文章编号:1004-0609(2009)06-1074-06

工艺条件对气雾化制备SnAgCu合金粉末特性的影响

刘文胜,彭 芬,马运柱,崔 鹏,陈仕奇,刘有长

(中南大学 粉末冶金国家重点实验室,长沙 410083)

摘 要:采用紧耦合气雾化法制备SnAgCu无铅焊料合金粉末,研究雾化压力和熔体过热度对粉末粒径和形貌的影响。采用干筛筛分法对所制备的粉末进行分级,采用激光粒度分析仪和扫描电镜分别对粉末的粒径、形貌和微观组织进行表征。结果表明:当雾化压力为0.7 MPa、熔体过热度为20~30 ℃时,制备的无铅焊料合金粉末中值粒径为40.10 ?m,颗粒表面光洁、球形度高;当过热度为20~30 ℃、雾化压力由0.7 MPa增大至2.5~3.0 MPa时,粉末中值粒径由40.10 ?m减小至32.22 ?m,颗粒表面缺陷明显增多;当雾化压力为0.7 MPa、熔体过热度由30 ℃提高至50 ℃时,粉末粒径仅略微减小,但球形度明显降低;气雾化快速冷凝产生富Ag和Cu相,且富Ag和Cu相弥散分布在Sn基体内。

关键词:SnAgCu;合金粉末;无铅;气雾化

中图分类号:TF 123. 1 文献标识码: A

Effect of procedure conditions on characteristics of SnAgCu alloyed powder prepared by gas atomization

LIU Wen-sheng, PENG Fen, MA Yun-zhu, CUI Peng, CHEN Shi-qi, LIU You-chang

(State Key Laboratory of Powder Metallurgy, Central South University, Changsha 410083, China)

Abstract:SnAgCu lead-free solder powders were prepared by close-coupled gas atomization. The effects of gas atomization pressure and melt superheat on the powder size and morphologies were investigated. Dry sieving was used to classify the alloyed powder. Laser light diffractometry and scanning electricity microscopy were used to characterize the size and morphologies of the powder. The results indicate that when the gas atomization pressure is 0.7 MPa and the melt superheat is 20?30 ℃, the alloyed powder with mass medium diameter of 40.10 ?m is obtained, which is satellite-free and high sphericity. When the superheat is 20?30 ℃, with the gas atomization pressure increasing from 0.7 MPa to 2.5?3.0 MPa, the powder size decreases from 40.10 ?m to 32.22 ?m whereas the surface defective of the powder increases obviously. When the gas atomization pressure is 0.7 MPa, with the melt superheat increasing from 30 ℃ to 50 ℃, the powder size decreases a little but the sphericity of the powder becomes worse. Rich Ag and Cu phase forms during quick cooling of gas atomization, disperses well in the Sn-matrix.

Key words: SnAgCu; alloyed powder; lead-free; gas atomization

无铅化是表面组装技术用焊料的发展趋势。目前,无铅焊料的研究主要集中在中温段合金体系,如Sn-Cu、Sn-Ag和Sn-Zn等二元系合金,Sn-Ag-Cu[1]、Sn-Ag-Bi和Sn-Zn-Bi等三元合金。Sn-Ag-Cu系焊料能在降低Sn-Ag合金熔点的同时保持良好的焊接性能,并能减少所焊材料中铜的溶蚀[2],逐渐成为无铅焊料研究的热点。

目前,制备无铅焊料合金粉末的主要方法有超声雾化、离心雾化和气雾化法,其中采用气雾化法所获得的粉末具有粒径细小、球形度高和氧含量低等特点[3?4],具备规模化生产的能力。国内部分研究者采用气雾化法制备无铅焊料合金粉末[5?6],所获得的粉末粒度细小,但形貌不理想。新型的紧耦合气雾化技术提高了能量传输效率,所获得的粉末具有粒度更细,分布更窄和球形度更高等优异性能[7]。本文作者采用紧耦合气雾化法制备SnAgCu无铅焊料合金粉末,并分别研究雾化压力和熔体过热度对粉末特性的影响。

1 实 验

实验采用银粉、铜粉和锡锭等为原材料,其纯度均达到99.95%。按照w(Sn)?w(Ag)? w(Cu)=96.5:3.0:0.5配比在ZGJL?0.01?50?4型真空中频感应熔炼炉中制备SnAgCu母合金。然后以高纯氮气作为雾化气体,将母合金在PSI HERMIGA Gas Atomisers紧耦合气雾化设备中雾化制备SnAgCu无铅焊料合金粉末。

采用JEOL?6360LV扫描电子显微镜检测粉末表面形貌和截面微观组织形态,采用EDX分析系统对粉末的组分进行测试,采用MICRO?PLUS激光粒度分析仪(BSM)对粉末的粒度进行表征,并用干筛筛分法对所制备的合金粉末进行分级。

2 结果与分析

2.1 雾化压力和熔体过热度对粉末粒径的影响

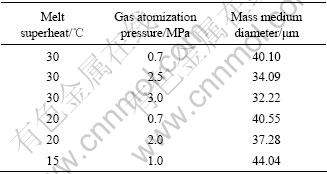

表1所列为不同过热度和雾化气体压力条件下所获得的粉末中值粒径检测结果。从表1可以看出,在30 ℃的熔体过热度条件下,粉末中值粒径随雾化压力的增大而降低,粉末中值粒径由0.7 MPa时的40.10μm减小为3.0 MPa时的32.22 μm。而20 ℃熔体过热度条件下,粉末中值粒径也表现了相似的变化规律。这是因为雾化压力通过影响雾化气体出口速度和气体质量流率等来影响雾化过程,从而影响制备的粉末粒径。UNAL等[8]认为典型的雾化过程可以归纳为两步破碎过程:金属液流与雾化气体在喷嘴边缘相遇并发生强烈的动量和热量交换,熔体发生破碎,形成一系列的大液滴,这是初次雾化过程,该过程中雾化压力越大,气流速度与动能越大,气流与液流相互作用越强烈,所形成的流场紊乱度越高,破碎进行得越充分,初次雾化得到的液滴就越小;初次雾化得到的金属液滴受气流作用被加速,在加速过程中,作用在液滴上的气动力与表面张力的平衡受到破坏,液滴将进一步破碎,即经历二次雾化[9]。雾化压力越大,雾化气流的速度越大,气流与金属液流的相对速度越大,由于速度差而引起的二次雾化过程进行得越充分,从 而得到更多更细的粉末颗粒。因而雾化压力增大, 雾化破碎过程进行得更充分,所获得的粉末中值粒 径减小。

表1 不同工艺条件所制得的粉末激光粒度检测结果

Table 1 Results of powder sizes by BSM under different process conditions

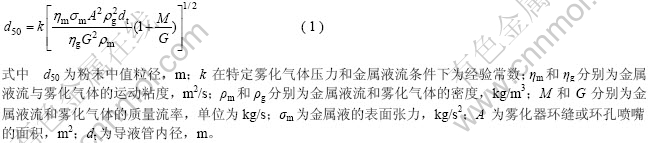

图1所示为雾化压力为0.7 MPa时不同熔体过热度下所得粉末筛分分级结果。由图1可见,过热度分别为20和30 ℃时,所得筛分粉末各粒度级质量分数相差不大;当过热度增大到50 ℃时,筛分粉末的中细颗粒比例明显增多,说明适当提高过热度可降低所得粉末粒径。这是因为过热度的提高使得金属液流粘度和表面张力下降,金属液流更容易发生形变和破碎。在雾化气流剪切应力作用下,粘度小的流体容易被破碎,有利于粉末粒径的减小。金属液流破碎过程是体系表面积增大的过程。表面张力小的液流发生破碎时,环境需要对液流所做的表面功减小。因此,液流表面张力的下降有利于破碎。LUBASKA[10]研究了表面张力等影响粉末粒径的因素,得到了如下经验公式:

由式(1)可见,金属液流的表面张力和粘度越小,所获得的粉末中值粒径越小。此外,熔体过热度的提高将使得金属液冷却凝固时间延长,液流发生形变破碎的时间相应延长,这也有利于破碎过程。

图1 雾化压力0.7 MPa时不同熔体过热度获得的粉末粒度分布

Fig.1 Distribution of powder sizes by sieving at gas atomization pressure of 0.7 MPa and different melt superheats

由表1还可以看出,当雾化压力为0.7 MPa、 熔体过热度为30 ℃时,所获得粉末的中值粒径(40.10 μm)比雾化压力为1.0 MPa而熔体过热度为15 ℃所获得的(44.04 μm)小。即使采用更高的雾化压力,过低的熔体过热度所获得的粉末粒径也较大,因此,过低的熔体过热度不利于得到细粉。但过高的熔体过热度也不利于制备细粒粉末,还将造成能源浪费和设备 损耗。

因此,适当提高熔体过热度,将降低金属液流的表面张力和粘度,使得发生破碎的时间延长,有利于雾化破碎,从而获得的粉末粒径更小。

2.2 熔体过热度和雾化压力对粉末形貌的影响

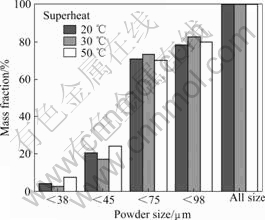

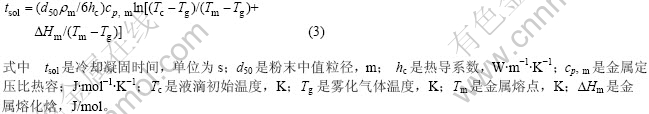

图2所示为不同熔体过热度所制备粉末的SEM像。由图2可知,过热度50 ℃时,粉末球形度较差,部分颗粒呈近球形和水滴状,卫星颗粒很多(见图2(a));过热度为20和30 ℃时所获得的粉末颗粒球形度较好,表面光洁(见图2(b)和(c))。过热度为15 ℃时所得粉末颗粒表面光洁,球形度较好,但存在长条和哑铃形粉末颗粒(见如图2(d))。

图2 不同熔体过热度时制得粉末的SEM像

Fig.2 SEM images of powders prepared at different melt superheats and gas atomization pressures: (a) Melt superheat 50 ℃, gas pressure 0.7 MPa; (b) Melt superheat 30 ℃, gas pressure 0.7 MPa; (c) Melt superheat 20 ℃, gas pressure 0.7 MPa; (d) Melt superheat 15 ℃, gas pressure 1.0 MPa

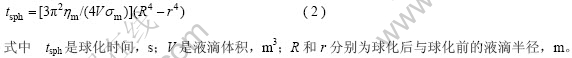

气雾化时,金属液流破碎后形成的液滴会在随后的飞行过程中冷却凝固成颗粒。颗粒形貌即由其冷却凝固过程中的形变决定。液滴受表面张力的作用会发生球化,受重力和气流冲刷作用将发生不规则形变,液滴之间相互作用则产生粘接和焊接等现象。在液滴冷却凝固过程中,球化作用能否充分进行将决定最终粉末球形度。金属液滴球化是粘度和表面张力综合作用的结果,其所需时间为[11?12]

金属液滴冷却凝固的时间与雾化液滴初始温度、冷却速率有关,可表示为[13]

当tsph<tsol时,凝固时间较长,一方面,球形金属液滴冷却凝固前发生相互碰撞的几率增大,产生卫星球的机会增多,同时受到气流的冲刷、重力作用等外界因素影响而发生形变的可能性也增大;另一方面,金属液滴温度升高,粘度和表面张力随之减小,粘度小的液滴易受气流冲刷、重力作用等外界因素影响而发生形变,表面张力的减小又弱化了液滴的球化作用。这将对粉末颗粒的球形度和表面产生不利影响。

当tsph≈tsol时,金属液滴能在冷却凝固的同时发生充分球化,形成球形度高的粉末。如果不与未凝固颗粒碰撞,凝固后的球形粉末的飞行过程能保持其光洁表面和高的球形度。

当tsph>tsol时,金属液滴在发生充分球化前就已经凝固,破碎产生的不规则液滴形成了椭球和近球形的粉末颗粒。

由此可见,合适的熔体过热度对于得到球形度高的粉末非常重要。 熔体过热度20 ℃和30 ℃时制备的雾化粉末球形度高,表面光洁。而相对于过热度50 ℃而言,某些金属液滴在发生球化同时也受其他因素的影响而略有变形,粉末中存在近球形和水滴状的大颗粒,同时未凝固颗粒发生碰撞的机会增大而形成卫星颗粒。过低的过热度(15 ℃),液滴凝固时间很短,某些液滴在发生充分球化甚至破碎前就已经凝固,因此,在粉末中存在长条和哑铃形粉末颗粒。

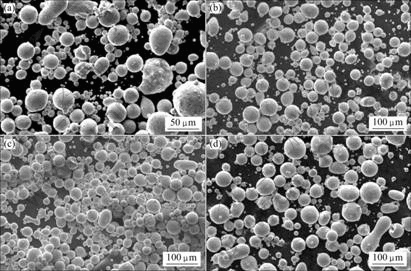

图3所示为熔体过热度20和30 ℃的条件下不同雾化气体压力时所获得粉末的SEM像。由图3可见,粉末基本为球形,但是表面粘附了大量的卫星粉末。比较图3(a)、(b)和图2(c)、(b)可以看出,在20 ℃过热度条件下,雾化压力从0.7 MPa增大到2.0 MPa后,粉末形貌变差,卫星粉末数量增多;在过热度30 ℃条件下,雾化压力从0.7 MPa增大到2.5 MPa后,粉末形貌有相似的变化规律。这是因为不同尺寸的金属液滴在雾化破碎后的飞行过程中冷凝状态不同、加速度也不同造成的。一方面,尺寸不同的颗粒冷却凝固速度不同,其中大颗粒凝固速度慢,小颗粒凝固速度快,因而大小颗粒的凝固状态存在差别。另一方面,大颗粒加速慢,小颗粒加速快,大小颗粒的飞行速度也不同,从而大小颗粒之间的碰撞在空间上成为可能。这些凝固状态不同的颗粒由于飞行速度的差异而发生碰撞,形成了不同的粉末形貌。如凝固的小颗粒与未凝固的大颗粒碰撞,两颗粒可能形成包裹、部分包裹、焊接和粘附等形态[14]。颗粒粒径差别越大,其速度差越大,凝固状态的差别也越大,因此,越有可能发生碰撞,从而在大颗粒表面粘附了大量的卫星粉末。雾化压力越大,气流速率越大,气流与金属液滴的相互作用越强烈,引起不同颗粒间的速度和凝固状态差别越大,使得金属液滴发生碰撞的可能性增大,卫星粉末大大增加。 OZBILEN[15]关于气体压力对粉末形状的影响研究也发现,较高雾化压力时获得的镁粉形貌 更差。

图3 增大雾化压力所制得粉末的SEM像

Fig.3 SEM images of powders with larger gas pressures: (a) 20 ℃ melt superheat, 2.0 MPa gas pressure; (b) 30℃ melt superheat, 2.5 MPa gas pressure

2.3 气雾化SnAgCu合金粉末微观组织特性

2.3 气雾化SnAgCu合金粉末微观组织特性

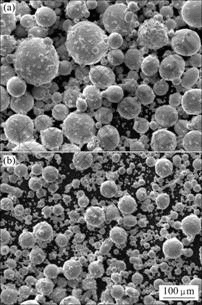

图4所示为雾化压力为2.0 MPa、熔体过热度为20 ℃时获得的合金粉末横截面的SEM像及EDX分析结果。由图4可知,粉末内部致密,组织分布较均匀,灰色基体上弥散分布着亮白的颗粒。亮白A处的EDX分析表明,其中Ag和Cu元素的含量相对合金(w(Sn)?w(Ag)?w(Cu)=96.5?3.0?0.5)配比明显偏高,因此,可以认为亮白处的弥散颗粒为富Ag和Cu相,灰色为Sn基体。富Ag和Cu相的弥散分布与气雾化快速冷凝过程密切相关。

图4 合金粉末横截面的SEM像及EDX分析结果

Fig.4 SEM image and EDX analysis results of transversal section in alloyed powders

3 结 论

1) 在熔体过热度为20~30 ℃、雾化压力为0.7 MPa条件下可获得中值粒径为40.10 ?m、表面光洁、球形度高的无铅焊料合金粉末。

2) 当熔体过热度为20~30 ℃,随雾化压力由0.7 MPa增加到3.0 MPa,粉末中值粒径由40.10 ?m减小至32.22 ?m,但卫星粉末大大增加。此外,在适当的雾化压力下,熔体过热度的提高,粉末中值粒径有所减小,但粉末球形度显著降低。

3) 气雾化制备的SnAgCu无铅焊料合金粉末中形成了微细富Ag和Cu相,且微细富Ag和Cu相弥散分布在Sn基体内。

REFERENCES

[1] 李晓延, 杨晓华, 吴本生, 严永长. SnAg及SnAgCu无铅焊料接头中金属间化合物在时效中的演变[J]. 中南大学学报(自然科学版), 2007, 38(1): 30?35.

LI Xiao-yan, YANG Xiao-hua, WU Ben-sheng, YAN Yong-chang. Evolution of intermetallic compounds in SnAg and SnAgCu lead-free solder joints during aging[J]. Journal of Central South University: Science and Technology, 2007, 38(1): 30?35.

[2] SUGANUMA K. 无铅焊接技术[M]. 宁晓山, 译. 北京: 科学出版社, 2004.

SUGANUMA K. Soldering technology of lead-free[M]. NING Xiao-shan, transl. Beijing: Science Press, 2004.

[3] BUCKLEY J. ASL improves atomization of solder powders[J]. Metal Powder Report, 1995, 50(2): 14.

[4] LAWLEY A. Encyclopedia of materials: Science and technology (Atomization part)[M]. Amsterdam: Elsevier, 2008: 387?392.

[5] 许天昊, 赵麦群, 邸小波, 李 涛, 刘 阳, 张文韬. 过热度对无铅焊锡雾化粉末特性的影响[J]. .材料导报, 2005, 19(4): 128?130.

XU Tian-hao, ZHAO Mai-qun, DI Xiao-bo, LI Tao, LIU Yang, ZHANG Wen-tao. Influences of superheat of alloy on the properties of free-lead solder power of SnAgCu system[J]. Materials Review, 2005, 19(4): 128?130.

[6] 赵麦群, 赵高扬, 于喜良, 袁晓宇. 无铅焊锡粉末超音速雾化技术的研究[J]. 粉末冶金技术, 2003, 21(2): 96?98.

ZHAO Mai-qun, ZHAO Gao-yang, YU Xi-liang, YUAN Xiao-yu. The study on supersonic atomization for making Pb-free solder powder[J]. Powder Metallurgy Technology, 2003, 21(2): 96?98.

[7] 欧阳鸿武, 陈 欣, 余文焘, 黄伯云. 气雾化制粉技术发展历程及展望[J]. 粉末冶金技术, 2007, 25(1): 53?59.

OUYANG Hong-wu, CHEN Xin, YU Wen-tao, HUANG Bai-yun. Progress and prospect on the gas atomization[J]. Powder Metallurgy Technology, 2007, 25(1): 53?59.

[8] UNAL A. Effect of processing variables on particle size in gas atomization of rapidly solidified aluminium powders[J]. Materials and Technology, 1987, 3(12): 1029?1039.

[9] 李清泉. 紧密耦合气体雾化制粉原理[J]. 粉末冶金工业, 1999, 9(5): 3?17.

LI Qing-quan. The principle of powder production by the close-coupled gas atomization[J]. Powder Metallurgy Industry, 1999, 9(5): 3?17.

[10] LUBANSKA H. Correlation of spray ring data for gas atomization of liquid metals[J]. Journal of Metals, 1970, 22(2): 45?49.

[11] RAO P. Shape and other properties of gas atomized metal powders[D]. Phildelphia: Drexel University, 1973.

[12] RAO P, TALLMADGE J A. Change of shape of metal droplets in quench atomization[C]// Proceeding of 1971 Fall Powder Metallurgy Conference Metal Powder Industries Federation, New York, 1972: 251?266.

[13] SEE J B, JOHNSTON G H. Interactions between nitrogen jets and liquid lead and tin streams[J]. Powder Technology, 1978, 21: 119?133.

[14] DUNKLEY J. Collisions in space[J]. Metal Powder Report, 2002, 57(11): 20?22.

[15] OZBILEN S. Influence of atomizing gas pressure on particle shape of Al and Mg powders[J]. Powder Technology, 1999, 102(2): 109?119.

基金项目:国家军工配套资助项目(JPPT-115-2-1057)

收稿日期:2008-07-08;修订日期:2008-12-16

通讯作者:刘文胜,副教授,博士;电话:0731-8877825;E-mail: liuwensheng@mail.csu.edu.cn

(编辑 龙怀中)