退火超细晶纯铝的拉伸性能各向异性及相关屈服点现象

来源期刊:中国有色金属学报(英文版)2018年第4期

论文作者:洪霞 Andrew William GODFREY 刘伟

文章页码:585 - 591

关键词:超细晶铝;回复退火;力学性能各向异性;屈服下降;延展性

Key words:ultrafine-grained aluminum; recovery annealing; mechanical anisotropy; yield drop; ductility

摘 要:经退火处理的超细晶纯铝AA1090在拉伸试验中表现出明显的屈服点现象及力学性能的各向异性。为进一步解释该材料的拉伸性能各向异性,利用电子背散射衍射技术对退火处理后材料的取向信息进行分析。结果表明,沿与轧制方向成45°的拉伸试样所呈现出的较差的力学性能归因于强轧制织构的作用,并且各方向屈服下降的程度与试样中软取向晶粒(Schmid因子>0.45)的百分比相关。另外,伸长率的各向异性大致符合Considère准则;运用晶体学织构只能解释部分的力学性能各向异性行为,同时还需考虑显微组织结构各向异性的作用。

Abstract: It is found that tensile flow curves of samples of annealed ultrafine-grained aluminum AA1090 show the development of a yield point and a significant mechanical anisotropy. To rationalize the anisotropic tensile behavior, the orientation data of the annealed material were measured using electron backscatter microscopy. It is found that the inferior mechanical properties of samples tested at 45° to the rolling direction may be attributed to a strong rolling texture effect and that the anisotropic magnitude of the yield drop may be related to the proportion of grains with soft orientations (defined as those with Schmid factor greater than 0.45) in the sample. Additionally, it is found that the anisotropy in tensile ductility is in general agreement with a Considère criterion analysis and that the mechanical anisotropy in the samples is only partly explained by the crystallographic texture, where microstructural anisotropy may also play a role.

Trans. Nonferrous Met. Soc. China 28(2018) 585-591

Xia HONG, Andrew William GODFREY, Wei LIU

Key Laboratory of Advanced Materials (MoE), School of Materials Science and Engineering, Tsinghua University, Beijing100084, China

Received 28 December 2016; accepted 24 March 2017

Abstract: It is found that tensile flow curves of samples of annealed ultrafine-grained aluminum AA1090 show the development of a yield point and a significant mechanical anisotropy. To rationalize the anisotropic tensile behavior, the orientation data of the annealed material were measured using electron backscatter microscopy. It is found that the inferior mechanical properties of samples tested at 45° to the rolling direction may be attributed to a strong rolling texture effect and that the anisotropic magnitude of the yield drop may be related to the proportion of grains with soft orientations (defined as those with Schmid factor greater than 0.45) in the sample. Additionally, it is found that the anisotropy in tensile ductility is in general agreement with a Considère criterion analysis and that the mechanical anisotropy in the samples is only partly explained by the crystallographic texture, where microstructural anisotropy may also play a role.

Key words: ultrafine-grained aluminum; recovery annealing; mechanical anisotropy; yield drop; ductility

1 Introduction

Aluminum with an ultrafine-grained (UFG) structure is of interest for structural applications on account of its enhanced strength compared with material with normal grain size. An ultrafine-grained structure can be introduced by the application of severe plastic deformation. Several such techniques exist, but heavy cold rolling is one of the most convenient approaches for refinement of grains. Although refinement of grains is a suitable way for improvement of strength, depending on the microstructure, deleterious characteristics, such as the early onset of plastic instability and reduced tensile elongation [1-5] may also be found in these materials. As the grain size of ultrafine-grained materials is on the sub-micrometer scale, the dislocation storage efficiency inside the individual grains is poor, and grain boundaries are thought to play an important role in plastic deformation [6,7]. This causes a lower work hardening rate and a higher dynamic recovery rate in UFG metals, thus leading to inferior mechanical properties.

It should be recognized that good ductility is required with regard to the formability of metals. To restore some ductility in UFG metals, a post-deformation recovery annealing is usually applied [1,8]. Under certain conditions, this annealing may produce a drop in yield stress [1-3,6,9,10]. In addition, rolled aluminum exhibits a significant anisotropy in mechanical properties, as typified by different tensile flow curves when tested with the tensile axis aligned at different angles from the rolling direction [11-16]. However, the anisotropy in yield drop magnitude has not been studied, and the underlying causes of mechanical anisotropy are still not well understood. It is believed that the crystallographic texture of the material is one of the primary sources of plastic anisotropy [17-20], although other factors, such as grain shape and morphology [14,20], may also play a role. An understanding of mechanical anisotropy, and its correlation with texture, is therefore important for the development of simulations and models of formability [19,21], moreover, to help control the final mechanical properties.

The aim of the present work is not only to reveal the anisotropic mechanical behavior and related yield point phenomena in annealed UFG pure aluminum, but also to further elucidate the intrinsic mechanisms of the anisotropy, based on the analysis of both microstructure and texture. The Considère criterion and a texture-based Schmid/Taylor factor analysis are used to rationalize the observed mechanical anisotropy, and to estimate the contribution of texture to the mechanical anisotropy.

2 Experimental

Commercial purity aluminum AA1090 was used in the present work in the form of aluminum plate cold-rolled to a thickness of 1.0 mm (~80% rolling reduction). The initial material has a UFG structure with an average boundary spacing of ~0.78 μm measured perpendicular to the rolling direction (RD). In order to investigate the mechanical anisotropy of the material, dog-bone shaped specimens with a gauge length of 10 mm were cut from the plate along four different directions, namely 0°, 30°, 45° and 90° with respect to RD. In order to determine the annealing conditions required to develop a significant yield drop and good ductility, a series of initial tests were first carried out at various temperatures and annealing durations, with the mechanical behavior for each evaluated by tensile testing only at 90° to RD. Based on the flow curves obtained, annealing conditions for the full investigation on mechanical anisotropy were chosen as 528 K (255 °C) for 4 h and 558 K (285 °C) for 2 h. All tensile tests were carried out at room temperature using a WDW-100 tensile machine with a constant crosshead speed of 1 mm/min. Tensile properties were estimated from the standard true stress-true strain plots. For each sample direction and material condition, two samples were tested to ensure reproducibility. Microstructural characterization of the material prior to tensile testing was carried out using electron backscatter diffraction (EBSD) on samples cut to reveal the transverse plane (containing both the rolling and normal directions). Samples for EBSD observations were prepared by electro-polishing using an electrolyte consisting of 90% ethanol and 10% perchloric acid. Orientation data were collected using an Oxford Instruments EBSD system attached to a field emission scanning electron microscope. The EBSD maps shown in this work were taken at an operating voltage of 20 kV, using a step size of 0.8 μm. Minimal data cleaning was carried out, consisting three iterations of the noise-reduction filter in the Channel 5 software using a setting of 5/8 neighbors.

3 Results

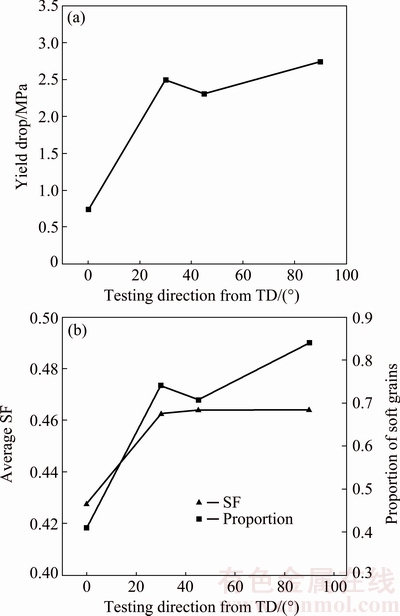

The true stress-true strain curves for samples tested along 90° to RD after annealing at various conditions are shown in Fig. 1(a). In all cases after annealing, the strength of the samples decreases and better ductility is achieved. The flow curves at 0°, 30°, 45°, and 90° to RD for samples annealed at 528 K for 4 h or 558 K for 2 h are shown in Figs. 1(b) and (c). The differences between the flow curves for different tensile directions highlight a significant anisotropy in mechanical behavior for both annealing conditions. In terms of yield strength, the specimens tested at 0° and 90° to RD show similar values, with the lowest strength of the specimen tested along 45° to RD. A yield drop phenomenon is also clearly observed in the flow curves for samples annealed at 528 K for 4 h. To show this more clearly, the yield drop region is magnified in the inset of Fig. 1(b). It is interesting to note that the magnitude of the yield drop varies with tensile direction. The variation in yield drop magnitude with angle to RD is shown in Fig. 3(a), where it is seen that testing along RD (0° to RD) results in the smallest yield drop, whereas testing along TD (90° to RD) results in the largest yield drop. In addition, a clear anisotropy in the tensile ductility is also observed. This is most evident in the tensile curves for samples annealed at 558 K for 2 h (Fig. 1(c)), where it is seen that the tensile elongation increases with tensile direction in the sequence of 45°, 30°, 90° and 0°. It can be noted that among the four testing directions, specimens tested at 45° to RD possess the worst mechanical properties, exhibiting the lowest yield strength and elongation values.

Fig. 1 True stress-true strain curves for samples

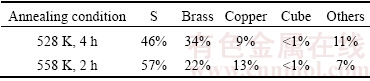

The microstructure and texture of the annealed samples are shown in Fig. 2. Under the recovery annealing conditions examined in this work, the material predominantly maintains a typical cold-rolled microstructure, showing a lamellar structure elongated along RD, even though the grains coarsen and a small number of recrystallized grains are found in the sample annealed at 558 K for 2 h. Based on line intercept measurements perpendicular to RD, the average boundary spacing in these samples are determined to be ~1.8 μm for the sample annealed at 528 K for 4 h and ~1.9 μm for the sample annealed at 558 K for 2 h. The crystallographic texture of the annealed samples is summarized in Table 1. In both cases, a strong rolling texture is found, consisting mainly of S {123}<634>, Brass {110}<112> and Copper {112}<111> components.

Table 1 Proportion of each texture component in annealed samples

4 Discussion

4.1 Yield drop anisotropy

In body centered crystal (BCC) structure materials, the yield drop is generally associated with interactions between dislocations and solute atoms or impurities. For the case of commercial purity UFG aluminum, it is believed that the observation of a yield drop can be attributed to a lack of a sufficient density of mobile dislocations to satisfy the applied strain rate [6]. With decreasing grain size, the mean free path of dislocations is no longer determined by the dislocation structure, but is limited by the grain boundaries. In this material, the large grain boundary area can act also as effective sink for dislocations, especially in the recovery-annealed condition. This in turn reduces the mobile dislocation density, and thus a higher velocity of dislocations is required to fulfill the imposed macroscopic strain rate. Consequently, the increased dislocation velocity can be related to the raising of the yield stress. After a certain plastic strain, however, dislocation interactions eventually result in an increase in the density of dislocation sources, leading to a fall in the stress required to maintain the applied strain rate, and hence a yield drop phenomenon occurs.

To rationalize the observed yield drop anisotropy, the Schmid factor (SF) for the slip systems with the highest resolved stress was calculated for each measured crystal orientation in the EBSD map of the sample annealed at 528 K for 4 h, by taking into account of different tensile testing directions of 0°, 30°, 45° and 90° from the RD. The results are shown in Fig. 3(b), where it is seen that the 0° direction is relatively hard compared with tensile testing along either the 30°, 45° or 90° directions. The proportion of soft grains (defined here as volume fractions with SF>0.45) was also calculated as a function of test direction, and is shown in Fig. 3(b). This plot shows a similar trend to that for the drop in yield stress as a function of tensile test direction, suggesting that the magnitude of the yield drop may be related to the proportion of soft grains in the sample. It is easy to understand that more dislocations will be active in the sample if it possesses more soft grains when being subjected to a certain stress; therefore, a larger increase in the mobile dislocation density at yield may lead to a larger subsequent yield drop.

Fig. 2 EBSD maps of samples

Fig. 3 Yield stress drop (a) and average Schmid factor (SF) and proportion of soft grains (with SF>0.45) (b) as function of tensile testing direction for samples annealed at 528 K for 4 h

4.2 Inhomogeneous ductility

Both tensile curves for the two different annealing conditions show clear anisotropy in tensile ductility. Moreover, the tensile elongation after annealing at 558 K for 2 h shows a continuous increase in tensile ductility as the tensile axis is varied in the sequence from 45° to 30° to 90° and to 0°. As work hardening is often limited in UFG structures due to the limited dislocation storage efficiency of fine grains, the early presence of plastic instability (necking) is strongly associated with material failure. The onset of plastic instability during the tests can be predicted based on the Considère criterion, which is expressed by

(1)

(1)

where s and ε are true flow stress and true strain, respectively. Although the Considère criterion is traditionally obtained from solid mechanics considerations, recently, it has been shown that it can also be derived following the intrinsic evolution laws for dislocation density [22]. Values for the critical stress at the onset of necking for different tensile directions, calculated using the Considère criterion, are given in Table 2. It is found that the anisotropy in elongation is in general agreement with the variation in critical stress for necking, suggesting that the early occurrence of plastic instability may severely limit the desirable elongation in this material. Even though the coarsened microstructure and a few recrystallized grains in the matrix contribute to the ductility, for the 30°, 45°, 90° testing directions, the material still fails soon after necking because of the lacking of efficient mechanisms to disperse the plastic flow. It can be seen that significant work hardening in the 0° testing direction sample accompanies the total elongation, and this is discussed further in the next section.

Table 2 Critical stresses for different testing directions predicted by Considère criterion based on tensile curves of samples annealed at 558 K for 2 h

4.3 Texture effects on mechanical anisotropy

In order to determine the effects of crystallographic texture on the mechanical anisotropy, both the SF and the Taylor factor, M, have been calculated as a function of tensile testing direction for the sample annealed at 558 K for 2 h. The SFs under uniaxial tension were calculated as described in Section 4.1. Taylor factors for each testing direction were calculated using the in-built capability of the Channel 5 post-processing software. To take into account the different tensile directions and to avoid the limitation in the software that the M can only be calculated along a direction parallel to one of the EBSD map axes, the orientation data were exported, then rotated about the sample normal direction by a certain angle and re-imported to the Channel 5 software, to allow the determination of the M along directions of 0°, 30°, 45° and 90° from the RD. The calculated M values were additionally checked by a manual calculation based on the Bishop and Hill method. Figure 4 shows the distribution of SF and M values for each direction, and the average SF and M values for different directions are summarized in Figs. 5(a) and (b). The calculations show that the 45° direction is a soft direction, with large SF and small M values, corresponding to the observation that testing along this direction results in the poorest mechanical properties. It is suggested that the larger fraction of soft grains with SF near 0.5 in the 45° direction sample allows the spreading of plastic deformation to take place more easily in a localized manner, thus quickly leading to the sample failure by the development of intense shear bands. Although the distributions of Taylor factor for the 0° and 90° directions are similar, the wider distribution of SF values for the 0° sample compared with the 90° sample may contribute to the difference of mechanical properties between these two directions, with the dispersion of relatively hard grains in the sample tested along 0° helping to limit the localization of plastic deformation. The presence of grains with relatively hard orientations acting as barriers to constrain the spreading of deformation may contribute to the work hardening in the 0° direction.

Fig. 4 Distributions of Schmid factor, SF (a, c, e, g), and Taylor factor, M (b, d, f, h), for different tensile directions of samples annealed at 558 K for 2 h

Fig. 5 Distribution of average SF (a) and average M (b) for samples annealed at 558 K for 2 h as a function of tensile testing directions from rolling direction, and M normalized flow curves for different tensile testing directions (c)

Although the mechanical anisotropy can be partly rationalized by the distributions of SF and M values for each sample, this does not fully account for the experimental observations. In particular, the 30° direction has larger M values and similar SF values compared with the 90° direction sample, but shows worse properties, indicating that the general texture could not be the only source for the anisotropy, and other factors such as the spatial distribution or percolation of relatively soft grains may also influence the final properties. Similarly, Fig. 5(c) replots the tensile flow curves after normalization by the mean Taylor factor, in order to remove the influence of the crystallographic texture on the anisotropy. The resulting curves still show significant differences, highlighting the fact that the crystallographic texture of the material only contributes partly to the mechanical anisotropy, and that the microstructural anisotropy should also be taken into account [23].

5 Conclusions

1) The tensile flow curves of samples annealed at 528 K for 4 h show clear development of a yield point, which is attributed to the lack of mobile dislocations. The magnitude of the observed yield drop varies with angle between RD and the tensile testing axis, and is demonstrated to be related to the relative proportion of grains with soft orientations under each testing condition.

2) A significant anisotropy with regard to ductility is found in the samples annealed at 558 K for 2 h, with the elongation increasing in the sequence of 45°, 30°, 90° and 0°. It is found that the anisotropy in elongation is in general agreement with a Considère criterion analysis.

3) It is demonstrated that the poor mechanical properties of samples tested at 45° to RD may be attributed to a strong rolling texture effect. Further analysis shows that the crystallographic texture contributes only partly to the mechanical anisotropy in the samples, and microstructural anisotropy is also needed to be taken into account.

References

[1] LEE N S, CHEN J H, KAO P W, CHANG L W, TSENG T Y, SU J R. Anisotropic tensile ductility of cold-rolled and annealed aluminum alloy sheet and the beneficial effect of post-anneal rolling [J]. Scripta Materialia, 2009, 60: 340-343.

[2] HUNG P C, SUN P L, YU C Y, KAO P W, CHANG C P. Inhomogeneous tensile deformation in ultrafine-grained aluminum [J]. Scripta Materialia, 2005, 53: 647-652.

[3] TSUJI N, ITO Y, SAITO Y, MINAMINO Y. Strength and ductility of ultrafine grained aluminum and iron produced by ARB and annealing [J]. Scripta Materialia, 2002, 47: 893-899.

[4] LEE N H, CHEN J H, KAO P W, TSENG T Y, SU J R. Anisotropic tensile properties of recovery annealed aluminum alloy sheet [J]. Materials Science and Engineering A, 2011, 528: 1979-1986.

[5] WANG Yin-min, CHEN Ming-wei, ZHOU Feng-hua, MA En. High tensile ductility in a nanostructured metal [J]. Nature, 2002, 419: 912-915.

[6] YU C Y, KAO P W, CHANG C P. Transition of tensile deformation behaviors in ultrafine-grained aluminum [J]. Acta Materialia, 2005, 53: 4019-4028.

[7] LI Y J, ZENG X H, BLUM W. Transition from strengthening to softening by grain boundaries in ultrafine-grained Cu [J]. Acta Materialia, 2004, 52: 5009-5018.

[8] WANG Bo, CHEN Xian-hua, PAN Fu-sheng, MAO Jian-jun, FANG Yong. Effects of cold rolling and heat treatment on microstructure and mechanical properties of AA 5052 aluminum alloy [J]. Transactions of Nonferrous Metals Society of China, 2015, 25: 2481-2489.

[9] TAKATA N, OKITSU Y, TSUJI N. Dynamic deformation behavior of ultrafine grained aluminum produced by ARB and subsequent annealing [J]. Journal of Materials Science, 2008, 43: 7385-7390.

[10] REN Jiang-wei, SHAN Ai-dang. Strengthening and stress drop of ultrafine grain aluminum after annealing [J]. Transactions of Nonferrous Metals Society of China, 2010, 20: 2139-2142.

[11] LEE E W, KALU P N, BRANDAO L, ES-SAID O S, FOYOS J, GARMESTANI H. The effect of off-axis thermomechanical processing on the mechanical behavior of textured 2095 Al-Li alloy [J]. Materials Science and Engineering A, 1999, 265: 100-109.

[12] TAJALLY M, EMADODDIN E. Mechanical and anisotropic behaviors of 7075 aluminum alloy sheets [J]. Materials and Design, 2011, 32: 1594-1599.

[13] ROY S, SATYAVEER S D, SUWAS S, KUMAR S, CHATTOPADHYAY K. Microstructure and texture evolution during accumulative roll bonding of aluminium alloy AA5086 [J]. Materials Science and Engineering A, 2011, 528: 8469-8478.

[14] CHENG X M, MORRIS J G. Tensile anisotropy of strip cast and direct chill cast 5182 aluminium alloy [J]. Materials Science and Technology, 2002, 18: 1413-1416.

[15] FOURMEAU M,  T, BENALLAL A, LADEMO O G, HOPPERSTAD O S. On the plastic anisotropy of an aluminium alloy and its influence on constrained multiaxial flow [J]. International Journal of Plasticity, 2011, 27: 2005-2025.

T, BENALLAL A, LADEMO O G, HOPPERSTAD O S. On the plastic anisotropy of an aluminium alloy and its influence on constrained multiaxial flow [J]. International Journal of Plasticity, 2011, 27: 2005-2025.

[16] ESMAEILIZADEH R, KHALILI K, MOHAMMADSADEGHI B, ARABI H. Simulated and experimental investigation of stretch sheet forming of commercial AA1200 aluminum alloy [J]. Transactions of Nonferrous Metals Society of China, 2014, 24: 484-490.

[17] MONDAL C, SINGH A K, MUKHOPADHYAY A K, CHATTOPADHYAY K. Effects of different modes of hot cross-rolling in 7010 aluminum alloy: Part II. Mechanical properties anisotropy [J]. Metallurgical and Materials Transactions A, 2013, 44: 2764-2777.

[18] HU Jian-guo, IKEDA K, MURAKAMI T. Effect of texture components on plastic anisotropy and formability of aluminium alloy sheets [J]. Journal of Materials Processing Technology, 1998, 73: 49-56.

[19] ZHANG K, HOLMEDAL B, HOPPERSTAD O S, DUMOULIN S, GAWAD J, VAN-BAEL A, VAN-HOUTTE P. Multi-level modelling of mechanical anisotropy of commercial pure aluminium plate: Crystal plasticity models, advanced yield functions and parameter identification [J]. International Journal of Plasticity, 2015, 66: 3-30.

[20] YANG Yong-biao, XIE Zhi-ping, ZHANG Zhi-min, LI Xu-bin, WANG Qiang, ZHANG Yan-hui. Processing maps for hot deformation of the extruded 7075 aluminum alloy bar: Anisotropy of hot workability [J]. Materials Science and Engineering A, 2014, 615: 183-190.

[21] ENGLER O, AEGERTER J. Texture and anisotropy in the Al-Mg alloy AA5005. Part II: Correlation of texture and anisotropic properties [J]. Materials Science and Engineering A, 2014, 618: 663-671.

[22] YASNIKOV I S, VINOGRADOV A, ESTRIN Y. Revisiting the Considère criterion from the viewpoint of dislocation theory fundamentals [J]. Scripta Materialia, 2014, 76: 37-40.

[23] JUUL JENSEN D, HANSEN N. Flow stress anisotropy in aluminum [J]. Acta Metallurgica et Materialia, 1990, 38: 1369-1380.

洪 霞,Andrew William GODFREY,刘 伟

清华大学 材料科学与工程学院 先进材料教育部重点实验室,北京 100084

摘 要:经退火处理的超细晶纯铝AA1090在拉伸试验中表现出明显的屈服点现象及力学性能的各向异性。为进一步解释该材料的拉伸性能各向异性,利用电子背散射衍射技术对退火处理后材料的取向信息进行分析。结果表明,沿与轧制方向成45°的拉伸试样所呈现出的较差的力学性能归因于强轧制织构的作用,并且各方向屈服下降的程度与试样中软取向晶粒(Schmid因子>0.45)的百分比相关。另外,伸长率的各向异性大致符合Considère准则;运用晶体学织构只能解释部分的力学性能各向异性行为,同时还需考虑显微组织结构各向异性的作用。

关键词:超细晶铝;回复退火;力学性能各向异性;屈服下降;延展性

(Edited by Bing YANG)

Foundation item: Project (50971074) supported by the National Natural Science Foundation of China

Corresponding author: Andrew William GODFREY; Tel: +86-10-62788317; E-mail: awgodfrey@mail.tsinghua.edu.cn

DOI: 10.1016/S1003-6326(18)64691-6