Trans. Nonferrous Met. Soc. China 22(2012) 1613-1619

Effect of heat treatment on tensile deformation behavior of Ni-Co film/Fe substrate systems

ZHANG Min-jie1,2, PAN Yong1,2, ZHOU Zhao-feng1,2, LI Wei1,2, HUI Jian-ke1,2, LEI Wei-xin1,2

1. Faculty of Materials and Optoelectronics Physic, Xiangtan University, Xiangtan 411105, China;

2. Key Laboratory of Low Dimensional Materials and Application Technology of Ministry of Education,

Xiangtan University, Xiangtan 411105, China

Received 18 July 2011; accepted 23 February 2012

Abstract: The effects of heat treatment on microstructure and tension property of Ni-Co film/Fe substrate systems were investigated. The deformation and fracture morphologies of Ni-Co films/Fe substrate systems were studied by in-situ scanning electron microscopy (in-situ SEM) before and after heat treatment. The results show that a Ni-Co/Fe diffusion layer appears between the film and substrate after heat treatment; the elongation of film/substrate system increases with increasing the heat treatment temperature. Both the strength and ductility of the film/substrate system are preferable when heat treatment temperature is 650 oC, meanwhile the maximum elongation is up to 46%. During tensile deformation, the deformation behaviors of Ni-Co film/Fe substrate are quite different before and after heat treatment. The samples after heat treatment went through the progress of holes’ emergence, growth and extension, whereas the samples without heat treatment accompanied with no holes, just cracked instead, showing that appropriate heat treatment is helpful to improve the toughness of material, and mechanical properties.

Key words: heat treatment; Ni-Co alloy; tensile deformation; fracture

1 Introduction

With the development of metal film preparation technology, the pulse electro-deposition, as a simple, highly active and low cost deposition method, had been used to deposit nano-crystalline films [1-3]. With respect to the deposition of nano-crystalline film, the pulse electro-deposition had been extensively used to improve the hardness, wear and corrosion resistance of electroplated metal films [3,4].

However, the final properties of metal film/substrate system depend not only on the electro-deposition process [5,6] but also on machining deformation process. The surface cracks emergence, the adhesive strength between film and substrate during and after machining deformation process significantly affect the appearance and usability of metal material [7,8]. It was reported that heat treatment was widely used on 304 stainless steel [9], aluminum alloy [10,11] and nickel films [12,13] in order to improve their machining properties for eliminating alloy imbalance phase and over saturation [14] as well as reducing surface cracks, and enhancing adhesion strength of film to substrate [15,16]. However, previous experiments of heat treatment put more emphasis on the properties of magnetic performance [14,17] and hot deformation behavior [18-20] instead of mechanical property of the film/substrate systems. Due to the fact that heat treatment may have prominent influence on the final mechanical property of the film/substrate systems, investigation of mechanism of the film/substrate system is intensively necessary.

In the present work, a well-defined Ni-Co film/Fe substrate system is used to investigate the effect of heat treatment temperatures on the microstructure and tensile property of Ni-Co film/Fe substrate by in-situ tensile experiments. Tension deformation behavior of the Ni-Co film/substrate system is studied.

2 Experimental

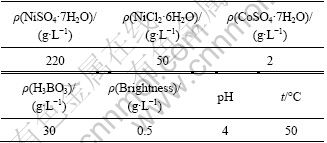

Ni-Co films were prepared by pulse electro-deposition. The main electrolyte compositions and experimental conditions are listed in Table 1 where all chemicals were of analytic grade. Then the samples were annealed for 3 h at the temperature of 550, 600, 650, 700 and 750 ℃ in nitrogen protective atmosphere with a purity of 99.9%. Then the samples were cooled down in the protect atmosphere until room temperature. The thickness of the Ni-Co film was 4 μm and the Fe substrate was 300 μm.

Table 1 Compositions of electrolyte solution and plating conditions

Dog-bone-shaped tensile specimens were obtained by wire-electrode cutting to have a gauge section of 5 mm×2 mm. The tensile tests were performed at room temperature by an EHF-J micro-tensile test system with a strain speed of 0.5×10-2 mm/s. The deformation and fracture morphologies of Ni-Co film/Fe substrate systems were observed by in-situ SEM connecting to tensile system. The chemical composition was studied by the energy dispersive spectrometry (EDS, QUANTA 200). The Rigaku D/MAX-2500 X-ray diffusion detector (XRD) was used to calculate the average grain sizes and the texture density of the samples.

3 Results and discussion

3.1 Microstructure

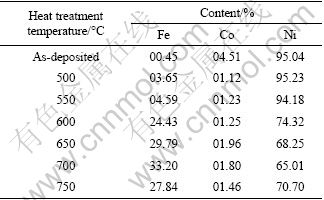

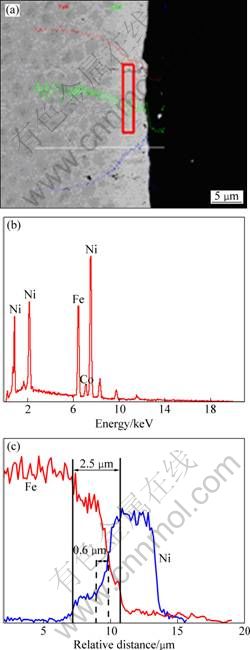

Table 2 shows the chemical element contents at different heat treatment temperatures, and the selected area is marked with the square frame in Fig. 1(a). It is obvious that with the increase of heat treatment temperature, the content of iron element increased correspondingly. This shows that the heat treatment promotes the movement activity of element. The higher temperature has greater effect on the element diffusion. The EDS of the selected area at 650 ℃ is shown in Fig. 1(b). It is clearly seen that the content of iron is much more than cobalt in the selected area which includes nickel, cobalt and iron. Figure 1(c) shows a fitting graph obtained from EDS data of line-scanning the section from substrate to film. The cobalt was omitted for its very low content. The section pattern of the Ni-Co film/Fe substrate system in Fig. 1(c) shows three parts, Ni-Co film, Ni-Co/Fe diffusion layer and Fe substrate, and the thickness of Ni-Co/Fe diffusion layer is 2.5 μm. Diffusion interface moved some distance of about 0.6 μm to Ni-Co film side because the elements in the film and substrate diffuse to each other during heat treatment, and the interface moves towards the Ni-Co film with a higher diffusion rate, which matches well with the Kirkendall effect [21].

Table 2 Element contents of selected area at different heat treatment temperatures

Fig. 1 SEM image showing section pattern of Ni-Co film/Fe substrate system at 650 ℃ (square frame is selected area) (a), EDS of selected area at 650 ℃ (b) and schematic of interface element distribution at 650 ℃ (c)

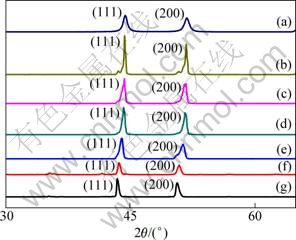

Texture directions of Ni-Co film at different heat treatment temperatures are examined by XRD. The obtained patterns are shown in Fig. 2. It is found that the structures of the Ni-Co films exhibit a preference of the (111) and (200) orientations. With increasing the heat treatment temperatures, the batches show that the preferential orientations are still along the (111) and (200) directions but with different intensities. No additional peaks could be detected, which indicates that no second phase is present. But the diffraction peaks shift left gradually with increasing the heat treatment temperature, indicating the formation of new solid solutions. Calculation using full-width half maximum in conjunction with the Scherrer formula shows that the grain size of Ni-Co film increases correspondingly with increasing the heat treatment temperatures.

Fig. 2 XRD patterns of samples with different heat treatment temperatures: (a) As-deposited; (b) 500 ℃; (c) 550 ℃; (d) 600 ℃; (e) 650 ℃; (f) 700 ℃; (g) 750 ℃

3.2 Mechanical behavior

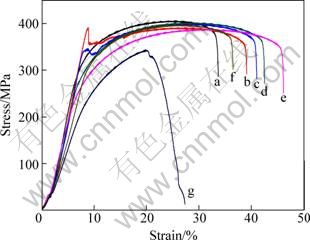

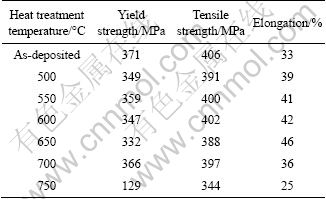

The stress—strain relationships of Ni-Co film/Fe substrate system at different heat treatment temperatures are shown in Fig. 3. Table 3 summarizes the results obtained from the tensile tests, from which it can be seen that the maximum values of both the yield strength and ultimate tensile strength are ~371 MPa and ~406 MPa, respectively. The heat treatment temperature has a significant influence on elongation of the samples. With increasing the heat treatment temperature the elongation increases firstly, and then decreases when the temperature exceeds 650 ℃. A maximum elongation of 46% was obtained at 650 ℃. Because higher temperature leads to some alloying element mutual dissolution, companying with changing structures and properties. Therefore, the temperature of heat treatment should be controlled in a certain value, not the more the better. From tensile curve we found that when heat treatment temperature is 750 ℃, the stress—strain curve changes inconformity with the standard tensile stress—strain curve of low carbon steel. According to the phase diagram we find that a extremely high heat treatment temperature leads to phase structure changed, which usually induces the grains size to increase greater, and performance of the Ni-Co film/Fe substrate system in strength and the plasticity is reduced. Due to the increment of roughness the grain boundary with increasing of grains size, a fracture may occur along the rough grain boundary, the plastic property of the Ni-Co film/Fe substrate system decreases obviously, while the ductility value begins to present abnormal with further decreasing plastic when the heat treatment temperature is above 750 ℃.

Fig.3 Stress—strain curves of Ni-Co film/Fe substrate system at different heat treatment temperatures: (a) As-deposited; (b) 500 ℃; (c) 550 ℃; (d) 600 ℃; (e) 650 ℃; (f) 700 ℃; (g) 750 ℃

Table 3 Mechanical properties of Ni-Co film/Fe substrate system at different heat treatment temperatures

3.3 Deformation behavior

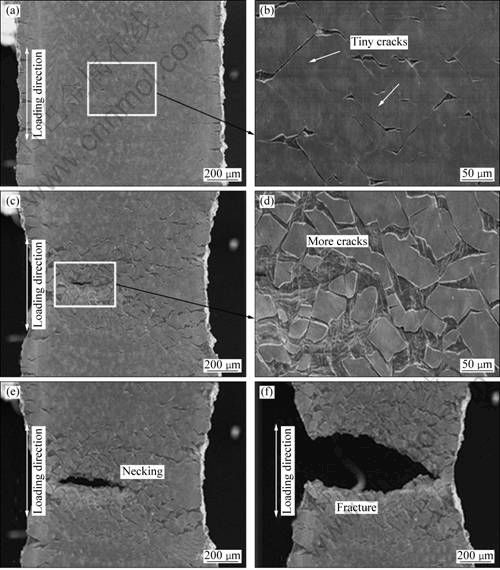

In order to research the deformation behaviors of the Ni-Co film/Fe substrate system before and after heat treatment, a continuous deformation and fracture processes were monitored by using in-situ SEM. Figure 4 shows the changed surface morphologies of as-deposited Ni-Co film/Fe substrate system without heat treatment. Figure 4(a) expresses the surface morphology at a strain of 0.10. Tiny cracks occurred along grain boundaries at a strain between 0.07 and 0.10. Figure 4(b) shows the enlarged picture of the square frame in Fig. 4(a). Every tiny crack in Fig. 4(b) shows slender along the loading direction at the midst and becomes large and deep at the both ends. Neck occurred at a strain of 0.30, and the peak load was obtained and accompanied with significant cracks in the necked region (Figs. 4(c) and (d)). Figure 4(e) shows the sample in vertical view at the strain of 0.31, from which a significant necking-down was observed. Along the direction of grains boundary, macroscopic cracks on the deformation surface of as-deposited samples are extending with increasing the tension deformation. When stain was up to 0.33 (Fig. 4(f)), the central macroscopic cracks extended enough result in the final facture, perpendicular to the loading direction.

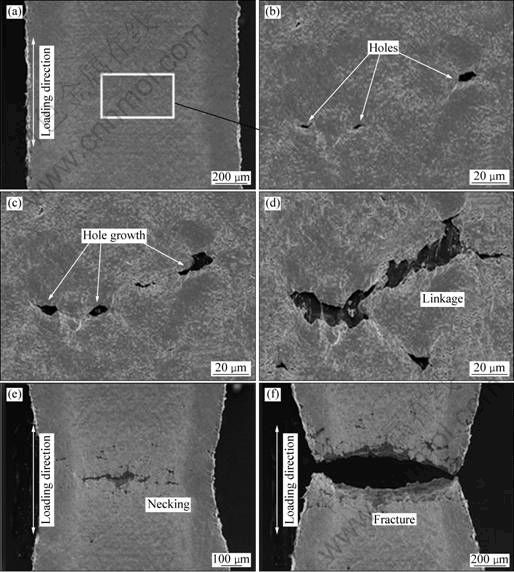

Similarly, the surface morphologies of the samples during tensile process at 650 ℃ are shown in Fig. 5, it is completely different with the as-deposited. Figure 5(a) shows the surface morphologies at a strain of 0.15. Figure 5 (b) shows a local enlarged picture of the square shape in the middle region of Fig. 5(a). Compared with as-deposited alloy, the sample after 650 ℃ heat treatment shows no cracks at a nominal strain of 0.15 whereas and just holes’ emergence instead. In Fig. 5(c), more holes form and grow up at larger strains, while in Fig. 5(d), holes are linked up one by one and form a macroscopic crack at a strain of 0.35. The crack direction is along the shear stress direction and has an angle of 45° to the loading axis. In addition, necking was observed in the vicinity of the mid-plane of the samples at a strain of 0.40 (Fig. 5(e)). At higher strains, more macroscopic cracks were observed with increasing the strain. Further growth of macroscopic cracks took place by joining the micro-holes to the main crack gap at the middle of tensile samples. Finally, facture occurred near the mid-plane perpendicular to the loading direction shown in Fig. 5(f).

Fig. 4 SEM images showing surface morphologies of as-deposited samples: (a),(b) ε=0.10; (c),(d) ε=0.30; (e) ε=0.31; (f) ε=0.33

Fig. 5 SEM images showing surface morphologies of Ni-Co film/Fe substrate system at 650 ℃: (a),(b) ε=0.15; (c) ε=0.25; (d) ε=0.35; (e) ε=0.40; (f) ε=0.45

The deformation processes of samples after heat treatment present good consistency and uniform properties compared with the as-deposited ones. With increasing tensile strains, a special deformation behavior occurs, accompanied with holes’ emergence, growth and extension process, whereas the samples without heat treatment accompany with no holes, just cracks instead. Based on the above two experimental observations, there are three possible reasons for this phenomenon to explain: 1) By electrochemical fabrication process, the samples are inevitable to introduce impurities and porosity [22]. Because of the existence of the defect, the sample’s adhesion strength between film and substrate is decreased, the cracks emerge at former flaws when samples are stretched. 2) With the help of heat treatment, the porosity decreases and the grain sizes enlarge, the grains in clusters should be deformed through dislocation activity and then provide the considerable strain hardening [23,24]. The samples have a good ability of resistance to deformation after heat treatment, which reveals the reason that no crack was found on the sample surface under the same tensional state. 3) As the alloy phases form, stress releasing and adhesion strength enhancing between film and substrate suppress early crack nucleation and propagation, the mechanical property of the Ni-Co film/Fe substrate system could be obviously improved by the heat treatment [25]. During the tensile deformation, the higher binding force between film and substrate results in synchronizing extension, the samples prefer to form holes instead of cracks under the same loading condition, which implies that the samples after heat treatment possess better plastic deformation ability.

4 Conclusions

1) The Ni-Co film/Fe substrate systems are prepared by pulse electro-deposition and heat treated at different temperatures of 500, 550, 600, 650, 700 and 750 ℃.

2) After heat treatment, a Ni-Co/Fe diffusion layer was formed apparently. The Ni-Co film/Fe substrate system exhibits (111) and (200) texture double preferred orientations before and after heat treatment. With increasing the heat treatment temperatures, diffraction peaks shif left gradually.

3) The maximum elongation of the Ni-Co film/Fe substrate system obtained at 650 ℃ is 46 %, both the yield strength and ultimate tensile strength are good at the temperature of 650 ℃.

4) After 650 ℃ heat treatment, the Ni-Co film/Fe substrate system presents a special deformation behavior. With increasing the tensile strain, the samples are accompanied with holes’ emergence, growth and extension processes, whereas those without heat treatment are accompanied with no holes, which just cracks instead.

References

[1] LAJEVARDI S A, SHAHRABI T. Effects of pulse electrodeposition parameters on the properties of Ni-TiO2 nanocomposite coatings [J]. Applied Surface Science, 2010, 256(22): 6775-6781.

[2] ADELKHANI H, GHAEMI M. Nano-structural tailoring of manganese dioxide by using pulse current electrodeposition [J]. Solid State Ionics, 2008, 179(39): 2278-2283.

[3] QU N S, ZHU D, CHAN K C, LEI W N. Pulse electrodeposition of nanocrystalline nickel using ultra narrow pulse width and high peak current density [J]. Surface and Coating Technology, 2003, 168(2-3): 123-128.

[4] ESFAHANI H A, VAEZI M R, NIKZAD B. Influence of SiC nanoparticles and saccharin on the structure and properties of electrodeposited Ni-Fe/SiC nanocomposite coatings [J]. Journal of Alloys and Compounds, 2009, 484: 540-544.

[5] SHANTHI C, BARATHAN S, JAISWAL R. The effect of pulse parameters in electro deposition of silver alloy [J]. Materials Letters, 2008, 62: 4519-4521.

[6] GYFTOU P, PAVLATOU E A, SPYRELLIS N. Effect of pulse electrodeposition parameters on the properties of Ni/nano-SiC composites [J]. Applied Surface Science, 2008, 254(18): 5910-5916.

[7] RUSSELL S G. An investigation of the fracture process zone near the tip of a steadily propagating tensile crack [J]. International Journal of Solids and Structures, 1989, 25(10): 1157-1175.

[8] SHI Y W, HAN Z X, ZHOU N N, LI J. The significance of crack depth in fracture toughness specimens for HSLA steel welds [J]. Engineering Fracture Mechanics, 1992, 41(1): 143-151.

[9] CHEN A Y, ZHANG J B. Necking propagated deformation behavior of layer-structured steel prepared by co-warm rolled surface nanocrystallized 304 stainless steel [J]. Materials Letters, 2007, 61: 5191-5193.

[10] XU T, LEE W B. Effect of heat treatment on the plastic flow behavior of an aluminum alloy under compressive loading[J]. Journal of Materials Processing Technology, 1997, 69: 90-94.

[11] MAHMUDI R. Plastic instability during tensile deformation of temper-annealed non-heat-treatable aluminium alloy sheets [J]. Journal of Materials Processing Technology, 1998, 82: 46-52.

[12] GU C D, LIAN J S. Enhanced tensile ductility in an electrodeposited nanocrystalline Ni [J]. Scripta Materialia, 2006, 54: 579-584.

[13] YANG Y, YAO N. Deformation and fracture in micro-tensile tests of freestanding electrodeposited nickel thin films [J]. Scripta Materialia, 2008, 58: 1062-1065.

[14] WANG S L. Electroless deposition of Ni-Co-B alloy films and influence of heat treatment on the structure and the magnetic performances of the film [J]. Thin Solid Films, 2007, 515: 8419-8423.

[15] CHOWDHURY S, LAUGIER M T, RAHMAN I Z. Measurement of the mechanical properties of carbon nitride thin films from the nanoindentation loading curve [J]. Diamond and Related Materials, 2004, 13: 1543-1548.

[16] LEE J M, KO D C, LEE K S, KIM B M. Identification of the bulk behavior of coatings by nano-indentation test and FE-analysis and its application to forming analysis of the coated steel sheet [J]. Journal of Materials Processing Technology, 2007, 187-188: 309-313.

[17] TIAN L L, XU J C, QIANG C W. The electrodeposition behaviors and magnetic properties of Ni-Co films [J]. Applied Surface Science, 2011, 257: 4689-4694.

[18] EBRAHIMI G R, ZAREI-HANZAKI A. The effect of heat treatment on hot deformation behavior of Al 2024 [J]. Journal of Materials Processing Technology, 2008, 206: 25-29.

[19] JANG J W, PARK I W. FE program development for predicting thermal deformation in heat treatment [J]. Journal of Material Processing Technology, 2002, 130-131: 546-550.

[20] SZCZEPANIK S, SLEBODA T. The influence of the hot deformation and heat treatment on the properties of P/M Al-Cu composites [J]. Journal of Material Processing Technology, 1996, 60: 729-733.

[21] KIRKENDALL E O. Diffusion of zinc in alpha brass. Diffusion of zinc in alpha brass [J]. Transaction of American Institute of Mining, Metallurgical, and Petroleum Engineers, 1947, 171: 130-142.

[22] WEERTMAN J R, FARKAS D. Structure and mechanical behavior of bulk nanocrystalline materials [J]. Mrs Bulletin, 1999, 24: 44-50.

[23] KUMAR K S, SURESH S, CHISHOLM M F. Deformation of electrodeposited nanocrystalline nickel [J]. Acta Materialia, 2003, 51: 387-405.

[24] SCHIOTZ J, JACOBSEM K W. A maximum in the strength of nanocrystalline copper [J]. Science, 2003, 301: 1357-1359.

[25] WANG Y M, MA E, CHEN M W. High tensile ductility in a nanostructured metal [J]. Nature, 2002, 419: 912-915.

热处理温度对镀镍钴钢带拉伸变形行为的影响

张敏捷1,2,潘 勇1,2,周兆锋1,2,李 玮1,2,惠建科1,2,雷维新1,2

1. 湘潭大学 材料与光电物理学院,湘潭 411105;

2. 湘潭大学 低维材料及其应用技术教育部重点实验室,湘潭 411105

摘 要:研究热处理温度对镀镍钴钢带微观结构和拉伸性能的影响。通过原位扫描电子显微镜观察镀镍钴钢带在拉伸变形过程中表面形貌的变化。结果表明:热处理后,镀镍钴钢带在镀层与基底之间形成镍/钴/铁扩散层,随着热处理温度的升高,钢带的伸长率逐渐增大;当热处理温度为650 ℃时,镀镍钴钢带的伸长率最大,为46%,抗拉强度和屈服强度适中。在拉伸变形过程中,镀镍钴钢带在热处理前、后呈现出不同的变形过程。未进行热处理的样品在拉伸变形过程中,表面形成裂纹,裂纹的扩展导致最终断裂;而热处理后,钢带在拉伸过程中表面没有裂纹的产生,孔洞的出现、生长和扩展而导致的最终断裂。这表明,适当的热处理有利于提高材料的韧性,改善其力学性能。

关键词:热处理;镍-钴合金;拉伸变形;断裂

(Edited by YANG Hua)

Foundation item: Project (2009FJ1002) supported by the Key Special Program for Science and Technology of Hunan Province, China; Project (11002121) supported by the National Natural Science Foundation of China

Corresponding author: PAN Yong; Tel/Fax: +86-731-58298399; E-mail: ypan@xtu.edu.cn

DOI: 10.1016/S1003-6326(11)61364-2