型材多道次热轧奥氏体演化三维有限元模拟

贺庆强1,孙佳2 ,赵军友1,闫成新1,袁宝民1,李翠翠1

(1. 中国石油大学 机电工程学院,山东 青岛,266580;

2. 青岛保税物流园区,山东 青岛,266555)

摘要:为了优化型材多道次热轧工艺制度,研究工艺参数对轧件几何尺寸及微观组织演化的影响;在借鉴现有数学模型的基础上,通过热模拟实验和金相分析建立描述Q235奥氏体晶粒加热长大、再结晶、道次间隙晶粒长大以及流变应力的数学模型;并通过编写用户子程序将其耦合到某11道次H型钢热轧工艺过程的三维热力微观组织有限元分析中,获得整个轧制过程中轧件内应力、应变、温度以及奥氏体晶粒的演化情况。研究结果表明:现有H型钢粗轧工艺可以细化腹板处的奥氏体组织;不同变形条件下多道次累积塑性应变数值相同时奥氏体细化程度相当。

关键词:H型钢;多道次热轧;奥氏体演化;数值分析

中图分类号:TG335 文献标志码:A 文章编号:1672-7207(2013)11-4468-06

3-D FEM simulation of austenite evolution in shape-metal multipass hot rolling

HE Qingqiang1, SUN Jia2, ZHAO Junyou1, YAN Chengxin1, YUAN Baomin1, LI Cuicui1

(1. College of Mechanical and Electronic Engineering, China University of Petroleum, Qingdao 266580, China;

2. China Merchants International Terminal (Qingdao) Co. Ltd., Qingdao 266555, China)

Abstract: In order to optimize the schedule of multi-pass hot rolling process of shape metal, effects of rolling parameters on the section size and microstructure evolution were investigated. Based on microstructure evolution equations available in literatures, a set of mathematic equations were reproduced to model the evolution of austenite grain size, recovery, static and dynamic recrystallisation and their effects on flow stress of materials. The equations were implemented into the commercial FE solver through subroutine programs for fully three dimensional thermo-mechanically coupled simulation of an eleven-pass hot rolling process, and then the distribution of stress, strain, temperature and the evolution of austenite grain size in cross section of beam blank were obtained. The simulation results show that the refined austenite grain mainly locates on the web of blank, and the grain is refined to a certain extent if the accumulated plastic strain under different rolling parameters is equivalent.

Key words: H-beam; multipass hot rolling; austenite evolution; numerical analysis

金属材料经受多道次高温塑性成型工艺时,其微观组织在成型过程中、道次间隙及成型后发生一系列相互连续的变化,成品内最终的微观组织及分布决定了产品的主要力学和物理性能。因此,为了分析现有加工工艺制度并进行合理优化,必须准确预测不同加工条件下微观组织的演化过程。从20世纪70年代末期开始,研究者在建立成型过程数学模型以及工艺过程的数值分析方面开展了大量研究和分析工作,其中,数学模型研究主要包括:坯料加热过程中晶粒长大数学模型研究[1],热变形过程中微观组织演化模型研究[2-3],冷却过程中组织相变数学模型研究[4]等。而有关成型工艺过程的数值分析主要包括:单道次或多道次板带材轧制分析[5-7],单道次线材热轧分析[8],多道次热轧微观组织演化过程的二维分析[9],模锻过程金属微观组织演化分析[10],利用广义平面应变法进行多道次型材热轧过程分析[11]等。为了准确分析H型钢多道次热轧工艺参数对奥氏体演化过程的影响,应进行三维热力微观组织耦合分析。但是,直接采用现有商用有限元软件分析时,由于轧件截面形状的巨大变化导致单元形态恶化,使计算精度降低直至无法完成分析过程。为此,本文作者在网格重构数值分析流程[12]基础上,进一步通过编写用户子程序把描述微观组织演化过程的数学模型耦合到计算分析过程中,并以某典型规格H型钢多道次粗轧工艺过程为例,完整地分析热轧过程的热、力、微观组织的演化过程,验证计算方法的有效性并对现有工艺参数对微观组织的演化过程的影响进行总结。

1 加热过程晶粒长大动力学模型

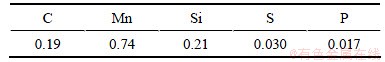

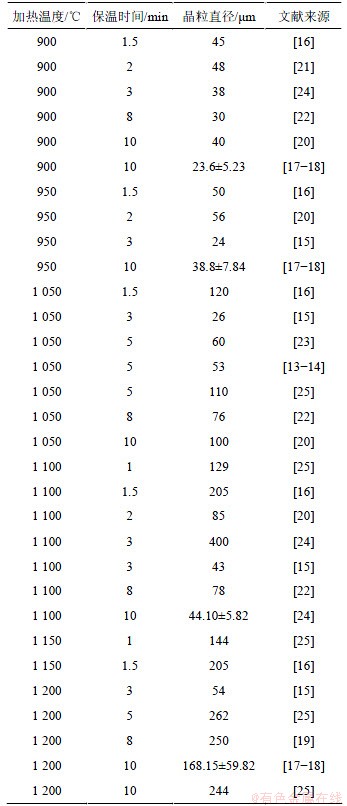

除了薄板坯连铸连轧工艺外,连铸坯通常都要重新加热到高于奥氏体化温度,进行均热和扩散处理,使坯料内组织和成分均匀。保温温度和时间决定了奥氏体的晶粒度。表1所示为材料的主要化学成分,表2所示为对同一种材料奥氏体晶粒的实验观测结果[13-25]。由表2可见:现有观测结果存在较大差别,以900 ℃为例,文献[22]中,保温8 min奥氏体晶粒直径为30 μm,文献[16]中保温1.5 min奥氏体晶粒直径为45 μm。为此,本文进行了进一步地实验观测,实验流程如下。

(1) 采用带WZK-1可控硅温度控制器的加热炉对试样加热,保温一定时间使其奥氏体化,后迅速放入事先准备好的足量冷水中进行淬火。

表1 Q235主要合金成分

Table 1 Chemical composition of Q235 质量分数/%

表2 奥氏体晶粒的实验观测结果

Table 2 Experiment data of Austenite grain

(2) 用砂轮打磨掉试样表面的氧化皮,研磨抛光后制作金相观测试样。

(3) 用过饱和苦味酸和餐具洗洁精配置成腐蚀剂,在加热到70 ℃左右时放入金相试样,在一般情况下要保温5~7 min,利用MM-6金相显微镜即可观测到原始奥氏体晶界。

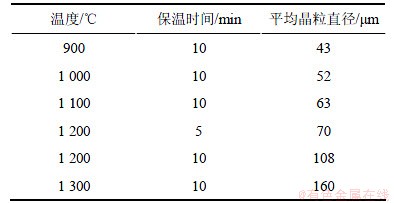

实验观测结果见表3。

表3 实验观测结果

Table 3 Experiment data of Austenite grain

建立如下数学模型来计算奥氏体晶粒的平均直径d:

(1)

(1)

式中:d0为未长大时的奥氏体晶粒直径,μm;A为待定参数;T为奥氏体化温度,K;t为保温时间,min;R=8.314 J/(mol·K),为通用气体常数。经过计算,对于Q235钢,d0=30 μm,A=1.56×1012。

2 热轧过程奥氏体再结晶预报模型

再结晶分数的数学模型为

(2)

(2)

式中:t0.5为再结晶完成50%所需时间;静态再结晶时,q=1;动态再结晶时,q=1.5。

临界动态再结晶塑性应变的数学模型为

(3)

(3)

完成50%再结晶所需时间的数学模型为

(4)

(4)

温度补偿应变速率参数为

(5)

(5)

3 道次间隙晶粒长大动力学模型

对于复杂断面型钢热轧过程而言,道次间隙时间tip通常超过了完成95%再结晶所需的时间,所以,必须考虑道次间隙的晶粒长大。采用下面的数学模型计算道次间隙期间晶粒直径的变化。

若仅发生静态再结晶,并且tip-K1t0.5≥1,则

(6)

(6)

若发生了动态再结晶,并且tip-K2t0.5≥1,则

(7)

(7)

若仅发生静态再结晶,并且tip-K1t0.5<1,则

(8)

(8)

若发生了动态再结晶,并且tip-K2t0.5<1,则

(9)

(9)

式中:K1~K6为材料常数,对于Q235钢,K1=4.32;K2=2.65;K3=1.5×1027;K4=8.2×1025;K5=4.0×107;K6=1.2×107;tip为轧制道次间隙时间;dMRX为动态再结晶奥氏体晶粒直径;dSRX为静态再结晶奥氏体晶粒直径。

4 H型钢多道次热轧工艺分析

4.1 基于网格重构数值分析流程

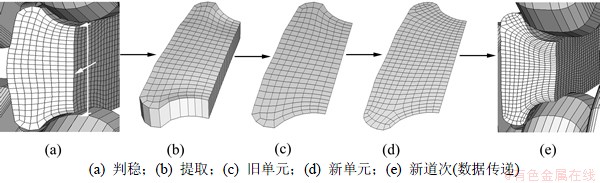

以某典型规格(截面高×宽为400 mm×200 mm,腹板厚为8 mm;翼缘厚为13 mm)H型钢2道次粗轧及间隙为例,给出多道次典型热轧过程的数值分析流程示意图。整个流程如下:(1) 建立首道次热轧三维热力微观组织耦合分析模型,在分析过程中,与设定的稳态判断条件进行对比,满足条件后形成稳态单元集合并终止该道次分析过程,见图1(a);(2) 提取稳态单元集合的几何数据建立道次间隙温度场和微观组织演变分析模型,利用程序提取并传递节点数据,见图1(b)~(d);(3) 建立下一道次热轧三维热力微观组织耦合分析模型,利用程序提取并传递温度场、微观组织演变等参数, 见图1(e)。

4.2 热轧工艺过程分析结果

H型钢采用如下生产流程:用步进式加热炉在1 310 ℃对矩形截面坯料加热并保温150 min后出炉;经高压水除鳞后进入可逆式粗轧机进行多道次粗轧;切头后进入由5架万能轧机和2架轧边机组成的连轧机组进行精轧。按照式(1)计算出加热后坯料内的初始奥氏体晶粒直径大约为390 μm。

图1 典型热轧过程数值分析流程示意图

Fig.1 Schematic flow chart of numerical procedure

采用基于稳态判断的数值分析流程[12]对多道次热轧进行数值分析,获得各道次轧制过程中及入精轧前轧件的等效塑性应变、温度、再结晶分数、奥氏体晶粒直径等参数的分布云图,分析时考虑道次间隙期间轧件向周围环境的散热及奥氏体晶粒的长大。

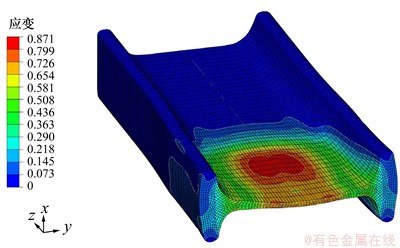

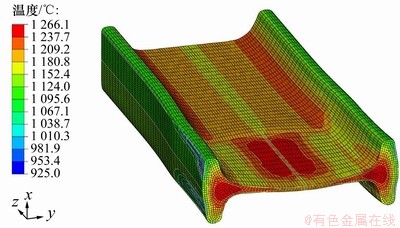

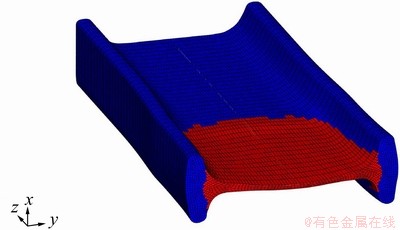

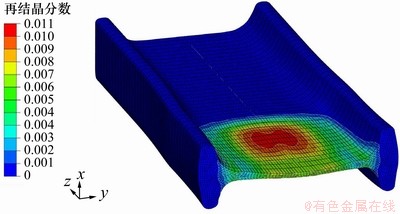

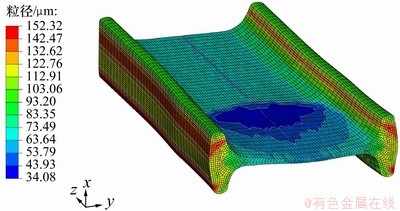

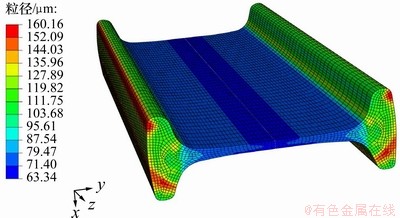

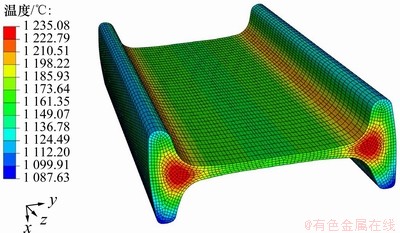

图2所示为经过多道次粗轧后轧件内等效塑性应变的分布情况,图3所示为此时的温度分布。从图2和3可以看出:各道次轧制时最大塑性变形出现在轧件腹板的中间部位。在仿真过程中,微观组织分析程序自动判断能够发生动态再结晶的范围,并计算动态再结晶分数、动态再结晶后的奥氏体晶粒直径,分别如图4~6所示。

图2 等效塑性应变分布云图

Fig.2 Predicted distributions of equivalent effective plastic strain

图3 温度分布云图

Fig.3 Predicted distributions of temperature

从图6可以看出:最小的奥氏体晶粒直径在34 μm左右,处于轧件腹板和轧辊的接触区域。最大的晶粒直径为152 μm左右,处于轧件的翼缘处,所以,经过多道次热轧,腹板内奥氏体晶粒得到了显著的细化。图7和图8所示分别为入精轧时轧件内奥氏体晶粒直径以及温度的分布情况。

图4 动态再结晶发生的区域

Fig.4 Predicted distributions of dynamic recrystallisation zone

图5 动态再结晶分数分布云图

Fig.5 Predicted distributions of dynamic recrystallisation fraction

图6 奥氏体晶粒粒径分布云图

Fig.6 Predicted distributions of dynamic recrystallisation grain

图7 入精轧前轧件奥氏体晶粒粒径分布云图

Fig.7 Predicted distributions of dynamic recrystallisation grain size before finish rolling

图8 入精轧前的轧件内温度分布云图

Fig.8 Predicted distributions of temperature before finish rolling

5 结论

(1) 经过多道次粗轧过程后,坯料内各部位奥氏体晶粒均得到了不同程度的细化,但腹板和翼缘处晶粒的细化程度和分布情况差别较大:由于腹板处的塑性变形能够诱发动态再结晶的发生,有效细化了奥氏体晶粒,晶粒尺寸比较均匀;反之,翼缘处的奥氏体晶粒未能得到有效细化,晶粒粗大而且分布不均。所以,细化翼缘的奥氏体晶粒必须依靠后续的精轧连轧过程实现。

(2) 从粗轧结束至入精轧的时间内,轧件内的奥氏体由于发生亚动态再结晶或者静态再结晶而长大:腹板晶粒由34 μm长大为64 μm;翼缘处最大的奥氏体晶粒直径由152 μm长大为160 μm。所以,为了有效利用粗轧对腹板奥氏体晶粒的细化作用,必须尽量减少粗轧后到入精轧机组的传送和切头时间。

(3) 制定轧制规程时必须考虑不同部位奥氏体晶粒的演变过程及其特点,粗轧规程以有效细化腹板晶粒为目标,对于翼缘只要保证其形状符合入精轧机组的要求即可;而精轧规程则以实现翼缘处的晶粒细化为主。

(4) 只要所有道次的累积塑性变形达到一定程度,不同温度/变形条件下腹板奥氏体晶粒的最小直径均在30~50 μm之间;在相同出炉温度下,采用2 m/s左右的轧制速度,腹板奥氏体晶粒直径的最小值接近30 μm。

参考文献:

[1] Hodgson P D. Microstructure modeling for property prediction and control[J]. Journal of Materials Processing Technology, 1996, 60(1/2/3/4): 27-33.

[2] Lin J, Liu Y. A set of unified constitutive equations for modeling microstructure evolution in hot deformation[J]. Journal of Materials Processing Technology, 2003, 143/144: 281-285.

[3] Serajzadeh Siamak. A mathematical model for evolution of flow stress during hot deformation[J]. Materials Letters, 2005, 59(26): 3319-3324.

[4] Ohjoon K. A technology changes and for the prediction and mechanical properties in control of micro-structural steel[J]. ISIJ International, 1992, 32(3): 350-358.

[5] DU Linxiu, ZHANG Zhongping, SHE Guangfu, et al. Austenite recrystallization and controlled rolling of low carbon steels[J]. Journal of Iron and Steel Research, International, 2006, 13(3): 31-35, 50.

[6] Reed R C, Akbay T, Shen Z, et al. Determination of reaustenitisation kinetics in Fe-0.4C steel using dilatometry and neutron diffraction[J]. Materials Science and Engineering A, 1998, 256(1/2): 152-165.

[7] Ahmed H, Wells M A, Maijer D M, et al. Modeling of microstructure evolution during hot rolling of AA5083 using an internal state variable approach integrated into an FE model[J]. Materials Science and Engineering A, 2005, 390(1/2): 278-290.

[8] Liu Y, Lin J. Modeling of micro-structural evolution in multi-pass hot rolling[J]. Journal of Materials Processing Technology, 2003, 143/144: 723-728.

[9] Hodgson P D, Gibbs R K. A mathematical model to predict the mechanical properties of hot rolled C-Mn and micro-alloyed steels[J]. ISIJ International, 1992, 32(12): 1329-1338.

[10] Anell E. Application of mathematical modeling to hot rolling and controlled cooling of wire rods and bars[J]. ISIJ International, 1992, 32(3): 440-449.

[11] Wang F, Zhu Q, Lin J, et al. Prediction of micro-structural evolution in hot rolling[J]. Journal of Materials Processing Technology, 2006, 177: 530-533.

[12] 贺庆强, 张勤河, 刘克强, 等. H型钢开坯过程的热力耦合有限元分析[J]. 系统仿真学报, 2007, 19(1): 19-20, 55.

HE Qingqiang, ZHANG Qinhe, LIU Keqiang, et al. Fully coupled temperature-displacement simulation of h-shape metal cogging[J]. Journal of System Simulation, 2007, 19(1): 19-20, 55.

[13] 田景, 杨王玥, 孙祖庆. 工艺参数对低碳钢形变强化相变的影响[J]. 材料热处理学报, 2005, 26(5): 62-67.

TIAN Jing, YANG Wangyue, SUN Zuqing. Influence of process parameters on the deformation enhanced ferrite transformation in a low carbon steel[J]. Transactions of Materials and Heat Treatment, 2005, 26(5): 62-67.

[14] 田景, 王国柱, 杨王玥, 等. 变形温度对形变强化相变完成时临界应变量的影响[J]. 塑性工程学报, 2006, 13(2): 80-84.

TIAN Jing, WANG Guozhu, YANG Wangyue, et al. Influence of deformation temperature on the critical strain for completion of DEFT[J]. Journal of Plasticity Engineering, 2006, 13(2): 80-84.

[15] 沈丙振, 方能炜, 沈厚发. 低碳钢奥氏体再结晶模型的建立[J]. 材料科学与工艺, 2005, 13(5): 516-520.

SHEN Binzhen, FANG Nengwei, SHEN Houfa, et al. Construction of the recrystallization model of low carbon steel during deformation[J]. Materials Science and Technology, 2005, 13(5): 516-520.

[16] 王瑞珍, 杨忠民, 赵燕, 等. 普通低碳钢奥氏体晶粒细化及其对变形强化相变铁素体晶粒尺寸的影响[J]. 钢铁研究, 2001(4): 21-24.

WANG Ruizhen, YANG Zhongmin, ZHAO Yan, et al. Austenite grain refinement and its influence on ferrite grain size of strain enhanced transformation for plain low carbon steel[J]. Research on Iron and Steel, 2001(4): 21-24.

[17] 杨王玥, 胡安民, 齐俊杰, 等. 低碳钢多道次热变形中的应变强化相变与铁素体动态再结晶[J]. 金属学报, 2000, 36(11): 1192-1196.

YANG Wangyue, HU Anmin, QI Junjie, et al. Strain-enhanced transformation and ferrite dynamic recrystallization of plain low carbon steel in successive hot deformation[J]. Acta Metallurgica Sinica, 2000, 36(11): 1192-1196.

[18] 杨王玥, 胡安民, 孙祖庆. 低碳钢奥氏体晶粒尺寸的控制[J]. 金属学报, 2000, 36(10): 1050-1054.

YANG Wangyue, HU Anmin, SUN Zuqing. Control of austenite grain size in a low carbon steel[J]. Acta Metallurgica Sinica, 2000, 36(10): 1050-1054.

[19] 傅云义, 杨平, 杨王玥, 等. 粗大奥氏体晶粒中应变诱导铁素体形成特点[J]. 北京科技大学学报, 2000, 22(2): 170-173.

FU Yunyi, YANG Ping, YANG Wangyue, et al. Characterization of strain induced ferrite formed in coarse austenite grained Q235 steel[J]. Journal of University of Science and Technology Beijing, 2000, 22(2): 170-173.

[20] 黄原定, 杨王玥, 孙祖庆. Q235钢的铁素体组织细化及其与力学性能关系[J]. 金属热处理, 2000(9): 1-3.

HUANG Yuanding, YANG Wangyue, SUN Zuqing. Microstructure refinement of Q235 steel and its effect on tensile properties[J]. Heat Treatment of Metals, 2000(9): 1-3.

[21] 窦晓峰, 鹿守理, 赵辉. Q235钢动态再结晶模型的建立[J]. 北京科技大学学报, 1998, 20(5): 465-470.

DOU Xiaofeng, LU Shouli, ZHAO Hui. Establishment of dynamic recrystallization model of Q235[J]. Journal of University of Science and Technology Beijing, 1998, 20(5): 465-470.

[22] 杨平, 崔凤娥, 傅云义, 等. Q235碳素钢应变诱导相变中的应力-应变曲线分析[J]. 金属学报, 2001, 37(6): 609-616.

YANG Pin, CUI Fenge, FU Yunyi, et al. Analysis of σ-ε curves during strain induced transformation in Q235 plain carbon steel[J]. Acta Metallurgica Sinica, 2001, 37(6): 609-616.

[23] 赵磊, 郑为为, 杨王玥, 等. Q235碳素钢多道次热变形中的组织演变及性能[J]. 北京科技大学学报, 2004, 26(5): 507-511.

ZHAO Lei, ZHENG Weiwei, YANG Wangyue, et al. Microstructure evolution and properties of Q235 plain carbon steel in multi-pass hot deformation[J]. Journal of University of Science and Technology Beijing, 2004, 26(5): 507-511.

[24] 王瑞珍, 杨忠民, 车彦民. 低碳钢Q235形变奥氏体的静态再结晶[J]. 钢铁研究学报, 2006, 18(3): 33-37.

WANG Ruizhen, YANG Zhongmin, CHE Yanmin. Static recrystallization of deformed austenite in low carbon steel Q235 journal of iron and steel research[J]. Journal of Iron and Steel Research, 2006, 18(3): 33-37.

[25] Sun W P, Hawbolt E B. Comparison between static and metadynamic recrystallization: An application to the hot rolling of steels[J]. ISIJ International, 1997, 37(10): 1000-1009.

(编辑 赵俊)

收稿日期:2012-10-18;修回日期:2012-12-22

基金项目:山东省中青年科学家奖励基金资助项目(BS2011ZZ020);青岛市科技计划项目(13-1-4-257-JCH);中央高校基本科研业务费专项资金资助项目(12CX04062A)

通信作者:贺庆强(1978-),男,山东东阿人,博士,副教授,从事金属高温塑性成形过程的综合数值分析研究;电话:0532-86983310;E-mail: heqingqiang_upc@163.com