DOI:10.19476/j.ysxb.1004.0609.2019.06.04

P-ECAP挤压ZK60镁合金空心壁板工艺参数优化

石 磊1, 2,闵志宇1,贺俊光2,姚 怀2,刘 亚2,张 伟1

(1. 洛阳理工学院 材料科学与工程学院,洛阳 471023;

2. 河南科技大学 材料科学与工程学院,洛阳 471023)

摘 要:为了确定合理的工艺参数可行域,利用有限元法模拟了ZK60镁合金空心壁板挤压成形宏观场变量分布,并通过实验验证了模拟结果。研究分三个步骤,首先通过等温热压缩实验获得ZK60镁合金应力应变关系,其工艺参数覆盖典型的加工工艺状态;其次,建立不同工艺参数的有限元模型;最后,根据等效应变、温度场、速度场分析确定工艺参数可行域。结果表明:坯料温度度400~420 ℃时,等效应变和温度场分布不均匀;480 ℃时,等效应变分布均匀,但出口温度太高,超过520 ℃。在挤压速度为5~7.5 mm/s时,温升小,温度均匀性好;挤压速度大于10 mm/s,温升大,温度不均匀;挤压速度越大,流速场越不均匀。因此,合适的温度为440~460 ℃,挤压速度小于7.5 mm/s。

关键词:镁合金;工艺参数;挤压;有限元模拟

文章编号:1004-0609(2019)-06-1161-09 中图分类号:TG376.2 文献标志码:A

在轻质合金的挤压研究中,热成形能力是一个热点,尤其是运输领域所用的轻质合金板的成形能力备受关注[1]。在由铸坯到锻件的加工中,工艺参数决定了工件的力学性能和热成形能力,因此研究工艺参数显得尤为重要[2-3]。在热变形过程中的温度和挤压速度往往是影响微观组织演变的重要因素,因此工艺参数成为合金变形过程中研究的热点[4-5]。在高温变形过程中,坯料初始温度和挤压速度影响合金的流变性能,进而影响合金在成形区流动均匀性。在成形区的流动均匀性进而影响合金的内应力、流速场过度不均匀甚至会产生褶皱或裂纹。因此温度和挤压速度成为合理工艺参数的要素,也是微观组织发生动态再结晶判据中最重要的因素[6-8]。GUO等[9]和LI等[10]研究了工艺参数对峰值温度等宏观表现等的影响规律,获得了工艺参数中初始坯料温度和挤压速度的最佳组合等可行域。

采用数值模拟和实验研究相结合的方法研究合金的成形能力是一种经济有效的方法[11-12]。孙宇等[13]综述了多种用于模拟的方法,其中有限元法精确度较高。谢建新等[14]通过有限元法分析分流孔的配置方案对金属流动行为、挤压温度及成形质量的影响。赵国群等[15]研究分析不同边界条件对AZ31 镁合金变形的等效应变分布,确定了等效应变分布不均匀是导致材料微观组织和力学性能不均匀的因素。王斌等[16]分析了变形温度和变形速度对合金等效应变、等效应 力、温度场以及变形载荷的影响规律,确定了工艺参数的最优区间。工艺参数对成形能力和成形质量的重要性不言而喻,前人采用该方法研究优化了金属材料的各种塑性成形的工艺参数可行域,然而,在镁合金等通道转角分流挤压(Prothole-equal channel angular pressing, P-ECAP)中的工艺参数对成形能力的研究目前的研究尚未见报道,而且是一个值得研究的方向。

本研究中,通过热压缩实验获得了镁合金在不同应变速率和温度时的应力-应变关系曲线;然后利用上述数据,建立通过P-ECAP模具挤出空心壁板的宏观成形有限元模型。最后,利用有限元模型结合实验研究工艺参数对宏观温度场、速度场、等效应变等的影响规律,进而确定工艺参数的可行域。

1 实验

1.1 原料

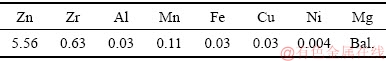

实验用原材料为ZK60镁合金,其成分见表1。

表1 ZK60镁合金化学成分

Table 1 Chemical composition of AZ31 magnesium alloy (mass fraction, %)

1.2 研究方法

为了预测挤压温度对ZK60镁合金空心壁板的宏观变形情况,该研究分为两个步骤。

1) 热压缩实验:通过线切割加工d 10 mm×15 mm的原始坯料试样,利用Gleeble-1500试验机在不同的温度、应变速率和应变量的工艺条件下进行热压缩实验。该工艺条件覆盖ZK60镁合金空心壁板的工件成形区域工作条件,其工艺参数如下:应变速率为10、1、0.1和0.01 s-1,温度为250、300、350、400、450和500 ℃,应变范围为0.69~1.39(相对压下量为50%~ 75%)。在热压缩中采用通CO2气体保护为防止氧化,在试样的两端涂抹石墨水剂以减小摩擦。

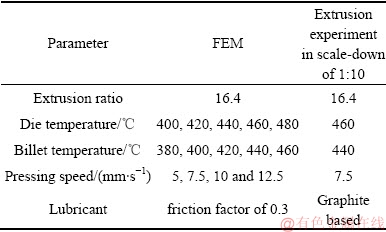

2) 制定挤压工艺参数(见表2),利用热压缩实验得到的应力应变数据作为材料模型的本构,通过基于DEFORM-3D软件所建立的有限元模型,并通过实验验证有限元模型的可靠性,最后模拟得到镁合金空心壁板在挤压成形过程中的宏观场变量演变规律。由于空心壁板的挤压实验成本较高,本文研究中将几何结构按10:1的比例进行缩小后进行挤压实验。将模拟结果与缩比实验所得到的挤压力挤出件进行比较讨论;按比例缩小后的应变量和应变速率不会发生变化,具有可行性。

表2 ZK60镁合金空心板的挤压工艺参数

Table 2 Hot extrusion parameters of ZK60 magnesium alloy hollow plate

2 ZK60镁合金空心壁板挤压有限元模型

2.1 挤压系统几何结构

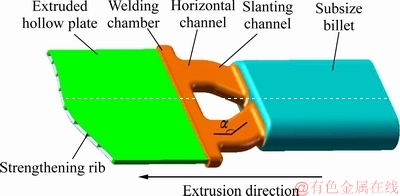

基于Solidworks软件,设计了挤压筒、工件和挤压模具。金属的流动过程如图1所示。利用较小的坯料加工较大的板材是一种新的技术,目的是节省挤压力,SHI等[17]报道了一种被称为P-ECAP挤压的技术,提出了利用小坯料挤压铝合金实心壁板的几何结构,在传统分流模的通道中植入了等通道转角结构,不但能细化晶粒提高挤出件强度指数,还可以通过降低总挤压比进而降低挤压力。

本文研究的结构与该研究相似,但由于镁合金空心壁板的结构特征,在分流模上增加了型芯。关于P-ECAP结构的介绍已在文献[17-19]中详尽,本文不予累述。本文研究的对象是宽度为798.7 mm,厚度为15 mm,均布加强筋7处,加强筋和壁厚均为4 mm,可用于高速列车覆盖件。

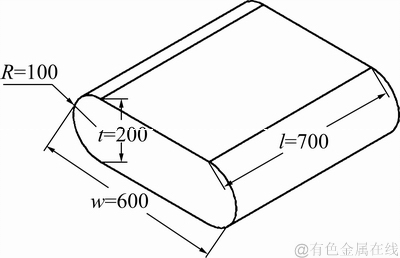

根据P-ECAP挤压技术结构特点,绘制了挤压系统的几何结构。考虑坯料的流动性和减少流动死区以避免过大剪切力等因素,设计了坯料的形状[1],如图2所示;其中挤压比为坯料的横截面积与挤出工件的横截面之比,实验和模拟中挤压比的值如表2所示。

图1 合金成形流动示意图

Fig. 1 Basic design of metal flow

图2 坯料形状和尺寸特征

Fig. 2 Structure and size of flat billet (Unit: mm)

2.2 有限元模型的建立

在Solidworks软件中将该挤压系统的几何结构装配完成,考虑到该结构沿挤压方向具有两个对称面,为了提高有限元模拟的效率和精度,沿对称面将几何结构剖切开,基于DEFORM-3D软件,取1/4进行有限元建模和模拟。

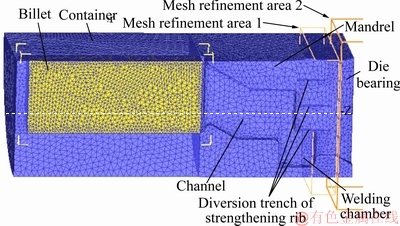

图3所示为挤压系统结构的1/4建立的有限元模型,除了坯料以外的其余部分均设置为刚体,坯料设置为塑性材料。包括模具和挤压筒等工具均选为H13钢,坯料采用热压缩实验中建立的应力应变关系数据作为ZK60镁合金的变形本构。选用Newton-Raphson迭代法进行求解,将网格划分为四面体网格,并且在模具工作带附近的空间区域针对工件设计了网格细化,主变形区与其他区域的网格体积比为1:6,即图3中的网格细化区域1;由于挤出板为薄壁结构,因此挤出板部分的网格细化为1:3,即图3中的网格细化区域2。摩擦模型选为采用的是库伦摩擦模型,关于有限元建模更为详细的介绍请见文献[17-19]。

图3 挤压系统有限元模型和结构示意图

Fig. 3 Geometric and FE models P-ECAP extrusion (1/4 model)

图4 实验挤出的ZK60镁合金空心壁板

Fig. 4 Hollow sheet-metal of ZK60 magnesium alloy plate in P-ECAP extrusion

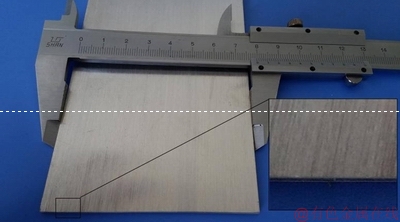

通过缩比实验研究挤出了ZK60镁合金壁板,宽度为79.9 mm,厚度为1.5 mm,均布加强筋7处,加强筋和壁厚均为0.4 mm,如图4所示。由于通过缩比实验获得的空心壁板壁厚较小,图4中将带有加强筋的区域进行了局部放大。针对在缩比实验中的情况建立了对应结构的有限元模型。

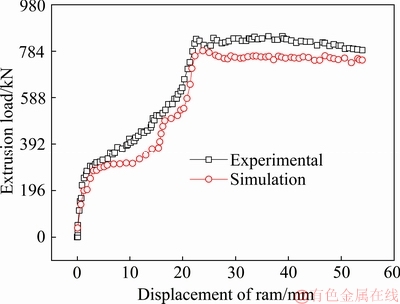

按照P-ECAP系统挤压ZK60的模具结构进行1:10缩小后的模拟和实验研究的挤压力随位移变化情况如图5所示。两种方法得到的挤压力在挤压杆位移为23 mm时达到峰值,两种研究方法的载荷相对误差峰值为11.15%。两条曲线有1处交点,这相当于在局部的误差为0,误差最大处为13.86%。从模拟数据可知,在挤压力达到峰值前,挤压力有3个增加区域:1) 分流变形。2) 等通道转角变形;显然,在进入焊合腔前,由于ECAP结构带来的变形导致了挤压力的增大,但这种变形时进入焊合腔的金属产生了更多的应变量,即挤出之前的预变形[20],这将有利于挤出。3) 焊合腔的填充和挤出工作带的变形。而实验记录的数据这种阶段性上升并不明显,可能跟记录仪器误差有关。挤压力达峰值之后,挤压力有缓降趋势,这是由于挤压筒内的坯料减少,坯料与模具之间的摩擦力减小导致的;变形过程中必然有温升,可能也是导致挤压力缓降的原因之一。两种研究方法的得到的挤压力结果对比表明,有限元模型是可靠的。

图5 P-ECAP模拟和实验中的挤压力对比

Fig. 5 Comparison of extrusion load during P-ECAP extrusion from FE simulation and experiment

3 模拟结果分析

3.1 等效应变分布规律

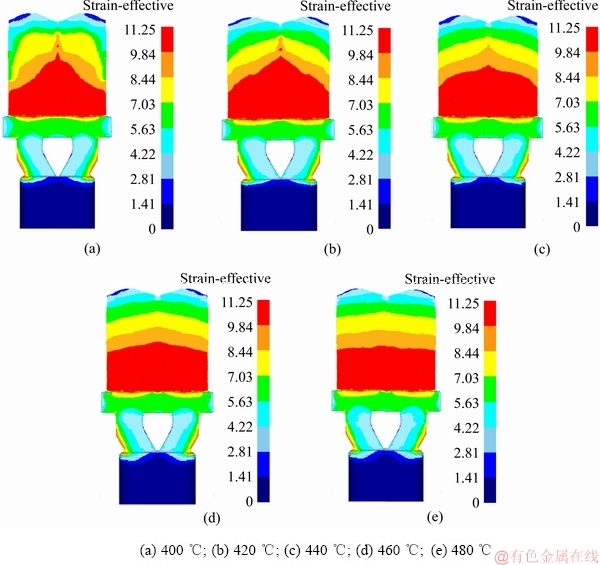

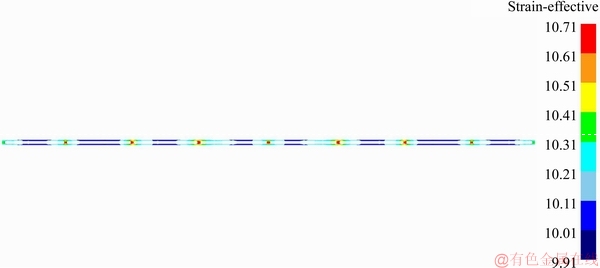

图6所示为不同初始坯料温度时ZK60镁合金在挤压过程中的等效应变分布情况。在不同的坯料初始温度时,等效应变场的是不同的,温度的高低影响了流动性;在较低温度400~420 ℃时,在两股合金的焊合处,等效应变在挤出横断面上呈“山字形”焊合面处的等效应变值高于同截面的其他部分;随着温度升高,等效应变在相同的横截面上越接近,坯料温度为480 ℃时,不论焊合前后,两股合金在同一横截面上的等效应变几乎相等,区间边界线近乎一条直线。

为此,截取了温度为480 ℃时距离末端为500 mm处的横断面等效应变场。如图7所示。在该界面上,等效应变分布非常均匀,其值约为9.91~10.71之间。但是在加强筋处,等效应变值稍大,可能与摩擦导致的应变量增大有关,加强筋处的合金在三个方向上与模具接触。导致了局部等效应变稍大。

图6 不同初始坯料温度时变形体的等效应变分布

Fig. 6 Contours of effective strain of workpieces at different initial temperatures

图7 480 ℃时变形体横截面的等效应变分布

Fig. 7 Contours of effective strain on cross section of workpiece at 480 ℃

标准差SD值可确定某一变量在某一规定的区域中的分布均匀性,SD值越小则越均匀。SD定义为

(1)

(1)

式中: ,xi为第i个节点处的变量值;

,xi为第i个节点处的变量值;

xa为所有节点处变量的平均值;N为考察界面节点的数量。

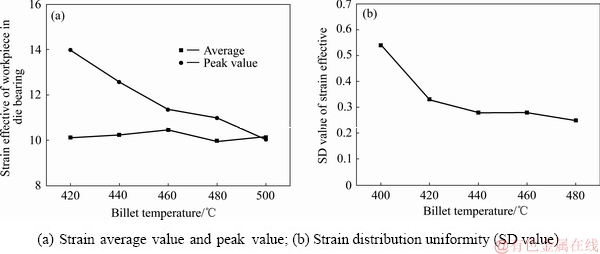

图8所示为不同初始坯料温度时空心壁板模口处等效应变的平均值、峰值和SD值。由图8可知,当温度增大时,挤出空心壁板在考查截面上的峰值减小,平均值保持不变;如前所述,温度的升高增加了合金的流动性,使变形趋于均匀。随着坯料原始加热的温度从400 ℃上升到480 ℃,SD值逐渐降低,其中,在400 ℃至420 ℃时降低幅度较大;因此温度对等效应变的均匀性具有影响,尤其在420 ℃以下时影响更显著。

3.2 温度场分布规律

图8 不同初始坯料温度时壁板横截面上的等效应变

Fig. 8 Distribution of strain on cross section of workpieces with different initial temperatures

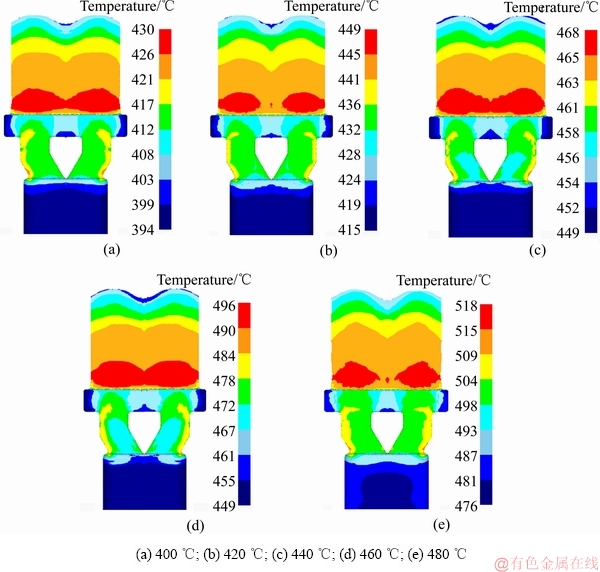

图9 不同初始坯料温度时变形体的温度场分布云图

Fig. 9 Temperature contours of workpieces at different initial temperatures

图9所示为不同初始坯料温度时,挤压速度为7.5 mm/s时变形体的温度场分布规律。针对任意一个初始坯料温度,变形体均有近似一致的规律;首先,由于考虑到变形起热,考虑了将模具温度比坯料温度低20 ℃,因此坯料温度在挤压过程中微降;其次,坯料在进入分流孔时具有第一次温升,这是由于径缩变形造成的;而后坯料进入分流孔中的转角,有轻微温升;坯料进入焊合腔后,由于填充过程流速一定会降低,这个阶段的温升比模具与坯料的热传导作用小,所以显示出了一定的温降;最后坯料在工作带处的剧烈变形导致了最明显的温升。

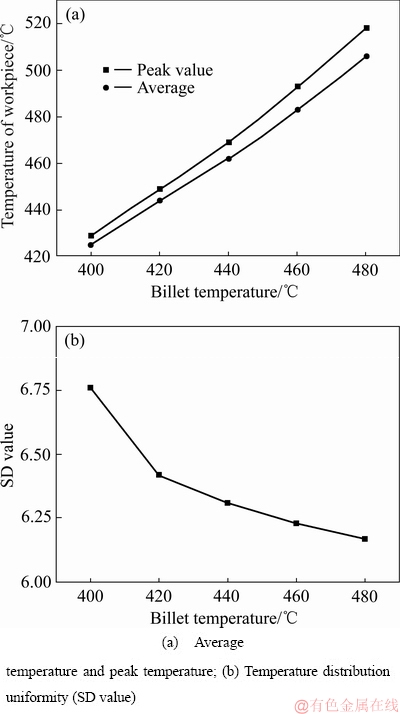

图10所示为具出口处变形体的平均温度和峰值温度以及温度的SD值。随着坯料温度的升高,整个变形体的温度也有规律的呈线性升高。模具出口处合金温度SD值随着初始坯料温度的升高有缓慢降低的趋势,说明在温度较高时,模具出口处的温度分布更均匀。在400~420 ℃时,SD值降低幅度最大,然后随着温度的升高,SD值降幅较小。说明在420 ℃以下的温度可能不是合适的挤压温度。而坯料初始温度480℃时,出口温度最高接近520 ℃,对镁合金属于较高的温度,可能会出现表面颜色变黑等过热现象,不亦采用。因此从本节数据分析,合适的温度应为440~460 ℃。

图10 不同初始坯料温度时工作带区域变形体的温度情况

Fig. 10 Distribution of extruded hollow sheet-metal at die bearing with different initial temperatures

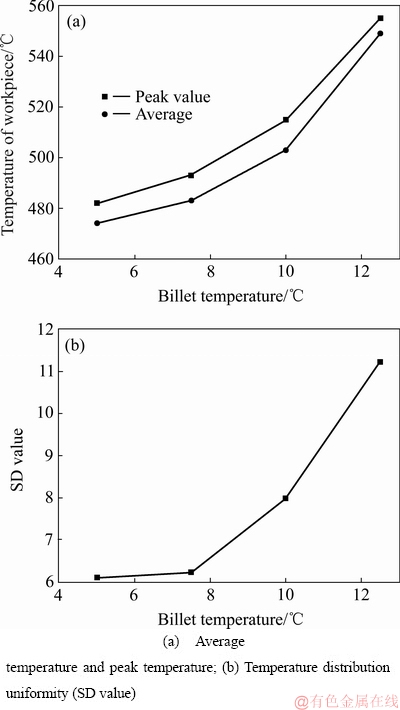

图11所示为坯料温度460 ℃和不同挤压速度时工作带区域变形体的温度情况。在挤压速度为5~7.5 mm/s时,温度升幅不大,其分布均匀性也较好。但是在挤压速度升高至10 mm/s及以上时,温度升幅较大,其分布均匀性也下降,SD值猛增。根据该部分研究结果判断,速度不宜过高,以不超过7.5 mm/s为宜。

图11 不同挤压速度时工作带区域变形体的温度情况

Fig. 11 Distribution of extruded hollow sheet-metal at die bearing with different extrusion speeds

3.3 速度场分布规律

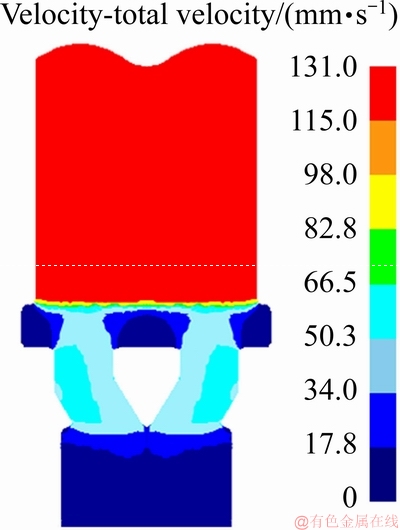

由于不同初始坯料温度时候的速度场近乎一致,因此本节取坯料温度为460 ℃时的情况分析,如图12所示。在远离分流孔的坯料区,各节点速度值均为挤压杆速度7.5 mm/s;在靠近分流孔的区域,坯料的速度开始增大。进入分流孔后的合金坯料速度约为45 mm/s左右,这个由阶段挤压比决定的,坯料的截面积是两个分流孔截面之和的6倍左右。由于焊合腔的截面积较大,合金进入焊合腔后速度降低,焊合腔的两端均有流动死区,靠近边缘处部分节点的速度值接近于0;最后,坯料在工作带附近加速,在挤出工作带后以均匀的速度流出,离开模具口后,为刚性体,速度不再变化,统计的20个节点平均值为123.15 mm/s。

图12 温度为460℃、挤压杆速度7.5 mm/s时速度场分布云图

Fig. 12 Contours of velocity at temperature of 460 ℃ and ram velocity of 7.5 mm/s

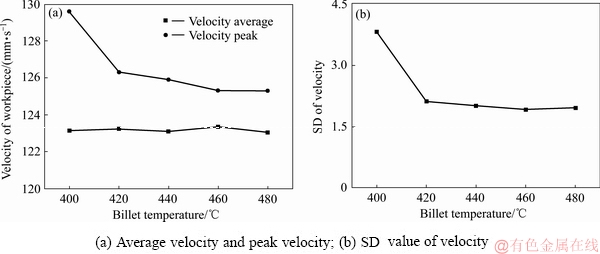

图13所示为温度对流速场影响情况的分析结果。分析了在工作带处的平均流速、峰值流速和流速的SD值。平均流速随温度变化无明显变化,而峰值流速则随温度的升高而降低,尤其是在温度为420 ℃以下更明显,无论是峰值速度还是SD值,表现出近乎一致的规律,在温度超过420 ℃后,变化微小。该现象说明在温度较低时流速场的不均匀性较大,也暗示了在温度低于420 ℃时不是合适的加工温度。

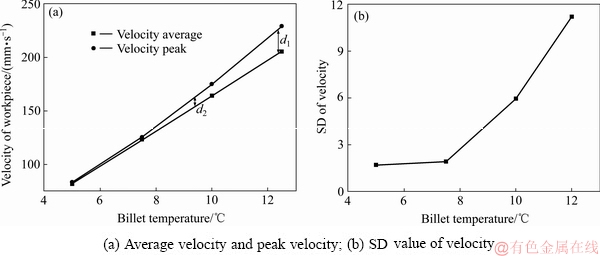

图14所示为挤压杆速度对流速场的影响结果分析情况。在图13(a)中,显然d1>d2,而且这种趋势随着挤压速度的增大有扩大趋势,即:随着挤压速度的增大,峰值速度和平均速度的差值明显增大,表示在挤出空心镁合金壁板的横截面上的流速场的不均匀性增大。图13(b)中关于流速场的SD值也表明了这一现象。随着挤压速度的增大,尤其是速度大于7.5 mm/s以后,SD值剧烈增大,表明速度越快,流速场越不均匀。

图13 不同温度时工件在工作带处的速度场分析

Fig. 13 Distribution of extruded sheet-metal at die bearing with temperature

图14 不同挤压速度时工件在工作带处的速度场分析

Fig. 14 Distribution of extruded hollow sheet-metal at die bearing with ram speed

4 结论

1) 坯料温度度400~420 ℃时,等效应变分布最不均匀,在挤出壁板中间大边缘小;温度为480 ℃时,等效应变分布最均匀;加强筋处等效应变稍大;随着坯料温度的增大,SD值逐渐降低,400~420 ℃区间变化幅度最大。随着坯料温度的升高,变形体的温度呈线性升高。温度SD值随坯料温度的升高缓慢降低。坯料温度从400 ℃升高到420 ℃,温度SD值降低幅度最大。420 ℃以下的温度不是合适的挤压温度。坯料温度480 ℃时,出口温度过高,不亦采用。峰值流速随温度的升高而降低,420 ℃以下最明显;合适的温度应为440~460 ℃。

2) 三个温升阶段分别为:Ⅰ坯料在进入分流孔,温升明显;Ⅱ坯料进入分流孔中的转角,有轻微温升;Ⅲ坯料在工作带处的剧烈变形导致了最明显的温升;一个温降阶段为坯料进入焊合腔后,温升比模具与坯料的热传导作用小,总体显示为温降。

3) 在速度为5~7.5 mm/s时,变形导致的温度的升幅小,温度的分布均匀性好,挤压速度升高大于10 mm/s,温度的升幅较大,温度SD值猛增。 随着挤压速度的增大,峰值速率与平均速率的差值增大,速度大于7.5 mm/s以后,速度SD值剧烈增大,速度越快,流速场越不均匀。速度不宜超过7.5 mm/s。

致谢:

第一作者特别感谢导师西北工业大学已故杨合教授在世时对该论文内容的指导。

REFERENCES

[1] 石 磊. 铝合金等通道转角分流大宽展挤压成形机理研究[D]. 西安: 西北工业大学, 2015.

SHI Lei. Investigation on deformation mechanism of aluminum alloy during porthole ECAP spread extrusion[D]. Xi’an: Northwestern Polytechnical University, 2015.

[2] GUO Z H, HOU H, ZHAO Y H, QU S W. Optimization of AZ80 magnesium alloy squeeze cast process parameters using morphological matrix[J]. Transactions of Nonferrous Metals Society of China, 2012, 22(2): 411-418.

[3] YU Z Q, ZHOU G S, TUO L F, SONG C F. Optimization of extrusion process parameters of Incoloy028 alloy based on hot compression test and simulation[J]. Transactions of Nonferrous Metals Society of China, 2017, 27(11): 2464-2473.

[4] PARK S H, YOU B S, MISHRA R K, SACHDEV A K. Effects of extrusion parameters on the microstructure and mechanical properties of Mg-Zn-(Mn)-Ce/Gd alloys[J]. Materials Science and Engineering A, 2014, 598: 396-406.

[5] HUI Y, SUNG H P, BOMG S Y, YOUNG M K, HUA S Y, SUNG S P. Effects of extrusion speed on the microstructure and mechanical properties of ZK60 alloys with and without 1 wt% cerium addition[J]. Materials Science and Engineering A, 2013, 583: 25-35.

[6] YU J Q, ZHAO G Q, CUI W C, ZHANG C S, CHEN L. Microstructural evolution and mechanical properties of welding seams in aluminum alloy profiles extruded by a porthole die under different billet heating temperatures and extrusion speeds[J]. Journal of Materials Processing Technology, 2017, 247: 214-222.

[7] HWANG Y M, CHANG C N. Hot extrusion of hollow helical tubes of magnesium alloys[J]. Procedia Engineering, 2014, 81: 2249-2254.

[8] ZHAO M J, WU Z L, CAI H M. Effects of mandrel angle on hydrostatic extrusion process of magnesium alloy tube[J]. Rare Metal Materials & Engineering, 2017, 46(5): 1214-1218.

[9] GUO L G, DANG L, YANG H, ZHANG J, ZHENG W D. Identification of processing window for extrusion of large thick-walled Inconel 625 alloy pipes using response surface methodology[J]. Transactions of Nonferrous Metals Society of China, 2016, 26(7): 1902-1911.

[10] LI W J, DENG K K, ZHANG X, NIE K B, XU F J. Effect of ultra-slow extrusion speed on the microstructure and mechanical properties of Mg-4Zn-0.5Ca alloy[J]. Materials Science & Engineering A, 2016, 677: 367-375.

[11] 卢立伟, 赵 俊, 陈胜泉, 刘龙飞, 曾文兵. 镁合金正挤压-扭转变形的数值模拟与实验研究[J]. 中国有色金属学报, 2015, 25(9): 2350-2357.

LU Li-wei, ZHAO Jun, CHEN Sheng-quan, LIU Long-fei, ZENG Wen-bing. Numerical simulation and experimental research of AZ31 Mg alloys processed by direct extrusion and torsional deformation[J]. The Chinese Journal of Nonferrous Metals, 2015, 25(9): 2350-2357.

[12] 卢立伟, 尹振入, 胡少华, 刘龙飞, 石东风, 杨碧莲. 镁合金双向挤压-螺旋变形的数值模拟与实验研究[J]. 稀有金属材料与工程, 2016, 45(6): 1467-1472.

LU Li-wei, YIN Zhen-ru, HU Shao-hua, LIU Long-fei, SHI Dong-fen, YANG Bi-lian. Numerical simulation and experimental research of AZ31 Mg alloys processed by dual- directional extrusion and spiral compound deformation[J]. Rare Metal Materials and Engineering, 2016, 45(6): 1467-1472.

[13] 孙 宇, 周 琛, 万志鹏, 任丽丽, 胡连喜. 金属材料动态再结晶模型研究现状[J]. 材料导报, 2017, 31(7): 12-16.

SUN Yu, ZHOU Chen, WAN Zhi-peng, REN Li-li, HU Lian-xi. Current research status of dynamic recrystallization model of metallic materials[J]. Materials Review, 2017, 31(7): 12-16.

[14] 黄东男, 李静媛, 张志豪, 谢建新. 方形管分流模双孔挤压过程中金属的流动行为[J]. 中国有色金属学报, 2010, 20(3): 488-495.

HUANG Dong-nan, LI Jing-yuan, ZHANG Zhi-hao, XIE Jian-xin. Metal flowing behaviors during diplopore extrusion of square tube with porthole die[J], The Chinese Journal of Nonferrous Metals, 2010, 20(3): 488-495.

[15] 任国成, 赵国群, 徐淑波, 王桂青. AZ31镁合金等通道转角挤压变形均匀性有限元分析[J]. 中国有色金属学报, 2011, 21(4): 848-855.

REN Guo-cheng, ZHAO Guo-qun, XU Shu-bo, WANG Gui-qing. Finite element analysis of homogeneous deformation of AZ31 magnesium during equal channel angular pressing process[J]. The Chinese Journal of Nonferrous Metals, 2011, 21(4): 848-855.

[16] 王 斌, 易丹青, 顾 威, 王宏伟, 吴春萍, 方西亚. ZK60镁合金型材挤压过程有限元数值模拟[J]. 材料科学与工艺, 2010, 18(2): 272-278.

WANG Bin, YI Dan-qing, GU Wei, WANG Hong-wei, WU Chun-ping, FANG Xi-ya. Finite element numerical simulation on extrusion process of ZK60 magnesium alloy sectional material[J]. Materials Science & Technology, 2010, 18(2): 272-278.

[17] SHI L, YANG H, GUO L G, DANG L, ZHANG J. Large-scale manufacturing of aluminum alloy plate extruded from subsize billet by new porthole-equal channel angular processing technique[J]. Transactions of Nonferrous Metals Society of China, 2014, 24: 1521-1530.

[18] SHI L, LI H, JIN W Z, MINZ Y, LIAOG H, WANGX F. Portholes-equal channel angular pressing: Novel technique for extrusion of 6061 aluminum alloy tube by subsize billet[J]. The International Journal of Advanced Manufacturing Technology, 2016, 85: 355-363.

[19] SHI L, WEN J B, REN C. The prediction of microstructure evolution of 6005a aluminum alloy in a P-ECAP extrusion study[J]. Journal of Materials Engineering & Performance, 2018, 27: 2566-2575.

[20] PARK S H, KIM H S, BAE J H, CHANG D Y, YOU B S. Improving the mechanical properties of extruded Mg-3Al-1Zn alloy by cold pre-forging[J]. Scripta Materialia, 2013, 69(3): 250-253.

Optimization of process parameters for ZK60 magnesium alloy hollow plate in P-ECAP extrusion

SHI Lei1, 2, MIN Zhi-yu1, HE Jun-guang2, YAO Huai2, LIU Ya2, ZHANG Wei1

(1. School of Material Science and Engineering, Luoyang Institute of Science and Technology, Luoyang 471023, China;

2. School of Materials Science and Engineering, Henan University of Science and Technology, Luoyang 471023, China)

Abstract: Finite element modeling (FEM) was applied for predicting the processing window in extruded ZK60 magnesium alloy and simulated results were experimentally validated. First, stress-strain relationship of ZK60 magnesium alloy during deformation was studied by means of isothermal compression test, where the processing parameters were chosen to reproduce the typical industrial conditions. Second, FEM of deformation of ZK60 magnesium alloy were established. Finally, the processing window was confirmed by temperature field, velocity filed and strain-effective analysis. The finite element analysis results show that distribution of strain-effective and temperature are nonuniform in die bearing at 400-420 ℃. The distribution of strain-effective is uniform but the temperature of workpiece in die bearing is too higher than 520 ℃ at billet temperature of 480 ℃. The temperature rise is insignificantly at ram speed of 5-7.5 mm/s and obviously at ram speed over 10 mm/s. The processing window of temperature is between 440 ℃ and 460 ℃ and the ram speed is less than 7.5 mm/s.

Key words: magnesium alloy; processing parameters; extrusion; finite element modelling

Foundation item: Project(2015GGJS-109) supported by the Subsidizing Plan of Young Backbone Teachers in Higher Education Institutions of Henan Province China; Project(2016M602238) supported by the Chinese Postdoctoral Science Foundation; Project(182300410208) supported by the Natural Science Foundation of Henan Province, China; Project(17A430025) supported by the Key Scientific Research Foundation of Higher Education Institutions of Henan Province, China

Received date: 2018-06-22; Accepted date: 2018-11-28

Corresponding author: MIN Zhi-yu; Tel: +86-18336789996; E-mail: 2418836435@qq.com

(编辑 何学锋)

基金项目:河南省高等学校青年骨干教师资助计划项目(2015GGJS-109);中国博士后面上基金资助项目(2016M602238);河南省自然科学基金资助项目(182300410208);河南省高等学校重点科研基金(17A430025)

收稿日期:2018-06-22;修订日期:2018-11-28

通信作者:闵志宇,教授,博士;电话:18336789996;E-mail:2418836435@qq.com