工艺参数对CVI-TaC沉积速率的影响

陈招科, 熊 翔, 李国栋, 肖 鹏, 张红波, 尹 健, 黄伯云

(中南大学 粉末冶金国家重点实验室, 长沙 410083)

摘 要: 利用TaCl5-Ar-C3H6 -H2反应体系, 采用化学气相渗透(CVI)法在炭毡中沉积TaC, 并研究了CVI工艺参数如气体流速、 滞留时间、 沉积温度、 沉积压力和H2的加入等对碳化钽在炭毡中沉积速率(用炭毡质量分数的增加来表示)的影响。 研究表明: CVI-TaC受表面反应控制的最大气体流速为40cm/s, 最小滞留时间为1.2s; 沉积速率与沉积温度之间的关系不符合Arrhenius方程, 沉积速率随沉积温度的升高先增加后减小, 在950℃时达到最大值; 在1000℃时,CVI过程受孔隙扩散所控制; 沉积速率随沉积压力的升高以及H2的加入而急剧增加。

关键词: TaC; 炭毡; 化学气相渗透; 扩散; 沉积速率 中图分类号: TQ050.4

文献标识码: A

Influences of process parameters on deposition rate of CVI-TaC

CHEN Zhao-ke, XIONG Xiang, LI Guo-dong, XIAO Peng,ZHANG Hong-bo, YIN Jian, HUANG Bai-yun

(State Key Laboratory of Powder Metallurgy,Central South University, Changsha 410083, China)

Abstract: TaC was deposited by chemical vapor infiltration(CVI) method with TaCl5-Ar-C3H6 -H2 system in carbon fiber felt. The influences of CVI process parameters, such as gas velocity, residence time, deposition temperature, deposition pressure and the addition of H2, on the deposition rate(expressed by the mass fraction increment of the sample) of TaC were studied. The results show that CVI-TaC process is controlled by surface reaction, the maximum gas velocity is 40cm/s and the minimum residence time is 1.2s. The relationship between the deposition rate and the preform temperature do not accord with Arrhenius formula. The deposition rate increases firstly with the increase of temperature, reaches the maximum value at 950℃. At 1000℃, the CVI process is controlled by pore diffusion. The deposition rate increases obviously with the increase of deposition pressure and the addition of H2.

Key words: TaC; carbon felt; chemical vapor infiltration(CVI); diffusion; deposition rate

碳化钽(TaC)熔点高达4143K[1], 是耐温最高的几种化合物之一。 它具有优异的高温力学性能、 抗高速气流(粒子流)冲刷性能和抗烧蚀性能, 并与C/C复合材料具有良好的化学相容性及物理相容性[2], 在C/C复合材料的高温抗氧化、 抗烧蚀性能研究中, 一直受到许多材料工作者的重视[2-13]。 可用于制备Cf/TaC复合材料的方法有如下几种: 冷压-烧结法、 热等静压法、 熔渗法、 化学气相渗透法, 等。 然而, 用于制备炭纤维增强难熔金属碳化物, 前3种方法都具有无法避免的缺陷, 例如在用冷压-烧结和热等静压法制备Cf/TaC的过程中, 由于炭纤维与高硬度的TaC颗粒直接接触, 在压制时, 炭纤维会受到严重损伤; 另外, 冷压-烧结法制备的复合材料密度较低, 热等静压法所需制备温度高、 制备样品尺寸小且形状简单, 而熔渗法则存在TaC熔液粘滞流动性能差及制备温度高的缺点。 相比之下, 化学气相渗透(CVI)法具有如下优点[14]: 能够沉积各种元素及组分; 高纯; 高密度, 理论上能达到100%; 材料能在熔点下形成; 材料具有近似网络结构; 不会严重损伤炭纤维。 其主要缺点就是制备周期长及成本高。

化学气相渗透过程包括许多步骤, 其中最重要的是反应物气体扩散进炭毡孔隙, 以及随后在炭纤维表面形成TaC涂层的沉积反应。 为了使炭毡中所有炭纤维获得整体一致均匀的TaC沉积, 并使炭毡预制体能获得最大的致密度, 必须使CVI过程受表面反应所控制, 也就是说反应物在孔隙中的扩散速率要远大于纤维表面发生的TaC沉积速率, 这可通过优化CVI工艺参数来实现。 目前, 采用CVI方法在炭毡中沉积TaC的研究报道较少, 更未见相关的工艺参数研究。 因此, 本文作者对炭毡中CVI-TaC的沉积工艺参数进行比较系统的研究, 以达到优化CVI-TaC工艺的目的。

1 实验

1.1 原材料

本研究采用环形炭毡作为预制体, 其规格为d70mm×d50mm×10mm, 原始密度为0.16g/cm3。

1.2 制备过程

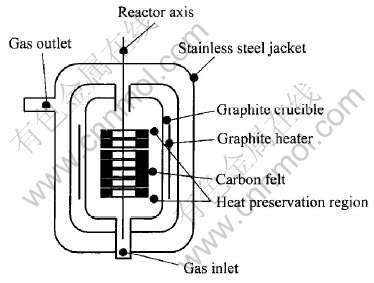

从进入CVI炉内保温区1cm处开始, 沿反应器轴向依次装载7个炭毡样品。 图1所示为CVI反应器内样品装载及CVI反应器示意图。

为减少TaC涂层对纤维的损伤, 首先在炭纤维上制备一层热解C。 然后采用TaCl5-Ar-C3H6-H2体系在炭毡中炭纤维表面化学气相沉积TaC涂层。 TaCl5是一种在较低温度下就可获得较高蒸气压的物质, 因此被用做Ta源在炭纤维上制备TaC涂层。 固态的TaCl5粉末在蒸发器中被加热蒸发形成TaCl5蒸气, 由氩气作为载气并与其它气体一起进入CVI反应器, 剂量由流量计控制。 在反应器中TaCl5蒸气与其它气体通过扩散进入炭毡体, 在H2的作用下被还原形成Ta并与丙烯分解出来的C发生反应形成TaC。

图1 CVI反应器示意图

Fig.1 Schematic diagram of CVI reactor

1.3 参数设计

本文主要研究沉积工艺参数如气体流速、 滞留时间、 沉积温度、 沉积压力以及H2的加入对化学气相渗透TaC沉积速率的影响情况。

反应器中平均气体流速、 滞留时间计算公式分别如式(1)和(2)所示:

式中 为反应器中平均气体流速, cm/s; t为气体在反应器中滞留时间, s;

为反应器中平均气体流速, cm/s; t为气体在反应器中滞留时间, s;  t, RC为反应器中总的气体流速, mL/min; A为反应器横截面积, cm2; V为反应器体积, cm3。

t, RC为反应器中总的气体流速, mL/min; A为反应器横截面积, cm2; V为反应器体积, cm3。

根据理想气体平衡状态方程

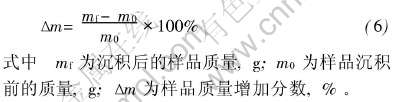

每一步实验参数都在前一步实验结果上进行优化设计, 设计如表1所示,  c, gas、

c, gas、  d, gas、 vC3H6则根据式(3)、 (4)和(5)进行计算得出。

d, gas、 vC3H6则根据式(3)、 (4)和(5)进行计算得出。

1.4 样品检测

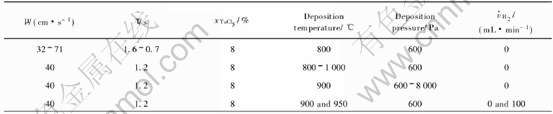

沉积速率用炭毡质量增加分数表示。 计算公式如下:

样品的质量用精确度为0.01g的电子天平对样品进行称量。

利用JEOL-6360LV型扫描电子显微镜(SEM)观察TaC沉积后样品微观结构。 利用日本理学D/max2550VB+18K转靶X射线衍射仪(XRD)分析了炭纤维表面涂层的物相成分。 其涂层物相组成如图2所示。 由图2可以看出, 涂层成分主要是TaC。

2 结果与讨论

2.1 气体流速与滞留时间

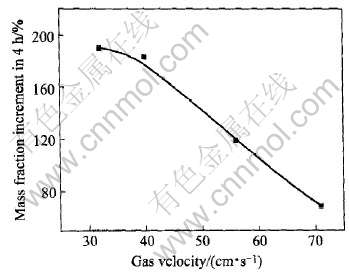

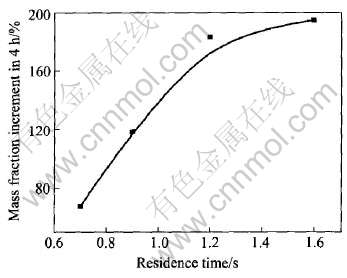

沉积速率与气体流速存在复杂的关系。 当沉积过程由表面化学反应控制时, 沉积速率不依赖于沉积区的气体流速; 若沉积过程是扩散控制, 则气体流速对沉积速率有显著的影响。 反应器中平均气体流速及滞留时间与沉积速率的关系如图3和4所示。 由图3和4可知, 当气体流速很大而滞留时间很小时, 沉积速率很小, 这主要由于气体流速相对较大, 大部分气体还没来得及在反应器中停留, 就被系统抽出反应器。 当滞留时间小于1.2s时, 沉积速率随滞留时间增加线性增加, 这主要是随着滞留时间的增加, 反应气体能在反应器中停留更多时间, 从而反应更充分。 而在更高的滞留时间阶段(>1.2s), 沉积速率基本上达到平衡状态, 在这里, 反应气体有足够的时间发生反应, 沉积工艺受表面反应所控制。 研究认为, 反应器中CVI-TaC过程受表面反应控制的最大气体流速为40cm/s,最小滞留时间为1.2s。

表1 CVI-TaC工艺参数设计

Table 1 Designed process parameters for CVI-TaC

图2 炭纤维表面涂层的X射线衍射谱

Fig.2 XRD pattern of coating on carbon fiber

图3 CVI工艺中气流速率对沉积速率的影响

Fig.3 Effect of gas velocity on deposition rate in CVI process

图4 CVI工艺中滞留时间对沉积速率的影响

Fig.4 Effect of residence time on deposition rate in CVI process

2.2 沉积温度

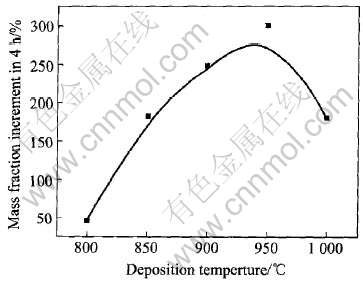

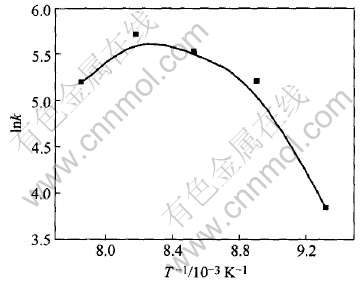

沉积温度是CVI过程中最重要的参数之一。 沉积温度对沉积速率的影响非常大, 大量研究表明, 随着沉积温度的提高, 沉积速率会逐渐增加, 低温下沉积速率随着温度升高递增的趋势较快, 而高温下沉积速率随着温度升高而递增的趋势减缓。 图5所示为沉积温度对CVI-TaC沉积速率的影响。 图6所示为沉积速率的自然对数与温度倒数的曲线。

图5 沉积温度对CVI-TaC沉积速率的影响

Fig.5 Effect of deposition temperature on deposition rate in CVI-TaC process

图6 TaC沉积速率的自然对数与温度倒数的曲线

Fig.6 Logarithm of deposition rates of TaC in carbon felt as function of reciprocal of temperature

从图5可以看出, 沉积速率随着沉积温度的升高先增加后减小, 在950℃时达到最大值。 对于动力学控制的过程而言, 在单对数坐标系中, 沉积速率与绝对温度的倒数呈直线关系。 从图6沉积速率(k)的自然对数与温度倒数之间类似抛物线的曲线关系来看, 在800~950℃的温度范围内, TaC在炭毡中的化学气相渗透反应速率与沉积温度之间的关系不符合Arrhenius方程。

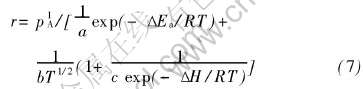

综合温度对沉积过程的影响, 可用式(7)表示温度对沉积速率的影响[15]:

式中 p0为反应剂初始分压; ΔH为过程的焓变; a、 b、 c为常数。 由此公式可以看出, 温度对表面过程的影响比较复杂, 方程式中既有动力学项[1/a·exp(-Q/RT)], 也有热力学项[1/c·exp(-ΔH/RT)]。 在单对数坐标系中, 沉积速率与绝对温度倒数之间应该是比较复杂的曲线关系, 线性关系只是一个特例。 在本研究中, 二者为抛物线关系, 说明在800~950℃的温度区间内, TaC在炭毡中的沉积过程并不是单一步骤起控制作用, 而是动力学和热力学过程共同作用的结果。

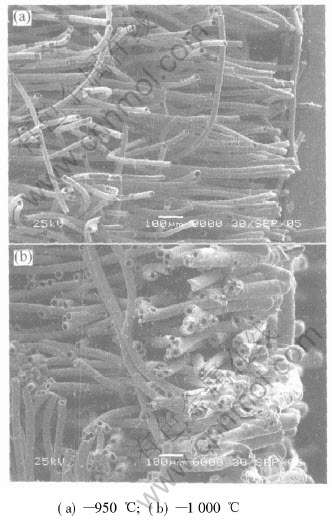

TaC在炭毡中的沉积速率在950℃时达到最大值, 在1000℃时, 沉积速率反而下降的主要原因在于渗透过程已由孔隙扩散所控制, 这可由图7来证明。 当整个工艺过程都被孔隙扩散所限制时, 大多数反应气体在到达炭毡中心孔隙前已经发生了反应, 表层孔隙迅速被TaC堵塞, 并关闭孔隙通道, 阻止反应气体进入内部孔隙沉积, 从而位于炭毡中间的孔隙得不到填充, 基体不能够获得完整的沉积。 导致样品的增重减少, 据此而计算出来的沉积速率则较小。

图7 不同温度下炭纤维毡中化学气相沉积TaC的SEM像

Fig.7 SEM images of CVI-TaC in carbon felt at different deposition temperatures

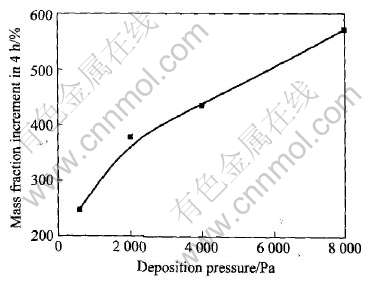

2.3 沉积压力

压力对CVI-TaC的影响比较复杂。 一般来说, 系统总压力升高, 会使化学气相渗透过程在较低的温度就会被扩散控制, 减小系统总压, 表面化学反应控制和扩散控制的过渡点将转移到更高的温度。 系统总压减小的同时也导致反应物分压减小, 沉积速率相应减小。

图8所示为沉积压力对CVI-TaC沉积速率的影响。 由图8可知, 沉积速率随着沉积压力的增加急剧增加。 这一规律是容易理解的, 由于在其它参数, 如气体流量和温度相同的情况下, 反应室中的压力是随抽气速率所控制的, 若抽气速率较快, 则反应室中的沉积压力减小; 相反, 若反应室中沉积压力增加, 则说明抽气速率较慢, 因此, 滞留在反应室中可以参加反应的物质就相应增多, 随着反应室中反应气体气压的逐渐增大, 可还原的TaCl5物质就多, 这样在其它条件确定并优化的前提下, 还原出的Ta就逐渐增多, 从而使沉积速率相应的增大。

图8 沉积压力对CVI-TaC沉积速率的影响

Fig.8 Effect of deposition pressure on deposition rate in CVI-TaC processs

2.4 氢气的加入

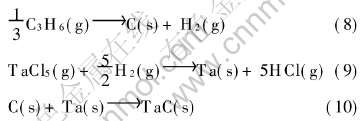

氢气的加入对炭毡中CVI-TaC的过程影响非常大, 对于CVI炉内发生的反应, 可由式(8)、 (9)和(10)来描述[2]:

式(10)是一个自发反应, TaC在炭毡内的沉积反应由式(8)和(9)制约。 根据公式(8)和(9)可知, H2对丙烯的热分解起抑制作用, 而对TaCl5还原成Ta则起促进作用。

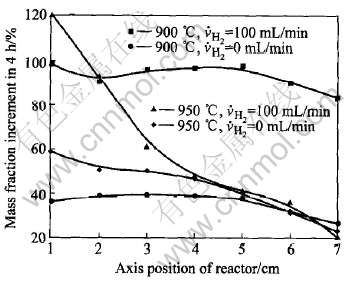

H2对化学反应渗透TaC沉积速率的影响结果如图9所示。 由图9可知, 当温度为900及950℃时, H2的加入均使沉积速率急剧增加。 这主要是随着H2的加入, 加快了反应式(8)的进行, 使得沉积速率相应提高。

图9 氢气的加入对CVI-TaC沉积速率的影响

Fig.9 Effect of addition of H2 on deposition rate of CVI-TaC

从图9还可以看出, 在900℃时, 随着H2的加入, 每个样品的沉积速率都大幅度提高, 而在950℃时, 只有在沉积位置为1、 2和3cm处的样品沉积速率才大幅度提高, 在沉积位置4~7cm时, H2对沉积速率的影响极微或没有影响。

当沉积温度为900℃时, 由于温度较低, 丙烯的裂解反应以及TaCl5的还原反应速度较慢, 由于丙烯裂解反应进行得不充分, 分解出来的H2或氢原子较少, 使TaCl5还原反应速度更慢, 过多的TaCl5蒸气没来得及还原就离开了反应室, 使得沉积速率普遍较小。 额外H2的加入能够补偿丙烯裂解不充分所带来损失, TaCl5能够充分的被还原从而更好地在炭毡上发生沉积, 故样品质量增加较为明显。

950℃时, 丙烯的裂解反应速度加快, 其分解出来的H2或氢原子可充分满足TaCl5还原反应的要求, TaCl5的还原及其它表面化学过程能充分的进行, H2作为反应气体加入, 更加促进了TaCl5的还原, 使TaCl5在刚进入反应器就被剧烈的消耗, TaCl5浓度沿反应器位置急速下降。 在沿反应器位置4cm处, 由于TaCl5浓度急剧下降, 过量H2的加入对沉积的影响不大。

3 结论

1) CVI-TaC受表面反应控制的最大气体流速为40cm/s, 最小滞留时间为1.2s。

2) 沉积速率与沉积温度之间的关系不符合Arrhenius方程, 沉积速率随沉积温度的升高先增加后减小, 在950℃时达到最大值; 在1000℃时,CVI过程受孔隙扩散所控制。

3) 沉积速率随沉积压力的升高以及H2的加入急剧增加。

REFERENCES

[1]马福康, 邱向东, 贾厚生, 等. 铌与钽[M]. 长沙: 中南工业大学出版社, 1997: 19.

MA Fu-kang, QIU Xiang-dong, JIA Hou-sheng, et al. Niobium and Tantalum[M]. Changsha:Central South University Press, 1997: 19.

[2]李国栋, 熊翔, 黄伯云. 温度对CVD-TaC涂层组成、 形貌与结构的影响[J]. 中国有色金属学报, 2005, 15(4): 565-571.

LI Guo-dong, XIONG Xiang, HUANG Bai-yun. Effect of temperature on composition, surface morphology and microstructure of CVD-TaC coating[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(4): 565-571.

[3]闫志巧, 熊翔, 肖鹏, 等. 液相浸渍C/C复合材料反应生成TaC的形貌及其形成机制[J]. 无机材料学报, 2005, 20(5): 1195-1200.

YAN Zhi-qiao, XIONG Xiang, XIAO Peng, et al. Morphology and formation mechanism of TaC made by liquid phase infiltration method in C/C composites[J]. Journal of Inorganic Materials, 2005, 20(5): 1195-1200.

[4]崔红, 苏君明, 李瑞珍, 等. 添加难熔金属碳化物提高C/C复合材料抗烧蚀性能的研究[J]. 西北工业大学学报, 2000, 18(4): 669-673.

CUI Hong, SU Jun-ming, LI Rui-zhen, et al. On improving anti-ablation property of multi-matrix C/C with refractory metal carbide[J]. Journal of Northwestern Polytechnical University, 2000, 18(4): 669-673.

[5]何捍卫, 周科朝, 熊翔. C/C复合材料抗烧蚀TaC涂层的制备[J]. 稀有金属材料与工程, 2004, 33(5): 490-493.

HE Han-wei, ZHOU Ke-chao, XIONG Xiang. Preparation of anti-ablation TaC coating on C/C composite material[J]. Rare Metal Materials and Engineering, 2004, 33(5): 490-493.

[6]Sinani I L, Chuzhko R K,Chernikov Y P. Growth kinetics of tantalum carbide layers produced on graphite by pyrolysis of TaCl5[J]. Inorganic Materials, 1998, 34(4): 342-344.

[7]Sinani I L, Chuzhko R K,Chernikov Y P. Kinetics of the growth of tantalum carbide layers on graphite substrates upon pyrolysis of tantalum pentachloride [J]. Neorg Mater, 1995, 31(5): 663-667.

[8]Chuzhko R K, Repnikov N N, Sinani I L. Diffusion-limited step of tantalum carbide growth on graphite[J]. Zh Fiz Khim, 1993, 67(5): 1024-1027.

[9]Veligdan J, Branch D. Deposition and modification of tantalum carbide coatings on graphite by laser interactions[A]. Materials Research Society Symposium[C]. Pittsburgy PA: Materials Research Society, 1993: 575-580.

[10]Sayir A. Carbon fiber reinforced hafnium carbide composite[J]. Journal of Materials Science, 2004, 39: 5995-6003.

[11]Kim C, Grummon D S, Gottstein G. Processing and interface characteristics of graphite fiber reinforced tantalum carbide matrix composites[J]. Scripta Metallurgica et Materialia, 1991, 25(10): 2351-2356.

[12]Courtright E L, Prater J T, Holcomb G R, et al. Oxidation of hafnium carbide and hafnium carbide with additions of tantalum and praseodymium[J]. Oxidation of Metals (Historical Archive), 1991, 36(5-6): 423-437.

[13]Patterson M C L, He S, Fehrenbacher L L, et al. Advanced HfC-TaC oxidation resistant composite rocket thruster[J]. Materials and Manufacturing Processes, 1996, 11(3): 367-379.

[14]程基伟, 罗瑞盈, 王天民. 炭/炭复合材料高温抗氧化研究的现状[J]. 炭素技术, 2001(5): 28-33.

CHENG Ji-wei, LUO Rui-ying, WANG Tian-min. Review of the study on the high temperature oxidation resistance of C/C composites[J]. Carbon Techniques, 2001(5): 28-33.

[15]孟广耀. 化学气相淀积与无机新材料[M]. 北京: 科学出版社, 1984.

MENG Guang-yao. Chemical Vopor Deposition and New Inorganic Materials[M]. Bejing: Science Press, 1984.

(编辑李艳红)

基金项目: 国家重点基础研究发展规划资助项目( 2006CB600908)

收稿日期: 2006-03-21; 修订日期: 2006-07-19

通讯作者: 陈招科; 电话: 0731-8836864; E-mail: pallettechen@163.com