文章编号:1004-0609(2007)04-0596-06

铌基合金包埋渗法制备抗氧化硅化物涂层及其组织形成

赵陆翔,郭喜平,姜嫄嫄

(西北工业大学 凝固技术国家重点实验室,西安 710072)

摘 要:利用包埋渗法在铌基合金上制备抗氧化硅化物涂层,渗硅温度分别为1 050、1 150和1 250 ℃,渗硅时间分别为2、5、10、15和20 h。利用SEM、EDS和XRD等检测手段分析涂层的结构、元素分布及相组成等,并对涂层形成的反应机理及反应动力学进行讨论。结果表明:涂层的相组成为(Nb, X)Si2(X表示Ti, Cr, Hf和Al等元素);涂层具有双层结构,且上层较为致密;涂层与基体之间达到了冶金结合,通过扩散形成过渡层及互扩散区;在包埋渗温度分别为1 050、1 150和1 250 ℃时,涂层生长的动力学曲线均符合抛物线规律。

关键词:铌基合金;包埋渗;涂层;过渡层;互扩散区;反应动力学

中图分类号:TG 146.4 文献标识码:A

Preparation and structural formation of oxidation-resistant silicide coatings on Nb-based alloy by pack cementation technique

ZHAO Lu-xiang, GUO Xi-ping, JIANG Yuan-yuan

(State Key Laboratory of Solidification Processing, Northwestern Polytechnical University, Xi’an 710072, China)

Abstract: Oxidation-resistant silicide coatings on an Nb-based alloy were prepared by pack cementation technique. The holding temperatures were 1 050, 1 150 and 1 250 ℃ and the holding time were 2, 5, 10, 15 and 20 h, respectively. The structure, phase constituents and compositional distribution in the coatings were analyzed by SEM, EDS and XRD techniques. The formation mechanism and growth kinetics of the coatings were discussed and measured. The results show that the phase constituent of the coatings is (Nb, X)Si2 (X represents Ti, Cr, Hf and Al elements). Double layers exist in the coatings, and the upper layer is denser. A transitional layer and a diffusion zone form between the coating and base material. The coating growth kinetics at 1 050, 1 150 and 1 250 ℃ were all fitted well to parabolic laws.

Key words: Nb-based alloy; pack cementation; coating; transitional layer; diffusion zone; reaction kinetics

铌基合金由于具有高熔点、高强度、耐腐蚀以及适中的密度等特性,因而成为21世纪重要的高温结构候选材料,但是铌基合金的高温抗氧化性能较差,纯铌甚至在600 ℃就发生“pesting”氧化现象,严重制约了其在实际中的应用[1-4]。目前,改进铌及铌基合金高温抗氧化性能的方法主要有合金化与涂层保护。合金化在提高铌基合金高温抗氧化性能的同时,有可能降低其力学性能,因此通过合金化提高铌基合金高温抗氧化性能的作用是有限的。涂层保护是兼顾铌基合金力学性能和高温抗氧化性能的切实有效的途径。

材料的抗氧化涂层应与基体有较强的结合力及相匹配的热膨胀系数,而且涂层材料的密度不应远高于基体材料。硅化物涂层密度低、熔点高,具有良好的热稳定性,使用温度可达1 600 ℃[5-8]。另外硅化物涂层在特别高的温度氧化时会在涂层表面形成流动的SiO2玻璃膜,具有自愈能力,可以弥合由于热应力产生的裂纹,因而具有很强的抗氧化能力。国内外的一些学者采用各种方法制备出综合性能较好的硅化物涂层。美国成功研制了R512A(Si- 20Cr-5Ti)涂层材料,用它涂覆的C-103合金(Nb-10Hf-Ti)已应用于航天飞机的发动机推力室上[9]。Vilasi研究出一种新的铌合金硅化物涂层,该涂层与Nb3Fe3CrSi6有相同结构,其中用Ti取代Nb,用Co或者Ni取代Fe,实验表明这种涂层具有很好的抗氧化能力[10]。Ryosuke利用熔盐法在铌表面沉积了约10 μm厚的NbSi2,有效避免了低温时就会发生的“pesting”氧化现象[11]。中国科学院、中南大学等单位也开展了相应的研究,制备出铌合金表面抗氧化性能较好的硅化物涂层[12-13]。

在各种涂层制备工艺中,包埋渗法的涂层与基体的粘结力强,并可同时渗入多种元素及可以制备200 μm以上的涂层,因而应用广泛。本文作者采用固体粉末包埋渗工艺在铌基合金表面制备了高温抗氧化性能优越的硅化物涂层,并分析了涂层的相组成、组织形貌及反应动力学。

1 实验

1.1 基体材料及粉末渗剂的准备

通过真空自耗电弧熔炼得到名义成分(摩尔分数,%)为Nb-24Ti-6Cr-3Al-16Si-4Hf-1.5B-0.05Y的母合金锭,线切割出9 mm×9 mm×9 mm的块状试样,再经80#~800#水砂纸依次打磨,然后超声波清洗,再烘干备用。渗剂由三部分组成:被渗元素粉末(Si粉,20%,质量分数),催化剂(NaF,5%)及填充剂(SiC,75%),渗剂经过4 h的球磨。

1.2 涂层的制备过程

将被渗试样埋入装有渗剂的Al2O3坩埚中,盖好盖子后,用粘结剂密封。渗硅实验在高温高真空可控气氛包埋渗炉中进行。装料完毕之后将包埋渗炉抽真空到10-2 Pa以下加热,包埋渗炉的升温速率为20 ℃/min,系统加热到700 ℃时停止抽真空并充氩气保护。渗硅温度分别为1 050、1 150和1 250 ℃,渗硅时间分别为2、5、10、15和20 h。包埋渗实验后试样在炉中冷却到室温,然后超声波清洗20 min。

1.3 涂层的分析

利用扫描电镜(SEM,JSM-6460)观察涂层的组织形貌;利用X射线衍射仪(XRD,荷兰Panalytical X’ Pert PRO)及能谱仪(EDS)确定涂层的相组成及微区成分;利用光学显微镜(OLYMPUS PM-G3)测量涂层的厚度。

2 结果与分析

2.1 涂层的结构及相组成

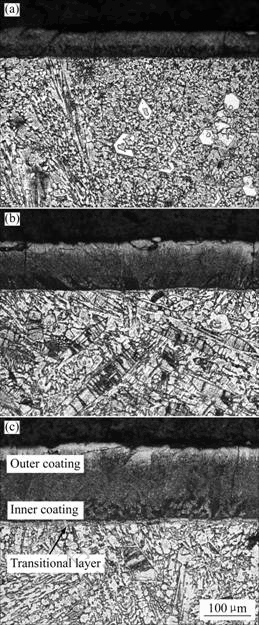

图1(a),(b)和(c)所示分别为1 050 ℃包埋渗15 h、1 150 ℃包埋渗15 h和1 250 ℃包埋渗15 h的涂层组织。由图可见,涂层具有双层结构,上部组织较为致密;下部组织较为疏松,在其中有很多孔洞。在涂层与基体之间可以清晰地观察到有一过渡层,该层的界面平直,与涂层和基体的结合都较为紧密,厚约5~10 μm。随包埋渗时间的延长,涂层的厚度显著增加,并且出现了更多的裂纹。裂纹只存在于涂层中,未延伸至基体,其扩展方向基本垂直于涂层与基体的界面。

图1 涂层横截面的光学金相

Fig.1 Cross-sectional optical micrographs of coatings: 1 050 ℃, 15 h; (b) 1 150 ℃, 15 h; (c) 1 250 ℃, 15 h

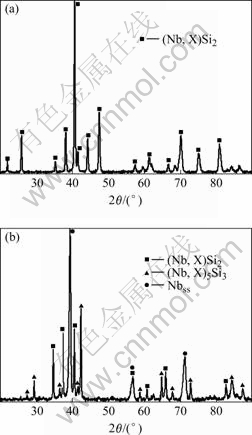

将1 250 ℃包埋渗2 h涂层从表面开始以10 μm为单位不断减薄,共减薄70 μm。每次减薄后进行X射线衍射分析,直至试样露出基体组织。比较剥层X射线衍射的结果可以发现,在露出基体组织之前,涂层各部分的XRD谱均相同,如图2(a)所示,图中各衍射峰与纯NbSi2衍射峰有一些偏移,这是由于Ti、Cr、Hf和Al等元素取代了部分Nb形成了(Nb, X)Si2结构(X表示Ti, Cr, Hf和Al等元素)的化合物。经实验测定,(Nb, X)Si2涂层与铌基合金基体的线性热膨胀系数分别为11.2×10-6和8.3×10-6 K-1,二者较为接近,因此该硅化物涂层适合作为铌基合金的保护涂层。图2(b)所示是1 250 ℃包埋渗硅2 h过渡层的XRD谱。由图可见,该过渡层的相组成为(Nb, X)Si2、(Nb, X)5Si3和Nbss(X表示Ti, Cr, Hf和Al等元素)。在图谱中出现了较强的Nbss的衍射峰,这是由于过渡层的厚度非常小,在剥层时一些地方已经露出了基体。如图2(b)所示,(Nb, X)Si2所对应的衍射峰强度较弱,说明其相对含量较小。

图2 1 250 ℃包埋渗2 h的涂层和过渡层的XRD谱

Fig.2 XRD patterns of coating and transitional layer after pack cementation at 1 250 ℃ for 2 h: (a) Coating; (b) Transitional layer

经过大量分析,发现对于同一温度下不同时间或在不同温度下的包埋渗试样,其涂层与过渡层的相组成均类似于图2的结果。

2.2 涂层的组织形貌及成分分析

通过对在1 050、1 150和1 250 ℃分别包埋渗不同时间后试样的观察发现,对于同一包埋渗温度下不同时间或不同包埋渗温度的试样,涂层的组织形貌及结构基本相同,但随着包埋渗时间的延长或包埋渗温度的升高,涂层中的晶粒越来越粗大,裂纹与孔洞也越来越多。

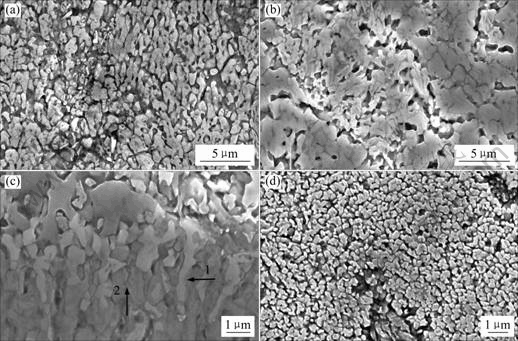

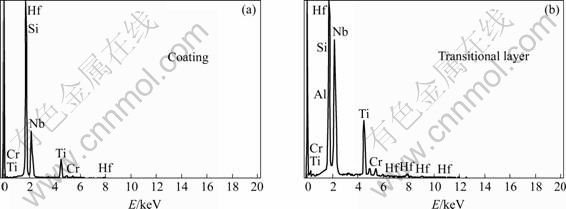

图3(a)与(b)所示分别为1 250 ℃包埋渗10 h涂层横截面上部与下部的SEM形貌。从图3(a)可以看出,涂层上部的组织主要为分布均匀致密的柱状晶,其生长方向基本垂直于涂层与基体的界面,长度约为1~5 μm,宽度约为0.5~1 μm,面积约占90%。另外还有一些等轴状晶粒分布于柱状晶之间,直径约为0.2~1 μm。只有极少量的孔洞存在于涂层的上部。从图3(b)可以看出,涂层下部主要由直径约为0.5~2 μm的粒状晶组成,其面积约占60%,另外就是和涂层上部相同的柱状晶,但较为疏松。大量的显微孔洞出现于晶粒之间,这些显微孔洞可以有效降低涂层的弹性模量,可能对提高涂层的抗热震性能有利。涂层中的这种疏松结构与Si原子的扩散有关[13],Si原子在硅化物中的扩散需要Si在亚晶格中的空位发生反向流动,或沿晶界运动,大量空位逐渐聚合则形成了显微孔洞。如图4(a)所示,EDS分析结果表明,如图4(a)涂层和过渡层中,Si的摩尔分数均为66%~68%,与NbSi2中的Si含量相同。在NbSi2中Nb摩尔分数应为33%,而实际含量约为18%~20%,因此可以推断涂层的相组成为(Nb, X)Si2(X表示Ti、Cr、Hf和Al等元素)。这种涂层结构更为紧密,有利于抗氧化性能的提高。

图3 1 250 ℃包埋渗10 h试样的SEM形貌

Fig.3 SEM images of specimen after pack cementation at 1 250 ℃ for 10 h: (a) Outer coating; (b) Inner coating; (c) Transitional layer; (d) Surface of coating

如图3(c)所示,在过渡层中可以观察到少量的垂直于基体的柱状晶,长度约为0.5~2 μm。EDS的分析结果表明,这些晶粒(如图中箭头1所示)的成分符合分子式(Nb, X)Si2,而其它区域内灰暗的晶粒(如图中箭头2所示)的成分符合分子式(Nb, X)5Si3(X表示Ti、Cr、Hf和Al等元素)。另外对过渡层进行了EDS的面扫描分析(图4(b))可知,(Nb+X)?Si的摩尔比在0.8~1.0的范围内,由此推知过渡层的相组成可能为(Nb, X)5Si3及(Nb, X)Si2,且(Nb, X)5Si3为基体相,与X射线衍射的结果相吻合。有研究指出,(Nb, X)5Si3过渡层的存在,可以提高单相(Nb, X)Si2的抗氧化性能[11],有效防止(Nb, X)Si2中的微裂纹向基体内的延伸[14]。

图3(d)所示为涂层表面的高倍SEM形貌。由图可见,晶粒堆积非常紧密,粒径大部分小于1 μm,表明涂层比较致密。但从宏观金相照片中可以发现涂层表面有一些不规则的裂纹,这是由于NbSi2具有六方结构,滑移系较少,因此本身比较脆,从而在高温冷却时由于应力作用导致表面开裂,这将影响涂层阻挡氧的渗入,从而影响其抗氧化能力。

图4 1 250 ℃包埋渗10 h(a)涂层及(b)过渡层的EDS面扫描图谱

Fig.4 EDS map scanning patterns of coating and transitional layer after pack cementation at 1 250 ℃ for 10 h: (a) Coating; (b) Transitional layer

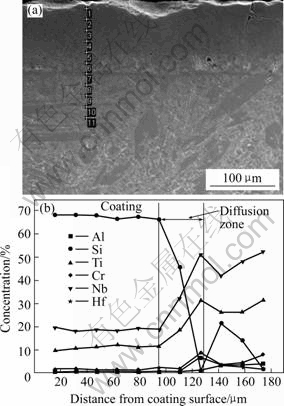

图5(a)和(b)所示分别是1 250 ℃包埋渗5 h涂层横截面的组织形貌及各元素沿涂层厚度方向分布的EDS分析结果。在涂层的下部存在厚度约为30 μm的互扩散区(包含过渡层),此区域在SEM形貌图中没有明显界面,但可以通过各元素含量的变化来识别,从图5(b)可以看出,涂层内各元素含量在距离涂层表面约100 μm的范围内基本保持不变,但在100 μm之后Si含量呈直线下降,而Ti, Nb等元素的含量却迅速上升。过了一定距离之后,这种Si含量下降而其他元素上升的趋势停止,各元素含量随厚度方向的变化逐渐平稳,这一成分突变的区域即为互扩散区。互扩散区为涂层与基体之间提供了非常重要的成分梯度,此梯度使得从涂层到基体之间的热膨胀系数平稳过渡,有效保证了包埋渗试样随炉冷却时涂层的完整性,减少了由于基体与涂层之间热膨胀系数的不匹配而产生的微裂纹[15]。

图5 1 250 ℃包埋渗5 h涂层横截面的组织形貌和成分分析

Fig.5 SEM micrograph (a) and concentration profile (b) of cross-section of coating after pack cementation at 1 250 ℃ for 5 h

2.3 涂层形成动力学

2.3.1 涂层形成的反应机理

Si粉与活化剂NaF在一定温度下生成气态的卤化物SiFx,SiFx在化学势能梯度的驱使下扩散至铌基合金基体表面,并发生分解、置换或歧化等可能的相界面反应,从而生成活性Si原子[16]。反应生成的活性Si原子首先吸附在基体表面自由能高的各点上,然后陆续被基体金属吸收,并逐渐扩散到基体金属中。

新硅化物相的形成是由各硅化物的化学稳定性及Si和其它各元素的扩散动力学决定的,由于Nb5Si3的生成焓(-516.8 kJ/mol)低于NbSi2的(-161 kJ/mol)[17],所以在反应开始的瞬间,活性Si原子与Nb反应生成Nb5Si3层(见反应(1)),随着活性Si原子的进一步扩散,Nb5Si3与Si反应生成NbSi2(见反应(2))。随后的反应是由活性Si原子或Nb原子在已形成的NbSi2层中的扩散速率控制的,作为反应界面前沿的Nb5Si3不断向铌基合金基体内部推进。

在反应前期活性Si原子的扩散较为充分,因此形成的涂层组织较为致密,随着NbSi2层的不断增厚,活性Si原子的扩散速率越来越慢,所以涂层的生长速度也越来越慢,导致在反应后期涂层的组织较为疏松。在反应的最后阶段,因为活性Si原子的扩散已经非常困难,没有充足的活性Si原子与Nb5Si3反应,所以形成了Nb5Si3过渡层。

2.3.2 反应动力学

实验所用包埋渗炉采用的是线性控温模式,升温和降温过程都可能发生渗镀,但在数据处理时渗硅时间仍按保温时间2、5、10、15和20 h计算。利用光学显微镜的显微标尺测量不同温度下包埋渗不同时间后试样的两个对边上的涂层厚度,在不同位置处各测量20个点,然后取其平均值。

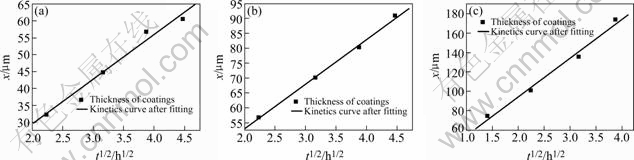

图6的示分别为1 050、1 150和1 250 ℃包埋渗不同时间后涂层厚度随时间平方根变化的规律。如图所示,对于这3个温度,涂层生长的动力学曲线均符合抛物线规律,意味着涂层的生长是由扩散控制的。拟合后的曲线方程为:

图6 不同温度下包埋渗时涂层厚度与时间平方根的关系曲线

Fig.6 Reaction kinetics curves at different holding temperatures: 1 050 ℃; (b) 1 150 ℃; (c) 1 250 ℃

包埋渗温度为 1 050 ℃时

x=3.08+13.26 t1/2

R=0.991 2 (3)

包埋渗温度为1 150 ℃时

x=22.85+15.03t1/2

R=0.999 1 (4)

包埋渗温度为1 250 ℃时

x=14.27+40.00 t1/2

R=0.994 6 (5)

由3个曲线方程的斜率值可以看出,随保温时间的增加,涂层的生长速度加快,而且1 250 ℃时的生长速度较1 050和1 150 ℃时的大很多。

3 结论

1) XRD与EDS的分析结果表明,涂层的相组成为(Nb, X)Si2;过渡层的相组成为(Nb, X)5Si3和(Nb, X)Si2(X表示Ti、Cr、Hf和Al等元素),其中(Nb, X)5Si3为基体相。

2) 涂层具有双层结构。上部的组织主要为分布均匀致密的柱状晶,其生长方向基本垂直于涂层与基体的界面;下部的组织主要为粒状晶,但较为疏松。过渡层界面平直,与涂层和基体结合都较为紧密。在涂层的下部存在有一定厚度的互扩散区。对于不同包埋渗条件下的试样,涂层的形貌及结构大致相同。

3) 在包埋渗温度分别为1 050、1 150和1 250 ℃时,涂层生长的动力学曲线均符合抛物线规律。

REFERENCES

[1] Bewlay B P, Jackson M R, Zhao J C, et al. A review of very-high-temperature Nb-silicide-based composites[J]. Metall Mater Trans A, 2003, A34: 2003-2043.

[2] XIAO Lai-rong, CAI Zhi-gang, YI Dan-qing, et al. Morphology, structure and formation mechanism of silicide coating by pack cementation process[J]. Trans Nonferrous Metals Soc China, 2006, 16(s1): s239-s244.

[3] 冯景苏. 铌应用的新进展[J]. 稀有金属材料与工程, 1994, 23(3): 7-12.

FENG Jing-su. New progress of applications of niobium[J]. Rare Metal Materials and Engineering, 1994, 23(3): 7-12.

[4] Sarath E, Menon K, Mendiratta M G. High temperature oxidation in multicomponent Nb alloys[J]. Material Science Forum, 2005, 475/479: 717-720.

[5] Tatemoto K, Ono Y, Suzuki R O. Silicide coating on refractory metals in molten salt[J]. Journal of Physics and Chemistry of Solids, 2005, 66: 526-529.

[6] Nicholls J R. Advances in coating design for high-performance gas turbines[J]. MRS Bulletin, 2003, 9: 659-670.

[7] Zhao J C, Westbrook J H. Ultrahigh-temperature materials for jet engines[J]. MRS Bulletin, 2003, 9: 622-630.

[8] Murayama Y, Hanada S. High temperature strength, fracture toughness and oxidation resistance of Nb-Si-Al-Ti multiphase alloys[J]. Science and Technology of Advanced Materials, 2002, 3: 145-156.

[9] Bewlay B P, Jackson M R, Lipsitt H A. The balance of mechanical and environmental properties of a multielement niobium-niobium silicide-based in situ composite[J]. Metall Mater Trans A, 1996, A27: 3801-3808.

[10] Vialsi M, Francois M, Podor R. New silicides for new niobium protective coatings[J]. Journal of Alloys and Compounds, 1998, 264: 244-251.

[11] Suzuki R O, Ishikawa M, Ono K. NbSi2 coating on niobium using molten salt[J]. Journal of Alloys and Compounds, 2002, 336: 280-284.

[12] 王 禹,郜嘉平,李云鹏,等. 铌合金硅化物涂层的结构及高温抗氧化性能[J]. 无机材料学报, 2000, 15(1): 143-149.

WANG Yu, GAO Jia-peng, LI Yun-peng, et al. Microstructure and oxidation- resistance of silicide coatings on C-103 niobium alloys[J]. Journal of Inorganic Materials, 2000, 15(1): 143-149.

[13] 殷 磊,易丹青,肖来荣,等. 铌表面MoSi2高温涂层的形貌和结构研究[J]. 稀有金属材料与工程, 2005, 34(1): 91-94.

YIN Lei, YI Dan-qing, XIAO Lai-rong, et al. The morphology and the structure of MoSi2 high temperature coating on niobium[J]. Rare Metal Materials and Engineering, 2005, 34(1): 91-94.

[14] Glushko P I, Semenov N A, Strigunovskii S V. Oxidation resistance of niobium coated with titanium disilicide[J]. Powder metallurgy and Metal Ceramics, 2000, 39: 560-562.

[15] Xiang D, Rose S R, Datta P K. Codeposition of Al and Si to form oxidation-resistant coatings on γ-TiAl by the pack cementation process[J]. Materials Chemistry and Physics, 2003, 80: 482-489.

[16] 李 明,宋力昕,乐 军,等. 铌表面固体粉末包埋渗硅研究[J]. 无机材料学报, 2005, 3(20): 764-767.

LI Ming, SONG Li-xin, LE Jun, et al. Microstructure and mechanism of pack siliconizing on niobium[J]. Journal of Inorganic Materials, 2005, 3(20): 764-767.

[17] Fernandes P B, Coelho G C. Thermodynamic modeling of the Nb-Si system[J]. Intermetallics, 2002, 10: 993-999.

基金项目:教育部新世纪优秀人才支持计划项目及国家自然科学基金资助项目(50271056)

收稿日期:2006-09-11;修订日期:2007-01-23

通讯作者:郭喜平,教授;029-88494873; E-mail: xpguo@nwpu.edu.cn

(编辑 何学锋)