文章编号:1004-0609(2010)03-0540-05

激光表面纹理加工对Ti6Al4V空蚀性能的影响

连 峰,张会臣,高玉周,庞连云

(大连海事大学 机械工程系,大连 116026)

摘 要:采用激光表面改性的方法对Ti6Al4V合金进行纹理加工。采用表面粗糙度测试仪、接触角测量仪和X射线衍射仪对激光纹理加工试样的表面特性进行表征,采用磁致伸缩超声振动仪对试样的抗空蚀特性进行测试,采用光学显微镜和扫描电子显微镜对试样空蚀前、后的表面形貌进行观测。结果表明:经激光表面纹理加工,试样的硬度由337HV提高到550HV,水接触角增大10?;激光纹理加工试样的抗空蚀特性有所改善,特别是对于具有较小间距网格形状的表面纹理试样,其表面空蚀面积的比例小于抛光试样的1/10;激光纹理加工试样的抗空蚀特性的改善与硬度梯度效应、缓冲空泡运动和限域作用等效应相关。

关键词:钛合金;表面纹理;空蚀;激光加工

中图分类号:TH117.1 文献标识码:A

Effects of surface texture manufacturing by laser on cavitation characteristics of Ti6Al4V alloy

LIAN Feng, ZHANG Hui-chen, GAO Yu-zhou, PANG Lian-yun

(Department of Mechanical Engineering, Dalian Maritime University, Dalian 116026, China)

Abstract: Ti6Al4V alloy was treated by laser surface modification method. The characterization of surface properties of Ti6Al4V specimens was conducted with surface profiler, contact angle measurer and X-ray diffractometer. The cavitation erosion resistances of Ti6Al4V specimens were measured by ultrasonic vibrator. The cavitation erosion topographies of Ti6Al4V alloy specimens were analyzed by scanning electron microscopy and optical microscopy. The results indicate that the hardness of specimens increases from 337HV to 550HV after modified by laser texture manufacturing. The water contact angles of the specimens are increased by 10?. The cavitation erosion resistances of all specimens by laser texture manufacturing were improved, especially for the grid texture specimens with small space. The area percent of cavitation erosion of the above specimens is less than one tenth of that of the polished Ti6Al4V specimens. The enhancement of cavitation erosion resistances of laser texture manufacturing specimens is related to the hardness gradient effect, cushion of bubble motion and limited area action.

Key words: titanium alloy; surface texture; cavitation erosion; laser manufacturing

空化与空蚀一直是设计船舶螺旋桨、海洋结构物及水力机械时考虑的一个重要因素。空化与空蚀对上述机械装置的有害作用已被充分证明,并已得到广泛研究[1?3]。现有的研究主要集中在机械装置的结构设 计[4?5]和材料选择[6?7]两个方面。前者主要是为了避免或减少空化现象的发生,后者则是为了提高装置的抗空蚀能力。近年来,随着人们对空化空泡与材料表面相互作用研究的深入,材料的表面设计与改性成为抗空蚀设计的一个主要手段[8?9]。通过对材料的表面设计与改性来改变空化空泡的发生和运动特性,减小空化空泡溃灭时对零件表面的损伤,从而改善机械装置的抗空蚀特性。

在关于激光加工对材料空蚀特性影响的研究中,SZKODO[10]研究了激光合金化处理45钢的微结构与空化阻力的关系,结果表明,当微结构中含有一定量的奥氏体时材料易出现应变硬化,从而可获得较高的空蚀阻力。TANG等[11]对船舶螺旋桨用青铜采用铝粉进行激光表面合金化处理,结果表明,单相微结构的形成和较高的硬度使空蚀阻力得到提高。钛合金具有比强度高,耐腐蚀强等优异的力学和物理化学性能,已被广泛应用于水翼船等船舶与海洋工程领域。HIROMI等[12]采用旋转圆盘测试仪对纯钛和钛合金在海水中的空蚀特性进行的研究表明,试样的空蚀阻力随硬度的提高而提高。现有的研究中有关钛合金进行激光表面纹理加工改善其抗空蚀特性的报道很少。为此,本文作者对激光表面纹理加工的钛合金的力学和抗空蚀特性进行研究,旨在为抗空蚀材料的表面设计提供依据。

1 实验

1.1 试样表面纹理加工

试样材料为Ti6Al4V,尺寸为10 mm×10 mm×1.5 mm。在进行表面纹理加工以前,试样分别用360#、800#和1000#砂纸进行精磨,然后进行抛光处理。试样表面纹理加工采用武汉华工激光工程有限责任公司生产的HGL-LSY50F激光加工设备,激光波长为1 064 nm,最大激光输出功率为50 W,加工时使用的电流密度为12.5 A。加工的表面纹理包括直线纹理和网格纹理,间距分别为0.05和0.10 mm,其中,网格纹理直线间的夹角为90?。

1.2 试样的性能测试与表征

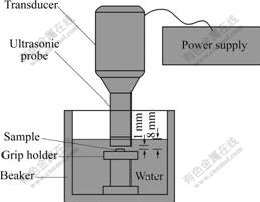

试样空蚀特性采用磁致伸缩超声振动仪进行测试。振动仪的结构和试样的安装如图1所示。超声振动仪的电流强度为1 A,电压为200 V,振动频率为(20±1)kHz,最大振幅为(40±1)mm。实验在室温进行,实验时间为60 min。

试样的表面粗糙度采用德国Hommel T6000表面形貌仪进行测试。用德国产的Easy-Drop 型接触角测量仪测定去离子水在试样表面的接触角并计算表面能。试样的表面形貌采用Phillips XL30扫描电子显微镜和OLYMPUS GX51光学显微镜进行表征。样品经过激光表面纹理加工后组织结构的变化采用日本Rigaku Corporation 生产的D/MAX?Ultima+型X射线衍射仪(XRD)进行分析。在XRD测试时,采用Cu Kα辐射,λ=0.154 06 nm,管电压为40 kV,管电流为20 mA,扫描速度为1(?)/min,扫描角分辨率为0.02?。

图1 磁致伸缩超声振动仪结构和试样的安装示意图

Fig.1 Sketch map of ultrasonic vibrator and specimen setting

采用MH?6型维氏显微硬度计测试试样的硬度,施加载荷为9.8 N,每个试样测试3个点,取平均值。

2 结果与讨论

2.1 激光加工表面的形貌特征与力学特性

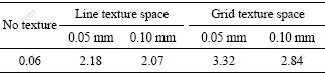

试样的表面粗糙度在激光纹理加工前、后如表1所列。网格纹理试样的表面粗糙度大于直线纹理试样的表面粗糙度,并且无论直线纹理还是网格纹理都有随着间距的增加,表面粗糙度降低的趋势。这主要是由于当间距较小时,材料的瞬时凝固相互影响,导致表面变得更加粗糙;当间距较大时,这种相互影响就弱很多。

表1 间距分别为0.05和0.10时具有不同表面纹理试样的表面粗糙度

Table 1 Surface roughness of specimens with different textures at spaces of 0.05 and 0.10 mm

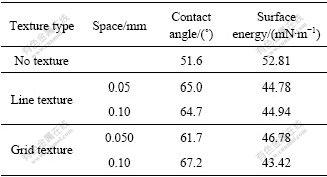

在激光纹理加工前、后,试样的水接触角和计算得到的表面能如表2所示。可以看出,激光纹理加工后的试样的水接触角大于加工前的,计算得到的表面能低于加工前的。对于直线纹理试样,间距对接触角影响不大;而对于网格纹理试样,在间距较大时,试样的接触角也较大。表面纹理加工试样接触角的增大可由Wenzel给出的模型来解释[13],即液体浸入沟槽后,使接触角测量的半径减小,从而导致接触角增大。对于直线纹理试样,水滴在侧面的流动没有约束,所以,水接触角不受纹理间距的影响;对于网格纹理试样,水滴在侧面的流动受到限制,间距较大的网格更有利于控制水滴的流动区域,因此,试样的水接触角较大。

表2 间距分别为0.05和0.10时具有不同表面纹理试样的水接触角和表面能

Table 2 Contact angles and surface energies of specimens with different textures

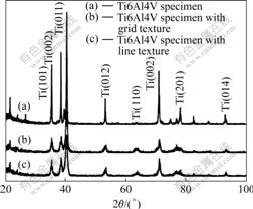

激光纹理加工试样的横截面图如图2所示。激光纹理加工层的厚度约为43.5 μm,加工层厚度变化均匀。硬度测试结果表明,未进行激光纹理加工的Ti6Al4V试样的硬度为337HV。激光纹理加工的试样,在表面纹理的波峰处硬度较高,处于硬度范围的上限, 600HV左右;在凹谷处硬度较低,处于硬度范围的下限,550HV左右。试样表面经过激光纹理加工后,硬度显著提高。在表面纹理的波峰处,由于温度变化梯度大,冷却速度快,硬化程度较大。试样的XRD谱如图3所示。经过激光纹理加工的试样的谱线峰变平缓,发生宽化,说明表面出现非晶化。这是由于激光加热和冷却的速度很快造成的,与激光纹理加工后试样硬度的变化趋势一致。

图2 激光纹理加工试样的横截面形貌

Fig.2 Cross-sectional morphology of specimen after surface texture treatment by laser

图3 试样的XRD谱

Fig.3 XRD patterns of specimens

2.2 加工表面的空蚀磨损特性

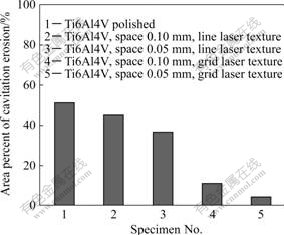

基于Photoshop软件,采用图像处理的方法对光学显微镜下空蚀试样表面的形貌进行分色处理,计算试样的空蚀面积[14?15],选择空蚀最严重的区域,得到不同激光纹理加工试样的表面空蚀面积占试样分析区域面积(约为2.37 mm2)的百分比如图4所示。由图4可以看出,经激光纹理加工后,Ti6Al4V试样的空蚀磨损面积都有降低,特别是对于小间距网格纹理的Ti6Al4V试样,磨损面积明显减小,不到Ti6Al4V抛光试样空蚀面积的1/10。对于直线纹理试样,空蚀面积虽然有减小,但减小幅度不大。

图4 试样表面的空蚀面积

Fig.4 Cavitation erosion area percents of specimens

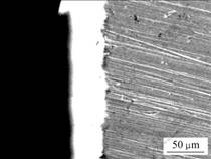

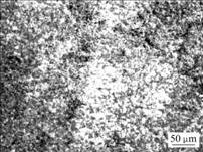

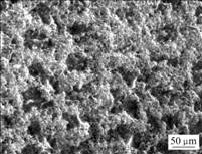

试样表面的空蚀磨损形貌如图5~7所示。由图5可以看出,Ti6Al4V抛光试样表面呈海绵状,空蚀磨损严重。从间距为0.1 mm的直线纹理试样表面的空蚀形貌可以看出,试样表面也出现海绵状的空蚀形貌,但不像抛光试样那样连成一片,仍显露出纹理加工的痕迹。图7(a)所示为间距0.05 mm的直线纹理试样表面的空蚀形貌,可以看出试样加工的纹理清晰可见,在纹理的突起处,出现典型的空蚀特征,而在纹理的凹陷处则没有明显的空蚀特征。图7(b)所示为间距0.05 mm的网格纹理试样表面的空蚀形貌,可以看出试样表面的网格状纹理没有受到破坏,且看不到明显的空蚀迹象。间距为0.1 mm的网格纹理的表面形貌与此类似。

图5 Ti6Al4V抛光试样的空蚀形貌

Fig.5 Topography of cavitation erosion of Ti6Al4V polished specimen

图6 间距为0.1 mm的直线纹理Ti6Al4V试样的空蚀形貌

Fig.6 Topography of cavitation erosion of Ti6Al4V specimen line texture at space of 0.1 mm

图7 Ti6Al4V试样的空蚀形貌

Fig.7 Topographies of cavitation erosion of Ti6Al4V specimens: (a) 0.05 mm space line texture; (b) 0.05 mm space grid texture

由空蚀面积曲线和试样空蚀表面形貌可以看出,网格纹理加工样品表面具有良好的抗空蚀特性,其主要原因如下:首先,经过激光表面纹理加工,试样的硬度明显提高。适当的硬度梯度,即保持了足够的强度,又有利于吸收空泡溃灭时产生的能量;网格纹理抗空蚀性比直线纹理强主要是因为表面纹理使空泡对表面的垂直作用变成空泡作用表面后有方向性的改变,从而导致方向改变,即表面纹理可以缓冲空泡的运动,网格纹理可以在各个方向改变空泡的作用,而直线纹理则只能在某个特定的方向上改变空泡的作用。其次,表面纹理结构影响空泡的流动特性,对空蚀的发生具有限域作用。

3 结论

1) 经过激光表面纹理加工后,Ti6Al4V试样的水接触角增大,硬度提高到550HV;网格纹理试样的表面粗糙度大于直线纹理试样的表面粗糙度。

2) 经过激光表面纹理加工后,试样的抗空蚀磨损特性显著提高,特别是对于网格纹理的Ti6Al4V试样,空蚀面积不到抛光Ti6Al4V试样的空蚀面积的1/10。

3) 经过激光表面纹理加工后,试样抗空蚀性能的增强可归结为硬度梯度效应、缓冲空泡运动和限域 作用。

REFERENCES

[1] MATEVZ D, BERND S, BRANE S. Development of a cavitation erosion model[J]. Wear, 2006, 261: 642?655.

[2] AFANASIEV K E, GRIGORIEVA I V. Numerical investigation of three dimensional bubble dynamics[J]. Journal of Engineering Mathematics, 2006, 55: 65?80.

[3] SOYAMA H, FUTAKAWA M. Estimation of cavitation intensity from the time taken for bubbles to develop[J]. Tribology Letters, 2006, 23(1): 23?26.

[4] HSIAO C T, CHAHINE G L. Numerical study of cavitation inception due to vortex/vortex interaction in a ducted propulsor [J]. Journal of Ship Research, 2008, 52(1): 114?123.

[5] VORTMANN C, G. SCHNERR H, SEELECKE S. Thermodynamic modeling and simulation of cavitating nozzle flow[J]. International Journal of Heat and Fluid Flow, 2003, 24: 774?783.

[6] MATEVZ D, BERND B, BERND S, BRANE S. Relationship between cavitation structures and cavitation damage[J]. Wear, 2004, 257: 1176?1184.

[7] SOYAMA H, FUTAKAWA M, HOMMA K. Estimation of pitting damage induced by cavitation impacts[J]. Journal of Nuclear Materials, 2005, 343: 116?122.

[8] NICOLAS B, MANISH A, CLAUS-DIETER O, DETTEF L. Cavitation on surfaces[J]. Journal of Physics: Condensed Matter, 2005, 17: S3603?S3608.

[9] NICOLAS B, MANISH A, STEPHAN M D, DETTEF L. Interaction of cavitation bubble on a wall[J]. Physics of Fluid, 2006, 18: 121505-1?10.

[10] SZKODO M. Relationship between microstructure of laser alloyed C45 steel and its cavitation resistance[J]. Journal of Materials Processing Technology, 2005, 162: 410?415.

[11] TANG C H, CHENG F T, MAN H C. Laser surface alloying of marine propeller bronze using aluminium powder, part I: Microstructural analysis and cavitation erosion study[J]. Surface & Coating Technology, 2006, 200: 2602?2609.

[12] HIROMI M, MOTOHIRO Y, SHUJI H. Effect of materials and solution temperatures on cavitation erosion of pure titanium and titanium alloy in seawater[J]. Wear, 2007, 262: 522?528.

[13] 施政余, 李 梅, 赵 燕, 路庆华. 润湿性可控智能表面的研究进展[J]. 材料研究学报, 2008, 22(6): 561?571.

SHI Zheng-yu, LI Mei, ZHAO Yan, LU Qing-hua. Advance of smart surfaces with controllable wettability[J]. Chinese Journal of Materials Research, 2008, 22(6): 561?571.

[14] DIODATI P, MARCHESONI F. Time-evolving statistics of cavitation damage on metallic surfaces[J]. Ultrasonics Sonochemistry, 2002, 9: 325?329.

[15] SHUJI H, KOHEI M, ZHANG Q L. Formulation of cavitation erosion behavior based on logistic analysis[J]. Wear, 2004, 257: 1064?1070.

基金项目:国家自然科学基金资助项目(50675024);辽宁省自然科学基金资助项目(20082143)

收稿日期:2009-05-12;修订日期:2009-09-27

通信作者:连 峰,副教授,博士;电话:0411-84723319;E-mail: fengfeng0425@yahoo.com.cn

(编辑 杨 华)