文章编号:1004-0609(2009)05-0949-06

红土镍矿在NaOH亚熔盐体系中的预脱硅

赵昌明,翟玉春,刘 岩,段华美

(东北大学 材料冶金学院,沈阳 110004)

摘 要:研究常压下高浓度氢氧化钠浸取红土镍矿的预脱硅过程,考察搅拌强度、液固比、氢氧化钠浓度、反应温度和原矿粒径对红土镍矿中硅的反应率的影响。结果表明:二氧化硅的反应率受克-金-布产物层固膜扩散控制, 并由阿累尼乌斯方程得到反应的表观活化能为53.74 kJ/mol。结合动力学实验结果和电子扫描电镜(SEM)及X射线能谱(EDAX)分析,证明在反应过程中通过固相产物层的内扩散为反应过程的控制步骤。

关键词:红土镍矿;预脱硅;亚熔热体系;浸出;氢氧化钠

中图分类号:TF 11.31 文献标识码:A

Pre-desilication of laterite in NaOH sub-molten salt system

ZHAO Chang-ming, ZHAI Yu-chun, LIU Yan, DUAN Hua-mei

(School of Materials and Metallurgy, Northeastern University, Shenyang 110004, China)

Abstract: The leaching mechanism of silicon dioxide from a laterite by concentrated NaOH under the atmosphere pressure was studied. The effects of stirring speed, mass ratio of alkali-to-ore, initial NaOH concentration, reaction temperature and particle size on the reaction rate of silicon dioxide were reported. The results show that the experimental data of the reaction rate are fit to the Crank-Ginsting-Braunshtein’s diffusion-through-layer-reaction-control-model. According to the Arrhenius expression, the apparent activation energy for the leaching reaction is 53.74 kJ/mol. The results of the kinetic experiment and SEM and EDAX analysis prove that the internal diffusion on the solid product layer is the rate-controlling step in the leaching process.

Key words: laterite; pre-desiliconization; sub-molten salt system; leaching; sodium hydroxide

镍是一种重要的战略有色金属,具有良好的机械强度、延展性和化学稳定性,在国民经济和国防建设中具有重要的地位[1-3]。镍在冶金材料、电池、医疗卫生和军工等领域应用日益扩大[4-8]。世界上可开采的镍资源有两类,一类是硫化矿,另一类是红土镍矿[9-10]。由于硫化矿成熟的提取工艺,60%镍产量来源于硫化矿。世界可供开发的硫化矿资源已经不多,而红土镍矿资源丰富,采矿成本低,因此,开发利用红土镍矿具有重要的现实意义[11-12]。

红土镍矿是镍的硅酸盐氧化型矿物,矿中镍含量在1%左右,而二氧化硅含量高达40%~50%。二氧化硅含量过多,会造成处理红土镍矿时产生大量废渣,给环境带来很大负担。因此,研究新的红土镍矿处理方法,使其有价元素都得以合理利用具有重要意义。本课题组采用常压高浓碱浸取红土镍矿脱硅,将其制成白炭黑。本文作者研究搅拌强度、液固比、氢氧化钠浓度、反应温度和原矿粒径等条件对红土镍矿反应过程的影响和反应动力学,此工作尚未见文献报道。

1 实验

1.1 实验试剂和仪器

实验所用的红土镍矿组成十分复杂,矿中元素的含量分别为(质量分数):SiO2 51.4%、Al2O3 3.99%、NiO 0.852%、MgO 11.1%和Fe2O3 16.1%等,所用氢氧化钠为AR级;水为去离子水。

成分分析采用岛津ICPQ-100型ICP-AES装置。

反应釜由不锈钢制成,自带加热套,通过KWT型可控硅温度控制器控温,用镍铬-镍硅热电耦测温,温控精度为±2 ℃,反应器上装有搅拌装置和回流冷凝管,其接口处、采样口以及釜盖均采取密封措施,利用取样勺取样,实验装置如图1所示。

图1 实验装置图

Fig.1 Experimental apparatus: 1—AC adjustable voltage speed controller; 2—Agitator; 3—Reflux condenser; 4—Thief hatch; 5—Nipple; 6—Thermocouple; 7—Electrical bar; 8—Temperature controller; 9—Oil-bath; 10—Stirrer; 11—Thermocouple; 12—Digital display device

1.2 实验方法

称取一定量氢氧化钠放入反应釜中,加入去离子水至设定浓度,开通回流冷凝管中的冷却水,并开始搅拌。将反应釜升温到设定温度,待体系温度恒定后,按一定的液固比(NaOH溶液质量与红土镍矿的质量比)加入红土镍矿,反应开始计时,定时取液体样,样品经骤冷、过滤、洗涤,用ICP-AES分析其硅含量。

2 结果与讨论

2.1 搅拌强度的影响

红土镍矿与碱溶液反应是固-液反应过程。在反应温度为185 ℃,氢氧化钠浓度为80%,液固比为5?1,原矿粒径为44~53 μm的条件下,考察搅拌强度对二氧化硅反应率的影响,结果如图2所示。由湿法冶金动力学原理可知,在固-液多相浸出反应过程中,控制步骤为液膜扩散时,搅拌强度对反应率(α)影响大,通常可提高反应率40%~65%。但从图2可发现,搅拌强度对二氧化硅反应率影响并不大,这说明液膜扩散不是过程的控制步骤。当搅拌强度大于450 r/min时,对反应率的影响很小,故本研究在搅拌转速为450 r/min下进行。

图2 不同转速时反应率随时间的变化

Fig.2 Relationship between reaction rate and leaching time

2.2 原矿粒径的影响

在反应温度为185 ℃,氢氧化钠浓度为80%,液固比为5?1,搅拌转速为450 r/min条件下,考察原矿粒径对二氧化硅反应率的影响,结果如图3所示。从图3可看出,原矿粒径的大小对二氧化硅反应率有明显的影响,随原矿粒径的减小,二氧化硅反应速率显著增大,这是由于随原矿粒径的减小,比表面积增大,内扩散阻力减小,加快了反应速率。不同原矿粒径下,二氧化硅反应率代入克-金-布动力学方程[13-15]:f (α) = 1+2(1-α)-3(1-α)2/3=kt,得出f (α)与反应时间t呈良好的直线关系。这说明反应过程受通过产物层的内扩散所控制。

图3 不同粒径时的SiO2反应率和f (α)随时间的变化

Fig.3 Relationships between α or f (α) and leaching time for various particle sizes

2.3 液固比的影响

在反应温度为185 ℃,氢氧化钠浓度为80%,搅拌转速为450 r/min,原矿粒径为44~53 μm条件下,考察不同液固比对二氧化硅反应率的影响,如图4所示。从图4可知,当液固比超过5?1时,在反应120 min后,二氧化硅的反应率随液固比增大几乎不变,而在液固比为5?1的条件下,体系中的氢氧化钠大大过量,从而能保证氢氧化钠浓度在反应过程中基本保持不变。不同液固比下的f (α)与反应时间也呈直线关系。这说明在不同液固比下,红土镍矿在高浓度碱溶液中的反应过程也都为内扩散控制。

2.4 氢氧化钠浓度的影响

在反应温度为185 ℃,液固比为5?1,搅拌转速为450 r/min,原矿粒径为44~53 μm条件下,考察氢氧化钠浓度对二氧化硅反应率的影响,如图5所示。从图5可知,二氧化硅的反应率随氢氧化钠浓度的增大而升高,这说明初始氢氧化钠浓度的增大可以强化红土镍矿的反应,这是由于随初始氢氧化钠浓度的增大,体系中OH-离子的活度增大,提高化学反应速率和传质推动力,加速了红土镍矿的反应率。初始氢氧化钠浓度增大,溶液黏度增大,反应过程的外扩散传质阻力增大,反应率应下降,但实验结果却恰好相反,这也就从另一方面说明了反应过程不受外扩散控制。从图5可知,在不同初始氢氧化钠浓度下,f (α)与浸出时间同样呈直线关系。这说明改变氢氧化钠浓度,红土镍矿在高浓氢氧化钠溶液中的反应过程仍然符合 克-金-布动力学模型。

2.5 反应温度的影响

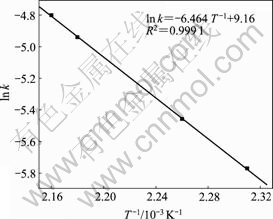

在氢氧化钠浓度为80%,液固比为5?1,搅拌转速为450 r/min,原矿粒径为44~53 μm条件下,考察反应温度对二氧化硅反应率的影响,如图6所示。从图6可知,温度对反应的影响显著,二氧化硅反应率随反应温度升高迅速增大。温度升高,化学反应速率及反应物、产物的扩散速率增加。在不同反应温度下,f (α)与浸出时间同样呈良好的线性关系。将图6中各温度下f (α)与浸出时间之间的关系进行线性回归,所得直线斜率即为不同温度下的k值。根据Arrhenius方程得 。将lnk对1/T作图,结果如图7所示,为一条直线。由直线斜率可求得在实验条件下,浸出反应表观活化能E=6 464R=53.74 kJ/mol。此活化能包括本征化学反应活化能以及物质传递过程的综合结果。

。将lnk对1/T作图,结果如图7所示,为一条直线。由直线斜率可求得在实验条件下,浸出反应表观活化能E=6 464R=53.74 kJ/mol。此活化能包括本征化学反应活化能以及物质传递过程的综合结果。

图4 不同液固比时的SiO2反应率和f (α)随时间的变化

Fig.4 Relationship between α or f (α) and leaching time under different mass ratios of alkali-to-ore

图5 不同NaOH浓度时的SiO2反应率和f (α)随时间的变化

Fig.5 Relationships between α or f (α) and leaching time under various NaOH concentrations

由以上分析可知,在所有的实验条件下得到的动力学实验数据均符合克-金-布动力学方程,这说明反应过程确为通过固相产物层的内扩散所控制。因此,在实验温度范围内,原矿粒径44~53 μm的红土镍矿在高浓氢氧化钠溶液中的浸出动力学方程可描述如下:

图6 不同反应温度时的SiO2反应率和f (α) 随时间的变化

Fig.6 Relationships between α or f (α) and leaching time under different reaction temperatures

图7 lnk 与T -1的关系

Fig.7 Relationship between lnk and T -1

3 浸出机理分析

红土镍矿在氢氧化钠溶液中的反应为

mMgO·nSiO2+Fe2O3+NaOH=

Na2O·nSiO2+Fe(OH)3+mMg(OH)2+H2O

红土镍矿在反应过程中会有固体产物(FeOH)3和Mg(OH)2生成。根据反应动力学分析结果,红土镍矿在高浓氢氧化钠溶液中的反应过程为通过固相产物层的内扩散所控制。为证明固膜的存在,在反应温度为185 ℃、氢氧化钠浓度为80%、原矿粒径为44~53 μm的条件下,将反应不同时间后的红土镍矿粒经喷金处理后,采用扫描电镜观察其形貌变化,结果如图8所示。

图8(a)表明,反应前红土镍矿的表面光滑、致密度高,矿石结晶完善,图8(b)显示红土镍矿在反应80 min后,矿粒表面变得粗糙。为查明固相产物层的组成,用X射线光电子能谱对其元素组成进行了分析(见图9)。结果表明,红土镍矿在反应前,矿粒表面各元素的质量分数分别为:Si 26.886%、Al 8.010%、Fe 16.606%、Mg 12.066%、Ni 5.449%。反应80 min后红土镍矿颗粒表面各元素的质量分数为:Si 1.259%、Al 0.574%、Fe 17.602%、Mg 37.421%、Ni 5.448%。从分析结果可知,红土镍矿在反应后,其表面固相产物的主要组成元素为Fe、Mg和Ni等,Si和Al含量较反应前大大减少。这证明了固相产物层的存在,与动力学研究结果是一致的,进一步证明了反应过程为通过固相产物层的内扩散所控制。

图8 红土镍矿和部分反应渣的SEM像

Fig.8 SEM images of laterite(a, b) and partially leached laterite(c, d)

图9 红土镍矿与反应渣表面的EDAX谱

Fig.9 EDAX patterns of laterite(a) and partially leached laterite(b)

4 结论

1) 研究红土镍矿与高浓度氢氧化钠的反应,得出搅拌强度、液固比、氢氧化钠浓度、反应温度和原矿粒径与反应率的关系。

2) 反应过程受由内扩散控制,满足克-金-布动力学方程。

3) 红土镍矿在高浓度氢氧化钠中的反应过程符合固膜扩散控制的收缩未反应核模型,受产物层的内扩散控制。在温度为150~190 ℃,初始氢氧化钠浓度为80%,液矿比为5?1 的条件下,原矿粒径为44~53 μm的红土镍矿在高浓度氢氧化钠中的反应动力学方程为

REFERENCES

[1] KOTZSE I J. Pilot Plant production of ferronickel from nickel oxide ore sand dusts in a DC arc furnace[J]. Minerals Engineering, 2002, 15: 1017-1022.

[2] 朱景和. 世界镍红土镍矿资源开发与利用技术分析[J]. 世界有色金属, 2007(10): 7-9.

ZHU Jing-he. Exploration laterite-nickel ore and analysis on utilization technology[J]. World Nonferrous Metals, 2007(10): 7-9.

[3] 刘 岩, 翟玉春, 王 虹. 镍生产工艺研究进展[J]. 材料导报, 2006, 20(3): 79-81.

LIU Yan, ZHAI Yu-chun, WANG Hong. Research on production process of nickel[J]. Materials Review, 2006, 20(3): 79-81.

[4] 刘大星. 从镍红土镍矿中回收镍、钴技术的进展[J]. 有色金属(冶炼部分), 2002(3): 6-10.

LIU Da-xing. Recent development in nickel and cobalt recovery technologies from laterite[J]. Nonferrous Metals, 2002(3): 6-10.

[5] 张守卫, 谢曙斌, 徐爱东. 镍的资源、生产及消费状况[J]. 世界有色金属, 2003(11): 9-14.

ZHANG Shou-wei, XIE Shu-bin, XU Ai-dong. Status quo of nickel resources, production and consumption[J]. World Nonferrous Metals, 2003(11): 9-14.

[6] 李宜轩, 杨立明, 胡顺峰. 进口印尼红土镍矿质量状况及贸易对策[J]. 金属矿山, 2008(6): 6-8.

LI Yi-xuan, YANG Li-ming, HU Shun-feng. Quality analysis of imported indonesian laterite-nickel ore and trade countermeasures[J]. Metal Mine, 2008(6): 6-8.

[7] 刘 瑶, 丛自范, 王德全. 对低品位镍红土镍矿常压浸出的初步探讨[J]. 有色矿冶, 2007, 23(5): 28-30.

LIU Yao, CONG Zi-fan, WANG De-quan. Primary probe into normal atmospheric leaching of low-nickel laterites[J]. Non-Ferrous Mining and Metallurgy, 2007, 23(5): 28-30.

[8] MOSKALYK R R, ALFANTAZI A M. Niekel laterite processing and electrowinning praetiee[J]. Minerals Engineering, 2002, 15(20): 593-605.

[9] NAYAK J C. Production of ferro-nickel from Sukinda laterites in rotary kiln—electric furnace[J]. Trans Indian Inst Met, 1985, 38(3): 241-247.

[10] PICKLES C A. Drying kinetics of nickeliferous limonitic laterite ores[J]. Minerals Engineering, 2003, 16(12): 1327-1338.

[11] 张友平, 周渝生, 李肇毅, 李维国. 红土镍矿资源特点和火法冶金工艺分析[J]. 铁合金, 2007(6): 18-21.

ZHANG You-ping, ZHOU Yu-sheng, LI Zhao-yi, LI Wei-guo. Characteristics of laterite resource and analysis on its pyrometallurgy process[J]. Ferro-Alloys, 2007(6): 18-21.

[12] 李建华, 程 威, 肖志海. 红土镍矿处理工艺综述[J]. 湿法冶金, 2004, 23(4): 191-194.

LI Jian-hua, CHENG Wei, XIAO Zhi-hai. Review on process technologies of laterite-nickel ore[J]. Hydrometallurgy of China, 2004, 23(4): 191-194.

[13] 畅永锋, 翟秀静, 符 岩, 李斌川, 张廷安. 还原焙烧红土镍矿的硫酸浸出动力学[J]. 分子科学学报, 2008, 24(4): 241-245.

CHANG Yong-feng, ZHAI Xiu-jing, FU Yan, LI Bin-chuan, ZHANG Ting-an. Sulphuric acid leaching kinetics of pre-reduced laterite ores[J]. Journal of Molecular Science, 2008, 24(4): 241-245.

[14] 吴一峰, 刘峙嵘, 曾 凯, 李 鹰. 铝土矿渣浸取动力学研究[J]. 化工矿物与加工, 2008, 37(5): 9-10.

WU Yi-feng, LIU Zhi-rong, ZENG Kai, LI Ying. Study on leaching kinetics of bauxite[J]. Residue, Industrial Minerals & Processing, 2008, 37(5): 9-10.

[15] 严永华, 刘期崇, 夏代宽, 王建华. 磷酸分解磷矿石的动力学[J]. 高校化学工程学报, 1998, 12(3): 265-270.

YAN Yong-hua, LIU Qi-chong, XIA Dai-kuan, WANG Jian-hua. Reaction kinetics of phosphate ore in phosphoric acid[J]. J Chem Eng of Chinese Univ, 1998, 12(3): 265-270.

基金项目:国家重点基础研究发展计划资助项目(2007CB613603)

收稿日期:2008-10-07;修订日期:2009-02-15

通讯作者:翟玉春,教授,博士;电话:024-83687731;E-mail: lnzhaochangming@yahoo.com.cn

(编辑 李向群)