DOI: 10.11817/j.ysxb.1004.0609.2021-37953

孔挤压对不同铝合金斜耳片疲劳性能的影响

刘莹莹,任凯鑫,李洁洁,周 年

(西安建筑科技大学 冶金工程学院,陕西 西安 710055)

摘 要: 采用芯棒直接挤压对7050和2A97铝合金斜耳片进行孔挤压强化,对比分析了其在孔挤压前后的疲劳性能,并通过OM、SEM、XRD、TEM及Abaqus软件,研究了两种合金的微观组织、疲劳断口形貌及残余应力分布。结果表明:孔挤压强化可有效提高两种合金斜耳片的疲劳性能,尤其对2A97斜耳片的提高效果更加显著,其疲劳循环周次提高幅度可达71.87%。耳片疲劳寿命得以提高的原因是经孔挤压后,两种耳片孔周围疲劳源的位置由孔内壁表面转移至孔内壁近表面处,疲劳源的数量也明显减少,并且在孔周围形成了位错胞状结构和残余压应力。2A97合金孔挤压强化效果较好主要是因为孔挤压后产生了较多处的细小位错环和较大的残余应力,使得其疲劳裂纹萌生和扩展速率的降低幅度较大而产生的。

关键词: 7050铝合金;2A97铝合金;斜耳片;孔挤压;疲劳性能

文章编号:37953 中图分类号:TG146 文献标识码: A

飞机上的带孔结构件由于受交变载荷的作用,易在孔周围出现应力集中,造成疲劳损伤而严重影响飞机的安全和使用寿命[1~3],因此,提高带孔件的疲劳性能具有重要意义。

目前常采用孔挤压强化工艺来提高带孔件的疲劳性能,该技术可以改善孔周围组织和应力分布情况,提高带孔件的疲劳寿命,在航空领域得到了广泛应用[4,5]。研究者们对多种铝合金材料开展了孔挤压强化研究,如7A85合金[6]、7B04合金[7]、7075合金[8]、2024合金[9,10]、2124[11]、2297铝合金[12]等,主要集中在残余应力分布和微观组织等方面。

7050铝合金具有强度高、塑性好等优点,已成为大飞机制造业通用的结构材料[13];2A97铝锂合金是我国自主研发的第三代铝合金,与7×××系铝合金相比,铝锂合金具有低密度、高比强度、高比模量等优点,因而作为承力构件和刚度构件而广泛应用于军事、航空等领域[14]。

本文研究了国产7050合金和2A97两种铝合金斜耳片在孔挤压前后的疲劳性能,对比分析了两种合金的孔挤压强化效果,拟用2A97合金替代7050合金从而达到减重和提高环境适应性的目的,此外研究结果也可为飞机上不同部位铝合金耳片在材料选择、尺寸设计、强化技术选用等方面提供一定的工艺技术参数和理论基础。

1 实验材料及方法

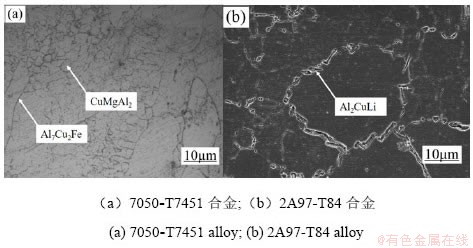

实验材料为10 mm厚的7050铝合金和2A97铝合金,其热处理状态分别为T7451和T84。采用OLYMPUS GX51光学显微镜观察两种合金的微观组织,如图1所示;采用EDX4500H铝合金化学元素分析仪测得的两种合金化学成分如表1所示。

由图1可以看出,7050-T7451铝合金由CuMgAl2、Al7Cu2Fe相和杂质相组成,晶界清晰可见,晶粒尺寸大小不均匀,形状基本为等轴形,部分晶粒呈现出较大的团聚现象(图1a);2A97-T84铝合金中存在大量的分布均匀的Al2CuLi(T1)相,晶粒呈块状且均匀分布,晶界清晰可见 (图1b)。

图1 两种合金的显微组织

Fig.1 Microstructure of the two alloys

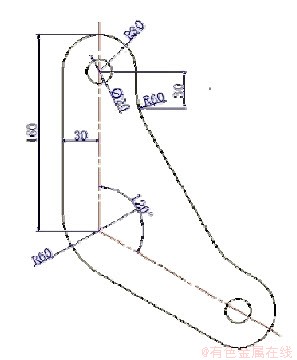

将两种合金按图2的要求进行斜耳片试样的加工,随后在WDW2010电子万能试验机上采用芯棒直接挤压的方法进行孔挤压:挤压前先对耳孔内表面涂抹润滑剂MoS2以降低挤压芯棒工作段与耳孔内壁的摩擦力,接着将耳片置于与带孔垫圈同轴处,之后将二者放置于试验机压缩夹具上并插上芯棒,随后调节设备的横梁直到夹具的上夹头与芯棒接触为止。最后,压头以1 mm/min的速度将挤压芯棒缓慢压入耳片,直到芯棒的工作段完全离开耳片的耳孔内壁为止。挤压时的过盈量为5.3 %,耳孔直径为Φ19 mm,芯棒工作端的直径为Φ20 mm。

室温疲劳试验按HB5287-1996在Zwick Amsler 150 HFP 5100疲劳试验机上进行。采用D8 ADVANCE A25 X射线衍射仪和Abaqus有限元模拟分析软件对孔挤压前后应力分布情况进行模拟。采用JEM 2000透射电镜和VEGAⅡ扫描电子显微镜对试样组织及断口形貌进行观察,其中腐蚀剂为:1 HF+1.5 HCL+2.5 HNO3+95 H2O。

图2 斜耳片试样的形状与尺寸(mm)

Fig.2 Shape and size of the oblique lug (mm)

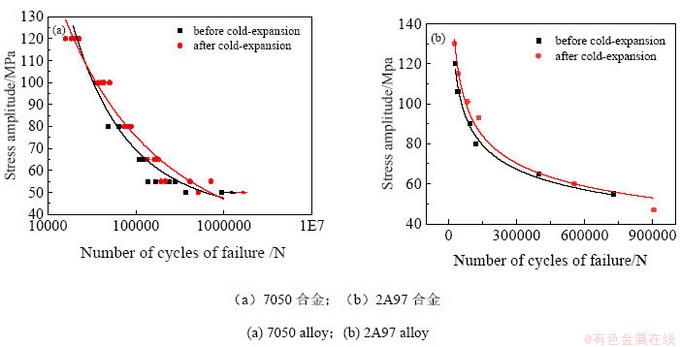

表1 两种合金的化学成分(%)

Table 1 The chemical compositions of two alloys(%)

2 结果与讨论

2.1 S-N曲线

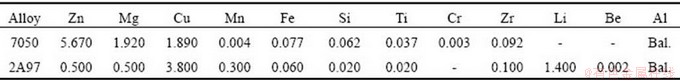

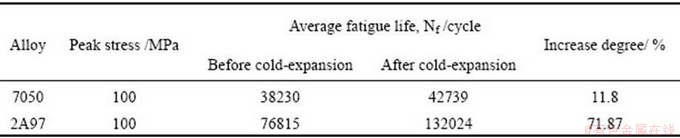

图3、表2分别为两种铝合金斜耳片孔在挤压前后的S-N曲线和疲劳试验结果。对比可知:孔挤压后两种铝合金斜耳片的疲劳寿命均得到了提高,且2A97合金的强化效果更加显著。如表2所示,当峰值应力为100 MPa时,7050合金斜耳片孔挤压前后的中值疲劳寿命分别为38230周和42739周,提高幅度为11.8%;而2A97合金斜耳片孔挤压前后的中值疲劳寿命分别为76815周和132024周,提高幅度达71.87%。

图3 孔挤压前后两种铝合金斜耳片的S-N曲线

Fig.3 S-N curve of oblique lugs before and after extrusion

表2 两种合金斜耳片的疲劳性能(峰值应力为100MPa)

Table 2 Fatigue properties of the oblique lugs (Peak stress is 100MPa)

2.2 残余应力测试结果分析

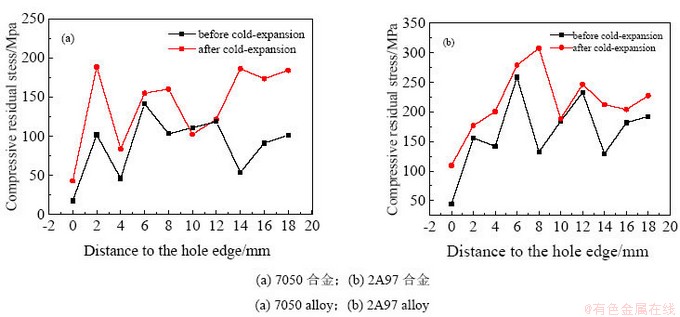

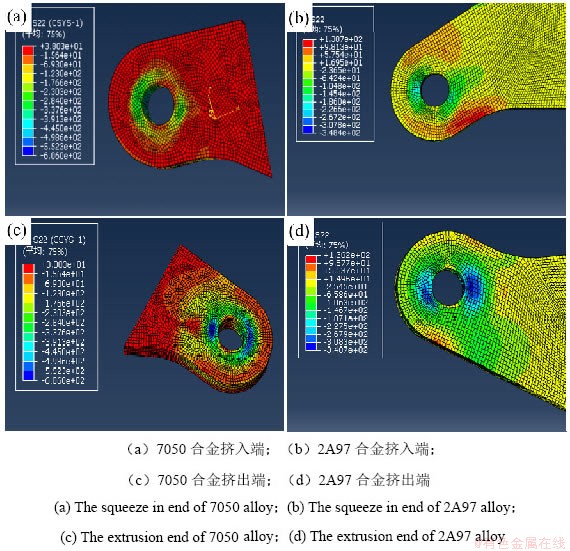

图4为孔挤压前后两种铝合金斜耳片的周向残余应力分布情况。可以看出,经孔挤压后,两种合金孔壁表层金属均发生了应力重构,形成了较高的残余压应力,其中7050和2A97合金斜耳片的最大残余应力值分别是187.5MPa和307.8MPa,提高幅度分别为43.75 MPa和49.1 MPa,位置由距孔6 mm分别向内延伸至14 mm(图4a)和8 mm处(图4b)。图5为孔挤压前后两种合金斜耳片的周向残余应力云图。可以看出,挤入端和挤出端均产生了残余压应力,且挤出端的残余压应力影响区分布更广、残余压应力值更高。

对比两种合金模拟和试验所得的残余应力场可以得出,残余应力场的分布规律基本一致,但7050合金和2A97合金的模拟值与试验值的误差分别为15%和13%,这可能是因为耳片在制备过程中表面不够平滑,影响了X射线的聚焦精度,或者是因为在数值模拟分析过程中采取简化步骤等原因,造成模拟值与测量值之间存在一定的差异。

图4 两种合金挤压前后斜耳片的残余应力分布曲线

Fig.4 Residual stress distribution curve of oblique lugs before and after extrusion

图5 两种合金斜耳片挤入端和挤出端的周向残余应力云图

Fig.5 Circumferential residual stress nephogram of the squeeze and extrusion end of oblique lugs

2.3 微观组织分析

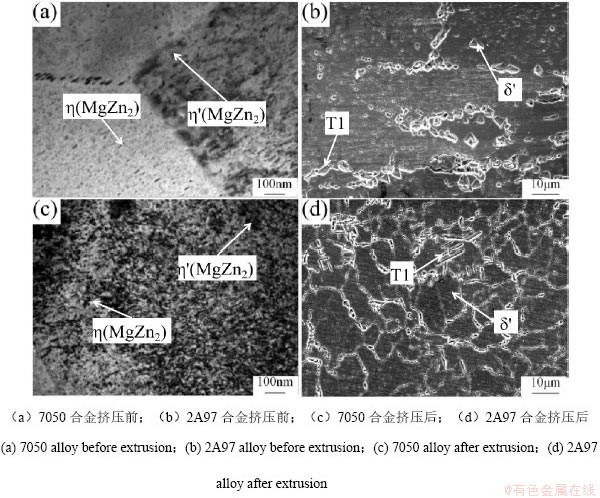

图6为两种合金孔挤压前后的透射组织。可以看出,孔挤压使孔壁材料的微观组织发生了改变。孔挤压前,7050合金是细小的针状η(MgZn2)强化相和盘状η'(MgZn2)析出相(图6a),2A97合金挤压为尺寸较小的呈饼状或块状的δ'相和T1相未再结晶组织(图6b)。而经孔挤压后,由于两种合金耳片孔内壁表层金属受到芯棒的挤压产生了剧烈的塑性变形,晶界发生滑移和扭曲,因此晶体内部均产生了大量位错并缠结成位错胞状结构(图6c、6d),且在2A97合金中形成了较多处的细小位错环,此外2A97合金中的球状δ'相及针状T1相的层错能较高[15],促进共面滑移,引起位错的增殖,同时使裂纹发生偏析,促进裂纹闭合,提高了裂纹扩展的抗力。因此,孔挤压后2A97合金耳片的疲劳寿命提高幅度相比7050合金大一些。

图6 两种合金孔挤压前后的透射组织

Fig.6 TEM microstructure of the two alloys before and after extrusion

2.4 疲劳断口形貌

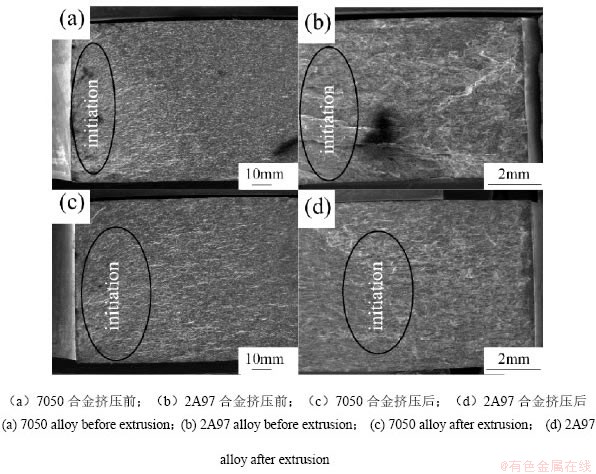

图7为两种铝合金斜耳片在孔挤压前后的宏观断口形貌。可以看出,挤压前后的试样断口均产生了疲劳裂纹,但疲劳源的位置和数量却发生了改变:由孔内壁表面转移至孔内壁近表面处,且数量明显减少(图7c、7d)。这说明孔壁金属产生了残余压应力,有效抑制孔壁边缘的应力集中现象,减小孔壁表面裂纹萌生的几率,阻碍孔壁内侧表面疲劳裂纹的产生,从而改变了裂纹源的位置和数量[16]。

图8为两种铝合金斜耳片在孔挤压前后的微观断口形貌。可以看出,孔挤压后疲劳条带变窄(图8c、8d),且2A97合金斜耳片的疲劳辉纹更加细密(图8d)。此外,结合微观组织可以看出,孔壁表层金属产生了位错胞状结构和残余应力,阻碍了疲劳裂纹尖端向前扩展,缩短了裂纹扩展的距离,降低了裂纹扩展的速率,使得疲劳条带变窄(图8c、8d),从而提高了耳片的疲劳寿命。

图7 孔挤压前后的宏观断口形貌

Fig. 7 Macro-fracture morphology before and after extrusion

图8 孔挤压前后的微观断口形貌

Fig. 8 Micro-fracture morphology before and after extrusion

3 结论

1)孔挤压工艺可显著提高两种铝合金斜耳片的疲劳性能,且2A97铝合金斜耳片的强化效果较好,当峰值应力为100 MPa时其疲劳循环周次提高幅度达71.87%。

2)孔挤压使两种合金耳片孔壁材料的微观组织发生了改变,挤压后均在晶体内部产生了大量位错并缠结成位错胞状结构,并在2A97合金中形成了较多处细小的位错环,同时由于2A97合金中δ'相和T1相的层错能较高,引起位错增殖,使裂纹发生偏析,促进裂纹闭合,提高了裂纹扩展的抗力,使得其疲劳寿命提高幅度较大。

3)两种合金斜耳片均在挤压过程中形成了位错胞状结构和残余压应力,降低了裂纹尖端应力,阻碍了裂纹萌生和进一步扩展,疲劳条带变窄,从而提高了耳片的疲劳性能,且与7050合金相比,2A97合金斜耳片的位错环较多,残余应力值较大,疲劳辉纹较细密,因此其孔挤压的强化效果更好。

REFERENCES

[1] 孙宇幸, 刘莹莹, 张君彦,王梦婷,李洁洁. 应力集中和应力比对TC18合金锻件疲劳强度的影响[J].稀有金属, 2019, 43(07): 699-705.

SUN Yu-xing, LIU Ying-ying, ZHANG Jun-yan, WANG Meng-ting, LI Jie-jie. Effects of stress concentration and stress ratio on fatigue strength of TC18 alloy forgings[J].Rare Metals,2019,43(07):699 -705.

[2] 张乐, 刘莹莹, 孙宇幸, 薛希豪. 缺口和平均应力对TC18棒材疲劳强度的影响[J].中国有色金属学报, 2018, 28(12): 2450-2456.

ZHANG Le, LIU Ying-ying, SUN Yu-xing, XUE Xi-hao. Influence of notch and average stress on fatigue strength of TC18 bars[J]. The Chinese Journal of Nonferrous Metals, 2018, 28(12): 2450-2456.

[3] LIU Ying-ying, ZHANG Le, SHI Xiao-nan, XUE Xi-hao. High-cycle fatigue properties and fracture behavior of Ti-5Al-5Mo-5V-1Cr-1Fe titanium alloy [J]. Rare Metal Materials and Engineering, 2018, 47(12): 3666-3671.

[4] FU Yu-can, Ge Ende, SU Hong-hua, XU Jiu-hua, LI Ren-zheng. Cold expansion technology of connection holes in aircraft structures: A review and prospect[J]. Chinese Journal of Aeronautics, 2015, 28(04): 961-973.

[5] LIU Jie,Xu H.L,Zhai H.B,Yue Z.F.Effect of detail design on fatigue performance of fastener hole[J].Materials and Design, 2010, 31(2):976-980.

[6] WEN Shi-zhen, Liu Cui-yun, WU Ruo-lin, MA Chao-li.The effect of hole extrusion on the high-cycle fatigue properties of 7A85 aluminum alloy straight lugs[J].Rare Metal Materials and Engineering, 2015, 44(10): 2358-2362.

[7] HOU Shuai, ZHU You-li, CAI Zhi-hai, WANG Yan-li, NI Yong-heng, DU Xiao-kun. Effect of hole cold expansion on fatigue performance of corroded 7B04-T6 aluminum alloy[J]. International Journal of Fatigue, 2019, 126:210-220.

[8] Z. Emami Geiglou,TN Chakherlou. Investigating the effect of cold expansion process on the fatigue behavior of aluminum alloy 7075-T6 in double-lap shear joints[J]. Proceedings of the Institution of Mechanical Engineers, Part L: Journal of Materials: Design and Applications, 2019, 233(8):1645-1660.

[9] 王连庆,卞江, 张晗, 吴圣川. 孔挤压强化对2024铝合金疲劳性能的影响[J].航空材料学报, 2020, 40(06): 45-51.

WANG Lian-qing, BIAN Jiang, ZHANG Han, WU Sheng-chuan. The effect of hole extrusion strengthening on the fatigue properties of 2024 aluminum alloy[J]. Journal of Aeronautical Materials, 2020, 40(06): 45-51.

[10] H.D. Gopalakrishna, H.N. Narasimha Murthy,M. Krishna, M.S. Vinod, A.V. Suresh. Cold expansion of holes and resulting fatigue life enhancement and residual stresses in Al 2024-T3 alloy-An experimental study[J]. Engineering Failure Analysis, 2009,17(2): 361-368.

[11] 伊琳娜, 汝继刚, 黄敏, 宋德玉, 王亮.孔挤压强化对2124铝合金疲劳寿命及微观组织的影响[J].航空材料学报, 2016, 36(05):31-37.

YI Lin-na, RU Ji-gang, HUANG Min, SONG De-yu, WANG Liang. Effects of hole extrusion strengthening on fatigue life and microstructure of 2124 aluminum alloy[J]. Journal of Aeronautical Materials, 2016, 36(05):31-37.

[12] HUANG Yong-jie, LI Hai-tao, YANG Xu,GUAN Zhi-dong, LI Zeng-shan, SUN Ying. Improving the fatigue life of 2297-T87 aluminum-lithium alloy lugs by cold expansion, interference fitting, and their combination[J]. Journal of Materials Processing Tech., 2017, 249: 67-77.

[13] 刘兵, 彭超群, 王日初, 王小锋, 李婷婷.大飞机用铝合金的研究现状及展望[J].中国有色金属学报, 2010, 20(09):1705-1715.

LIU Bing, PENG Chao-qun, WANG Ri-chu, WANG Xiao-feng, LI Ting-ting. Research status and prospects of aluminum alloys for large aircraft[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(09): 1705-1715.

[14] 高文理, 闫豪, 冯朝辉, 陆政. 时效制度对2A97铝锂合金组织和力学性能的影响[J].中国有色金属学报, 2014, 24(05): 1206-1211.

GAO Wen-li,YAN Hao, FENG Chao-hui, LU Zheng. The effect of aging system on the structure and mechanical properties of 2A97 aluminum-lithium alloy[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(05): 1206-1211.

[15] 马云龙, 林小红, 刘丹阳, 陆丁丁, 李劲风. 两种铝锂合金薄板析出相及动静态性能比较[J]. 稀有金属, 2019, 43(07): 673-678.

MA Yun-long, LIN Xiao-hong, LIU Dan-yang, LU Ding-ding, LI Jin-feng. Comparison of the precipitation phases and dynamic and static properties of two aluminum-lithium alloy sheets[J]. Rare Metals, 2019, 43(07): 673-678.

[16] 王艺淋, 潘清林,韦莉莉,李波,李晨. 高强7050-T7451铝合金厚板的疲劳断口特征[J].机械工程材料,2013, 37(06):26-30.

WANG Yi-lin, PAN Qing-lin, WEI Li-li, LI Bo, LI Chen. Fatigue fracture characteristics of high-strength 7050-T7451 aluminum alloy thick plates[J]. Materials for Mechanical Engineering, 2013, 37(06): 26-30.

Effect of hole extrusion on fatigue properties of different aluminum alloys oblique lugs

LIU Ying-ying, REN Kai-xin, LI Jie-jie, ZHOU Nian

(School of Metallurgical Engineering, Xi'an University of Architecture and Technology, Xi'an 710055, China)

Abstract: The oblique lugs of 7050 aluminum alloy and 2A97 alloy by mandrel direct extrusion were investigated, and the fatigue properties of the two kinds of alloy of oblique lugs before and after hole extrusion were compared and analyzed. Then the microstructure, fatigue fracture morphology and residual stress distribution of the two alloys were investigated by OM, SEM, XRD TEM and Abaqus software. The results show that the fatigue properties of these oblique lugs can be improved effectively by the hole extrusion strengthening process, especially for the 2A97 aluminum alloy oblique lugs. For example, while the peak stress is 100 MPa, the fatigue cycles of the strengthened 7050-T7451 alloy and 2A97-T84 alloy lug are increased by 11.8% and 71.87%, respectively. There are two main reasons for the increase in fatigue cycles. One reason is the variation of fatigue source position and number around the lug hole, they change from the surface of inner wall to near inner wall and the number of the fatigue sources is decreased obviously. The other reason is the formation of dislocation cell structure and residual compressive stress around the hole during extrusion. In addition, more smaller dislocation loops and larger residual stress are produced in the 2A97 alloy during extrusion, which makes the rate of initiation and propagation of fatigue crack decrease in some degree. Therefore, the strengthening effect of the 2A97 alloy d is better.

Key words: 7050 aluminum alloy; 2A97 alloy; oblique lugs; hole extrusion; fatigue properties

Foundation item: Project (2020KW-033) supported by The Key Research and Development Program International Cooperation Project of Shaanxi; Project (20JC024) supported by The Industrialization Project of Shaanxi Provincial Department of Education; Project (ZR2141) supported by The Science and Technology Fund of Xi'an University of Architecture and Technology.

Received date: 2021-3-23;Accepted date:

Corresponding author: Liu Yingying; Tel: 029-82205097;E-mail: wfllyy7779@163.com

基金项目:陕西省重点研发计划国际合作项目(2020KW-033);陕西省教育厅产业化项目(20JC024);西安建筑科技大学科技基金(ZR2141)

投稿日期:2021-3-23;修订日期:

通讯作者:刘莹莹,副教授,博士;电话:029-82205097;E-mail:wfllyy7779@163.com