后,采用4XB-TV金相显微镜进行观察,采用HITACHI H800透射电子显微镜对其微观结构进行观察分析,平行于横截面(X面)切割0.3 mm薄片,机械减薄至40~50 ?m,用冲子裁剪出直径为3 mm的圆 片,再进行电解双喷减薄,直至穿孔,然后在200 kV下进行透射电镜观察。采用MH-3型显微维氏硬度计测定硬度,载荷为245 N,加载时间10 s。根据阿基米德原理,采用排水法测定试样的相对密度,所用分析天平的最小精度为0.1 mg。用MTS809实验机进行室温压缩实验,取芯部试样尺寸为d 5 mm×7.5 mm,加载速率为8 ms-1。

2 结果与分析

2.1 微观组织分析

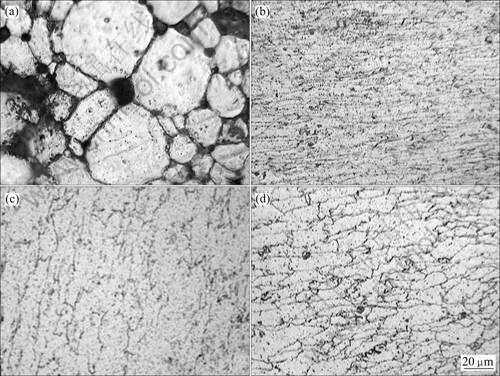

原始状态及采用3种路径挤压4道次后试样X面上(垂直于挤压流动方向)的光学显微组织如图3所示。

图3 纯铝烧结材料初始状态及200 ℃下不同工艺路径挤压4道次后的显微组织

Fig.3 Microstructures of pure Al sintered material before PITS-ECAP and after pressing four passes by different routes at 200 ℃: (a) Initial state; (b) Route A; (c) Route BC; (d) Route C

由图3可看出,挤压前试样的典型组织,基本为带有明显孔隙、大小分布不均匀的等轴晶,晶粒比较粗大,其平均尺度约为46.8 ?m;以路径A和路径C经过4道次挤压后分别得到了细长的流线状和等轴状的组织(见图3(b)和(d)) ,观察不到明显的孔隙存在;以路径BC挤压4道次后,晶粒发生显著的细化,部分晶界已经趋于模糊,此时通过光学显微镜已难以确定晶粒的大小(见图3(c))。

以路径BC为例观察不同道次挤压后试件横截面上的透射电镜组织,其结果如图4所示。由图4可看出,经过一道次挤压后,内部孔隙明显收缩闭合,在晶粒之间存在少量的小亚晶粒夹杂在中间,这些亚晶的尺寸有的小于1 ?m,晶粒内部产生位错,其中亚晶处可见大量位错堆积;经两道次挤压后,内部出现少量等轴亚晶,但晶粒大小不均匀,细晶所占比例还比较小,此时,亚晶界趋于清晰,晶界仍主要是由小角度晶界组成;经4道次挤压后,较大的晶粒进一步被细化,细晶数目明显增多,内部已经形成大量细小的等轴晶粒,晶界平直,趋向于大角度晶界,晶粒大小分布趋于均匀,平均尺寸约为1.5 ?m。

纯铝烧结体在PITS-ECAP过程中,纯剪切变形、应变量和内部高静水压力的共同作用是其晶粒细化和致密的主要原因。在变形初期,在剪切变形和静水压力的作用下,内部孔隙收缩闭合,基体组织发生强烈的剪切变形导致在晶粒内部产生大量的位错,位错运动、缠结形成位错胞和亚晶界,使得原始晶粒被破碎细化,产生大量的亚晶;随着变形的继续进行,累积应变量增大,亚晶粒数量增多,大小也趋于更加细小均匀,晶粒内部在不断产生新的位错的同时也促使其不断向亚晶界处移动,并在亚晶界处发生堆积、缠结和湮灭,导致小角度晶界向平滑的大角度晶界的转变,逐渐形成具有大角度晶界的等轴状超细晶结构。

此外,从图3中很清楚地看出,路径BC和路径A的细化效果明显优于路径C的。这是由于以不同路径下挤压时,剪切面、晶体结构和变形织构间的相互作用对晶粒的细化效果有着重要的影响。纯铝为典型的面心立方构,众所周知,面心立方结构材料的塑性变形主要机制是滑移,其主要滑移系是{111}<110>,共有12个滑移系。由金属学原理可知,4个(111)滑移面形成一个四面体,4个滑移面间的夹角均为70.5?。根据文献[16],对于90?模具,路径A、BC,C相邻两次挤压的剪切平面之间交角分别为90?、60?和0?。故可以认为,相邻两次的剪切面之间的夹角接近70.5?时才有利于激活{111}面上的位错滑移,其细化效果就越明显。

图4 200 ℃下BC路径挤压各道次下的TEM像

Fig.4 TEM images of samples after different passes by route BC at 200 ℃: (a) 1-pass; (b) 2-pass; (c) 4-pass

2.2 相对密度测量

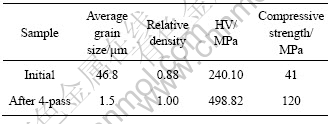

采用PITS-ECAP工艺能显著提高粉末多孔烧结材料的致密效果。以路径BC挤压的试样为例,通过排水法测量其相对密度得知,初始相对密度为0.88的块体材料,经过一道次挤压后相对密度可达0.99,挤压4次后完全致密(见表2)。 这是由于材料在PITS-ECAP变形过程中受到较大的剪切变形和静水压力共同作用的结果。在挤压的开始阶段,受变形影响,材料中孔隙的大小及形状发生改变,致密度有所提高;当材料进入模具转角地带时,由于剪应力的剧烈剪切作用,孔隙的形状将发生明显的改变,发生变形的同时又受到高静水压力作用,从而导致孔隙的大小发生改变,促使孔隙收缩闭合。

表2 PITS-ECAP前后试样的性能参数

Table 2 Characteristic parameters of samples before and after PITS-ECAP

2.2 挤压件力学性能测试

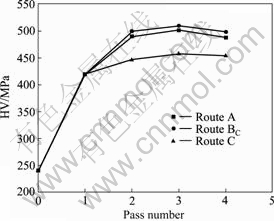

粉末多孔烧结材料的力学性能同其致密度及内部组织的大小存在着密切的关系,对不同工艺路径、不同挤压道次下试样横截面上的显微硬度进行测量,得到显微硬度随挤压道次的变化如图5所示。由图5可知,挤压一道次(累积应变为1)后试样显微硬度上升明显,平均硬度从240.10 MPa 提高至498.82 MPa,约比挤压前提高了75%;随后两道次的试样显微硬度继续上升,但随着挤压道次的继续增加,硬度上升幅度渐趋缓慢。从图5中还可看出,在挤压过程中各工艺路线的硬度变化趋势基本一致,其中路径A和BC获得的硬度值基本相同,略高于路径C所获的值,这与各挤压路径所获得的晶粒尺寸变化趋势基本吻合。由于变形初期材料内部孔隙明显收缩闭 合,致密度明显增大,同时晶粒内部产生大量的位错,位错不断增 殖,位错密度显著提高,形成大量的胞状结构和亚晶界等,使得材料塑性变形的抗力增大,出现加工硬化,硬度明显上升。随着变形的进行,一方面致密度增大到几乎接近于理论压实值不再有明显的提高;另一方面,虽然随着变形的进行,位错将会越来越多,但同时晶界也将很容易地当量堆积、吸收和湮灭位错,使得位错密度不会有很大的增高,而是基本保持在某一相对稳定的水平上,使得晶粒细化缓 慢,硬度值变化平缓。

图5 不同挤压路径下试样的显微硬度随挤压道次的变化

Fig.5 Change of microhardness of as-pressed samples with pass number under different strains routes

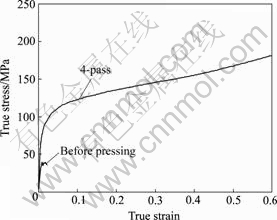

挤压前后材料的抗压屈服强度也如表2中所 列。图6所示为挤压前后试样真应力—应变曲线。由表2可看出,经过BC路径4道次挤压后,试样的抗压屈服强度明显增大,比初始下的屈服强度增加了两倍左右。这与图6的真实应力—应变曲线得到了很好的吻合。压缩性能的提高主要也归结于ECAP过程中材料致密度提高和晶粒细化共同作用的结果。致密度的有效提高,促使其力学性能也显著提高。同时,在变形过程中,亚微米晶粒的形成,位错密度的提高致使强度明显增大。

图6 压缩前后试样的真应力—应变曲线

Fig.6 Compressive stress—strain curves of samples before and after pressing

3 结论

1) 在200℃下,以纯铝粉末多孔烧结体为材 料,采用粉末包套-等通道转角挤压(PITS-ECAP)工艺制备了完全致密的块体超细晶材料。

2) 纯铝多孔烧结体经PITS-ECAP后,致密效果得到明显改善、晶粒得到了显著的细化,其中3种工艺路线的细化效果依次为:BC>A>C。初始平均晶粒尺寸为46.8 ?m,相对密度为0.88的试样具有明显孔隙组织,经路径BC 4道次挤压后得到了平均晶粒尺寸为1.5 ?m的完全致密组织。

3) ECAP工艺显著提高了烧结体的力学性能。3种路径下硬度的变化趋势基本相同。初始硬度为240.10 MPa,经过一道次挤压后提高到了75%,随着挤压道次的增加硬度值上升趋于平缓;采用BC路径挤压4次后,屈服强度由初始的41 MPa提高到了120 MPa左右。

REFERENCES

[1] SEGAL V M, REZNIKOV V I, DROBYSHEVKIY A E, KOPYLOV V I. Plastic working of metals by simple shear[J]. Russian Metallurgy, 1981, 1: 99-105.

[2] SHIN D H, KIM B C, KIM Y S. Microstructual evolution in a commercial low carbon steel by equal channel angular pressing[J]. Acta Materialia, 2000, 48(9): 2247-2255.

[3] REAB G I, SOSHNIKOVA E P, VALIEV R Z. Influence of temperature and hydrostatic pressure during ECAP on the microstructure of commercial-purity Ti[J]. Mater Sci Eng A, 2004, 387/389(1/2): 674-667.

[4] GHOLINIA A, PRANGNELL P B, MARKUSHEV M V. The effect of strain on the development of deformation structures in severely deformed aluminum alloys processed by ECAE[J]. Acta Materialia, 2000, 48(5): 1115-1130.

[5] 刘 咏, 唐志宏, 周科朝, 李志友. 纯铝等径角挤技术(Ⅰ)—显微组织演化[J]. 中国有色金属学报, 2003, 13(1): 21-26.

LIU Yong, TANG Zhi-hong, ZHOU Ke-chao, LI Zhi-you. Equal channel angular pressing process (ECAP) of pure Al(Ⅰ)—Microstructure evolution[J]. The Chinese Journal of Nonferrous Metals, 2003, 13(1): 21-26.

[6] NAKASHIMA K, HORITA Z, NEMOTO M, LANGDON T G. Influence of channel angle on the development of ultrafine grains in equal channel angular pressing[J]. Acta Materialia, 1998, 46(5): 1589-1599.

[7] LANGDON T G, FURUKAWA M, NEMOTO M, HORITA Z. Ultrafinegrained microstructure evolving during severe plastic deformation[J]. JOM, 2000, 52(4): 30-33.

[8] KIM H S. On the effect of acute angles on deformation homogeneity in equal channel angular pressing [J]. Mater Sci Eng A, 2006, 430(1/2): 346-349.

[9] EI-Danaf E A. Mechanical properties and microstructure evolution of 1050 aluminum severely deformed by ECAP to 16 passes[J]. Mater Sci Eng A, 2008, 487: 189-200.

[10] GUBICZA J, CHINH N Q, SZOMMER A, VINOGRADOV, LANGDON T G. Microstructural characteristics of pure gold processed by equal-channel angular pressing[J]. Scripta Materialia, 2007, 56(11): 947-950.

[11] CHANG S Y, LEE K S, CHIO S H, SHIN D H. Effect of ECAP on microstructure and mechanical properties of a commercial 6061Al alloy produced by powder metallurgy[J]. Journal of Alloys and Compounds, 2003, 354(1/2): 6-220.

[12] 周明智, 薛克敏, 李 萍. 粉末多孔材料等径角挤压过程热力耦合有限元数值分析[J]. 中国有色金属学报, 2006, 16(9): 1510-1516.

ZHOU Ming-zhi, XUE Ke-min, LI Ping. Coupled thermo- mechanical finite element analysis of metal with porosities during equal channel angular pressing process[J]. The Chinese Journal of Nonferrous Metals, 2006, 16(9): 1510-1516.

[13] XIA K, WU X. Back pressure equal channel angular consolidation of pure Al particles [J]. Scripta Materialia, 2005, 53(11): 1225-1229.

[14] NAGASEKHAR A V, TICK-HON Y, GUDURU R K, RAMAKANTH K S. Multipass equal channel angular extrusion of MgB2 powder in tubes[J]. Physica C, 2007, 466(1/2): 174-180.

[15] IWAHASHI Y, WANG T, HORITA Z, NEMOTO M, LANGDON T G. Principle of equal-channel angular pressing for the processing of ultra-fine grained materials[J]. Scripta Materialia, 1996, 35(2): 143-146.

[16] ZHU Y T, LOWE T C. Observations and issues on mechanisms of grain refinement during ECAP process[J]. Mater Sci Eng A, 2000, 291(1): 6-53.

基金项目:国家自然科学基金资助项目(50875072);安徽省自然科学基金资助项目(070414148)

收稿日期:2008-07-11;修订日期:2008-11-19

通讯作者:李 萍,教授,博士;电话:0551-2901368;E-mail: cisi_1314@126.com

(编辑 李艳红)