文章编号:1004-0609(2012)10-2970-07

从冶金级硅中加压去除杂质铝的动力学

于站良1, 2,谢克强2,郑叶芳3,陈家辉1, 2,马文会2,谢 刚1

(1. 昆明冶金研究院 冶金研究所,昆明 6500931;

2. 昆明理工大学 真空冶金国家工程实验室,昆明 650093;

3. 湖南武冈市第二中学,武冈 422400)

摘 要:研究加压浸出过程中盐酸溶液提纯冶金级硅过程的动力学特征以及去除杂质Al时颗粒粒度、反应温度、总压强、盐酸初始浓度等因素对动力学的影响。结果表明:反应过程符合核收缩模型的固态产物层扩散方程;反应过程中,表观反应活化能为34.067 kJ/mol,表观反应级数为0.346。硅粉粒度、温度、压强和盐酸浓度共同对Al去除率的影响的动力学数学模型经过不同条件下实验结果与计算结果进行对比验证,使用该模型计算所得结果与实验结果吻合较好。

关键词:冶金级硅;高压浸出;动力学;杂质;Al去除

中图分类号:TQ177 文献标志码:A

Kinetics of aluminum removal from

metallurgical grade silicon with pressure leaching

YU Zhan-liang1, 2, XIE Ke-qiang2, ZHENG Ye-fang3, CHEN Jia-hui1, 2, MA Wen-hui2, XIE Gang1

(1. Department of Metallurgy Research, Kunming Metallurgy Research Institute, Kunming 650031, China;

2. National Engineering Laboratory for Vacuum Metallurgy, Kunming University of Science and Technology,

Kunming 650093, China;

3. The Second Middle School of Wugang City, Wugang 422400, China)

Abstract: The kinetics of pressure leaching of purification of metallurgical grade silicon with hydrochloric acid was investigated. The effects of particle size, temperature, total pressure and acid concentration on the kinetics and mechanism of aluminum removal were studied. The results show that the reaction kinetic model follows the shrinking core model and the apparent activation energy (Ea) of the leaching reaction is 34.067 kJ/mol, and the apparent reaction order of aluminum removal with pressure leaching is 0.346. The kinetic equations for the effect of particle size, temperature, total pressure and acid concentration are obtained and a mathematical model of aluminum removal rate from metallurgical grade Si (MG-Si) is developed. The equation estimates the aluminum removal with very good agreement between experimental and calculated values.

Key words: metallurgical grade silicon; pressure leaching; kinetics; purity; aluminum removal

基金项目:国家自然科学基金资助项目(NSFC(51064014))

收稿日期:2011-09-16;修订日期:2012-03-29

通信作者:于站良,工程师,博士;电话:0871-5154344;传真:0871-5154344;E-mail: yzl3313@163.com

太阳能由于具备了其他常规能源所不具备的优点,如绝对的安全性、充分的清洁性、资源的充足性和相对广泛性等,使其得到了社会各界的广泛关注,并处于快速的发展中。受当前国际金融危机的扩散和蔓延,常规能源日益枯竭,世界各国均把大力发展新能源和可再生能源作为重振经济的重要途径。为对抗经济不景气,还要兼顾未来发展,近期世界各发达国家纷纷推出了以节能减碳为主轴的环保新能源产业方针,为太阳能产业发展带来了更多新机遇[1]。传统的西门子法及硅烷热分解法等多晶硅生产工艺存在价格昂贵、环境压力大等不足,且西门子法和硅烷法的关键技术目前还处在国外几家大型企业的掌控之中,他们对多晶硅的市场形成了垄断经营。因此,有必要寻找一条不依赖于现有多晶硅工艺的低成本低能耗的工艺。近年来,低成本、低能耗的太阳能级硅制备新技术新工艺有很多报道,其中,冶金法制备太阳能级硅技术已成为国内外研究的热点[2-4]。

在冶金法制备太阳能级硅的工艺中,一般采用两个步骤进行生产。第一步最好在冶金级硅工业上进行,冶金级硅被经过预处理后得到所谓的超冶金级硅(Upgrade metallurgical grade silicon, UMG-Si)[5-6]。目前,预处理的方法主要采用湿法浸出的方式去除冶金级硅中大部分的金属杂质。第二步为超冶金级硅进一步提纯至太阳能硅。

SANTOS等[7]从硅中杂质分布特性入手,讨论了硅粉粒度、时间、温度、浸出液浓度等因素对杂质浸出效果的影响。采用盐酸能够去除85%的杂质,而最后采用氢氟酸能够得到纯度为99.9%的硅粉。

MARGARIDO等[8-9]就Fe-Si合金酸浸精炼过程的动力学机理做了分析,研究指出,酸浸过程遵循裂化收缩模型,即合金颗粒(半径R)外部受到液体酸的浸蚀引起裂缝,裂缝发生在边沿并深入颗粒内部直至使颗粒发生破裂,使原来较大的颗粒分解成为许多微粒(半径r远小于R),微粒与酸进行反应,过程受化学反应控制。

MA等[10]和XIE等[11]比较了超声波场作用和普通机械搅拌作用下冶金级硅粉分别经过各种酸溶液处理后,主要金属杂含量变化情况。实验结果表明,超声波场作用能够大大提高主要金属杂质的去除率。

目前,国内外有关湿法提纯冶金级硅的报道很多,但是采用加压湿法冶金技术提纯冶金级硅的研究报道不多,而针对动力学方面的研究也很少。本文作者就加压湿法冶金技术提纯冶金级硅方面做了大量的前期工作[12-13]。在此,根据核收缩模型分析高压浸出过程杂质Al去除的动力学特征,分别获得颗粒粒度、反应温度、反应总压强、盐酸浓度等影响因素的拟合动力学方程;同时还发展冶金级硅中杂质Al去除的总动力学模型,并且为杂质Al的去除提供了最佳的参数。

1 动力学分析

本实验的动力学研究是在满足下列条件的情况下进行的:

1) 液体反应物或气体反应物的浓度在反应过程中保持恒定。本实验中采用大液固比(1 L浸出液中加入50 g冶金级硅粉),而冶金级硅粉中所含杂质的量为10-6级。反应消耗了的反应物可以忽略不计,反应液的浓度可以近似地认为是恒定的。此外,实验过程中氧分压恒定,即保持气体反应物浓度恒定;

2) 反应的固体是单粒级的颗粒。实验过程分别选取100~150 μm及75~100 μm的致密颗粒硅粉进行;

3) 反应过程中温度与搅拌速度保持恒定。

本文作者通过拟合杂质Al去除率与时间的关系,得到了反应过程符合固态产物层扩散控制的速度方程[12-13]:

(1)

(1)

式中:t为时间;x为杂质Al的去除率;cA0为盐酸溶液的初始浓度;a、b为化学计量系数;ρB为硅粉颗粒的密度;r 0为硅粉颗粒的尺寸;Ds为有效扩散系数。 令

(2)

(2)

式中:kd为相关反应系数。

因此,方程(1)可以转换为

(3)

(3)

令 后,方程(3)变为

后,方程(3)变为

(4)

(4)

因此,从方程(4)可知,在化学反应控制下,y与t呈线性关系。直线的斜率k与 成正比。

成正比。

2 实验

2.1 材料

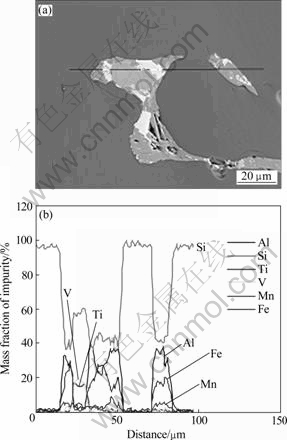

冶金级硅中金属杂质的分布情况和形貌如如图1(SEM/EDS线扫描图)所示。当测试线进入浅色部位时,冶金级硅的EDS分析结果出现了很明显的变化,硅的含量迅速下降,而其他杂质含量相继上升,随着颜色的不同,各杂质含量有着明显的不同。当测试线离开浅色部位回到深色部位的硅基体时,硅的含量又重新上升到100%附近。通过此线扫描分析进一步得知,杂质在硅中不仅发生了偏析,同时也在杂质内部发生了偏析。其主要原因是金属元素如Fe、Al、Mg、Sb、Sn、Zn、Cu、Au、Ni、Ti等在Si中拥有很高的分凝系数[2]。在熔体硅中,这些元素能够很好地溶解在其中,而在固体硅中,其溶解能力却非常弱,因此,在熔体硅的凝固过程中,大部分溶解能力弱的杂质将在固体硅中的晶体界面或裂缝处沉积下来。当冶金级硅被粉碎以后,大多数的晶体界面被暴露出来。如果冶金级硅块被粉碎到多晶硅晶粒相同大小的尺寸时,大部分出现在晶粒表面的金属杂质被暴露在外面,在酸浸除杂的过程中效果会提高很多。

图1 冶金级硅杂质的SEM像和EDS线分析

Fig.1 SEM image and EDS line analysis of impurity distribution of MG-Si

实验所用原料(冶金级硅)的杂质元素含量ICP-AES分析情况如表1所列。主要金属杂质为Fe (0.218 7%),Al(0.112%)、Ca(0.032%)、Ti(0.02%)。其他杂质的含量水平均比较低,诸如B、C、P等非金属杂质。由于这些非金属元素不能与酸溶液发生反应,因此,不能直接采用湿法冶金去除,而是采用其他的方法。

表1 实验所用的冶金级硅主要杂质含量

Table 1 Chemical composition in MG-Si (mass fraction, %)

2.2 样品准备与浸出实验

冶金级硅经过粉碎、筛分后得到不同粒级硅粉。称取50 g硅粉于2 L的锆材高压釜中,按照一定比例加入一定浓度的盐酸溶液,控制反应温度与反应压强进行反应。通过采用分光光度计分析液体中杂质Al的含量,并采用ICP-AES分析固体中Al的残余量。杂质Al的去除率按照方程(5)进行计算。

(5)

(5)

式中:x为杂质Al的去除率;m0为原料硅中杂质Al的含量;m1为反应后硅中杂质Al含量。

3 结果与讨论

3.1 硅粉粒度对杂质Al去除率影响

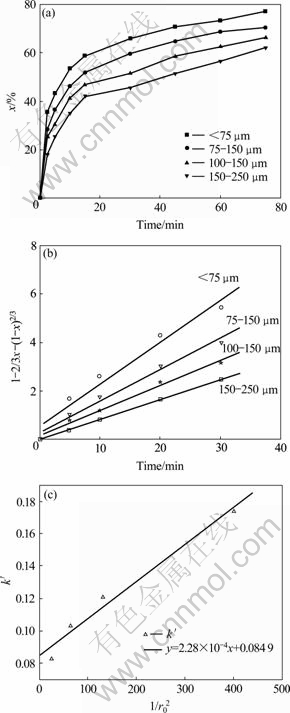

一般说来,杂质Al的去除率随着颗粒尺寸的减少而增加并存在一定的线性关系。在盐酸浓度为1.0 mol/L、反应温度120 ℃、搅拌速度为600 r/min、反应压强为1.60 MPa等条件下,进行不同粒度对冶金级硅粉中杂质Al去除率x的影响实验,其变化规律如图2(a)所示。图2(a)表明,硅粉粒度对Al去除率的影响是显著的,在粒度小于75 μm时,Al的去除率可明显提高。

将图2(a)的结果按式(4)进行拟合,得到图2(b)。由图2(b)得知,y与时间t具有良好的线性关系。将图2(b)中各直线斜率对粒度平方的倒数作图,将图2(b)中各直线斜率对粒度平方的倒数作图,得到k′与1/r02的关系图2(c)。从图2(c) 即可得到硅粉粒度对Al去除率影响的动力学方程为

(6)

(6)

图2 硅粉粒度对杂质Al去除率影响的动力学

Fig.2 Kinetics of effect of particles sizes on Al removal rate

3.2 温度对杂质Al去除率的影响

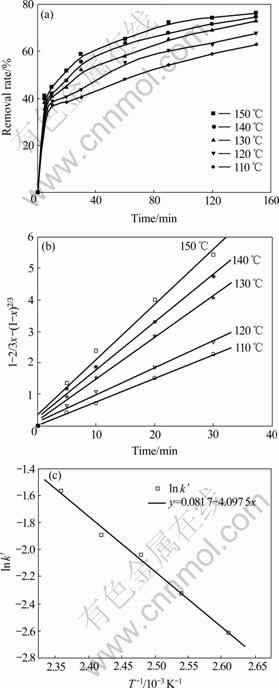

取50 g粒度为0.096~0.150 mm冶金级硅粉,盐酸浓度为1.0 mol/L、搅拌速度为600 r/min、反应压强为1.50 MPa。在该条件下,测定冶金级硅粉在不同温度下的杂质Al的去除率x随反应时间t的实验数据及变化规律,其结果如图3(a)所示。将图3(a)结果用式(4)进行拟合,结果如图3(b)所示。图3(a)和(b)表明:温度对冶金级硅中杂质Al的浸出速率的影响较大。

式(1)中当c与温度保持恒定时, 为常数,可称为表观速率常数,其值等于图3(b)各直线的斜率。以不同温度下反应k′的对数对温度的倒数作图,得到Arrhenius线如图3(c)所示。

为常数,可称为表观速率常数,其值等于图3(b)各直线的斜率。以不同温度下反应k′的对数对温度的倒数作图,得到Arrhenius线如图3(c)所示。

图3 反应温度对杂质Al去除率影响的动力学

Fig.3 Kinetics of effect of reaction temperature on Al removal rate

由图3(c)中的直线斜率可求出浸出反应表观活化能Ea=34.067 kJ/mol。从图3(c)结果即可建立温度对Al去除率影响的动力学方程如下:

(7)

(7)

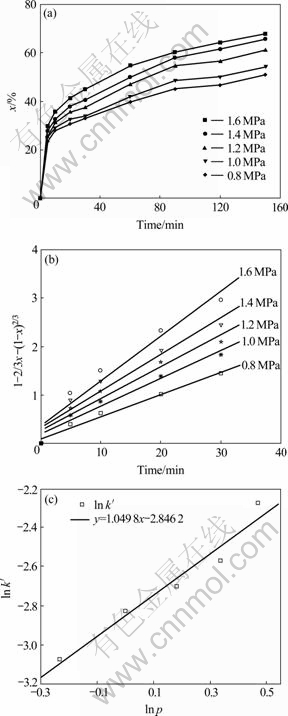

3.3 压强对杂质Al去除率的影响

取50 g粒度为0.096~0.150 mm冶金级硅粉,在盐酸浓度为1.0 mol/L、搅拌速度为600 r/min、反应温度为120 ℃的条件下,测定冶金级硅粉在不同压强p下杂质Al的去除率x随反应时间t的实验数据及其变化规律如图4(a)所示。

图4(a)结果表明,反应压强对Al去除率的影响比较显著。随着压强的升高,Al去除达到平衡所需时间缩短,Al的去除率加快。压力的大小对反应温度的提高有比较大的影响。随着压力的不断增加,反应温度也在不断升高。升高温度有助于加快反应。

图4 总压强对杂质Al去除率影响的动力学

Fig.4 Kinetic of effect of total pressure on Al removal rate

由图4(a)直线斜率取对数对压力取对数作图得到图4(b)。对图4(b)曲线进行回归,即可得到压力对Al浸出率影响的动力学方程为

(8)

(8)

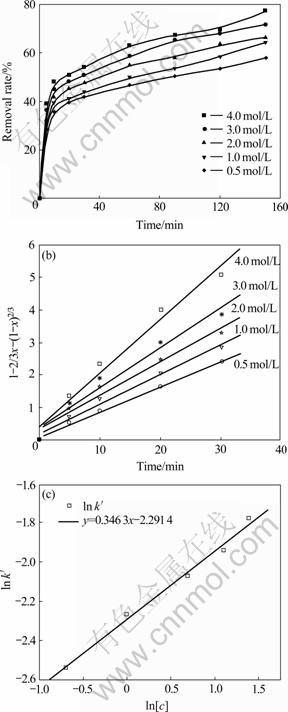

3.4 盐酸浓度对杂质Al浸出率的影响

取50 g粒度为0.096~0.150 mm冶金级硅粉,在反应温度120 ℃、搅拌速度为600 r/min、反应压强为1.60 MPa的条件下,测定冶金级硅粉在不同盐酸浓度初始浓度下的杂质Al的去除率x随反应时间t的变化规律如图5(a)所示。

图5 盐酸初始浓度对杂质Al去除率影响的动力学

Fig.5 Kinetic of effect of initial concentration of hydrochloric acid on Al removal rate

结果表明:在实验采用的酸度条件下,随着盐酸浓度的增加,Al的去除率逐步升高。以式(1)的形式拟合图5(a)的结果,得到y与酸浓度关系图,如图5(b)所示。用图5(b)中各直线的斜率取对数对酸浓度取对数作图,得到图5(c)。图5(c)表明,ln[HCl]与lnk′的关系为一直线,由直线斜率可求得反应的表观级数为0.346。由图5(c)得到盐酸浓度对Al浸出率影响的动力学方程为

(9)

(9)

3.5 杂质Al去除动力学方程的建立

上述相关实验表明,式(7)、(8)、(9)以线性关系存在。根据文献[12]得知,按照方程 ,(x1=1/x),可以将变量拟合成为一种总的线性方程。这个线性方程通过最后的回归分析可以获得基本的线性关系。通过SPSS统计软件对所有变量进行联合回归,得到方程为

,(x1=1/x),可以将变量拟合成为一种总的线性方程。这个线性方程通过最后的回归分析可以获得基本的线性关系。通过SPSS统计软件对所有变量进行联合回归,得到方程为

(10)

(10)

式中:T为温度,K;p为总压力,MPa;c为盐酸浓度,mol/L。

根据方程(3)和方程(10),得到各影响因素共同对杂质Al去除率影响的数学模型为

(11)

(11)

式中:r0为硅粉初始半径,mm;t为浸出时间,min。

根据式(10)计算不同条件下的Al的去除率,并将实验结果作为横坐标,以计算结果为纵坐标作图,并与y=x进行比较,考察实验结果与计算结果的吻合情况,所得结果如图6所示。由图6可见,用该模型计算所得结果与实验结果吻合较好。

图6 验证实验结果

Fig.6 Result of validation experiment

4 结论

1) 硅粉粒度的减小有利于杂质Al去除率的提高,浸出速率与硅粉的初始半径r02成反比关系。建立了硅粉粒度对Al去除率的动力学方程:

;

;

2) 反应温度升高有助于杂质Al的去除,随着反应温度升高,Al浸出达到平衡时间缩短。温度对Al去除率影响的动力学方程如下:

;Al去除的表观反应活化能为:Ea = 34.067 kJ/mol;

;Al去除的表观反应活化能为:Ea = 34.067 kJ/mol;

3) 压强提高有助于Al的去除。随着压强的升高,Al去除达到平衡所需时间缩短, Al的去除率加快。反应总压强对Al去除率影响的动力学方程: ;

;

4) 在盐酸浓度为0.5~4 mol/L范围内,Al去除率随酸度的增加而增加。盐酸浓度对Al去除率影响的动力学方程: ;Al去除的表观反应级数为0.346。

;Al去除的表观反应级数为0.346。

5) 建立了硅粉粒度、温度、压强和盐酸浓度共同对Al去除率影响的动力学数学模型:

。

。

经过不同条件下实验结果与计算结果进行对比验证,用该模型计算所得结果与实验结果吻合甚好。

REFERENCES

[1] 鲁 瑾. 金融危机下我国多晶硅行业面临的机遇与挑战[J]. 新材料产业, 2009, 5: 7-11.

LU Jing. The opportunities and challenges facing China’ polysilicon industry on the financial crisis[J]. Advanced Materials Industry, 2009, 5: 7-11.

[2] MORITA K, MIKI T. Thermodynamics of solar grade silicon refining[J]. Intermetallics11, 2003, 11: 1111-1117.

[3] WODITSCHA P, KOCH W. Solar grade silicon feedstock supply for PV industry[J]. Solar Energy Materials & Solar Cells, 2002, 72(1): 11-26.

[4] PIRES J C S, BRAGA A F B, MEI P R. The purification of metallurgical grade silicon by electron beam melting[J]. Journal of Materials Processing Technology, 2005, 169(1): 16-20.

[5] 马晓东. 冶金法去除工业硅中杂质的研究[D]. 大连: 大连理工大学, 2009.

MA Xiao-dong. Research on removal of impurities in metallurgical grade silicon by metallurgical method[D]. Dalian: Dalian University of Technology, 2009.

[6] SARTI D, EINHAUS R. Silicon feedstock for the multicrytalline photovoltaic industry[J]. Solar Energy Materials and Solar Cells, 2002, 72: 27-40.

[7] SANTOS I C, GONCALVES A P, SANTOS C S, ALMEIDA M, AFONSO M H, CRUZ M J. Purification of metallurgical grade silicon by acid leaching[J]. Hydrometallurgy, 1990, 23: 237-246.

[8] MARGARIDO F, FIGUEIREDO M O, MARTINS J P. The structural effect on the kinetics of acid leaching refining of Fe-Si alloys[J]. Materials Chemistry and Physics, 1994, 38: 342-347.

[9] MARGARIDO F, MARTINS J P, FIGUEIREDO M O, BASTOS M H. Kinetics of acid leaching refining of an industrial Fe-Si alloy[J]. Hydrometallurgy, 1993, 34(1): 1-11, 58, 59

[10] 马晓东, 张 剑, 吴亚萍, 李廷举. 超声场湿法提纯冶金级硅的研究[J]. 功能材料, 2008, 39(7): 1071-1073.

MA Xiao-dong, ZHANG Jian, WU Ya-ping, LI Ting-ju. Research on hydrometallurgical purification of metallurgical grade silicon under ultrasonic field[J]. Journal of Functional Materials, 2008, 39(7): 1071-1073.

[11] MA X D, ZHANG J, WANG T M, LI T J. Hydrometallurgical purification of metallurgical grade silicon[J]. Rare Metals, 2009, 28(3): 221-225.

[12] XIE K Q, YU Z L, MA W H, ZHOU Y, DAI Y N. Removal of iron from metallurgical grade silicon with pressure leaching[J]. Material Science Forum, 2011, 675/677: 873-876.

[13] YU Z L, XIE K Q, MA W H, YANG Z, GANG X, DAI Y N. Kinetics of iron removal from metallurgical grade silicon with pressure leaching[J]. Rare Metals, 2011, 30(6): 688-694.

[14] SOHN H Y, WADSWORTH M E. Rate process of extractive metallurgy[M]. New York: Plenum Press, 1979.

[15] ABDEL-AAL E A, RASHAD M M. Kinetic study on the leaching of spent nickel oxide catalyst with sulfuric acid[J]. Hydrometallurgy, 2004, 74: 189-195.

[16] XUE W. SPSS统计软件分析方法与应用[M]. 北京: 电子工业出版社, 2004: 233-235.

XUE W. SPSS statistical analytical method and application[M]. Beijing: Electronics Industry, 2004: 233-235.

(编辑 李艳红)