闪速磁化焙烧及铁矿物的微观相变特征

罗立群1, 2,余永富1, 3,张泾生3

(1. 武汉理工大学 资源与环境工程学院,湖北 武汉,430070;

2. 矿物资源加工与环境湖北省重点实验室,湖北 武汉,430070;

3. 长沙矿冶研究院,湖南 长沙,410012)

摘 要:针对酒泉钢铁(集团)公司粒度小于0.30 mm的富含镜铁矿、褐铁矿和镁(锰)菱铁矿难选铁粉料,介绍采用闪速磁化焙烧动态试验装置开发我国难选低品位细粒级铁矿资源的试验效果;对闪速磁化焙烧前、后相关产品进行光学显微镜观察、XRD和EPMA检测分析,研究焙烧前后铁矿物的相变情况及微观特性。研究结果表明:在弱还原气氛和740~800 ℃条件下,通过60 s之内的闪速磁化焙烧处理,可获得铁品位为55.51%~55.35%的弱磁选铁精矿;弱磁性细粒铁矿物的相变均转变为龟裂较为发育的人造磁铁矿,产物中未见菱铁矿和强磁性的γ-Fe2O3;人造磁铁矿其镜下微观形貌与反光特征仍有差异,且由菱铁矿中的Mg和Mn特征元素含量有差别,可将其区分。

关键词:铁矿物;闪速磁化焙烧;相变;微观特征

中图分类号:TD92;TD924 文献标识码:A 文章编号:1672-7207(2009)05-1172-06

Flash magnetic roasting and microstructure characteristics

& phase transformation of iron minerals

LUO Li-qun1, 2, YU Yong-fu1, 3, ZHANG Jing-sheng3

(1. School of Resources and Environmental Engineering, Wuhan University of Technology, Wuhan 430070, China;

2. Mineral Resources Processing and Environment Laboratory of Hubei, Wuhan 430070, China;

3. Changsha Research Institute of Mining and Metallurgy, Changsha 410012, China)

Abstract: Applying flash magnetizing roasting (FMR) equipment to exploit fine-grained iron materials which was granularity minus 0.30 mm powder and rich in specularite, limonite and Mg-Mn siderite from Jiuquan Iron & Steel (Group) Co. Ltd (JISC) were briefly reviewed. The phase transformation and microstructure characteristics of iron minerals were investigated with optical microscopy, XRD and EPMA measurements after and before FMR samples. In a weakly reducing atmosphere and at 740-800 ℃, JISC’s refractory powder ferrous material (<0.30 mm) is subjected to FMR for less than 60 s. Weakly magnetic separation iron concentrate with iron grade of 55.51%–55.35% are obtained. Weakly magnetic iron minerals are mainly converted into strongly magnetic material Fe3O4 with many cracks and no Mg-Mn siderite and γ-Fe2O3 can be found in iron material after FMR. Their fractured micro-surface and reflection of iron minerals after FMR are different in optical microscopy. It is possible to distinguish artificial magnetite from iron minerals after FMR, according to the proportion of the specific elements contenting Mg or Mn in siderite and specularite.

Key words: iron materials; flash magnetizing roasting; phase transformation; microstructure characteristic

磁化焙烧工艺主要是针对难分离的弱磁性铁物料,通过磁化焙烧处理将其转变成强磁性铁物料的物理化学过程。传统铁物料的磁化焙烧技术及装置,如竖炉块矿还原焙烧(物料粒度>15 mm)、回转窑还原焙烧(物料粒度15~0 mm)以及沸腾焙烧(物料粒度5~ 0 mm)只能处理粗粒和富含粗粒的物料,导致物料磁化焙烧时间长、还原过程缓慢且不均匀,有时磁化焙烧处理后的矿石质量总体效果不大[1-4]。然而,针对复杂难选的铁物料,磁化焙烧技术与装备的研究仍是解决此类铁矿石分选的关键技术之一[5-8]。

目前,我国每年有数以亿吨计 “收之不能、弃之可惜”的低品位难选强磁精矿、中矿和伴生弱磁性铁物料不能有效利用。由于物料粒度已经较小,通常为0.3 mm以下,而且物料粒度愈小,比表面积愈大,反应活性愈高,分选难度较大[9-10]。若采用传统的磁化焙烧工艺,则需要增加焙烧前的造球作业和焙烧后的磨矿作业;若能直接在流态化状态下进行磁化焙烧,并实现闪速化,则将极大提高磁化反应速度与焙烧效率,省去繁琐与耗能高的造球工艺和磨矿作业,简化工艺流程,降低能耗与生产成本,符合我国铁矿资源和生产特征。目前国内外对细粒级低品位粉状铁物料(物料粒度<0.3 mm)还原焙烧工艺和炉型的研究报道较少,需要从理论与实践上进行开拓性的深入细致研究[11-13]。在此,本文作者选择我国难选“红铁矿”—酒钢镜铁山铁矿为研究对象,介绍闪速磁化焙烧新技术的试验结果,研究其中不同铁矿物的相变及其微观特征。

1 实 验

1.1 样品及其性质

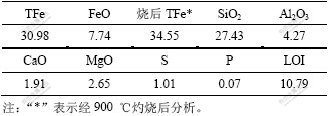

研究试样采自酒泉钢铁(集团)公司镜铁山桦树沟矿石的粉矿(粒径为15~0 mm)及由粉矿分选出来的中矿。矿石性质十分复杂,矿物嵌布粒度小,脉石含量较高;矿石结构呈条带状、块状和浸染状构造。可分选回收的3种铁矿物为弱磁性的镜铁矿、镁(锰)菱铁矿和褐铁矿,目前,3种铁矿物质量比约为2.4?1.0?1.4,粉矿的含铁品位一般为29%~31%;脉石矿物主要为碧玉、石英、重晶石和铁白云石等,围岩为千枚岩,其中大部分为铁质千枚岩[13-14]。各矿物的破碎磨矿性质及选别性质的差异较大,脉石矿物中碧玉和千枚岩等严重影响选矿作业的分选效果,致使酒钢粉矿的选别难度大,分选效率较低。试样多元素化学分析结果如表1所示,铁物相分析结果如表2所示。

表1 试样多元素化学分析结果

Table 1 Results of multi-element chemical analysis of samples w/%

表2 试样铁物相分析结果

Table 2 Results of phase analysis of iron w/%

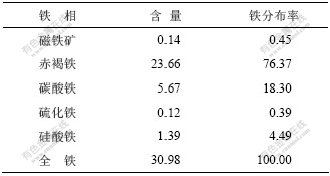

1.2 试验装置与方法

闪速磁化焙烧试验装置是基于磁化还原的温度和气氛条件,物料处于流态化运动条件下的快速磁化转变过程[15]。闪速磁化焙烧还原反应热态装置与测速控制系统主要由还原性气氛发生炉、流态化闪速还原炉、电加热与温度控制系统、供气与调节控制系统、物料添加与收集系统、测量与控制系统等组成,闪速磁化焙烧还原反应装置框图如图1所示。

图1 闪速磁化焙烧还原反应装置框图

Fig.1 Block diagram of reduction reaction equipment of FMR

热态实验装置的主要技术参数是:还原炉内径为50 mm;炉体高度为2 m,其中,加热带高度为1 m;炉膛温度≤1 000 ℃;磁化焙烧可操作时间最低可达10 s;测温系统温度控制误差在±5 ℃以内。

1.3 研究与检测方法

热态反应装置系统中的还原性气氛发生炉以焦炭或木炭为原料,以一定压力的空气为气化介质,产生以CO为主的还原性气体,其中,CO含量主要通过调节风量实现控制;具有一定温度的还原性气体经电加热器控温后,进入流态化闪速磁化还原炉,对待还原铁物料进行闪速磁化焙烧,以获得人造磁铁矿;磁铁矿由一定压力的惰性气体保护并由收集系统出料,经水淬后得到磁化焙烧样品。

由磁选管分选而确定焙烧产品中强磁性物的含量,以评定闪速磁化焙烧效果。对试样中的不同铁矿物及闪速磁化焙烧后的人造磁铁矿进行光学显微镜观察,研究焙烧前后铁矿物的相变情况及微观特性,运用X射线衍射(XRD)和电子探针(EPMA)对闪速磁化焙烧相关样品进行分析与鉴定,以确定闪速磁化焙烧时弱磁性铁矿物的相变规律与微观变化特征。

2 结果与讨论

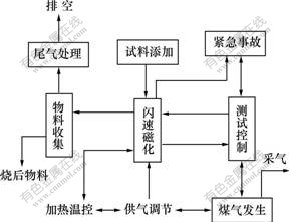

2.1 试样闪速磁化焙烧的综合结果

以酒钢中矿物料为考察对象,进行不同磁化焙烧操作条件组合试验,研究闪速磁化焙烧过程中物料磁化转变过程的规律。试验入口压差取1.95~2.15 kPa,物料粒度为0.30~0 mm,不同分布板温度、还原气氛与还原反应时间的闪速磁化焙烧综合结果如图2所示。

1—650 ℃; 2—800 ℃; 3—740 ℃, φCO=0~0.6%; 4—740 ℃, φCO=3.2%~4.5%

图2 不同温度和不同还原时间时的闪速磁化焙烧效果

Fig.2 Results of FMR under conditions of different temperatures and time

结果表明,将试验铁物料进行闪速磁化焙烧,焙烧矿磁性产品的铁收率随分布板温度的升高而提高,提高的幅度先大后小;在投料时分布板温度为650~ 800 ℃,CO的体积分数为0~4.5%,其临界气氛是控制CO的含量接近于0,为正值(即φCO≮0,而O2的含量为0),闪速磁化焙烧的效果较好。铁收率随还原反应气氛中CO的含量降低而提高,在分布板温度为740 ℃时投料,CO的含量为3.2%~4.5%,此时,铁收率仅为61.75%~66.09%,而当CO的含量为0.6%~0%时,铁收率达到72.38%~79.43%,升高幅度达到11%~13%,表明弱还原气氛对焙烧过程有利。

物料在“加入即出”(即投料后随即出料,操作时间小于3 s)到60 s的磁化焙烧时间内,铁收率总的趋势是增加的,一般为3%~5%。当分布板温度从650 ℃升高到740 ℃时,铁收率提高10%~12%,而当分布板温度从740 ℃升高到800 ℃时,铁收率提高4%~6%。表明铁收率增加幅度的显著性并没有分布板温度和CO的含量影响大,物料的磁化焙烧过程主要是通过投料后的“闪速时段”快速完成转化的。

2.2 闪速磁化焙烧前、后产品的显微特征

试样闪速磁化焙烧前、后的表观与物理化学性质都发生了显著变化。首先是外观颜色改变,粉体试样未焙烧前为深红色至枣红色,正常焙烧后,外观颜色变为深黑色至灰黑色;若试样条件控制不好或部分氧化,则焙烧后试样部分显示为黑红色或浅红色,磁性物的产率大大降低。

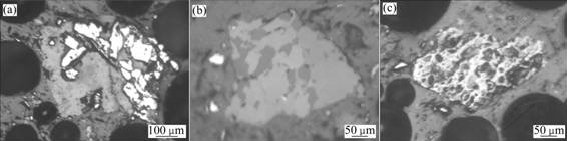

试样焙烧前铁矿物的显微特征如图3所示。从图3可见,试样中的铁矿物组成复杂,以细粒级分布为主,可见针状、纤维状或细鳞片状的镜铁矿(白色)与菱铁矿(灰白色)共生形成复杂的集合体(图3(a));对图3(b)中粒度为0.16 mm的菱铁矿集合体颗粒,碧玉(灰黑色)呈交代残余分布在菱铁矿(灰白)中;而褐铁矿呈多孔状集合体分布(图3(c)),部分呈网脉状分布在脉石间或交代于粒状菱铁矿的间隙中[14]。

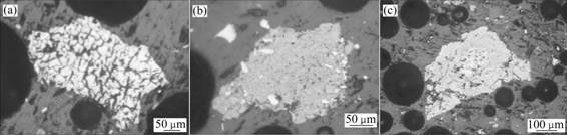

试料经过闪速磁化焙烧过程后,闪速磁化焙烧产品的显微特征如图4所示,从图4可见,试样中不同铁矿物的颗粒均可转变成人造磁铁矿,多数形成龟裂较为发育的人造磁性颗粒和人造磁铁矿集合体。但人造磁铁矿颗粒的形态特征呈现多样性,当颗粒性质比较单一时,形成龟裂极为发育的人造磁铁矿集合体(图4(a));当颗粒由不同种类弱磁性铁矿物组成时,人造磁铁矿颗粒特征也不同,如可能由菱铁矿和镜铁矿转变成的不同磁铁矿集合体(图4(b))。图4(c)所示的人造磁铁矿集合体中,核部比边缘的反射色高,可能是焙烧前的矿物种类与性质不同所致。具体矿物特征及铁矿物的种类来源需要进一步查证。

(a) 菱铁矿(灰白色)和镜铁矿集合体(白色);(b) 碧玉(灰黑色)呈交代残余分布在菱铁矿中,白色的为镜铁矿;(c) 多孔状褐铁矿集合体

图3 试样焙烧前铁矿物的显微特征图

Fig.3 Picture of optical microscopy on iron minerals of samples before FMR

(a) 龟裂极为发育的人造磁铁矿集合体;(b) 由菱铁矿和镜铁矿转变成的不同磁铁矿集合体;(c) 人造磁铁矿集合体,其反射色核部较边缘高

图4 闪速磁化焙烧产品的显微特征

Fig.4 Picture of optical microscopy on iron minerals of samples after FMR

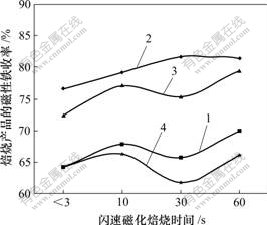

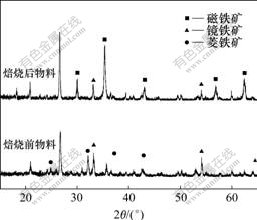

2.3 闪速磁化焙烧产品的XRD鉴定

应用X射线衍射(XRD)查明试样经闪速磁化焙烧后铁矿物的变化与强磁性物质的生成情况。焙烧前样品及闪速磁化焙烧后样品的X射线衍射分析结果如图5所示。

图5 闪速磁化焙烧前后试样的X射线衍射图谱

Fig.5 XRD patterns of samples before and after FMR

从图5可见,弱磁性铁物料在未焙烧前,含铁矿物的特征峰主要有:菱铁矿特征峰,晶面间距d1= 2.781 9,d2=3.574 7,d3=1.724 4;赤铁矿(酒钢试样即为镜铁矿)特征峰α-Fe2O3,d1=2.692 9,d2=1.692 2,d3=3.674 3。褐铁矿特征峰FeOOH不明显,却可见白云石的特征峰,如d=2.884 8。焙烧前,试样中未发现强磁性铁矿物的特征峰,表明试样中没有强磁性铁矿物或含量极少。经过闪速磁化焙烧后,焙烧后试样中具有强磁性磁铁矿的明显特征峰,且磁铁矿特征峰的峰形尖锐,峰值高耸,d1=2.534 7,d2= 2.972 2,d3= 2.101 8,表明试样经过闪速磁化焙烧过程产生了大量强磁性物质,而且结晶程度较高;而同样具有强磁性特征的γ-Fe2O3特征峰未出现,也未见菱铁矿的特征峰。说明试样通过闪速磁化焙烧以后,弱磁性铁矿物的闪速磁化焙烧过程是被还原转变为强磁性的Fe3O4[6, 16]。

另外,在焙烧产品试样中仍发现有赤铁矿(即镜铁矿)的特征峰,可能是样品中部分未完全转变为人造磁铁矿的镜铁矿所致。

2.4 人造磁铁矿的电子探针显微分析

为了确定闪速磁化焙烧试样中镜铁矿、菱铁矿和褐铁矿等弱磁性铁矿物的磁化转变情况和强磁性人造磁铁矿物Fe3O4的转化来源,可通过闪速磁化焙烧组成的人造磁铁矿集合体进行电子探针(EPMA)微区形貌与成分分析,以查明不同磁铁矿的生成或转变过程。由于矿石中的菱铁矿通常含有Mg和Mn,有可能通过Mg和Mn作为特征元素(或称示踪元素),区分菱铁矿与其他矿物的磁性转化特征;褐铁矿因风化变质,显微结构比较松散,且有可能因焙烧失去结晶水变得疏松多孔,易于与镜铁矿区分。

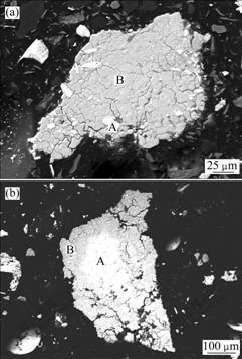

将焙烧试样中图4(b)和4(c)所示颗粒进行EPMA检测,其电子探针的背散射(BEI)显微照片与微区扫描点如图6所示。

A—由镜铁矿转变而成;B—由菱铁矿转变而成

图6 闪速磁化焙烧后的人造磁铁矿背散射图谱

Fig.6 Back-scattered electron image of man-made magnetite after FMR

从图6可见,尽管闪速磁化焙烧产物都为人造磁铁矿,但图谱中反射色较高的A区仅有单孔形、细短状裂纹,龟裂形式欠发育,磁铁矿很可能由镜铁矿转化而成;而反射色较低的B区裂隙宽大,龟裂发育极为普遍、完整,此磁铁矿极可能由菱铁矿分解释放出CO2后转化而成。

从图6中A微区和B微区点进行检测的扫描电镜能谱分析可知,在龟裂欠发育、反射色较高的A区,除Fe与Si以外,特征元素Mg和Mn(有的还有少量Ca)等没有出现,或峰值低、含量极少;而龟裂极为发育、反射色较低的B区,特征元素Mg和Mn(有的还有少量Ca)等的特征峰相当明显或峰值高,表明图6(a)和6(b)中所示A区的人造磁铁矿是由镜铁矿转变而来,而B区所示的人造磁铁矿是由菱铁矿转变而来。由于它们具有明显的Mg和Mn元素特征,故即使经磁化焙烧转变成磁铁矿后,仍然可以区分开来。

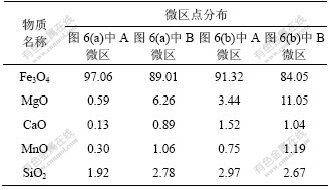

2.5 强磁性产物中微区组分分析

按照图6所示人造强磁性矿物中的A和B微区,以电子探针对微区点特征元素物质组成的探测结果,计算闪速磁化焙烧后的强磁性物质和特征物质组成的占有率,可定量地证明人造磁铁矿的不同铁矿物来源。电子探针微区特征物质组成计算结果如表3所示。

表3 电子探针各微区扫描点物质组成

Table 3 Composition of samples’ EPMA region w/ %

微区特征物质组成分析结果表明,图6(a)中磁铁矿确实是由菱铁矿和镜铁矿转变成的不同磁铁矿,其B区由菱铁矿转变的部分MgO含量达到6.26%,而对应的A区MgO含量只有0.59%,见表3。图6(b)中人造磁铁矿集合体,其核部的反射色比边缘的反射色较高部分是由镜铁矿转变而成的磁铁矿,因为A区的MgO含量虽然有3.44%,而对应的B区MgO含量高达11.05%,即为(镁)菱铁矿转变而成,从而定量确定A区和B区焙烧前不同铁矿物的转化来源。

3 结 论

a. 对酒钢镜铁山矿桦树沟矿区的铁矿试样,粒度小于0.30 mm的富含镜铁矿、褐铁矿和镁(锰)菱铁矿难选铁粉料,在弱还原气氛和740~800 ℃的试验条件下,通过60 s之内的闪速磁化焙烧处理,获得了铁品位为55.51%~55.35%(因矿石中镁、锰含量较高),闪速磁化焙烧效果良好。弱还原气氛和较高的还原温度对该试样的闪速磁化焙烧过程有利,而且物料的磁化焙烧过程主要是通过投料后的“闪速时段”快速完成转化的。

b. 富含镜铁矿、褐铁矿和镁(锰)菱铁矿的复杂铁矿粉料,经过闪速磁化焙烧后,均转变为龟裂较发育的人造磁性颗粒和人造磁铁矿集合体。其强磁性矿物均为Fe3O4,而未见菱铁矿的特征峰和具有强磁性的γ-Fe2O3特征峰;同时,仍可见少量未转化完全的赤铁矿(即镜铁矿)特征峰。

c. 不同种类弱磁性铁矿物转变为强磁性矿物Fe3O4以后,其镜下微观形貌与反光特征仍有差异,且由菱铁矿或镜铁矿转变而来的磁铁矿,仍然可以根据其特征元素Mg和Mn的含量差异将其区分。

参考文献:

[1] 罗立群, 乐 毅. 难选铁物料磁化焙烧技术的研究与发展[J]. 中国矿业, 2007, 16(3): 55-58.

LUO Li-qun, LE Yi. Applied researches and new developments of magnetizing roasting on iron materials[J]. China Mining Magazine, 2007, 16(3): 55-58.

[2] 罗立群. 菱铁矿的选矿开发研究与发展前景[J]. 金属矿山, 2006(1): 68-72.

LUO Li-qun. Explorative research on beneficiation of siderite and Its development prospect[J]. Metal Mine, 2006(1): 68-72.

[3] 罗立群, 张泾生, 刘千帆. 基于酒钢物料的磁化焙烧技术研究与应用[J]. 矿冶工程, 2006, 26(S1): 49-53.

LUO Li-qun, ZHANG Jing-sheng, LIU Qian-fan. Applications and researches on magnetizing roasting to JISCO iron materials[J]. Mining and Metallurgical Engineering, 2006, 26(S1): 49-53.

[4] Youssef M A, Morsi M B. Reduction roast and magnetic separation of oxidized iron ores for production of blast furnace feed[J]. Canada Metallurgical Quartyerly, 1998, 37(5): 419-428.

[5] 余永富, 张汉泉. 我国钢铁发展对铁矿石选矿科技发展的影响[J]. 武汉理工大学学报, 2007, 29(1): 1-7.

YU Yong-fu, ZHANG Han-quan. Influence of domestic iron and steel development on iron ore processing technology[J]. Journal of Wuhan University of Technology, 2007, 29(1): 1-7.

[6] O’Connor F, Cheung W H, Valix M. Reduction roasting of limonite ores: effect of dehydroxylation[J]. International Journal Mineral Processing, 2006, 80(2/4): 88-99.

[7] 罗立群, 张泾生, 高远扬, 等. 菱铁矿干式冷却磁化焙烧技术研究[J]. 金属矿山, 2004(10): 28-31, 35.

LUO Li-qun, ZHANG Jing-sheng, GAO Yuan-yang, et al. Research on dry cooling magnetic roasting technology for siderite ore[J]. Metal Mine, 2004(10): 28-31, 35.

[8] LUO Li-qun, ZHANG Jing-sheng, YU Yong-fu. Recovering limonite from Australia iron ores by flocculation-high intensity magnetic separation[J]. Journal of Central South University of Technology, 2005, 12(6): 682-687.

[9] 张泾生, 罗立群. 细粒物料磁分离技术的现状[J]. 矿冶工程, 2005, 25(3): 25-29.

ZHANG Jing-sheng, LUO Li-qun. Actuality of magnetic separation technique[J]. Mining and Metallurgical Engineering, 2005, 25(3): 25-29.

[10] Arol A I, Aydogan A. Recovery enhancement of magnetite fines in magnetic separation[J]. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 2004, 232(2/3): 151-154.

[11] 任亚峰, 余永富. 难选红铁矿磁化焙烧技术现状及发展方向[J]. 金属矿山, 2005, (11): 20-23.

REN Ya-feng YU Yong-fu. Present status and development orientation of magnetization roasting technology for refractory red iron ores[J]. Metal Mine, 2005, (11): 20-23.

[12] 陈耀明, 李 建. 氧化球团矿中Fe2O3的结晶规律[J]. 中南大学学报: 自然科学版, 2007, 38(1): 70-73.

CHEN Yao-ming, LI Jian. Crystal rule of Fe2O3 in oxidized pellet[J]. Journal of Central South University of Technology: Science and Technology, 2007, 38(1): 70-73.

[13] 刘千帆. 酒钢镜铁山铁矿石预选工艺研究[D]. 西安: 西安建筑科技大学冶金工程学院, 2003.

LIU Qian-fan. Technological Study on the Pre-separation of the Iron Ore from Jingtieshan Mine of JISCO[D]. Xi’an: School of Metallurgical Engineering, Xi’an University of Architecture and Technology, 2003.

[14] 罗立群, 管俊芳, 曹佳宏. 酒钢目前入选粉矿的矿石性质研究[J]. 金属矿山, 2007(4): 26-29.

LUO Li-qun, GUAN Jun-fang, CAO Jia-hong. Study on properties of powder feed to concentrator in Jiu Steel[J]. Metal Mine, 2007(4): 26-29.

[15] 余永富, 刘根凡, 梅 丰, 等. 难选氧化铁矿石闪速磁化焙烧反应速度的测试装置: 中国, ZL CN 2005 10019932.1[P]. 2006-05-24.

YU Yong-fu, LIU Gen-fan, MEI Feng, et al. Reaction rate measure apparatus on flash magnetizing roasting to refractory iron ore: China, ZL CN 2005 10019932.1[P]. 2006-05-24.

[16] 罗立群. 难选复杂铁物料流膜磁分离与闪速磁化焙烧新技术研究[D]. 武汉: 武汉理工大学资源与环境工程学院, 2006.

LUO Li-qun. New technique of film magnetic separation and flash magnetization roasting of refractory and complicated iron materials[D]. Wuhan: School of Resources and Environmental Engineering, Wuhan University of Technology, 2006.

收稿日期:2008-10-12;修回日期:2009-03-20

基金项目:国家“十五”科技攻关项目(2004BA615A-17);教育部博士点基金新教师项目(20070497048)

通信作者:罗立群(1968-),男,湖南长沙人,博士,从事矿物资源的高效利用与二次资源清洁选冶加工研究;电话:027-62857276;E-mail: lqluollq@hotmail.com