DOI: 10.11817/j.issn.1672-7207.2019.04.006

金刚石绳锯用Fe基预合金粉代Co性能

刘志环,张绍和

(中南大学 地球科学与信息物理学院,有色金属成矿预测与地质环境监测教育部重点实验室,

有色资源与地质灾害探查湖南省重点实验室,湖南 长沙,410083)

摘要:分别采用共沉淀法制备FeCoCu预合金粉和H2还原法制备单质Co粉,采用XRD和SEM对2种粉末及其烧结体进行物相分析和形貌观察,并测定2种烧结体试样的硬度、相对密度、抗弯强度及磨损质量损失等物理力学性能,同时研究分别以2种粉末为主要结合剂成分制作的金刚石绳锯的锯切石材的性能,从而研究FeCoCu预合金粉替代Co粉用于金刚石绳锯的可行性。研究结果表明:共沉淀法FeCoCu预合金粉实现了合金化,粉末呈近球状,粒度与H2还原法单质Co接近;FeCoCu和Co在各自最佳烧结温度烧结时,烧结体试样的硬度、相对密度、抗弯强度都十分接近,FeCoCu烧结体试样的抗弯强度损失率η及磨损质量损失m分别达到19.0%和1.412 g,而Co烧结体试样的η和m分别为15.2%和1.638 g,两者都具有较好的金刚石包镶性能和相近的匹配岩粉磨损的性能;FeCoCu基金刚石绳锯锯切G1306石材平均锯切效率达到9.8 m2/h,相对Co基绳锯提高16.7%,理论寿命为13.6 m2/m,相对Co基绳锯降低6.2%,其产品性价比优势更加明显。

关键词:FeCoCu预合金粉;金刚石绳锯;力学性能;微观结构;包镶性能

中图分类号:TM282 文献标志码:A 文章编号:1672-7207(2019)04-0796–10

Properties of Fe based pre-alloyed powder substitute Co application in diamond wire saw

LIU Zhihuan, ZHANG Shaohe

(Hunan Key Laboratory of Nonferrous Resources and Geological Hazards Exploration,

Key Laboratory of Metallogenic Prediction of Nonferrous Metals and Geological Environment

Monitoring Ministry of Education, School of Geosciences and Info-Physics, Central South University, Changsha 410083,China)

Abstract: The FeCoCu pre-alloyed powder was fabricated by co-precipitation method and Co powder was fabricated by H2 reduction method. Phase composition and morphology of the two kinds of powder and their sintered bodies were characterized by XRD and SEM. The hardness, relative density, bending strength and wear mass loss of the sintered bodies were measured. The properties of diamond wire saw cutting stone with the two kinds of powder as the main component of the matrix were studied, and then the feasibility of using FeCoCu pre-alloyed powder instead of Co powder in diamond wire saw was studied. The results show that alloying is realized in the FeCoCu pre-alloyed powder, and its particle size is close to that of Co powder by H2 reduction method with near spherical shape. The hardness, relative density and bending strength of FeCoCu and Co sintered bodies are very close when sintered at each optimal sintering temperature, the bending strength loss rate η and wear mass loss m of FeCoCu sintered body are 19.0% and 1.412 g, respectively, while the η and m of Co sintered samples are 15.2% and 1.638 g, all of which have good diamond wrapping properties and similar wear resistance suited to rock powder wear. The average sawing efficiency of FeCoCu based diamond wire saw is 9.8 m2/h, which is 16.7% higher than that of Co based sample when cutting stone G1306, and its theoretical tool life is 13.6 m2/m, which is 6.2% lower than that of Co based sample, and so the advantage of product performance to price is more obvious.

Key words: FeCoCu pre-alloyed powder; diamond wire saw; mechanical property; microstructure; diamond wrapping property

金刚石绳锯已广泛应用于石材矿山开采工程、深基坑支撑梁拆除工程中,具有切割面积不受限制、锯路规整、切割损伤小等优点[1–4]。串珠是金刚石绳锯的主要工作部件,一般采用粉末冶金方法制造,通过串珠内部合理分布的金刚石颗粒,在绳锯高速旋转带动下,采用“以磨代切”的方式,实现对加工对象的切割与分离[5–6]。采用粉末冶金法制造金刚石绳锯串珠,要求胎体材料具有较好的包镶金刚石颗粒的能力外,还需要具备与金刚石颗粒磨损相匹配的磨损性能以及一定的强度等[7–9]。绳锯串珠胎体材料的组成成分一般包含骨架材料、黏结相、改性成分等,骨架材料决定了胎体材料的主要性能特征;金属钴(Co)是优质的绳锯串珠结合剂材料,具有很好的对金刚石颗粒的润湿性,而且烧结体抗弯强度高,高Co含量金刚石绳锯往往具有较好的综合使用性能,但Co价格昂贵,而且属于国家战略性物质,因此,研究可代Co的预合金粉体材料成为目前金刚石绳锯主要的研究方向之一[10–13];近年来,行业较多集中于FeCoCu预合金粉的制备与应用技术的研究,而关于FeCoCu代Co机理的研究鲜有报道[14–16]。本文作者从金刚石绳锯串珠胎体材料设计原理入手,研究共沉淀法FeCoCu预合金粉烧结体的力学性能和摩擦磨损性能,并与单质Co烧结体的相关性能进行对比,探讨Fe基预合金粉替代Co粉的可行性;分别以FeCoCu和单质Co为骨架材料制作金刚石绳锯用于石材矿山开采,研究Fe基预合金粉与单质Co粉对切割性能的影响规律,同时探讨结合剂材料的物理力学性能与绳锯切割性能的关联 关系。

1 实验

1.1 粉末的制备

FeCoCu预合金粉采用共沉淀法制备。按表1所示各元素质量配比称取相应氯化物原材料,分别溶于去离子水中,形成FeCl2·4H2O,CoCl2·6H2O和CuCl2·2H2O等水化合物,混合配制成浓度为1.0 mol/L的草酸溶液,将金属盐溶液和草酸溶液通过加液釜以相同速率分别加入到反应釜中进行共沉淀反应,反应温度为50 ℃,充分搅拌后加入氨水溶液调整反应溶液的pH,使其保持在2左右,反应20 min后再静置沉淀2 h,获得FeCoCu复合草酸盐沉淀物,沉淀物经过过滤、清洗、煅烧和还原,得到所需要的预合金粉。单质Co粉采用草酸盐氢还原法生产,将高纯Co矿通过萃取形成Co的草酸盐,再通过高压H2还原、破碎、筛分,得到所需要的单质Co粉。

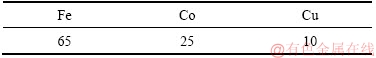

表 1 预合金粉中各元素名义成分组成(质量分数)

Table 1 Composition of pre-alloyed powder %

1.2 粉末烧结体的制备

分别将FeCoCu预合金粉和单质Co粉按重量要求装入石墨模腔,置于国产真空热压烧结炉中进行热压烧结,得到长×宽×高为30 mm×12 mm×6 mm的预合金粉烧结体试样。热压炉真空度为0.1 Pa,FeCoCu预合金粉烧结温度为840 ℃,Co粉烧结温度为880 ℃,保温保压时间和烧结压力两者都相同,分别为4 min和25 MPa。

分别在FeCoCu预合金粉和单质Co粉中添加体积分数为7.5%的金刚石颗粒(粒度为425~355 μm),混合均匀,然后,采用上述工艺分别制作出含金刚石的复合材料烧结体,研究2种烧结体的物理力学性能及对金刚石的包镶性能。

1.3 烧结体的性能测试与结构表征

采用排水法测试试样的密度,并根据测定的密度与烧结体的理论密度求出相对密度。采用TH300型洛氏硬度计测量不含金刚石烧结体试样的硬度,采用CMT4304万能材料试验机分别测试无金刚石与有金刚石试样的断裂载荷,并由此计算各自的三点抗弯强度,并通过日本JSM–6700F型扫描电镜观察试样断口形貌。

粉末烧结体对金刚石颗粒的包镶强度用抗弯强度损失率η表示,计算公式如下:

(1)

(1)

式中:σ1为不含金刚石烧结体的抗弯强度;σ2为含7.5%金刚石颗粒的烧结体的抗弯强度。

采用DHM–1型砂轮磨耗比测定仪检测无金刚石试样的磨损质量损失m,在相同实验条件下,m越小,则试样耐磨损性能越好,反之则越差。标准砂轮的硬度为3.2,线速度为20 m/s,试样加压质量为5 kg,测试时间为60 s,每种测定5个试样并取平均值。磨损质量损失m的计算公式如下:

m=m1–m2 (2)

式中:m为磨损质量损失;m1为试样在对磨前的质量;m2为试样与砂轮对磨后的质量。

1.4 金刚石绳锯切割性能试验

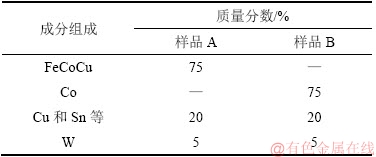

分别以FeCoCu预合金粉和单质Co粉为主要胎体成分,配以一定含量Cu和Sn等成型剂和助熔成分,并添加W作为胎体增强成分,具体成分见表2,制作金刚石绳锯并用于石材切割,检测绳锯的切割效率(单位为m2/h)和使用寿命(单位为m2/m),2种胎体成分的金刚石参数都相同,金刚石粒度都选用270~325 μm和325~380 μm,体积分数为9.5%,金刚石颗粒热冲击强度(TTI)要求大于80%。

绳锯串珠采用真空热压烧结法,串珠外径为11.5 mm,胎体内径为7.0 mm,烧结工艺参数与主要胎体成分的烧结工艺参数相同。绳锯固定方式为橡胶固定,橡胶硫化温度为280 ℃,注射压力为20 MPa。绳锯切割采用自制55 kW全自动矿山绳锯机,切割石材为G1306,单刀切割平方数为86.8 m2,切割5刀共计434 m2后统计切割效率平均值和切割寿命计算值。

表 2 金刚石绳锯胎体成分

Table 2 Composition of matrix material of diamond wire saw

2 绳锯切割hc的计算及对胎体的性能要求

金刚石绳锯在绳锯机飞轮带动下,以线速度vs高速旋转,当进给速度为vw时,包镶有金刚石磨粒的绳锯串珠以一定压力挤压石材表面,在法向压力和切向力共同作用下,实现对石材的材料去除,累计材料去除过程即可实现对石材的切断。绳锯宏观切割过程是由串珠表面实际出刃的金刚石累计切削作用完成的,因此,单颗金刚石平均切削厚度hc是研究绳锯切割性能的关键指标。绳锯切割运动学规律与金刚石线锯基本相同,只是工具结构不同,则绳锯单颗金刚石平均切削厚度计算公式为[17]

(3)

(3)

其中:hc为单颗金刚石平均切削厚度;vw为金刚石绳锯的进给速度;C为金刚石绳锯单位面积实际工作颗粒数;vs为绳锯线速度;β为金刚石切削刃的半锥角。

绳锯单位面积实际工作颗粒数C与绳锯串珠分布密度及单珠胎长有关系,设定串珠内金刚石体积分数为φc,金刚石平均粒度为d,假设绳锯串珠分布密度为40 粒/m,单珠胎体长度为6 mm,则金刚石绳锯单位面积实际工作颗粒数C的计算公式为[18]

(4)

(4)

其中:C为绳锯单位面积实际工作颗粒数;Ψ为金刚石实际工作颗粒数比例系数;φc为绳锯串珠内金刚石体积分数;k为金刚石出刃系数;d为绳锯串珠金刚石平均粒度。

将C代入式(3),并将定量设定为γ,则绳锯单颗金刚石切削厚度公式可修改为

(5)

(5)

单颗金刚石切削厚度hc即为被切割对象的岩屑尺寸。石材岩屑在相对运动及水流等作用下,以游离磨料的形式反作用于胎体,才使得金刚石颗粒在磨损到一定程度时,能及时脱落,新的金刚石颗粒能及时出刃,从而完成金刚石颗粒的“新陈代谢”。根据上述绳锯用于石材切割时的单颗金刚石切削机理可知,石材切割对于绳锯串珠胎体的性能要求应主要包括2个方面:一是胎体具备一定的抵抗岩屑磨损的能力,且应与串珠内部金刚石颗粒的设计参数相匹配。确定了金刚石参数、锯切工艺参数以及切割对象的性能,则可依据上述公式大致计算出串珠工作面实际出刃金刚石颗粒数、单颗金刚石单次切削厚度等参数,由此可确定岩屑尺寸,而串珠胎体的耐摩擦磨损性能的设计是与切割对象的岩屑尺寸、岩屑成分与硬度相关联的。二是胎体对金刚石磨粒的包镶能力。胎体对金刚石的包镶能力越强,在胎体耐磨损性能相同的条件下,金刚石的利用率越高,绳锯使用寿命能得到一定程度的提升,当然也要考虑由于包镶能力过高使金刚石不能及时脱落,从而导致绳锯锯切锋利度降低的可能性。综合以上分析,绳锯串珠胎体的耐磨损性能、包镶性能等性能参数,与绳锯锯切性能理论上应当存在一定的关联关系,若能建立胎体机械性能参数与绳锯锯切性能之间的关联关系,则可以通过机械性能的检测与分析,合理地选择和调整胎体的成分和比例。

3 结果与讨论

3.1 FeCoCu预合金粉与单质Co粉的形貌与特征

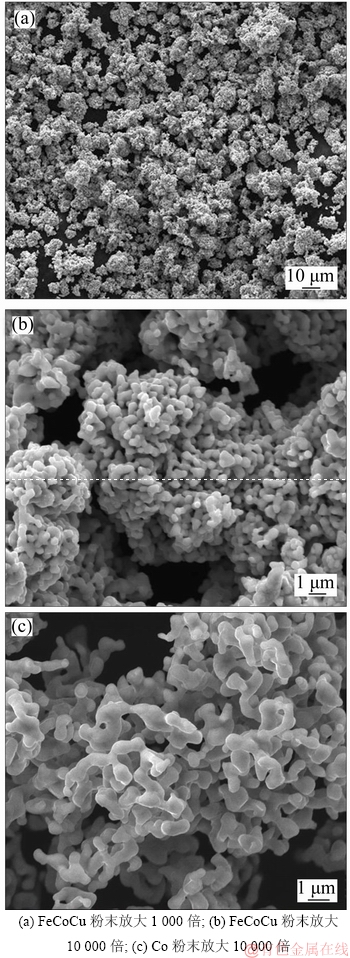

图1所示为共沉淀法FeCoCu预合金粉与H2还原法单质Co粉的SEM形貌,其中图1(a)所示为FeCoCu放大1 000倍SEM图,图1(b)和图1(c)所示分别为FeCoCu和单质Co放大10 000倍SEM图。图2所示为FeCoCu预合金粉的XRD图谱。由图1可知:FeCoCu预合金粉末和单质Co粉末的外形基本相同,都为近球形,粉末颗粒表面光滑,颗粒间形成聚合体,一次颗粒FeCoCu粉末的粒径为0.5~1 μm,Co粉的粒径为1~2 μm。粉末聚合体是指一次颗粒通过聚合形成的二次颗粒,一般有团粒和絮状体2种形式,低倍数下2种粉末都为团粒状,高倍数下都为絮状体。

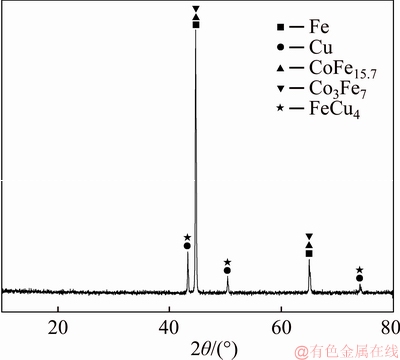

图2所示为共沉淀法FeCoCu预合金粉的XRD图谱。由图2可知:共沉淀法FeCoCu粉末不但存在Fe和Cu的单质相,而且存在CoFe15.7,Co3Fe7和FeCu4等金属间化合物,说明Co和Cu进入Fe的晶胞中,形成了固溶体,在烧结体内能起到固溶强化的作用,能提高烧结体的强度。从图2还可知:预合金粉末不存在Co的单质相,这是因为Co在合金粉中的含量较低,且Co与Fe属于同族元素,原子半径相近,Co在γ-Fe中的固溶度为100%,在共沉淀过程中,Co与Fe易产生原子交换,形成置换固溶体[19]。

3.2 FeCoCu预合金粉与单质Co粉烧结体的机械性能

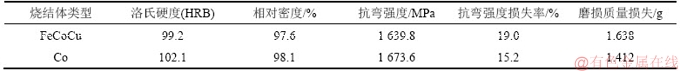

表3所示为FeCoCu预合金粉和单质Co粉分别在各自最佳烧结工艺时烧结后的试样的机械性能,包括硬度、三点抗弯强度、相对密度、强度损失率、磨损质量损失等。

由表3可知:共沉淀法FeCoCu预合金粉烧结体与单质Co粉烧结体的部分力学性能非常接近,但单质Co粉烧结体的各项力学性能指标都比FeCoCu预合金粉烧结体的优。表3中实验表明:一方面,Co的各项力学性能较好,是优良的结合剂材料;另一方面,共沉淀法FeCoCu预合金粉烧结体的硬度、相对密度及三点抗弯强度与Co粉烧结体的相比都相差不大,特别是三点抗弯强度达到1 639.8 MPa,相比常规Fe粉、FeCu合金粉烧结体的三点抗弯强度有较大提升,说明共沉淀法FeCoCu粉末由于实现了预合金化,具有固溶强化作用,烧结体的整体力学性能得到提升。

图 1 FeCoCu和Co粉末SEM图

Fig. 1 SEM images of FeCoCu and Co powders

图 2 FeCoCu预合金粉的XRD图谱

Fig. 2 XRD pattern of FeCoCu pre-alloyed powder

表 3 FeCoCu预合金粉和单质Co粉烧结体的力学性能

Table 3 Mechanical properties of pre-alloyed powders

表3所示的抗弯强度损失率η决定烧结体对金刚石磨粒包镶能力,η越小,烧结体对金刚石磨粒的包镶能力越强,反之越弱。由表3可知:FeCoCu预合金粉烧结体的抗弯强度损失率η为19.0%,稍大于单质Co粉烧结体的η (15.2%),由此可知,FeCoCu预合金粉烧结体对金刚石的包镶能力比单质Co粉烧结体的低,但两者差距不大,根据以往实验可知,一般金刚石工具结合剂骨架材料的抗弯强度损失率η在30%以上[20],因而,FeCoCu预合金粉烧结体的η仍然是较高的,对金刚石磨粒的包镶能力较强。

由表3可知:FeCoCu预合金粉烧结体的磨损质量损失为1.638 g,而单质Co粉烧结体的磨损质量损失为1.412 g,由此可知,FeCoCu预合金粉烧结体的耐磨损性能比单质Co粉烧结体的耐磨损性能更低,但两者相差不大。实践证明,Co粉是优良的金刚石工具结合剂骨架材料,往往在实际应用中具有较好的综合锯切性能,这是因为单质Co的耐磨损性能与被加工对象岩粉的磨损能力相互匹配[21]。FeCoCu预合金粉烧结体的耐磨损性能虽然低于单质Co烧结体的耐损性能,但是仍然具有与单质Co相近的抵抗岩粉磨损的能力。

3.3 FeCoCu预合金粉和单质Co粉烧结体的断口形貌分析

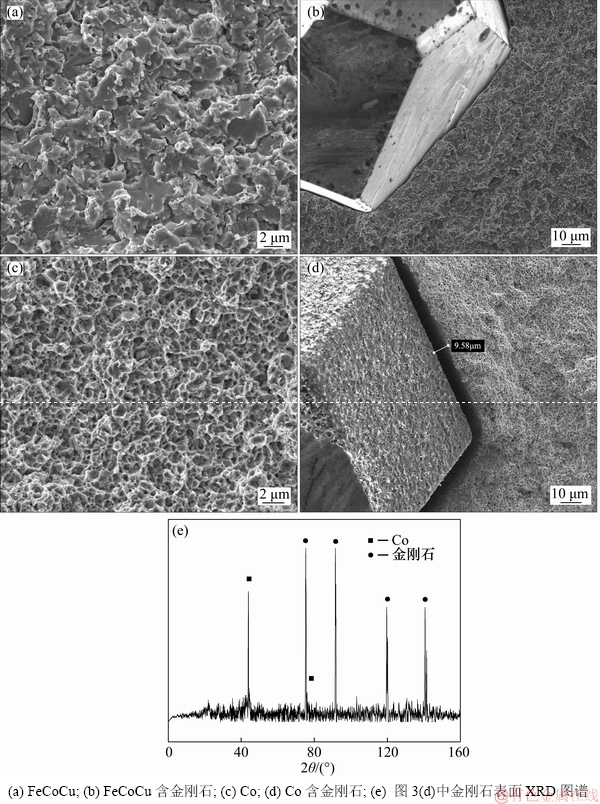

图3所示为FeCoCu预合金粉和单质Co粉不含金刚石胎体的断口SEM图及金刚石界面SEM图。

由图3(a)可知:FeCoCu预合金粉在840 ℃烧结时,晶粒粒径均匀,无异常长大现象;烧结体组织内部缺陷数量很少,断口上晶粒表面均布少量微细小孔,根据粉末冶金烧结原理,烧结后期,伴随晶界迁移过程,部分孔隙空位迁移到附近烧结颈界面,但总有部分孔隙因内部蒸汽压大于原子迁移动力,不能实现完全闭合[22]。金属试样断口形貌一般有沿晶断裂、穿晶断裂和韧窝断裂等3种断裂特征,从图3(a)可知:FeCoCu预合金粉烧结体断口主要为沿晶断裂和穿晶断裂的混合型断口,属于典型的脆性断裂特征,这是由生成的CoFe15.7,Co3Fe7和FeCu4等金属间化合物本身的特性所决定的,但由于固溶强化作用,晶粒界面结合强度较高,超过了晶粒本身的强度时会产生横穿晶粒的穿晶断裂,这是与FeCoCu烧结体试样三点抗弯强度较高相符合的。

从图3(b)可知:FeCoCu预合金粉末烧结体包镶金刚石的界面接触紧密,金刚石颗粒表面光滑。文献[23–24]中研究表明,在真空烧结条件下,870 ℃时Fe对金刚石表面开始有轻微浸蚀,但金刚石表面仍晶型完整;950 ℃以后Fe对金刚石浸蚀较严重,金刚石晶格中的C原子经接触界面进入γ-Fe中扩散并在远离金刚石一侧发生富集,因此,FeCoCu胎体在840 ℃烧结时没有与金刚石颗粒界面产生反应。依靠热胀冷缩效应产生的机械包镶力把持金刚石。但由于胎体烧结致密度高,且与金刚石颗粒的内界面张力小,胎体材料烧结时能很好地铺展在金刚石颗粒表面,并能产生对金刚石颗粒较强的支撑作用,因此,FeCoCu胎体对金刚石颗粒的包镶能力也较强,FeCoCu预合金粉烧结体的抗弯强度损失率也较低。

由图3(c)可知:单质Co粉在880 ℃烧结时,晶粒粒径均匀细小,无明显缺陷,孔隙数量少。烧结体断口主要为韧窝断裂形貌,属于塑性断裂特征,这是由于单质Co微细粉末颗粒在烧结时形成的晶粒粒径较小,根据Hall–Petch公式可知,晶粒粒径越小,晶粒界面结合强度越高,由于晶界结合强度增加,材料断裂时裂纹不容易沿晶界扩展,所以,烧结体在断裂前,晶粒发生明显的塑性变形,形成韧窝断裂的形貌。因此,单质Co烧结虽然没有产生合金体的固溶强化作用,但由于Co材料本身特性和粉末颗粒的烧结活性,烧结体具有较高的三点抗弯强度、致密度及硬度。

从图3(d)可知:单质Co胎体与金刚石界面有一定缝隙,缝隙尺寸达到9.58 μm,金刚石颗粒表面粗糙,有附着物存在。

将金刚石从胎体内取出,通过对金刚石表面的XRD分析,结果如图3(e)所示,检测为Co的单质,说明Co对金刚石表面润湿性较好,形成了较为牢固的Co的覆膜,提高了对金刚石的包镶能力,这正是单质Co烧结体抗弯强度损失率较低的原因。由于单质Co胎体对金刚石颗粒具有较高的包镶力,烧结体在弯曲断裂时,金刚石在较大拉伸张力作用下,会产生移位与松动,因此,微观观察胎体与金刚石界面有一定的缝隙存在。

图 3 2种粉末烧结体的断口形貌SEM图

Fig. 3 Fracture SEM images of two kinds of sintered bodies

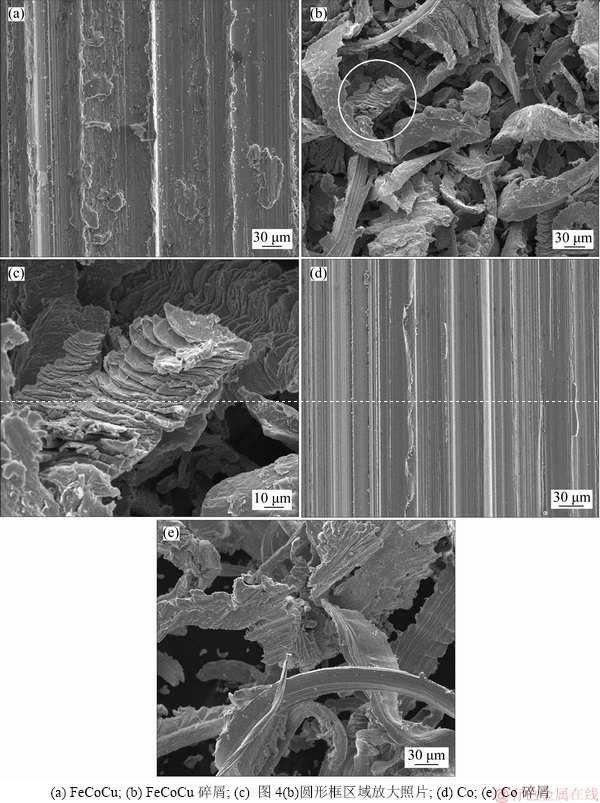

3.4 FeCoCu预合金粉和单质Co粉烧结体的摩擦磨损特征分析

图4所示为FeCoCu预合金粉和单质Co粉烧结体分别与标准砂轮对磨后,烧结体被磨削表面和磨削产生的碎屑SEM图。由图4(a)和图4(d)可知:FeCoCu烧结体试样被磨削表面单个磨粒切削槽宽度在60~70 μm之间,稍大于单质Co烧结体试样的切削槽宽度(40~50 μm),FeCoCu试样被磨削表面有少量的碎屑粘连,而单质Co试样被磨削表面切削槽边界光滑,表面无碎屑粘连现象。从图4(b)和图4(c)可知:FeCoCu试样被磨削的碎屑既包括长条状整体碎屑,也包括图4(b)圆圈内放大图所示的鱼鳞状堆积的块体,而单质Co试样被磨削的碎屑主要为长条状整块碎屑。以上现象的产生也是与烧结体试样的物理力学性能相关联的,FeCoCu烧结体试样的硬度较单质Co烧结体试样的硬度低,标准砂轮的磨粒压入试样表面深度更深,因此切削槽宽度更大,这也是FeCoCu烧结体试样磨损质量损失比单质Co烧结体试样稍高的原因;另外,由于FeCoCu烧结体合金成分具有一定的脆性,在与标准砂轮对磨时产生的碎屑因为材料的脆性而更易断裂,从而形成碎屑堆积的块体,而单质Co烧结体材料韧性相对更好,碎屑不易断裂,因而形成长条状整块碎屑体。

图 4 2种粉末烧结体的磨损表面及碎屑SEM形貌图

Fig. 4 SEM images of wearing face and detritus of sintered bodies

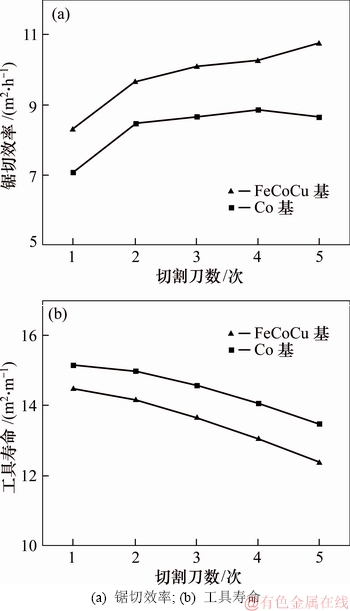

3.5 绳锯锯切性能对比分析

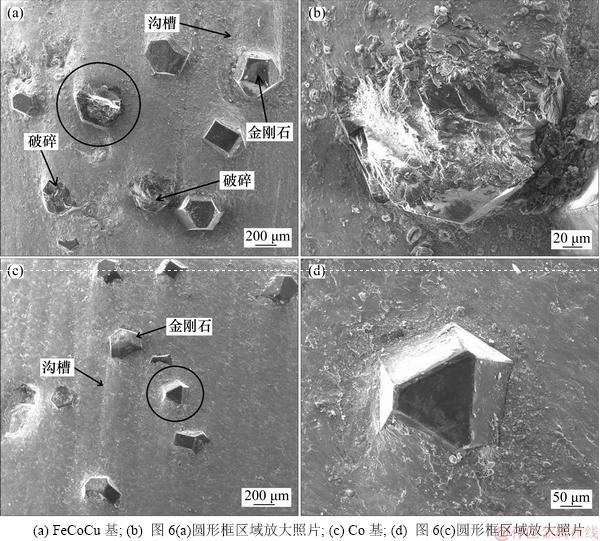

图5所示为分别以FeCoCu预合金粉和单质Co粉为骨架成分制作的金刚石绳锯切割石材的锯切性能曲线。图5(a)所示为2种胎体成分金刚石绳锯每切割86.8 m2后的切割效率对比图,共切割5刀,合计434 m2;图5(b)所示为工具理论寿命计算结果对比图。图6所示为锯切260.4 m2后不同胎体成分金刚石绳锯串珠工作面形貌SEM图。根据FeCoCu预合金粉的烧结特性,FeCoCu基胎体烧结温度为840 ℃,保温时间为5 min;Co基胎体烧结温度为870 ℃,保温时间为5 min。由图5(a)可知:FeCoCu基胎体和单质Co基胎体制作的金刚石绳锯在石材锯切的初期,锯切效率相对较低,锯切一定面积后,锯切效率达到相对稳定值,这是由于新开刃的绳锯串珠表面金刚石磨粒未达到最佳出刃高度,切削刃数量也未形成最佳“匹配”,切割一定面积之后,胎体磨损量高于金刚石磨损量,出刃高度“过高”的金刚石磨粒提前脱落,形成脱落坑,串珠表面有效参与切削的金刚石数量基本维持在一定范围内,切割效率逐步保持稳定。当锯切至173.6~347.2 m2之间时,2种胎体的金刚石绳锯锯切 效率都呈小幅上升的趋势,这是由于随着锯切量逐渐增加,绳锯逐渐消耗,外径逐渐减小,锯切阻力减小,锯切效率逐步上升。锯切至347.2 m2以后,FeCoCu基胎体绳锯锯切效率呈快速提升的趋势,而Co基胎体绳锯锯切效率呈小幅下降的趋势,且FeCoCu基胎体绳锯平均锯切效率明显比Co基胎体绳锯的高,达到9.8 m2/h,而Co基胎体绳锯平均锯切效率为8.4 m2/h,提高了16.7%。由图5(b)可知:FeCoCu基胎体和Co基胎体金刚石绳锯每切割86.8 m2所计算的理论寿命呈总体下降趋势,FeCoCu基胎体绳锯理论寿命比Co基胎体绳锯的稍低,FeCoCu基胎体绳锯理论寿命平均值为13.6 m2/m,而Co基胎体绳锯理论寿命平均值为14.5 m2/m,寿命减少6.2%。由此可知,以FeCoCu预合金粉为骨架成分制作的金刚石绳锯相对于传统的Co基结合剂绳锯用于石材切割时,锯切效率得到提升,而工具寿命相差较小,而FeCoCu预合金粉Co质量分数只有25%,因此,工具原材料成本减少,产品性价比优势更加明显。

图 5 FeCoCu基和Co基胎体绳锯锯切性能曲线图

Fig. 5 Cutting property curves of FeCoCu base and Co base diamond wire saw

从图6(a)和图6(b)可以看出:FeCoCu基胎体中,金刚石磨粒沿切削方向,其两侧有较深的沟槽,磨粒后端“蝌蚪状”支撑也较为明显,胎体对金刚石磨粒的包镶完整无缝隙,部分金刚石有破碎的形态;Co基胎体金刚石磨粒两侧沟槽相对较浅,胎体对金刚石的包镶完整无缝隙,但出刃高度相对较小,金刚石磨粒基本无破碎现象。由于2种串珠的金刚石参数设计完全相同,因此,串珠表面锯切后的形貌特征是与胎体性能密切相关的,而金刚石工具胎体性能在添加剂成分组成相同情况下,是由骨架相成分的性能所决定的[25]。FeCoCu烧结体的磨损质量损失比Co烧结体的高,因此,FeCoCu基胎体耐磨损性能比Co基胎体的低,故串珠表面沟槽相对较深,根据前述hc计算公式及胎体设计理论,属于胎体磨损稍快于金刚石磨损的情形。由于FeCoCu对金刚石包镶能力较强,金刚石不易脱落,因此,金刚石出刃高度相对较高,提高了金刚石的“容屑空间”[26],绳锯切割效率得到提升。正是因为金刚石出刃高,锯切石材时金刚石磨粒受到的力矩更大,当力矩大于金刚石的断裂强度时,金刚石易产生破碎,且金刚石断裂方向沿锯切作用的反方向,如图6(b)所示。由于FeCoCu基胎体耐磨损性能比Co基胎体的稍低,且金刚石破碎比例相对较高,因此,其工具寿命比Co基胎体的低。综上所述,串珠表面形貌与其锯切性能是相对应的,同时,在其他条件相同时,串珠胎体骨架相成分的机械性能与工具锯切性能有一定的关联关系,通过研究骨架相成分的机械性能,能预判工具的锯切性能,也可为骨架相成分的设计特别是代Co预合金粉末的设计提供理论依据。

图 6 FeCoCu基和Co基胎体绳锯工作面形貌图

Fig. 6 Surface morphologies of FeCoCu base and Co base diamond wire saw of beads

4 结论

1) 共沉淀法FeCoCu预合金粉为近球形,粉末晶粒粒径与H2还原法单质Co粉粒径相近;FeCoCu预合金粉不但存在Fe和Cu的单质相,还存在CoFe15.7,Co3Fe7和FeCu4等金属间化合物,在烧结时能起到固溶强化的作用,以期达到代Co的效果。

2) FeCoCu烧结体的硬度、相对密度、抗弯强度都与单质Co烧结体的接近;FeCoCu烧结体的抗弯强度损失率η达到19.0%,具有较高的对金刚石磨粒的包镶性能;其磨损质量损失为1.412 g与单质Co烧结体的较接近,具有相近的匹配岩粉磨损的性能。

3) FeCoCu预合金粉烧结体断口为沿晶断裂和穿晶断裂的混合型断口,属于脆性断裂特征,FeCoCu胎体包镶金刚石的界面紧密接触,金刚石颗粒表面光滑;单质Co烧结体断口主要为韧窝断裂,属于塑性断裂特征;Co在金刚石表面形成牢固的覆膜,提高了包镶能力。

4) 2种绳锯样品锯切效率都呈整体上升的趋势,工具寿命都呈逐渐降低的趋势,FeCoCu基胎体绳锯平均锯切效率达到9.8 m2/h,相对于Co基胎体绳锯提高了16.7%,理论寿命达到13.6 m2/m,相对Co基胎体绳锯只降低6.2%,而FeCoCu预合金粉相对于Co粉原材料成本降低,产品性价比优势更加明显。

参考文献:

[1] ERSOY A, ATICI U. Performance characteristics of circular diamond saws in cutting different types of rocks[J]. Diamond and Related Materials, 2004, 13(1): 22–37.

[2] WRIGHT D N, ENGELS J A. The environment and cost benefits of using diamond wire for quarrying and processing of natural stone[J]. Industrial Diamond Review, 2003, 63(4): 16–24.

[3] DAVID H. Diamond sawing removes highway hazard[J]. Industrial Diamond Review, 1997(3): 94–95.

[4] MARTIN J. Dry cutting of concrete parapets with a diamond wire saw[J]. Industrial Diamond Review, 2005, 65(1): 44–45.

[5] 邹庆化, 汤凤林, 杨凯华, 等. 热压金刚石工具材料及其致密化[J]. 中国有色金属学报, 2001, 11(2): 119–125.

ZOU Qinghua, TANG Fenglin, YANG Kaihua, et al. Hot pressed sintered matrix composites for diamond tools and its densification[J]. The Chinese Journal of Nonferrous Metals, 2001, 11(2): 119–125.

[6] 谢志刚, 刘心宇, 秦海青, 等. 金刚石制品用FeCoCu胎体的烧结与力学性能研究[J]. 中南大学学报(自然科学版), 2010, 41(6): 2178–2182.

XIE Zhigang, LIU Xinyu, QIN Haiqing, et al. Sintering and mechanical properties of FeCoCu fetal body applied for diamond tools[J]. Journal of Central South University (Science and Technology), 2010, 41(6): 2178–2182.

[7] 郭桦, 苏钰, 陈剑章, 等. Co基金刚石串珠胎体中W添加剂的作用[J]. 中国机械工程学报, 2007, 5(1): 108–112.

GUO Hua, SU Yu, CHEN Jianzhang, et al. Effect of W in Co-based matrix of diamond beads[J]. 2007, 5(1): 108–112.

[8] 戴秋莲, 徐西鹏, 王永初. 金属结合剂对金刚石把持力的增强措施及增强机制评述[J]. 材料科学与工程, 2002, 20(3): 465–468.

DAI Qiulian, XU Xipeng, WANG Yongchu. Measures used to improve bonding of diamond to matrix and bonding mechanisms[J]. Materials Science & Engineering, 2002, 20(3): 465–468.

[9] HUANG H, XU X P. Study on the wear of diamond beads in wire sawing[J]. Materials Science Forum, 2006, 532/533: 436–439.

[10] 谢德龙, 万隆, 刘志环, 等. 共沉淀法制备Fe-Cu基预合金粉的低温热压烧结[J]. 粉末冶金材料科学与工程, 2015, 20(1): 93–97.

XIE Delong, WAN Long, LIU Zhihuan, et al. Low-temperature hot press sintering of Fe-Cu based pre-alloyed powder manufactured by co-precipitation method[J]. Materials Science and Engineering of Powder Metallurgy, 2015, 20(1): 93–97.

[11] 谢志刚, 秦海青, 刘心宇, 等. 金刚石制品用FeCoCu预合金粉末的制备及应用研究[J]. 材料工程, 2011(3): 1–5.

XIE Zhigang, QIN Haiqing, LIU Xinyu, et al. Study on the preparation of the prealloyed powder and its application for diamond tools[J]. Journal of Materials Engineering, 2013(3): 1–5.

[12] PALUMBO M, CURIOTTO S, BATTEZZATI L A. Thermo-dynamic analysis of the stable and met stable Co-Cu and Co-Cu-Fe phase diagrams[J]. Calphad, 2006, 30: 171–178.

[13] XIE Delong, WAN Long, SONG Dongdong, et al. Low-temperature sintering of FeCuCo based pre-alloyed powder for diamond bits[J]. Journal of Wuhan University of Technology(Materials Science), 2016, 31(4): 805–809.

[14] VILLARDEL M, MURO P, SANCHEZ J M, et al. Consolidation of diamond tools using Cu-Co-Fe based alloys as metallic binders[J]. Powder Metallurgy, 2001, 44(1): 81–90.

[15] ANDERSON P B, GUEROLD S B, ANA D S, et al. Structure, microstructure and mechanical properties of PM Fe-Cu-Co alloys[J]. Materials and Design, 2010, 31: 522–526.

[16] AN K. Pressure assisted master sintering surface of Co, Cu and Fe powder mixture[J]. Powder Technology, 2013, 234: 117–122.

[17] 刘志环, 罗文来, 潘晓毅, 等. 单颗金刚石对光伏基础材料的加载实验[J]. 金刚石与磨料磨具工程, 2013, 33(4): 38–40.

LIU Zhihuan, LUO Wenlai, PAN Xiaoyi, et al. Loading experiments of single diamond grit on photovoltaic materials[J]. Diamond and Abrasives Engineering, 2013, 33(4): 38–40.

[18] 张绍和, 刘志环, 肖尊群. 金刚石锯片锋利性试验研究[J]. 粉末冶金技术, 2006, 24(2): 110–113.

ZHANG Shaohe, LIU Zhihuan, XIAO Zunqun. Experimental study on sharpness of diamond sawblades[J]. Powder Metallurgy Technology, 2006, 24(2): 110–113.

[19] 孙毓超, 刘一波, 王秦生. 金刚石工具与金属学基础[M]. 北京: 中国建材工业出版社, 1999: 100–101.

SUN Yuchao, LIU Yibo, WANG Qinsheng. Diamond tools and metallography[M]. Beijing: China Building Materials Industry Press, 1999: 100–101.

[20] 谢德龙, 万隆, 宋冬冬, 等. 金刚石工具用FeCoCu预合金粉组成对烧结特性的影响[J]. 中国有色金属学报, 2016, 26(3): 577–583.

XIE Delong, WAN Long, SONG Dongdong, et al. Effect of composition of FeCoCu pre-alloyed powders on sintering characters used for diamond tools[J]. The Chinese Journal of Nonferrous Metals, 2016, 26(3): 577–583.

[21] 郭桦, 陈剑章, 苏钰, 等. Co粉粒度对Co基绳锯串珠胎体性能的影响[J]. 超硬材料工程, 2006, 18(3): 11–14.

GUO Hua, CHEN Jianzhang, SU Yu, et al. Influence of cobalt grit on performance of cobalt-based bead matrix of wire saw[J]. Superhard Material Engineering, 2006, 18(3): 11–14.

[22] 黄培云. 粉末冶金原理[M]. 北京: 冶金工业出版社, 2011: 288–289.

HUANG Peiyun. Powder metallurgy principle[M]. Beijing: Metallurgical Industry Press, 2011: 264–268.

[23] 郭西缅, 王岚. Fe刻蚀金刚石的工艺因素[J]. 人工晶体学报, 1997, 26(2): 158–160.

GUO Ximian, WANG Lan. Influence factories of technology for etching diamond[J]. Journal of Synthetic Crystals, 1997, 26(2): 158–160.

[24] 陈霞. 金刚石圆锯片用铁基结合剂的研究[J]. 粉末冶金材料科学与工程, 1998, 3(2): 135–138.

CHEN Xia. The research of iron-based matrix for circular sawing sawblades[J]. Materials Science and Engineering of Powder Metallurgy, 1998, 3(2): 135–138.

[25] 储志强, 郭学益, 刘东华. 金刚石制品胎体金属粉末材料的分类与组成元素的作用机理[J]. 金属材料与冶金工程, 2016(5): 8–12.

CHU Zhiqiang, GUO Xueyi, LIU Donghua. Classification of diamond products matrix powder materials and mechanism of its constituent elements[J]. Metal Materials and Metallurgy Engineering, 2016(5): 8–12.

[26] 陈先. 容屑比对石材锯切过程的影响[J]. 石材, 1998(6): 29–31.

CHEN Xian. Effect of chip-holding ratio on sawing process of stone[J]. Stone, 1998(6): 29–31.

(编辑 杨幼平)

收稿日期:2018-07-13;修回日期:2018-10-12

基金项目(Foundation item):国家自然科学基金资助项目(41872186) (Project(41872186) supported by the National Natural Science Foundation of China)

通信作者:张绍和,博士,教授,博士生导师,从事地质工程等研究;E-mail:zhangshaohe@163.com