文章编号:1004-0609(2007)03-0410-07

SnCu钎料镀层与Cu/Ni镀层钎焊接头的界面反应

刁 慧,王春青,赵振清,田艳红,孔令超

(哈尔滨工业大学 材料科学与工程学院 微连接研究室,哈尔滨 150001)

摘 要:观察了不同焊接工艺条件下钎焊接头界面的微观结构,并对钎焊过程中的界面反应进行分析。探讨了钎缝界面处IMC的生长机制,通过对不同钎焊温度和保温时间下的IMC生长规律的分析建立铜锡化合物厚度与温度和时间的关系方程。结果表明:钎焊过程中SnCu钎料合金镀层与可焊性Cu层的界面处生成金属间化合物Cu6Sn5和Cu3Sn;化合物的生长厚度与焊接时间之间满足抛物线关系,表明化合物的生长为扩散反应控制过程,并随焊接时间的延长化合物的生长速率逐渐下降。

关键词:SnCu钎料镀层;Cu/Ni镀层;金属间化合物;钎焊;界面反应

中图分类号:TG 111 文献标识码:A

Interfacial reactions between Sn-Cu solder alloy and Cu/Ni coatings during reflow soldering

DIAO Hui, WANG Chun-qing, ZHAO Zhen-qing, TIAN Yan-hong, KONG Ling-chao

(Microjoining Laboratory, School of Materials Science and Engineering,

Harbin Institute of Technology, Harbin 150001, China)

Abstract: The interface microstructures of soldered joints under different soldering techniques were observed and analyzed. The interface reaction during soldering was studied. The growth mechanism of the IMCs was discussed and the influences of soldering temperature and dwell time on IMC evolution were investigated. The equation of the relationship between IMCs thickness and soldering conditions including soldering temperature and dwell time was developed. The results suggest that,during soldering, the joint interface between the solder and Cu/Ni coating exhibits a duplex structure of Cu6Sn5 and Cu3Sn intermetallic compounds (IMCs). A parabolic relationship exists between the growth of the IMC layer and soldering time. This indicates that the mechanism of IMC growth is a diffusion-controlled process. The growth rates for the intermetallic layers increase with soldering temperature, whereas decreases with time.

Key words: SnCu solder alloy coating; Cu/Ni coating; intermetallic compound; soldering; interfacial reaction

电子封装对小型、轻便、高密度、高可靠性的要求,导致倒扣封装技术的迅速发展,这极大地满足了电子产品中大功率、高速、小型化的趋势,因而倒扣封装在集成电路的封装工艺中占愈来愈重要的地位[1-4]。

本实验采用电镀技术将Ni过渡层、可焊性Cu层预置在铝合金表面,在Cu层表面电镀SnCu钎料合金镀层[5-6],在钎焊过程中在SnCu钎料/Cu镀层接头界面处生成金属间化合物。由于金属间化合物相具有硬脆的特性,生长厚度较小时可以在钎料和器件之间实现较好的冶金连接,但是化合物的过度生长将严重影响接头的性能[7-9]。对金属间化合物的形成机制及影响因素的了解将有助于控制其数量和分布,因而具有较大的实际意义。

1 实验

电镀采用直流电刷镀电源,通过弱电电路中的安培小时计计量电刷镀过程中消耗的电量实现对镀层厚度的控制。钎焊实验设备为热风再流焊机,温控精度为±1 ℃。

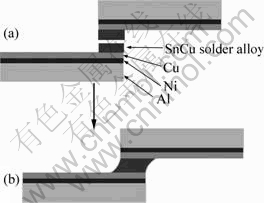

待镀铝板经除油、碱蚀、出光、浸锌等镀前预处理工艺以后,依次在表面上镀覆Ni层、Cu层以及SnCu钎料合金镀层。采用的镀层结构如图1所示。

图1 镀层结构示意图

Fig.1 Schematic plans of brush plating layers: (a) Before soldering; (b) After soldering

刷镀完成后,将试件放入热风再流焊炉中进行钎焊实验。在低于焊接温度40~60 ℃的条件下预热15~30 s,在(300±2) ℃、(340±2) ℃、(380±2) ℃下分别保温0.5、2、5、10、15和20 min后风冷至室温,冷却速率为3~10 ℃/s。

2 结果与分析

2.1 焊前镀层中元素分布分析

图2所示为Cu-SnCu界面处局部放大的SEM照片,由图可看出在Cu层与SnCu合金镀层界面处存在一层约1 μm的结合层。

图2 Cu-SnCu界面处局部放大SEM照片

Fig.2 Partially enlarged drawings of Cu-SnCu joint interface

图3所示为Cu-SnCu 结合界面处能谱分析结果,表明垂直于镀层方向上电镀SnCu合金的成分呈规律性变化。Cu-SnCu结合面处点a处的Cu含量为57.61%(质量分数,下同),随着电沉积的进行,合金镀层中的Cu含量逐渐减少。点b处Cu含量为45.83%,到达点c时,Cu含量降至21.42%。在Cu-SnCu 结合面处以上合金镀层的基体区域,合金中Cu、Sn元素沉积的含量达到一种稳定状态,其中合金基体中较亮区域,如点d处Cu含量为9.51%,较暗区域e处Cu含量为5.57%。

图3 Cu-SnCu界面处EDX分析

Fig.3 EDX analysis of Cu-SnCu joint interface: (a) Spot a in Fig.2; (b) Spot b in Fig.2; (c) Spot c in Fig.2; (d) Spot d in Fig.2; (e) Spot e in Fig.2

在合金镀液中,由于金属沉积发生在阴极/溶液界面上,沉积金属的相对浓度是决定沉积合金组成的最重要因素。扩散理论用于电沉积合金的基本方程为[10]

由于材料结构的相似性和物性的匹配,合金溶液中的Cu将优先沉积在Cu层的表面,Sn元素相对沉积的量较少,导致溶液中Cu离子的浓度下降;随着电沉积的进行,溶液、溶液/阴极界面处Cu离子的浓度梯度减小,先沉积的镀层结构发生改变,Cu优先沉积的动力降低,Cu和Sn的共沉积达到一种稳定状态,因此出现Cu-SnCu界面处向镀层基体中Cu含量逐渐减少并趋于稳定的一种过渡状态。

2.2 界面处金属间化合物的生长特点

在钎焊过程中, SnCu镀层熔化成为液态钎料,在固液两相界面上发生原子相互交换。随Cu原子的溶解,Cu层边缘形成Cu的富集区。当局部区域Cu含量达到Cu在液态Sn中的溶解极限时,Cu元素即以金属间化合物的形式析出,并以固相的Cu层为基体结晶生长。

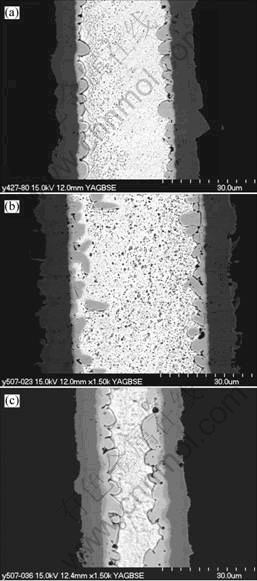

图4所示为焊接时间为2 min的焊缝SEM照片。界面处局部放大的SEM照片表明在Cu层与钎料的界面处生成了两层金属间化合物,如图5所示。由EDX分析结果(图6)可知扇贝状化合物颗粒为Cu6Sn5,Cu6Sn5与Cu层之间的薄层状化合物为Cu3Sn。

图4 焊缝的SEM剖面照片

Fig.4 Cross-sectional microstructures of joints soldered at different temperatures and time: (a) 300 ℃, 2 min; (b) 340 ℃, 2 min; (c) 380 ℃, 2 min

图5 焊缝界面处局部放大SEM照片

Fig.5 Partically enlarged SEM image of soldered joint

图6 界面处化合物EDX成分分析

Fig.6 EDX analysis of IMCs of Cu-SnCu joint interface: (a) Spot a in Fig.5; (b) Spot b in Fig.5

Cu6Sn5化合物为六方晶体结构,不同晶轴方向上Cu6Sn5生长速率不同[9],因此Cu6Sn5化合物颗粒呈扇贝状向钎料内部生长。在扇贝状化合物颗粒之间,存在着深达Cu镀层的凹槽。由于Cu在液态Sn中的扩散能量为17.5 kJ/mol,在Cu3Sn相中的扩散能量为65 kJ/mol[11],因此,这些凹槽是Cu原子向Cu6Sn5化合物颗粒与钎料界面处扩散的快速通道。Cu原子在凹槽底部溶解进入液态钎料中,快速扩散至扇贝状颗粒与钎料的界面处与Sn反应生成Cu6Sn5。在Cu6Sn5生长过程中,随着时间延长,化合物晶粒粗化生长。

对于晶粒半径为r的半球体,由于Gibbs-Thomson效应,在晶粒表面处溶质原子(Cu)的浓度cr为

由于化合物曲率半径不同而导致的溶质原子通量为:

从式(5)可以看出,在金属间化合物生长过程中,扇贝状晶粒形成后,已经形成的晶粒在横向(垂直于化合物生长方向)的粗化生长取决于粗化通量J的系数 中的3个因素:扩散系数D、钎焊温度T和溶质Cu在液态钎料中的饱和溶解度c0,其中Cu在液态钎料中的扩散系数受温度的影响很小,约为10-5 cm2/s,因此,Cu6Sn5的横向粗化生长主要取决于钎焊温度T和溶质Cu在液态Sn中的饱和溶解度c0。

中的3个因素:扩散系数D、钎焊温度T和溶质Cu在液态钎料中的饱和溶解度c0,其中Cu在液态钎料中的扩散系数受温度的影响很小,约为10-5 cm2/s,因此,Cu6Sn5的横向粗化生长主要取决于钎焊温度T和溶质Cu在液态Sn中的饱和溶解度c0。

生成的Cu6Sn5化合物层与Cu镀层组成一对扩散偶。在元素浓度梯度驱动力的作用下,Cu层与Cu6Sn5界面处发生元素的相互扩散。随着扩散过程的进行,当两种元素达到一定浓度配比时,便以Cu3Sn的形式析出,Cu3Sn化合物层以连续波浪层状的形式生长。

为了定量描述界面处金属间化合物的生长规律,分别测量不同焊接时间条件下两种化合物的生长厚度。

在钎焊过程中有一部分Cu6Sn5与Cu反应生成Cu3Sn而被消耗,因此直接测量所得的Cu6Sn5的厚度值与实际生成的Cu6Sn5的厚度值之间有偏差,应对测量所得的Cu6Sn5厚度值加以修正,即[12-13]:

根据修正后的化合物层厚度数据,作出不同钎焊温度条件下Cu3Sn与Cu6Sn5生长厚度与时间的关系曲线,结果如图7所示。

图7 化合物的生长曲线

Fig.7 Growth curves of intermetallic compounds from 300 ℃ to 380 ℃: (a) Cu3Sn phase; (b) Cu6Sn5 phase

依据曲线拟合得到不同温度时Cu3Sn的生长方程分别如式(9)~(11)所示:

300 ℃时

340 ℃时

380 ℃时

而Cu6Sn5的生长方程如式(12)~(14)所示:

300 ℃时

340 ℃时

380 ℃时

由以上分析可知:金属间化合物的生长厚度与时间的关系遵循抛物线定律,为扩散过程控制反 应[14-15]。且有

将化合物生长方程对时间求导数,得到Cu3Sn和Cu6Sn5的瞬时生长速率,结果如图8所示。Cu3Sn层位于Cu层和Cu6Sn5化合物层之间,其生长过程是依靠元素之间的固相扩散。固相扩散受温度和时间的控制,温度决定扩散速率;在一定温度下延长加热时间可以增加扩散量。从图8(a)可看出温度和时间对Cu3Sn生长的影响。随着焊接时间的增加,化合物层厚度增大,扩散过程所需的时间延长,Cu3Sn的生长速率逐渐下降。焊接温度升高加快了原子的扩散速率,对Cu3Sn的生长具有促进作用。

图8 化合物的瞬时生长速率

Fig.8 Growth rates of intermetallic compound layer: (a) Cu3Sn layer; (b) Cu6Sn5 layer

由图8(b)可看出,钎焊温度一定时,随着焊接时间的增加,Cu6Sn5的生长速率逐渐下降。这是由于Cu6Sn5化合物层厚度随着时间的增加逐渐增大,Cu层中的Cu原子扩散路程加大使得Cu6Sn5的生长速率下降;Cu6Sn5化合物颗粒的粗化生长使得Cu原子的快速扩散通道—凹槽密度减小,也会降低Cu6Sn5的生长速率。

钎焊时间小于2 min时,Cu6Sn5化合物层厚度较小,扇贝状化合物颗粒之间凹槽的密度较大,温度升高加快了原子的扩散速率,促进了Cu6Sn5的生长。随着钎焊时间的增加,Cu6Sn5扇贝状化合物颗粒发生明显的粗化生长,且温度越高粗化通量越大,凹槽密度的急剧下降将降低Cu6Sn5的生长速率,对化合物的生长起到抑制作用;钎焊温度升高对化合物的生长具有促进作用。在二者的共同作用下,钎焊时间小于5 min时,化合物的生长速率随温度升高而缓慢增加。当钎焊时间超过5 min时,380 ℃下Cu6Sn5化合物颗粒之间的凹槽基本消失,粗化生长的抑制作用大于温度升高的促进作用,使得Cu6Sn5的生长速率开始小于 340 ℃时的生长速率。

3 结论

1) SnCu钎料合金镀层与Cu镀层钎焊接头界面处生成的金属间化合物分别为Cu6Sn5和Cu3Sn。Cu6Sn5化合物颗粒呈扇贝状向钎料内部生长,Cu3Sn化合物层以连续波浪状的形式生长。

2) 金属间化合物层厚度与钎焊时间之间符合抛物线关系,表明钎焊过程中金属间化合物的生长为扩散控制反应。

3) Cu3Sn为固相扩散控制反应。焊接温度升高,原子的扩散速率加快促进化合物的生长。钎焊时间增加,化合物层厚度增大,原子的扩散路径增长,降低了化合物的生长速率。

4) 由于原子扩散路程的增长和化合物颗粒的粗化生长共同影响了Cu6Sn5的生长速率。焊接温度由300 ℃升高到340 ℃时,Cu6Sn5的生长速率随温度升高而缓慢增加。380 ℃条件下钎焊时间接近10 min时,Cu6Sn5的生长速率小于340 ℃时的生长速率。

REFERENCES

[1] Bhatgadde L G, Joseph S, Kulkarni S C. Electroless copper/nickel/gold plating of ferrite substrates[J]. Metal Finishing, 1996, 94(4): 45-46, 48: 50-51.

[2] James R F, Gerald O, Jane B. Selective electroless nickel deposition on copper as a final barrier/bonding layer material for microelectronics applications[J]. Applied Surface Science, 2002, 185(3/4): 289-297.

[3] Andrew S J G, Scott P, Christine J. Interconnecting to aluminum- and copper-based semiconductors (electroless- nickel/gold for solder bumping and wire bonding)[J]. Microelectronics Reliability, 2002, 42(2): 265-283.

[4] Vorobyova T N, Vrublevskaya O N, Vengura A V. The processes and the products of gold reduction in tetrachloroaurate electroless plating solutions[J]. Surface & Coatings Technology, 2005, 200(7): 2481-2488.

[5] Lugscheider E, Bobzin K, Lake M K. Deposition of solder for micro-joining on M.E.M.S. components by means of magnetron sputtering[J]. Surface and Coatings Technology, 2001, (142-144): 813-816.

[6] 朱奇农, 罗 乐, 肖 克, 杜黎光. Ni 对Sn96.5Ag3.5/Cu之间扩散行为的阻挡作用[J]. 中国有色金属学报, 2000, 10(2): 199-202.

ZHU Qi-nong, LUO Le, XIAO Ke, DU Li-guang. The obstructive function of Ni on the diffusion between Sn96.5Ag3.5/Cu[J]. The Chinese Journal of Nonferrous Metals, 2000, 10(2): 199-202.

[7] Takenaka T, Kano S, Kajihara M, et al. Growth behavior of compound layers in Sn/Cu/Sn diffusion couples during annealing at 433-473 K[J]. Materials Science and Engineering, 2005, A396: 115-123.

[8] Chang T C, Wang M C, Hon M H. Growth and morphology of the intermetallic compounds formed at the Sn-9Zn-2.5Ag/Cu interface[J]. Journal of Alloys and Compounds, 2005, 402: 141-148.

[9] Yoon J W, Lee Y H, Kim D G, Kang H B, Suh S J, Yang C W, Lee C B, Jung J M, Yoo C S, Jung S B. Intermetallic compound layer growth at the interface between Sn-Cu-Ni solder and Cu substrate[J]. Journal of Alloys and Compounds, 2004, 381: 151-157.

[10] 屠振密. 电镀合金原理与工艺[M]. 北京:国防工业出版社, 1993.

TU Zhen-mi. Principle and Technology of Electroplating Alloy [M]. Beijing: National Defence Industry Press, 1993.

[11] Hayashi A, Kao C R, Chang Y A. Reactions of solid copper with pure liquid tin and liquid tin saturated with copper[J]. Scripta Materialia, 1997, 37(4): 393-398.

[12] Bader S, Gust W, Hieber H, et al. Rapid formation of intermetallic compounds by interdiffusion in the Cu-Sn system[J]. Acta Met, 1995, 43(1): 329-337.

[13] 翟秋亚, 杨 扬, 徐锦锋, 郭学锋. 快速凝固Cu2Sn合金的组织形态及相结构[J]. 中国有色金属学报, 2006, 16(8): 1374-1379.

ZHAI Qiu-ya, YANG Yang, XU Jin-feng, GUO Xue-feng. Microstructural morphology and phase structure of rapidly solidified Cu-Sn alloy[J]. The Chinese Journal of Nonferrous Metals, 2006, 16(8): 1374-1379.

[14] Wu Y, Sees J A, Pouraghabagher C, Foster L A, Marshall J L, Jacobs E G, Pinizzotto R F. The formation and growth of intermetallics in composite solder[J]. Electron Mater, 1993, (22): 769-777.

[15] Fujiwara Y. Sn deposition onto Cu and alloy layer growth by a contact immersion process[J]. Thin Solid Films, 2003, 425(1/2): 121-126.

收稿日期:2006-06-30;修订日期:2006-12-11

通讯作者:王春青,教授,博士;电话:0451-86418725;E-mail:wangcq@hit.edu.cn

(编辑 龙怀中)