DOI: 10.11817/j.issn.1672-7207.2017.12.008

铸态AZ31B镁合金高温变形行为数学建模

马立峰1,贾伟涛1, 2,黄志权1,林金宝1

(1. 太原科技大学 重型机械教育部工程研究中心,山西 太原,030024;

2. 东北大学 材料电磁过程研究教育部重点实验室,辽宁 沈阳,110819)

摘要:采用Gleeble-1500热/力模拟试验机对铸态AZ31B镁合金圆柱试样进行轴向热压缩试验,并基于动态材料模型计算应变ε为0.4时的热加工图,研究镁合金热变形行为,以建立AZ31B镁合金真实应力与应变、温度及应变速率间的构效关系。研究结果表明:镁合金的变形激活能关于温度呈高度非均匀性分布,在整体范围内对该参数进行平均估算的方法导致Arrhennius本构方程产生较大拟合误差;将523~723 K 变形温度分解为523~573,573~623和623~723 K来分别建立Arrhennius本构方程,可有效提高该方程对峰值应力的预测精度;结合优化后的Sellars和Arrhennius模型,采用常用数学方程构建的热变形抗力模型能准确表征AZ31B镁合金在523~723 K及0.005~5.000 s-1范围内的热变形行为。

关键词:热加工图;峰值应力;变形抗力

中图分类号:TG146.2 文献标志码:A 文章编号:1672-7207(2017)12-3193-07

Mathematical modeling about as-cast AZ31B magnesium alloy deformation under high temperature

MA Lifeng1, JIA Weitao1, 2, HUANG Zhiquan1, LIN Jinbao1

(1. Heavy Machinery Engineering Research Center, Ministry of Education,Taiyuan University of Science and Technology, Taiyuan 030024, China;

2. Key Laboratory of Electromagnetic Processing of Materials, Ministry of Education,Northeastern University, Shenyang 110819, China)

Abstract: The as-cast AZ31B magnesium alloy cylindrical samples were compressed uniaxially by employing the Gleeble-1500 thermo-mechanical simulator. Using the dynamic material model, thermal processing diagram under the condition of ε=0.4 was calculated to study the thermal deformation behavior of AZ31B and further establish the structure-activity relationship between the true stress, strain, temperature and strain rate. The results show that the activation energy for hot deformation has a high nonuniform distribution over temperature. The average estimation for activation energy within the whole scope leads to larger fitting error of the Arrhennius constitutive equation. Decomposition of deformation temperature of 523-723 K into 523-573 K, 573-623 K and 623-723 K to establish the Arrhennius constitutive equation respectively can effectively improve the prediction accuracy of peak stress. The new hot compression deformation resistance model, which is established on the basis of the improved Sellars and Arrhennius models using simple and common mathematical equations, can accurately characterize the thermal deformation behaviors of AZ31B in the range of 523-723 K and 0.005-5.000 s-1.

Key words: thermal processing diagram; peak stress; deformation resistance

镁合金是实用金属中密度最低的金属,已经在航空、航天、交通运输、化工、火箭等工业部门得到广泛应用[1-2]。付雪松等[3]研究了不同变形温度、不同变形速率对AZ31镁合金变形组织的影响,其结果表明不同变形条件下镁合金的动态再结晶机制也不相同:当温度为603 K,应变速率为13.9 s-1时,以孪生形核为主要再结晶形核机制;当温度为673 K,应变速率为11.35 s-1时,以孪生动态再结晶方式为主要再结晶方式;当应变速率降低到4 s-1时,动态再结晶方式转变成旋转动态再结晶。王忠堂等[4]建立了适用于250~350 ℃,0.01~1 s-1条件的AZ31镁合金本构方程,方程的相对预测误差约为13%,预测误差较大且拟合变形条件范围较小。TAKUDAN等[5]研究了不同变形条件对AZ31镁合金流变应力与应变的影响规律,建立了流变应力与应变及应变速率间的关系模型,该模型可以预测150~300 ℃条件下各阶段流变应力,但并未考虑温度的直接影响,因此,用此模型预测时数据误差较大,最大拟合相对误差为18.32%。黄光胜等[6]考虑到AZ31镁合金在不同变形阶段的主变形机制有所差别,将高温本构模型划分为动态回复阶段以及稳态动态再结晶阶段来分别计算,该模型能够准确预测各个阶段的应力和应变,然而该模型的形式较为复杂,较难应用于实际工程。目前,已建立不同变形条件下的镁合金单向拉伸、压缩变形的本构模型[7-10],然而,针对模型的预测误差仍未提出有效的解决方法。针对变形抗力模型的研究很多,但由于所建模型的复杂性及预测范围的局限性,导致模型不能被充分应用于实际生产中。为此,本文作者分析AZ31B镁合金的热变形特性,建立形式较为简单的峰值应变数学模型和预测精度较高的峰值应力数学模型,并结合常用数学方程建立形式较为简单的变形抗力数学模型。

1 实验方法

选用银光镁业集团的AZ31B镁合金板材为试样材料,其化学元素组分如表1所示。将试样坯料加工成直径×长度为8 mm×12 mm的圆柱试样,分别在温度为523,573,623,673和723 K,应变速率为0.005,0.050,0.500和5.000 s-1条件下,采用Gleeble-1500D热模拟试验机对试样进行高温压缩实验,实验最大变形量为60%。压缩前试样的上、下2个端面涂抹机油粘上石墨片,以降低试样与压头之间的摩擦力对实验造成的影响。

表1 AZ31B镁合金板材化学元素质量分数

Table 1 Mass fraction of chemical elements of AZ31B magnesium alloy sheet %

2 结果和讨论

2.1 峰值应变模型的简化计算

采用Sellars模型处理Gleeble热压缩实验中峰值应变εp与初始铸态AZ31B镁合金晶粒直径do和Z参数之间的关系[11-12]:

(1)

(1)

式中: 为应变速率,s-1;Q为变形激活能,J/mol,与材料有关;T为温度,K;R为热力学气体常数,8.314 J/(mol·K);A1,m1和n1分别为与材料有关的常数。

为应变速率,s-1;Q为变形激活能,J/mol,与材料有关;T为温度,K;R为热力学气体常数,8.314 J/(mol·K);A1,m1和n1分别为与材料有关的常数。

(2)

(2)

板坯铸造采用东北大学的低频电磁连铸技术,该技术使得合金的铸态组织得到显著细化,合金元素的宏观偏析得到显著改善并且具有更高的成分和组织均匀性。铸态AZ31B镁合金原料晶粒结构如图1所示。若在相同位置和相同方向条件下进行取样,则可认为原始晶粒直径do近似相等,经简化后可得适用于铸态AZ31B镁合金的峰值应变模型:

(3)

(3)

式中:a,b和c分别为与材料有关的待求解系数。

通过Gleeble高温压缩试验得到峰值应变数据,如表2所示。

图1 铸态AZ31B镁合金原料晶粒结构图

Fig. 1 Microstructure of as-cast AZ31B magnesium alloy

对表中的数据按式(3)进行拟合,则峰值应变模型拟合结果为

(4)

(4)

拟合图形如图2所示。

表2 不同变形条件下峰值应变εp

Table 2 εp under different deformation conditions

图2 峰值应变的拟合图形

Fig.2 Fitted pattern of peak strain

2.2 热加工图的绘制

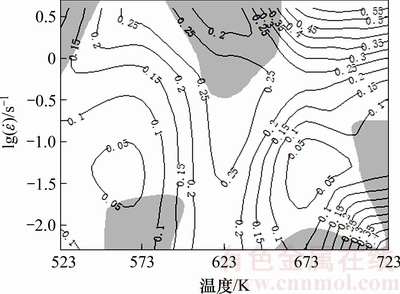

图3所示为铸态AZ31B镁合金在ε=0.4时的热加工图。由图3可知:铸态AZ31B镁合金的功率耗散效率随着应变速率增大而先减小后增大;随着温度升高而逐渐增大。在温度为683 K,应变速率为5.000 s-1时耗散效率最大约为55%。然而,流变失稳现象的出现区域有所不同;在523~553 K,高应变速率区域出现流变失稳现象;在553~593 K,低应变速率区域出现流变失稳现象;在593~653 K,中高应变速率以上区域出现流变失稳现象;在653~723 K,低应变速率区域(温度低于703 K)及温度高于703 K且应变速率小于0.2 s-1的区域均出现流变失稳现象(见图3)。

2.3 高精度峰值应力模型计算

镁合金的本构方程采用弹塑性体关于双曲正弦模型的热变形方程,即修正后的Arrhennius方程[13-16]:

(5)

(5)

式中:σ为流变应力,MPa;n为应力指数;A和α为与材料有关的常数。

对于双曲正弦模型,将 代入式(5)可得:

代入式(5)可得:

图3 铸态AZ31B镁合金在应变ε=0.4时的热加工图

Fig. 3 Thermal processing diagram of as-cast magnesium alloy AZ31B at ε=0.4

1) 当ασ≤0.3,sinh(ασ)≈ασ,其相对误差小于1.48%。式(5)可简化为

(6)

(6)

式中:A1=Aαn。

2) 当0.3<ασ<1.8,sinh(ασ)≈0.582 08(ασ+0.424 97)2,其相对误差为0.46%~2.80%。式(5)可简化为

(7)

(7)

3) 当1.8≤ασ,sinh(ασ)≈eασ/2,其相对误差小于2.80%。式(5)可简化为

(8)

(8)

式中:A3=A/2n。

塑性变形过程中的热流变应力模型为

(9)

(9)

其中:变形激活能Q是描述高温变形过程中原子重排难易程度的微观物理量,受金属本质、变形速率及变形温度等因素的影响[17],求解公式为

(10)

(10)

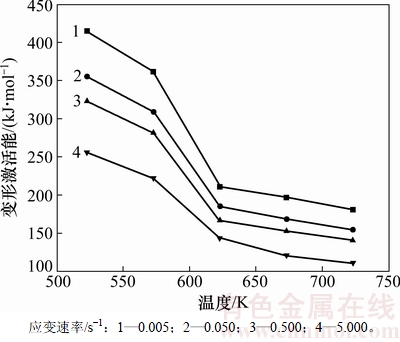

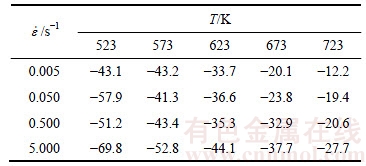

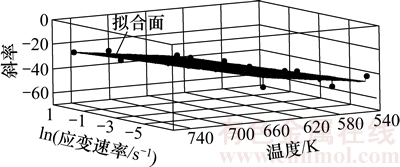

基于表3中不同条件下的峰值应力,对 和

和 进行线性拟合,求解523~723 K时的Q,绘制Q-T图,如图4所示。由图4可知:在不同应变速率条件下,随着温度升高,变形激活能Q逐渐减小,但是下降趋势有所不同;在573~623 K,Q呈急剧下降;在523~573 K和623~723 K,Q下降较为平缓。当拟合整体温度范围下的本构方程时,式(5)中的Q为诸多值的平均值

进行线性拟合,求解523~723 K时的Q,绘制Q-T图,如图4所示。由图4可知:在不同应变速率条件下,随着温度升高,变形激活能Q逐渐减小,但是下降趋势有所不同;在573~623 K,Q呈急剧下降;在523~573 K和623~723 K,Q下降较为平缓。当拟合整体温度范围下的本构方程时,式(5)中的Q为诸多值的平均值 = 229 870 J/mol。由图4可知整体方程只能准确预测573~623 K时的Q,而不能高精度预测其他温度范围下的Q。基于铸态AZ31B镁合金热加工图中功率耗散效率和流变失稳现象在不同温度范围下的分布特性,考虑到热变形本构方程和轧制流变应力数学模型的准确性,下面将整体变形温度范围523~723 K分解为523~573,573~623和623~723 K来分别建立本构方程。

= 229 870 J/mol。由图4可知整体方程只能准确预测573~623 K时的Q,而不能高精度预测其他温度范围下的Q。基于铸态AZ31B镁合金热加工图中功率耗散效率和流变失稳现象在不同温度范围下的分布特性,考虑到热变形本构方程和轧制流变应力数学模型的准确性,下面将整体变形温度范围523~723 K分解为523~573,573~623和623~723 K来分别建立本构方程。

表3 不同变形条件下的峰值应力σp

Table 3 σp under different deformation conditions MPa

图4 523~723 K条件下变形激活能

Fig. 4 Deformation activation energy of 523-723 K

1) 在523~573 K条件下的峰值应力模型(模型1)为

(11)

(11)

其中:

(12)

(12)

2) 在573~623 K条件下的峰值应力模型(模型2)为

(13)

(13)

其中:

(14)

(14)

3) 在623~723 K条件下的峰值应力模型(模型3)为

(15)

(15)

其中:

(16)

(16)

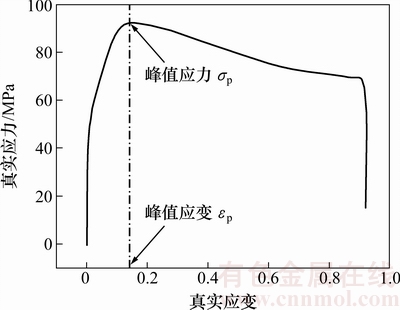

2.4 变形抗力模型的简化计算

以623 K,0.5 s-1压缩实验条件为例,观察镁合金热变形时的真实应力-应变曲线,如图5所示。由图5可知:在变形初始阶段,热变形过程中加工硬化的强化作用较为明显,导致流变应力关于应变呈急剧线性增长。随后,动态回复的软化作用开始产生影响,且随着变形增大软化强度逐渐增大,导致流变应力的增长趋于平缓。当变形到达某一程度后,加工硬化的强化作用与软化作用相抵消,此时,流变应力达到最大值,即峰值应力。当变形越过峰值后,动态再结晶的软化作用大于加工硬化的强化作用,结果导致曲线整体上呈应变软化趋势。随着变形继续,动态再结晶机制导致晶粒充分细化,细晶强化加剧热加工硬化作用,最后动态再结晶的软化作用和热加工硬化的强化作用处于相对平衡状态,即稳态流动阶段[18]。

图5 在623 K,0.5 s-1条件下压缩真实应力-应变曲线

Fig. 5 Stress-strain curve under condition of 623 K, 0.5 s-1

由图5可知:当ε≤εp时,曲线呈现抛物线形状,可采用二次曲线来表征该段模型;当ε>εp时,近似认为是一组斜率不等的直线,可采用直线来表征该段模型。不同变形条件下斜率k有所不同,则铸态AZ31B镁合金热变形抗力的模型为

(17)

(17)

对不同变形条件下ε>εp的应力-应变数据进行线性拟合,统计不同变形条件下直线斜率,如表4所示。经分析,斜率k关于温度T及 呈线性分布。经简化计算分析,用

呈线性分布。经简化计算分析,用

方程形式对表中数据进行拟合,斜率

方程形式对表中数据进行拟合,斜率 的拟合结果为

的拟合结果为

(18)

(18)

拟合图形如图6所示。

经统计,该方程的预测结果与实验结果相符,在较高温度范围及应变速率范围条件下平均拟合相对误差约为7.5%,最大拟合相对误差约为12.7%。综合式(4)~(18)可得铸态AZ31B镁合金的热变形抗力模型为

(19)

(19)

表4 不同变形条件下的直线斜率k

Table 4 k under different deformation conditions

图6  的拟合图形

的拟合图形

Fig. 6 Fitted pattern of

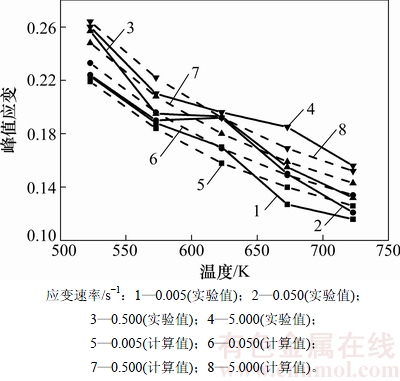

2.5 实验数据及理论计算数据对比分析

简化Sellars后峰值应变的实验值和预测值对比结果如图7所示。模型求解的最大相对误差约为12.07%,主要原因是:板坯的铸造采用了新技术,取样方式也尽量相同,由于材料本身的不均匀性,所取试样原始晶粒直径do不可避免地出现细微差别,最终导致峰值应变的预测误差。

图7 峰值应变实验值和计算值对比

Fig. 7 Comparison of experimental and calculated peak strain

将实验所得的峰值应力与式(11),(13)和(15)的计算值进行对比,如图8所示。由图8可知:随着温度升高,相对误差逐渐增大,主要原因是:Arrhennius方程的推导是基于固态颗粒的滑移理论,而铸态AZ31B镁合金材料中不可避免地存有一定量细小的半固态固相颗粒,当材料在高温条件下变形时,组织中的液相成分会大大增加。混有的半固态固相颗粒之间比较容易发生滑动与转动,即晶界滑动,有别于位错滑移机制,若仍用基于滑移理论的方程去表征变形机制,则会导致预测偏差。由图8还可知:温度范围越大,所求该范围内的模型预测精度越低,从而验证了分解温度范围求解单向压缩时热变形流变应力模型的必要性。

图8 不同模型峰值应力实验值和计算值的对比

Fig. 8 Comparison of experimental and calculated values of the peak stress

传统变形抗力计算模型[19]为

(20)

(20)

式中:η,n,m和κ为与材料有关的常数。

传统变形抗力计算模型(见式(20))的非线性拟合结果为

(21)

(21)

将不同变形条件下不同应变速率及不同应变量所对应的变形抗力的实验值与模型的预测值进行对比,结果如图9所示。经统计,最大拟合相对误差为34.36%,平均拟合误差为17.7%,拟合均方差为12.45 MPa。

前面建立的热变形抗力模型(见式(19))最大拟合相对误差约为9.8%,如图10所示。比较各阶段拟合结果可知:当ε≤εp时,所建立的二次曲线模型能够很好表征材料在动态回复阶段时的变形机制。然而,当ε>εp时材料发生明显的动态再结晶现象,引起变形高度的非线性变化趋势,导致直线模型拟合结果与实验结果之间偏差略大。

图9 应变量为0.05~0.80时变形抗力实验值和计算值对比

Fig. 9 Comparison of experimental and calculated values of strain value from 0.05 to 0.80

图10 应变量为0.05~0.80时变形抗力实验值和计算值对比

Fig. 10 Comparison of experimental and calculated values of strain value from 0.05 to 0.80

3 结论

1) 铸态AZ31B镁合金材料的耗散效率和流变失稳现象在不同温度范围内具有很大差别。变形激活能关于温度的高度非均匀性分布是传统Arrhennius整体本构方程拟合的主要误差来源。合理划分温度范围,分别建立热变形本构方程的方法能有效提高峰值应力本构模型的预测精度。

2) 铸态AZ31B镁合金的热变形特性可以应用数学上常用的二次曲线方程和直线方程来准确表征,在精确建立峰值应变及峰值应力模型的基础上,依据此特性原理可求解形式简单且适用于宽范围变形条件下的变形抗力数学模型。

参考文献:

[1] SUH J, VICTORIA-HERNANDEZ J, LETZIG D, et al. Improvement in cold formability of AZ31 magnesium alloy sheets processed by equal channel angular pressing[J].Journal of Materials Processing Technology, 2015, 217: 286-293.

[2] HUANG Xinsheng, Suzuki K, Chino Y, et al. Texture and stretch formability of AZ61 and AM60 magnesium alloy sheets processed by high-temperature rolling[J]. Journal of Alloys and Compounds, 2015, 632: 94-102.

[3] 付雪松, 陈国清, 王中奇, 等. AZ31镁合金热轧变形的动态再结晶机制[J]. 稀有金属材料与工程, 2011, 40(8): 1473-1477.

FU Xuesong, CHEN Guoqing, WANG Zhongqi, et al. Dynamic recrystallization mechanism of hot rolled AZ31 magnesium alloy deformation[J]. Rare Metal Materials and Engineering, 2011, 40(8): 1473-1477.

[4] 王忠堂, 张士宏, 齐广霞, 等. AZ31镁合金热变形本构方程[J]. 中国有色金属学报, 2008, 18(11): 1977-1982.

WANG Zhongtang, ZHANG Shihong, QI Guangxia, et al. Constitutive equation of thermal deformation for AZ31 magnesium alloy[J]. The Chinese Journal of Nonferrous Metals, 2008, 18(11): 1977-1982.

[5] TAKUDAN H, MORISHITA T, KINOSHITA T, et al. Modelling of formula for flow stress of a magnesium alloy AZ31 sheet at elevated temperatures[J]. Journal of Materials Processing Technology, 2005, 164/165(10): 1258-1262.

[6] 黄光胜, 汪凌云, 黄光杰, 等. AZ31镁合金高温本构方程[J]. 金属成形工艺, 2004, 22(2): 41-44.

HUANG Guangsheng, WANG Lingyun, HUANG Guangjie, et al. Constitutive equation of AZ31 magnesium alloy for high temperature[J]. Metal Forming Technology, 2004, 22(2): 41-44.

[7] YARITA I, NAOI T, HASHIZUME T. Stress and strain behaviors of Mg alloy AZ31 in plane strain compression[J]. JSME International Journal Series A Solid Mechanics and Material Engineering, 2005, 48(4): 299-304.

[8] ABU-FARHA F, KHRAISHEH M. Deformation characteristics of AZ31 magnesium alloy under various forming temperatures and strain rates[C]//Proceedings of the Eighth ESAFORM Conference on Material Forming, Cluj-Napoca, Romania, 2005: 627-630.

[9] KOIKE J, OHYAMA R, KOBAYASHI T, et al. Grain-boundary sliding in AZ31 magnesium alloys at room temperature to 523 K[J]. Materials Transactions, 2003, 44(4): 445-451.

[10] 郭 强, 严红革, 陈振华, 等. Mg-Al-Zn系合金高温压缩流变应力研究[J]. 湖南大学学报(自然科学版), 2006, 33(3): 75-79.

GUO Qiang, YAN Hongge, CHEN Zhenhua, et al. Flow stress of Mg-Al-Zn alloys during hot compression deformation at elevated temperatures[J]. Journal of Hunan University (Natural Sciences), 2006, 33(3): 75-79.

[11] MANNAN P, KOSTRYZHEV A G, ZUROB H, et al. Hot deformation behaviour of Ni-30Fe-C and Ni-30Fe-Nb-C model alloys[J]. Materials Science and Engineering A, 2015, 641: 160-171.

[12] SIYASIYA C W, STUMPF W E. Constitutive constants for hot working of steels: the critical strain for dynamic recrystallisation in C-Mn steels[J]. Journal of Materials Engineering and Performance, 2015, 24(1): 468-476.

[13] LUO Xiaoping, DANG S, KANG L. Compression deformation behavior of AZ81 magnesium alloy at elevated temperatures[J]. Advances in Materials Science and Engineering, 2014, 2014(12): 1-7.

[14] 余琨, 蔡志勇, 薛新颖, 等. 半连续铸造AZ31B镁合金的热压缩变形行为[J]. 中国有色金属学报, 2010, 20(11): 2075-2080.

YU Kun, CAI Zhiyong, XUE Xinying, et al. Hot-compressive deformation behavior of semi-continuous cast AZ31B magnesium alloy[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(11): 2075-2080.

[15] QUAN Guozheng, SHI Yu, WANG Yixin,et al. Constitutive modeling for the dynamic recrystallization evolution of AZ80 magnesium alloy based on stress-strain data[J]. Materials Science and Engineering A, 2011, 528(28): 8051-8059.

[16] LIN Y C, WEN Dongxu, DENG Jiao, et al. Constitutive models for high-temperature flow behaviors of a Ni-based superalloy[J]. Materials & Design, 2014, 59(19): 115-123.

[17] MIRZADEH H. Constitutive analysis of Mg-Al-Zn magnesium alloys during hot deformation[J]. Mechanics of Materials, 2014, 77: 80-85.

[18] GALIYEV A, KAIBYSHEV R, GOTTSTEIN G. Correlation of plastic deformation and dynamic recrystallization in magnesium alloy ZK60[J]. Acta Materialia, 2001, 49(7): 1199-1207.

[19] TAKUDA H, FUJIMOTO H, HATTA N. Modelling on flow stress of Mg-Al-Zn alloys at elevated temperatures[J].Journal of Materials Processing Technology, 1998, 80/81(98): 513-516.

(编辑 伍锦花)

收稿日期:2017-01-20;修回日期:2017-03-20

基金项目(Foundation item):国家自然科学基金资助项目(51105264);山西省高校青年学术带头人计划项目(TYAL);山西省科技攻关项目 (20130321010-03)(Project (51105264) supported by the National Natural Science Foundation of China; Project (TYAL) supported by the Plan for Youth Academic Leaders in Universities of Shanxi Province; Project (20130321010-03) supported by Key Project of Science and Technology Department of Shanxi Province)

通信作者:马立峰,博士,教授,从事金属轧制塑性变形工艺与控制技术研究;E-mail:tyust0208@ 163.com