文章编号:1004-0609(2008)10-1903-06

高铁一水硬铝石型铝土矿的低钙比烧结

刘桂华,张 明,肖 伟,彭志宏,周秋生,李小斌

(中南大学 冶金科学与工程学院,长沙 410083)

摘 要:研究烧结法处理我国高铁中等品位矿石的工艺条件,确定钙比为1.5时熟料中存在3CaO·2SiO2和2CaO·2SiO2。结果表明,增大钙比使熟料Al2O3溶出率、SiO2溶出率均有所降低;延长烧成时间,提高烧成温度有利于Al2O3溶出率的增加和SiO2溶出率的降低;提高铁铝比,熟料最佳烧成温度降低,烧成温度范围变窄;提出的Al2O3有效溶出率概念表明,钙比为1.5时,熟料烧成效果最好;确定高铁铝土矿适宜的烧成制度为:烧成温度1 250~1 300 ℃,烧成时间20~40 min,钙比1.5。

关键词:高铁一水硬铝石;烧结;低钙比;有效溶出率

中图分类号:TF 821 文献标识码: A

Sintering process of diasporic bauxite with high iron content at low ratio of lime to silica for alumina production

LIU Gui-hua, ZHANG Ming, XIAO Wei, PENG Zhi-hong, ZHOU Qiu-sheng, LI Xiao-bin

(School of Metallurgical Science and Engineering, Central South University, Changsha 410083, China)

Abstract:The sintering process of diasporic bauxite with high iron content was studied. The results show that 3CaO·2SiO2, and 2CaO·SiO2, are primarily formed in the sintering process when diasporic bauxite is sintered at soda ratio Na2O/(Al2O3+Fe2O3) of 1 and lime ratio CaO/SiO2 of 1.5. The increase of n(CaO)/n(SiO2) decreases the extraction of alumina and silica. The prolongation of sintering time and the increase of sintering temperature benefit the alumina extraction but reduce the silica extraction. The increase of the ratio of iron to alumina decreases the sintering temperature and narrows the sintering temperature range. The results from the Al2O3 available extraction rate also indicate that the high alumina extraction rate can be obtained at n(CaO)/n(SiO2) of 1.5. The feasible technology for sintering is as follows: sintering temperature 1 250-1 300 ℃, sintering time 20-40 min, n(CaO)/n(SiO2) of 1.5.

Key words: diaspore with high iron; sinter; low molar ratio of CaO to SiO2; available extraction rate

我国铝土矿主要属一水硬铝石型,80%左右是中低品位铝土矿(铝硅比小于8),具有高铝、高硅的特点,部分矿石含铁较高[1],如简单的用传统拜耳法处理因碱耗高、Al2O3回收率低、物料流量大,经济上不可行[2]。烧结法由于以mCaO·nSiO2形式进行铝硅分离,因而理论上不损失碱和铝,且具有资源回收率高,赤泥综合利用方便、产品白度高等特点[3],因此采用烧结法处理高铁中等品位铝土矿是一种较好的方法。但传统烧结法在处理高铁原料时,由于矿石铝硅比低,铁酸钠大量生成使烧结温度范围变窄,熟料烧结困难,因此一般在烧结过程中加入过量CaO使部分铁生成CaO·Fe2O3(CF)、2CaO·Fe2O3(C2F),以提高其烧结性能。这一方面导致熟料中Al2O3含量低,系统物料流量增大、技术经济指标欠佳;另一方面由于CF和C2F与Na2O·Al2O3发生反应,使Al2O3溶出率降低[4]。为提高中低品位高铁铝土矿的烧结性能,提高熟料中Al2O3含量,需研究低钙条件下熟料烧结过程中硅、铁的反应行为。有研究表明[5-8],在CaO-SiO2二元体系中存在CaO·SiO2、3CaO·2SiO2等低钙硅酸钙,但尚未确定高碱氧化铝熟料烧结体系中低钙硅酸钙的组成情况,国外对Al2O3生产过程中低钙硅酸钙的生成规律也鲜有报道。

本文作者研究高岭土碱石灰烧结体系硅钙化合物的生成,然后在降低钙比的条件下基于高浓度粗液研究配料C/S、氧化铁含量、烧成温度、烧成时间对高铁铝土矿熟料烧结过程的影响。

1 实 验

1.1 实验原料

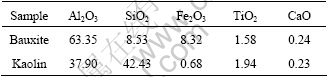

高铁铝土矿石和高岭土的化学成分如表1所列。

表1 铝土矿和高岭土的化学成分

Table 1 Chemical composition of bauxite and kaolinite sample(mass fraction, %)

CaO是由分析纯Ca(OH)2 在850 ℃下煅烧2.5 h制得;Na2CO3为分析纯;两者均细磨并过孔径为246 μm筛。烧结熟料溶出用调整液系用工业Al(OH)3和NaOH配制而成。

1.2 实验方法

1.2.1 熟料烧成

生料配比(碱比 、钙比

、钙比 、铁铝比

、铁铝比 )如下式:

)如下式:

= n(Na2O)/(n(Al2O3)+n(Fe2O3));

= n(Na2O)/(n(Al2O3)+n(Fe2O3));

= n(CaO)/ n(SiO2);

= n(CaO)/ n(SiO2);

=n(Fe2O3)/n(Al2O3)

=n(Fe2O3)/n(Al2O3)

式中 n为各物质的量,mol;x为物质的量之比。

按照 =1.0、

=1.0、 =0.08~0.20(按要求加入分析纯Fe2O3)、

=0.08~0.20(按要求加入分析纯Fe2O3)、 =0~2.0(两成分熟料C/S=0.03,记为0,下同)准确配入所需药品,充分混匀后置于刚玉坩埚中,在800 ℃下恒温预烧15 min后,迅速转移至高温马弗炉中,在设定温度下烧结一定时间,取出冷却至室温,细磨过孔径为246 μm筛,装入磨口瓶密封保存。

=0~2.0(两成分熟料C/S=0.03,记为0,下同)准确配入所需药品,充分混匀后置于刚玉坩埚中,在800 ℃下恒温预烧15 min后,迅速转移至高温马弗炉中,在设定温度下烧结一定时间,取出冷却至室温,细磨过孔径为246 μm筛,装入磨口瓶密封保存。

1.2.2 熟料溶出

熟料溶出实验在以甘油为加热介质、自动控温的DY-8群釜低压釜装置(中南工业大学机械厂)中进行。溶出浆液经真空抽滤,沸水洗涤,滤液定容后用容量法分析Al2O3及苛性碱(Na2O)浓度,用硅钼蓝分光光度法(7230G分光光度仪:上海分析仪器厂)测定二氧化硅含量,滤渣放入干燥箱中在(100±5) ℃烘干,称量,用于固相分析。

2 结果及讨论

2.1 高岭土的烧结过程

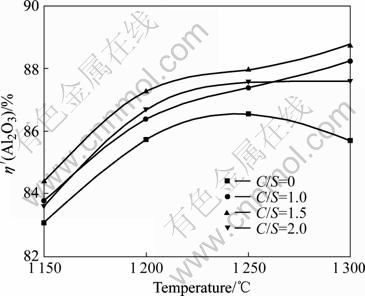

我国铝土矿中的硅矿物主要以高岭石(Al2O3·2SiO2·2H2O)形式存在[1, 3],研究高岭石在烧结过程中的反应行为对于降低钙比、提高熟料中Al2O3含量具有指导意义。将高岭土与CaO、Na2CO3按钙比1.0和1.5、碱比1.0混匀置于刚玉坩埚中,800 ℃恒温预烧15 min后,迅速转移到1 300 ℃高温马弗炉中烧结1 h。对烧结产物进行XRD分析,结果如图1所示。

图1 1 300 ℃烧结后不同C/S烧结料的XRD谱

Fig.1 XRD patterns of sinter with different C/S sintering at 1 300 ℃: (a) C/S=1, kaolin reacting with CaO; (b) C/S=1.5, kaolin reacting with CaO

如图1所示,在Na2O-Al2O3-SiO2-CaO体系中,C/S为1时,烧结产物为2CaO·SiO2和3Na2O·2Al2O3·4SiO2,CaO·SiO2峰不明显。这可能是由于CaO·SiO2在烧结过程中不稳定,与Na2O·Al2O3发生反应4(CaO·SiO2)+ Na2O·Al2O3=Na2O·Al2O3·2SiO2+2(2CaO·SiO2)所致。在C/S为1.5时,烧结产物中的硅酸钙物相为3CaO·2SiO2和2CaO·SiO2,说明3CaO·2SiO2可以与Na2O·Al2O3稳定存在[7-8]。

CaO-SiO2二元体系中存在3CaO·2SiO2[5-8]已得确证,但目前在复杂的Al2O3烧结系统中却未发现3CaO·2SiO2。本次实验以Na2O-Al2O3-SiO2-CaO多元体系为研究对象,证实物相中存在3CaO·2SiO2。LAURENT等[9]研究结果表明:3CaO·2SiO2在碱性体系中比2CaO·SiO2稳定。这说明在熟料中若出现3CaO·2SiO2时,溶出过程中Al2O3溶出率增大,二次反应损失减少。这为降低熟料中钙比至1.5、提高熟料中Al2O3含量、提高熟料溶出时Al2O3溶出率提供了理论依据。

2.2 高铁矿石的熟料烧成

基于测定熟料溶出后氧化铝溶出率、SiO2浓度变化规律研究各因素对高铁铝土矿烧成的影响。

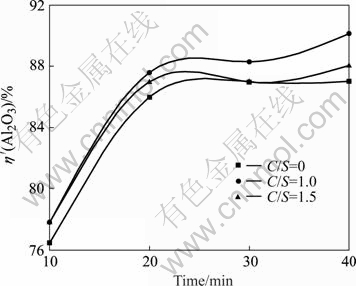

2.2.1 温度对熟料烧成的影响

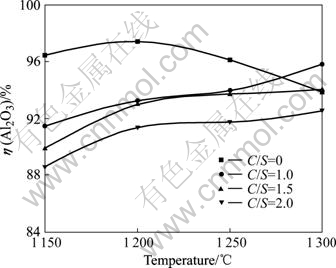

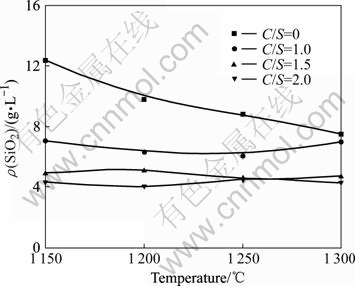

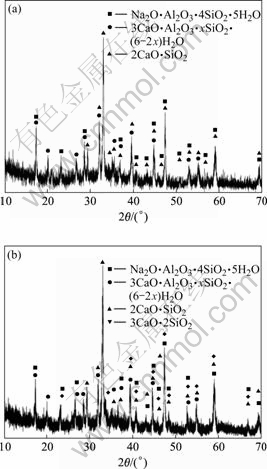

实验研究了碱比NR=1.0、烧成时间20 min、钙比 =0~2.0、烧成温度1 150~1 300 ℃时烧成熟料的变化,结果如图2和3所示。

=0~2.0、烧成温度1 150~1 300 ℃时烧成熟料的变化,结果如图2和3所示。

图2 生料C/S对熟料氧化铝溶出率的影响

Fig.2 Influences of C/S on alumina extraction rate of sinter after leaching

图3 生料C/S对熟料溶出液硅浓度的影响

Fig.3 Influences of C/S on silica concentration in aluminate solution after leaching aluminate solution for sinter leaching: ρ(Na2Ok)=114.90 g/L, ρ(Al2O3)=104.91 g/L, αk (Na2Ok/Al2O3) =1.80. Condition of sinter leaching: Temperature 80 ℃, time 20 min; addition of sinter 200 g/L; concentration of alumina in green liquor >180 g/L

实验发现,两成分烧结料颜色为黄绿色;三成分熟料颜色转化成灰褐色,且随着钙比的增大及温度的升高,颜色逐渐变黑。

图2~3可以看到,无论采用两成分还是三成分烧结,Al2O3溶出率均大于88%。两成分炉料在烧成温度 1 200 ℃、烧成时间20 min时Al2O3溶出率达到97.43%,继续升高温度,Al2O3溶出率逐渐降低,同时溶出液中SiO2浓度明显降低。这可能是高温下 (1 200~1 550 ℃)发生反应3Al2O3+2SiO2=3Al2O3·2SiO2生成不溶性的3Al2O3·2SiO2固溶体所致[10]。钙比相同的三成分炉料在升高温度时,Al2O3溶出率增大,溶出液SiO2浓度有小幅度的降低,如C/S=1的1 150和1 300 ℃烧成熟料,Al2O3溶出率分别为91.45%和95.83%,SiO2浓度则分别为7.08和7.01 g/L。这主要是在高氧化铝炉料中,钙比的升高导致烧成温度也相应升高所致。

2.2.2 钙比CR对熟料烧成的影响

图2~3表明,相同温度下,三成分熟料随着钙比的增加,Al2O3溶出率、溶出液SiO2浓度均逐渐降低。鉴于钙比高时溶出液中SiO2浓度低,脱硅过程中氧化铝损失少,尽管熟料溶出时氧化铝溶出率低,但过程氧化铝收率可能不低;而钙比低时,尽管熟料氧化铝溶出率高,但溶出液中SiO2浓度高,脱硅过程中将损失大量Al2O3,反而使Al2O3收率降低。为表征不同钙比条件下熟料中Al2O3进入溶出液中的实际量,引入有效溶出率的概念。根据钠硅渣的化学式(Na2O·Al2O3·1.7 SiO2·H2O)可知,脱去1 g/L的SiO2需要消耗1 g/L的Al2O3。因此,定义Al2O3有效溶出率为

式中 ρ1溶为溶出液Al2O3浓度,g/L;ρ1调为调整液Al2O3浓度,g/L;ρ3溶为溶出液SiO2 浓度,g/L;w熟为熟料中Al2O3总量。

将图2~3实验数据重新处理,结果如图4所示。

图4 不同温度下C/S对熟料Al2O3有效溶出率的影响

Fig.4 Influences of C/S on available extraction rate of alumina at different sintering temperatures

由图4可见,就Al2O3有效溶出率而言,不同烧成温度条件下,三成分熟料的溶出率要明显高于两成分熟料;而就钙比的影响而言,钙比为1.5的熟料Al2O3有效溶出率要优于其他钙比的熟料。其原因可能是熟料中硅酸钙物相发生了变化,图5所示为不同钙比烧成熟料溶出赤泥的X射线衍射谱。

图5所示的物相分析结果表明,钙比为1的熟料经溶出后,硅酸钙的主要物相为2CaO·SiO2,可能存在CaO·SiO2;钙比为1.5的熟料经溶出后,硅酸钙的主要物相为2CaO·SiO2、3CaO·2SiO2。这说明低钙硅酸钙的出现使Al2O3有效溶出率高,同时也说明3CaO·2SiO2在溶出过程中是稳定的。溶出赤泥中的水化石榴石和水合铝硅酸钠(钠硅渣),主要是由少量二次反应损失造成的

图5 烧成熟料溶出赤泥的X射线衍射谱

Fig.5 XRD patterns of red mud at different C/S: (a) C/S=1; (a) C/S=1.5

2.2.3 烧结时间对熟料烧成的影响

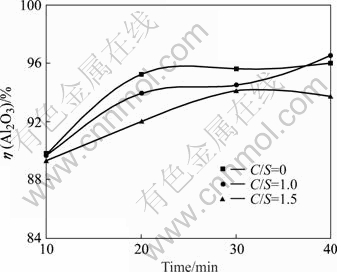

实验研究了1 250 ℃时烧成时间对熟料烧成的影响,结果如图6~7所示。

由图6可见,烧成时间为10 min时熟料的Al2O3溶出率偏低,延长至40 min时,熟料的Al2O3溶出率大幅提高。如:C/S为1.5时,烧成时间为10 min和40 min时,熟料中Al2O3溶出率分别为89.85%和96.01%。这是因为:烧成时间不足,烧成时有关反应难以完 成[11-13],熟料中常生成一定数量的不溶三元化合物,造成碱和铝的损失[14]。

图6 烧成时间对熟料氧化铝溶出率的影响

Fig.6 Influences of sintering time on extraction rate of sinter after leaching

不同烧成时间下Al2O3有效溶出率如图7所示。从图7可以看出,随着烧结时间的延长,Al2O3有效溶出率升高;同时钙比影响明显,在C/S为1、1.5、2.0,烧成时间为40 min 时,Al2O3有效溶出率分别为87.05%、90.17%和88.09%。图中结果还说明C/S为1.5时,有效溶出率最大。这与前面实验结果相吻合。

2.2.4  对熟料烧成的影响

对熟料烧成的影响

图7 烧成时间对熟料氧化铝有效溶出率的影响

Fig.7 Influences of sintering time on available extraction rate of alumina

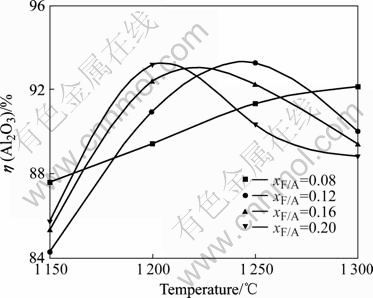

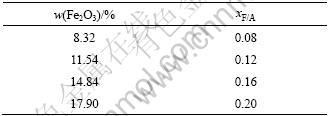

我国还有铁含量更高的铝土矿,为了探索更高铁含量铝土矿的熟料烧结性能,本研究加入分析纯的氧化铁[15],考察铁铝比(表2)对中等品位铝土矿烧结性能的影响,实验结果如图8所示。

图8  对熟料氧化铝溶出率的影响

对熟料氧化铝溶出率的影响

Fig.8 Influences of  on alumina extraction rate of sinter after leaching

on alumina extraction rate of sinter after leaching

实验室静态烧结的结果表明,炉料氧化铁含量达到17.9%,烧结产物为多孔烧结料,无过多液相,易磨细,烧结过程无困难。

由图8可见,生料中氧化铁含量越高,在低温下熟料氧化铝溶出率达到最大值时的烧成温度越低,最佳烧成温度范围变窄。如 为0.2时熟料氧化铝溶

为0.2时熟料氧化铝溶

出率达到最大值93.15%的温度为1 150 ℃, 为0.12时熟料氧化铝溶出率达到最大值93.23%的温度为1 200 ℃,而

为0.12时熟料氧化铝溶出率达到最大值93.23%的温度为1 200 ℃,而 为0.08时熟料氧化铝溶出率达到最大值92.15%的温度为1 250 ℃。这是因为生料中氧化铁含量越高,熟料烧结时液相越多,有利于扩散,从而有利反应的进行。

为0.08时熟料氧化铝溶出率达到最大值92.15%的温度为1 250 ℃。这是因为生料中氧化铁含量越高,熟料烧结时液相越多,有利于扩散,从而有利反应的进行。

表2 配料Fe2O3含量及

Table 2 Content of ferric oxide and ratio of iron to alumina

Sintering temperature 1 100-1 250 ℃, sintering time 20 min,  =1.0,

=1.0,  =2.0

=2.0

3 结论

1) 在Na2O-Al2O3-SiO2-CaO体系及Al2O3烧成熟料溶出渣相中,钙比为1.5时都存在3CaO·2SiO2稳定 物相。

2) 高铁中等品位矿石直接用烧结法处理,无论进行两成分或三成分烧结,均能取得较高的氧化铝溶出率,Al2O3溶出率可以达到97%;熟料Al2O3溶出率、溶出液SiO2浓度均随钙比增大而降低;炉料氧化铁含量增加,烧结温度降低,烧成温度范围变窄。

3) Al2O3有效溶出率的结果表明,钙比为1.5的熟料因为出现3CaO·2SiO2,溶出效果好。确定高铁矿石最佳烧成条件为:烧成温度1 250~1 300 ℃,烧成时间20~30 min,钙比1.5, =1.0。

=1.0。

REFERENCES

[1] 赵恒勤, 李 劼, 王立卓, 刘业翔. 中国铝土矿资源及氧化铝生产技术状况透析[J]. 矿产保护与利用, 2001(5): 38-42.

ZHAO Heng-qin, LI Jie, WANG Li-zhuo, LIU Ye-xiang. Review of current situation on bauxite resources and production technology of alumina in China[J]. Conservation and Utilization of Mineral Resources, 2001(5): 38-42.

[2] 顾松青. 我国的铝土矿资源和高效低耗的氧化铝生产技术[J].中国有色金属学报, 2004, 14(5): 92-97.

GU Song-qing. Alumina production technology with high efficiency and low consumption from Chinese bauxite resource[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(5): 92-97.

[3] 杨重愚. 氧化铝生产工艺学[M]. 北京: 冶金工业出版社, 1993: 176-179.

YANG Zhong-yu. The technology of alumina production[M]. Metallurgical Industry Press, 1993: 176-179

[4] 阿布拉莫夫В Я. 碱法综合处理含铝原料的物理化学原理[M]. 陈谦德等, 译. 长沙: 中南工业大学出版社, 1988: 156-158.

ABLAMOFF B R. Physical and chemical principles of comprehensive treatment of aluminum-containing raw materials by basic process[M]. CHEN Qian-de, et al, transl. Changsha: Central South University Press, 1988: 156-158.

[5] 李小斌, 刘祥民, 刘桂华, 彭志宏, 刘业翔. 强化烧结法生产氧化铝新工艺的研究与实践[J]. 中国有色金属学报, 2004, 14(6): 1032-1036.

LI Xiao-bin, LIU Xiang-ming, LIU Gui-hua, PENG Zhi-hong, LIU Ye-xiang. Study and application of intensified sintering process for alumina production[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(6): 1032-1036.

[6] LIU Gui-hua, Li Xiao-bin, PENG Zhi-hong, ZHOU Qiu-sheng. Behavior of calcium silicate in leaching process[J]. Trans Nonferrous Met Soc China, 2003, 13(1): 213-216.

[7] 吕卫君. 熟料烧结过程热力学分析[D]. 长沙: 中南大学, 2003.

LU Wei-jun. Thermodynamic analysis of alumina clinker sintering process[D]. Changsha: Central South University, 2003.

[8] 李小斌, 谭培龙, 吕卫君, 刘桂华, 彭志宏, 周秋生. 高岭石碱石灰的烧结过程[J]. 硅酸盐学报, 2006, 34(4): 422-426.

LI Xiao-bin, TAN Pei-long, LU Wei-jun, LIU Gui-hua, PENG Zhi-hong, ZHOU Qiu-sheng. Sintering process between kaolinit and alkali lim[J]. Journal of the Chinese Ceramic Society, 2006, 34(4): 422-426.

[9] LAURENT B, CATHERINE B, DOMINIQUE M JEAN-PIERRE C, BRUNO L H, PIERRE C. 29Si MAS NMR study of dicalcium silicate: the structural influence of sulfate and alumina stabilizers[J]. J Am Ceram Soc, 1995, 78(10): 2603-2608.

[10] 赵世柯, 黄 勇, 黄校先. 含Al2O/SiO2体系反应烧结过程中莫来石的形成[J]. 陶瓷学报, 2002, 23(3): 149-155.

ZHAO Shi-ke, HUANG Yong, HUANG Xiao-xian. Mullite formation mechanisms in reaction sintering of Al2O/SiO2 containing mixed powders[J]. Journal of Ceramic, 2002, 23(3): 149-155.

[11] KELMERS A D, CANON R M, EGAN B Z, FELKER L K, GILLIAM T M, JONES G, OWEN G D, SEELEY F G, WATSON J S. Chemistry of the direct acid leach, calsinter, and pressure digestion-acid leach methods for the recovery of alumina from fly ash[J]. Resources and Conservation, 1982, 9: 27l-279.

[12] KRALI D, MATKOVIC B, TROJKO R, YOUNG J F, CHAN C J. Preparation of dicalcium silicate at 950 ℃[J]. J Am Ceram Soc, 1986, 69(8): 170-172.

[13] TORRES-SANCHEZ R M, BASALDELLA E I, MARCO J F. The efect of thermal and mechanical treatments on kaolinite: characterization by XPS and IEP measurements[J]. J Colloid Interface Sci, 1999, 215(2): 339-344.

[14] 联合法生产氧化铝编写组. 联合法生产氧化铝[M]. 北京: 冶金工业出版社, 1975: 9-10.

Editorial group of combination of Bayer-sinter process for alumina production. Combination of Bayer-sinter process for alumina production[M]. Beijing: Metallurgical Industry Press, 1975: 9-10.

[15] MARITZ H C. 串联法生产氧化铝的新进展[M]. 贵州铝厂译. 北京: 中国科学技术出版社, 1991: 58-63.

MARITZ H C. New Development of alumina production in series process[M]. Guizhou Aluminum Factory transl. Beijing: China Science and Technology Press, 1991: 58-63.

基金项目:国家重点基础研究发展规划资助项目(2005CB623702)

收稿日期:2008-01-16;修订日期:2008-05-14

通讯作者:刘桂华,教授,博士;电话:0731-8877830;E-mail: ming_csu@yahoo.cn

(编辑 陈爱华)