文章编号:1004-0609(2014)10-2452-08

2A14铝合金挤压棒材的热处理工艺

孙进宝,王旭东,王胜强,张显峰,陆 政,冯朝辉

(中航工业集团公司 北京航空材料研究院,北京 100095)

摘 要:采用显微硬度测试、电导率测试、拉伸力学性能测试以及透射电镜观察,研究时效温度和时效时间对2A14大规格铝合金棒材力学性能和电导率的影响规律。结果表明:在相同的时效时间下,合金电导率随时效温度升高而逐渐升高;在相同的时效温度下,合金电导率随时效时间的延长而逐渐升高。固溶态2A14合金中存在与Al6Mn晶体结构相近的Al12(MnCu)3Si2粒子,此Al12(MnCu)3Si2粒子在合金再结晶过程中影响晶界迁移,抑制晶粒在固溶过程中的长大效应;时效后,合金中主要的强化相为S'相,但在140 ℃(或低于400 ℃)时效12 h的合金中,强化相数量较少,合金性能与固溶态接近;经160 ℃、12 h时效后,合金具有较好的综合力学性能,其抗拉强度和屈服强度分别为509 MPa和452 MPa,伸长率为10.1%;在180 ℃、12 h时效条件下处理后,合金中的S'相会明显粗化,屈服强度和抗拉强度大幅下降,伸长率升高,表现出明显的过时效特征。

关键词:2A14铝合金;力学性能:电导率;显微组织

中图分类号:TG 146.2;TG 146.4 文献标志码:A

Heat treatment technology of 2A14 alloy extruded bar

SUN Jin-bao, WANG Xu-dong, WANG Sheng-qiang, ZHANG Xian-feng, LU Zheng, FENG Zhao-hui

(AVIC Beijing Institute of Aeronautical Materials, Beijing 100095, China)

Abstract: The effects of aging temperature and aging time on the mechanical properties and electrical conductivity of 2A14 aluminum alloy were investigated by microhardness test, electrical conductivity test, tensile test and transmission electron microscopy (TEM). The results show that the electrical conductivity of the sample increases gradually with increasing temperature or aging time when the aging time or aging temperature are constant. The Al12(MnCu)3Si2 particles found in the solid solution 2A14 alloy has a similar crystal structure with Al6Mn, the Al12(MnCu)3Si2 particles affect the migration of grain boundary during recrystalline process and restrain the grain growth during solid solution. For the 2A14 alloy, the S' phase is the mainly strengthening precipitates. However, for the sample aged at 140 ℃ (or lower than 140 ℃) for 12 h, the mechanical properties are close to the sample in solution-treated condition due to less strengthening phase. After aging at 160 ℃ for 12 h, the alloy shows better combination mechanical properties, the ultimate tensile strength (UTS), yield strength (YS) and elongation are 509 MPa, 452 MPa and 10.1%, respectively. After aging at 180 ℃ for 12 h, with the increase of aging temperature and extension of aging time, the precipitate size of S' phase increases and the mechanical properties decrease obviously, which is a typical phenomena of over aging.

Key words: 2A14 alloy; mechanical property; electrical conductivity; microstructure

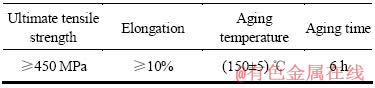

Al-Cu-Mg系铝合金是典型的时效强化合金,采用合适的固溶和时效处理可使该系铝合金具有较高的强度和良好的耐热性能,因此,被作为重要的结构材料,广泛应用于航空航天等领域[1-2]。2A14铝合金是典型的Al-Cu-Mg系合金[3-4],具有强度高、热塑性好、工作温度高等优点,属于锻造合金,也被称为高强度锻铝。2A14铝合金在航天领域主要用于制备形状复杂的自由锻件和精密模锻件,而航天部门锻件生产所用原材料均为挤压棒材。近年来,随着国家航天事业的发展,大规格挤压棒材(d≥300 mm),尤其对于高性能d 350 mm的挤压棒材(σb≥470MPa、δ≥8%)的需求越来越迫切。但目前2A14铝合金棒材仍然执行GB/T 3191—1998标准,而该标准只适用于d 150 mm以下挤压棒材,对于直径大于300 mm的大规格2A14铝合金棒材尚没有国家或行业热处理工艺执行标准和验收标准。现行工艺制度及标准技术指标见表1,该尺寸棒材已无法满足航天部门的需求[5]。

本文作者基于航天领域对高性能d 350 mm挤压棒材的需求,结合北京航空材料研究院铝镁合金及其工艺研究室对d 300 mm以上大规格2A14铝合金棒材的多年研究和生产经验,旨在通过热处理试验,测试并分析不同工艺制度下棒材的组织、电导率及力学性能,优化出最佳的热处理工艺,以指导大规格棒材2A14铝合金的生产。

表1 直径为22~150 mm T6-2A14铝合金现行技术标准及工艺制度

Table 1 Present technical standard and process system of T6-2A14 alloy with diameter of 22-150 mm

1 实验

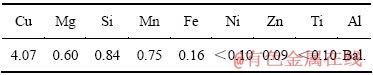

本试验所用d 350 mm挤压棒材,采用d 580 mm半连续铸造铸棒,经1.5万t挤压机挤压制备。本试验所用2A14铝合金材料的化学成分如表2所列。

表2 实验材料的化学成分

Table 2 Chemical composition of alloy (mass fraction, %)

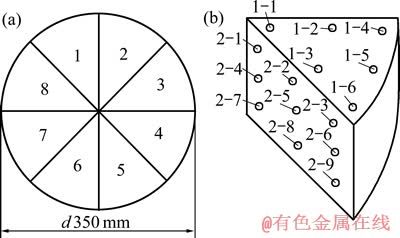

沿d 350 mm的2A14合金挤压棒材的中部切取厚度为400 mm的两块材料进行固溶处理,每块材料再分割成8块,共获得坯料16块,任选11块进行试验,试样取样方式如图1所示。

图1 试样取样部位和电导率测试位置

Fig. 1 Sampling position of artificial ageing(a) and testing position of electrical conductivity(b) of samples

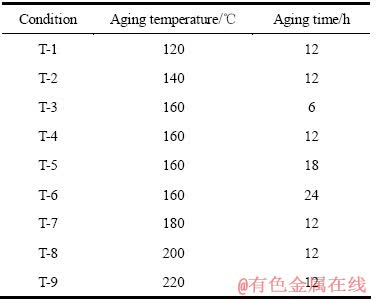

本实验中试验代号H112表示棒材为热加工态;SS表示试样处于固溶处理态;试样经503℃固溶保温3h后水淬,然后进行不同温度、时间的时效处理(T1~9为时效态),具体时效处理制度如表3所列。

表3 试样的时效制度

Table 3 Aging scheme of samples

拉伸和硬度测试试样的取样位置为沿棒材半径方向的1/2处,拉伸试验在WDW-100 kN试验机上进行,每个样品力学性能取3次拉伸的平均值,硬度采用HB-3000B-I布氏硬度计测量,每个试样打5个点,取其平均值。电导率的测试点如图1(b)所示,电导率测试在SIGMASCOPE SMP10型电导仪上进行。采用JEM-2010型透射电子显微镜(TEM)对合金不同时效状态下的微观组织进行分析,加速电压为200 kV。TEM试样经机械减薄至50 mm后,在25%硝酸+75%甲醇(质量分数)的电解液中进行双喷电解减薄,双喷液的温度控制在-20~30 ℃。

2 结果与分析

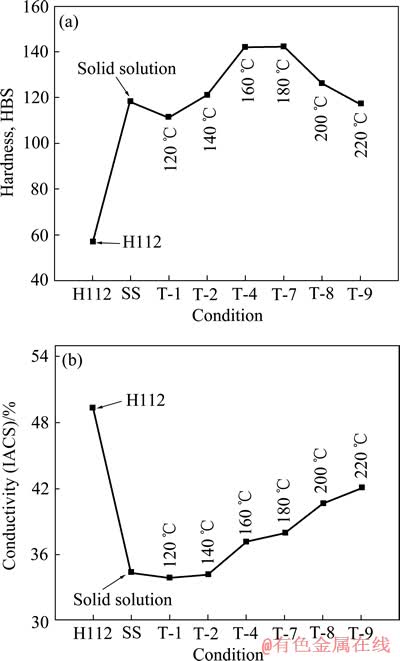

2.1 硬度和电导率

2A14铝合金在不同时效温度条件下经12 h时效时后的硬度变化曲线如图2(a)所示。由图2(a)可以看出,固溶后合金的硬度相比于H112状态合金有较大幅度的提高,达到118HBS。合金经120 ℃保温12 h时效后,硬度略有降低,为111HBS。在保温12 h的时效条件下,随着时效温度的升高,合金硬度先升高后降低,在160 ℃和180 ℃之间达到最高值;当时效温度大于180 ℃时,随着时效温度升高,合金硬度缓慢降低;当时态温度达到220 ℃时,合金硬度为117HBS,略低于固溶态合金的硬度。

图2 2A14铝合金在不同温度经12 h时效后的硬化曲线和电导率曲线

Fig. 2 Hardness (a) and electrical conductivity(b) curves of 2A14 aluminum alloys at different temperatures for 12 h

2A14铝合金在不同的时效温度条件下经12 h时效时后的电导率变化曲线如图2(b)所示。由图2(b)可以看出,与硬度变化相反,固溶后合金的电导率相比H112状态合金的有较大幅度的降低。合金在120~140 ℃保温12 h时效后,电导率变化不大,且相比与固溶态合金略有降低。当时效温度大于140 ℃,在同样的保温时间下(12 h),随着时效温度升高,合金电导率逐渐升高。

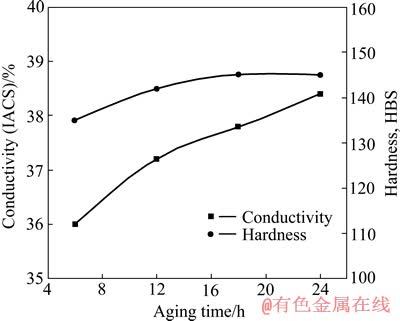

在160 ℃下进行时效,合金硬度和电导率随时效时间变化曲线如图3所示。对比图2和3可以看出,与温度对合金的硬度和电导率影响规律不同,在160 ℃时,经不同时效时间处理的合金均具有明显的时效硬化行为,且随着时效时间增加,显微硬度逐渐增大,在18 h达到最大值146HBS;当硬度达到最大值后,继续延长时效时间,合金进入过时效,硬度逐渐降低,但降幅较为缓慢。且随着时效时间延长,合金电导率迅速升高,在时效初期,合金电导率增长较快接近0.002 h-1,在时效12 h后,合金电导率上升趋势减慢,增速接近0.001 h-1。

图3 2A14合金经160 ℃时效后硬度和电导率与时效时间的关系

Fig. 3 Relationships among hardness and electrical conductivity of 2A14 alloys and aging time after aging at 160 ℃

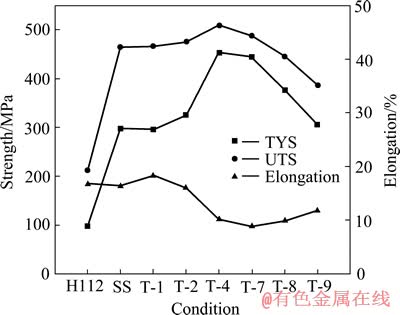

2.2 力学性能

在时效时间相同时(12 h),合金经不同时效温度时效后的抗拉强度(UTS)、屈服强度(TYS)和伸长率的变化曲线如图4所示。由图4可以看出,H112状态的合金经固溶处理后抗拉强度和屈服强度快速升高至465 MPa和297 MPa,伸长率基本保持不变;当时效12 h时,随着时效温度的升高,合金的抗拉强和屈服强度呈现先升高后降低的趋势;伸长率则是先升高后降低,之后又升高。与固溶态相比,合金在120 ℃时效,其抗拉和屈服强度基本没有变化;经过140 ℃时效后,合金的抗拉和屈服强度开始缓慢升高;在160 ℃达到了最高值,分别为509 MPa和452 MPa;当温度大于160 ℃,随着温度升高,合金的抗拉强度和屈服强度缓慢降低;到220 ℃时效时,合金的抗拉和屈服强度降低至386和305 MPa,与160 ℃相比,分别降低了24%和33%。经120 ℃时效合金的伸长率达到最高值为18.3%;经180 ℃时效后,合金的伸长率最低为8.8%,与最高值相比降低52%;当时效温度大于180 ℃,随着时效温度的升高,合金的伸长率缓慢增加;经220 ℃时效后,合金的伸长率为11.7%。

图4 合金在不同状态下的力学性能

Fig. 4 Mechanical properties of alloy under different aging temperatures

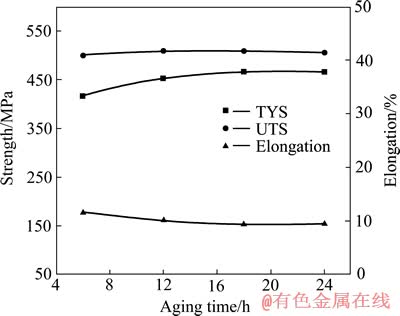

在160 ℃时效时,经过不同时效时间处理的合金抗拉强度、屈服强度和伸长率的变化曲线如图5所示。由图5可以看出,在6~24 h范围内,随着时效时间延长,合金的抗拉强度缓慢升高后降低,在12 h时达到最高值,但是整体变化幅度不大,抗拉强度均高于500 MPa;合金屈服强度在6~12 h内呈快速上升趋势, 12 h后,增速放缓,18 h后,趋于稳定为465 MPa;伸长率缓慢降低,最小为9.5%。

图5 160 ℃时不同时效时间下试样的力学性能

Fig. 5 Mechanical properties of alloys aging at 160 ℃ for different times

2.3 TEM组织

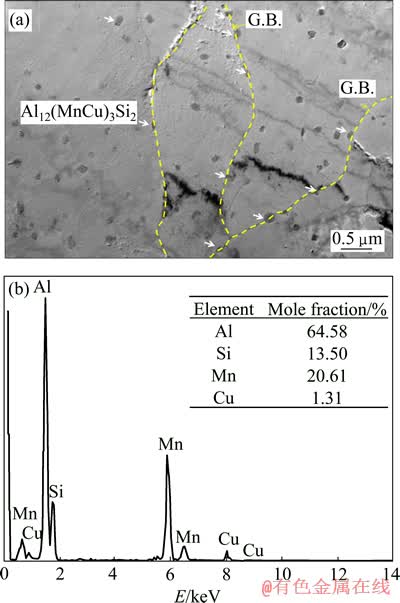

图6(a)所示为合金固溶处理后基体和晶界析出相的TEM明场形貌像。由图6(a)仔细观察可以发现,虽然2A14合金中并没有添加Zr元素,没有Al3Zr质点作为抑制再结晶相,但是在固溶处理后,合金的晶内和晶界上仍然分布大量尺寸200 nm左右的析出相。在透射电镜观察条件下,这些200 nm左右析出相进行能谱分析(EDS),其典型能谱分析结果如图6(b)所示,多个位置测量结果及平均值如表4所列。由表4可看出,该相由Al、Si、(Mn/Cu)按摩尔比为12:2:3组成,与文献[6]报道的Al12(MnCu)3Si2相成分很接近。Al12(MnCu)3Si2相与Al6Mn相结构相似,其a=0.6506 nm,b=0.7501 nm,c=0.8800 nm。RIOS等[7]在Al-1%Mn (质量分数)合金中研究发现Al6Mn粒子对于晶界迁移有钉轧作用,从图6(a)可以看到,很多Al12(MnCu)3Si2粒子位于晶界处且对晶界迁移产生了一定的影响,对晶界迁移起到了钉轧作用,因此,在适当的晶体学条件下,Al12(MnCu)3Si2粒子也可以在再结晶过程中抑制基体晶粒长大。

图6 固溶态试样的TEM像

Fig. 6 TEM image of solution-treated sample

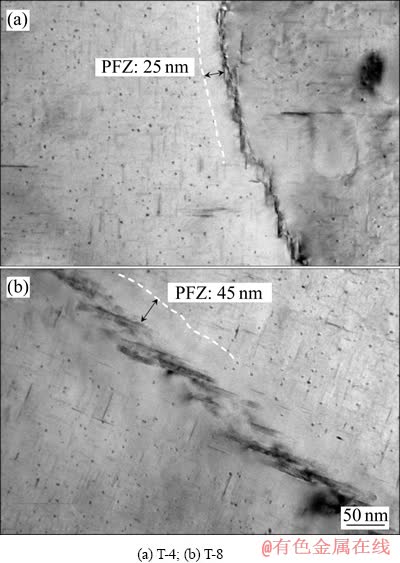

表4 Al12(MnCu)3Si2粒子能谱分析结果

Table 4 EDS result of Al12(MnCu)3Si2 particles

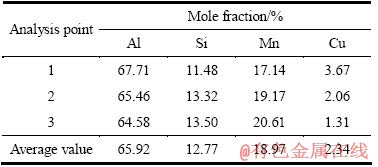

根据Al-Cu-Mg三元系富铝角相图及其他学者研究[8-9],当Al-Cu-Mg合金中Cu和Mg质量比(m(Cu)/m(Mg))大于8时,合金的主要强化相为θ′相;当m(Cu)/m(Mg)介于4到8之间,θ′相和S′相同时为强化相;当m(Cu)/m(Mg)为1.5~4时,强化相主要为S'相[10-11]。TEM微观组织表明:2A14合金中存在Ω和S′,其中S′相为主要强化相,Ω相成分与θ相相同是θ相在{111}Al面的变体。且相对于时效时间而言,时效温度对S'相形貌和尺寸的影响更大,因而,时效温度的调控范围比时效时间的调控范围窄[11-12]。同时,在对T-2合金进行观察时并未发现析出相,而其衍射斑点中只存在基体斑点,没有其他附加斑点的存在,这说明2A14铝合金在140 ℃时效12 h内没有θ相或S'相析出,或者析出相很少,以至透射电镜和衍射斑点均无法反应出这些析出相的信息。

图7所示为合金在160 ℃、12 h和200 ℃、12 h时效处理后[001]Al方向的TEM明场像及其衍射斑点。从图7(a)中可以观察到沿着[010]Al和[100]Al方向生长的针状析出相为S'相的特征斑点,尺寸小于50 nm。除了薄片状析出相S'相,在其电子衍射斑点[220]Al的1/3和2/3处以及[220]Al的1/3和2/3处也出现了附加Ω相的特征斑点,这4个衍射斑点代表了Ω相在{111}Al惯习面的4个等效面,但是在明场像上未见有明显的Ω相形貌。通过上述分析可知,2A14铝合金在160 ℃时效保温12 h时,合金中析出相为S'相和Ω相,而且S'相的数量明显多于Ω相的[13-14]。图7(b)所示为入射束方向为[001]Al的TEM像。从图7(b)中可以看到有针状的析出相,根据衍射斑点的特征,在(110)Al斑点周围的十字花形的衍射斑点是S'相的特征斑点,故图中垂直生长的针状析出相为S'相,其平均长度已达到约70 nm。

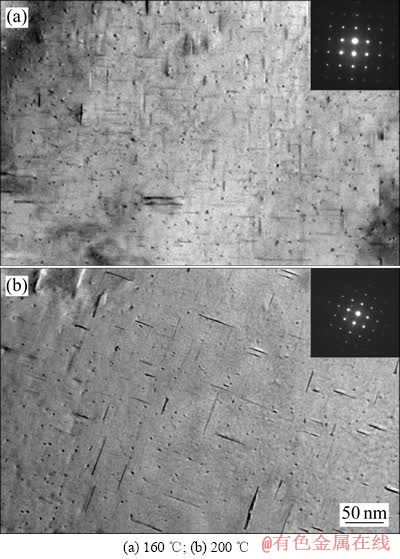

由于晶界处是合金中主要的缺陷位置,第二相析出所需的驱动力小[15-16],因而,第二相优先在晶界处析出,所以Al-Cu系合金具有晶界优先析出倾向[17]。图8所示为2A14铝合金经160 ℃和200 ℃时效12h后的TEM明场像。从图8可看出,保温12 h后,经160 ℃时效的合金的晶界无沉淀析出带(PFZ)的宽度大约为25 nm,晶界析出物尺寸约为30 nm×5 nm;而经200 ℃时效后,PFZ宽度大约为45 nm,且晶界析出物尺寸增大到约60 nm×10 nm。QUAN等[10]和韩 小磊等[14]研究表明,当时效温度高于150 ℃时,Al基体中的Cu元素在开始向晶界沉淀相扩散,且扩散系数随温度的升高而增大,因此,虽然两种样品中Cu元素向晶界沉淀相扩散的时间相同,但是提高温度将极大地增加Cu向晶界析出相的扩散量。因此,与低温时效相比,高温时效会使更多的溶质原子有足够的能量向晶界扩散,使得晶界析出相在时效过程中的粗化及不连续程度大大增加,同时增加了PFZ的宽度。这也说明,当合金在温度大于160 ℃状态下时效12 h后,合金处于过时效状态。

图7 相同保温时间不同时效温度2A14合金晶内析出相的TEM明像场

Fig. 7 Bright field TEM images and selected area diffraction spots of precipitates in grains of aged alloy after being held at different temperatures for 12 h

图8 2A14铝合金经160 ℃和200 ℃时效12 h后的TEM明场像

Fig. 8 Bright field TEM images of precipitates in matrix and grain boundary of 2A14 aluminum alloy after artificial heat treatment

3 讨论

已有研究表明[18],2A14铝合金作为一种高铜镁比的时效强化铝合金,析出相的尺寸决定了合金的最终性能,该合金的典型时效过程为:α过饱和固溶体→Cu-Mg原子团簇→S″相→S′相,α过饱和固溶体→Cu-Mg原子团簇→θ″相→θ′相→θ相。其中S'相是过渡相,经过长时间的时效会转变成S相,它与S相的成分相同,都是Al2CuMg,且晶体结构相同,二者之间只在晶格常数上有细微的区别。S'相呈针状或板条状,对于它的晶体结构目前还没有统一意见,有人认为,S'相和基体呈共格关系,晶格常数aS'=0.405 nm,bS'=0.906 nm,cS'=0.724 nm;另外一种说法则认为S'相与基体呈半共格关系,晶格常数为aS'=0.404 nm,bS'=0.925 nm,cS'=0.718 nm。但两种观点均表明本研究显示适当尺寸和分布的S'相对基体有很好强化作用。因为在Al基体中,Mg原子比Cu原子扩散时所需要能量低,且其与空位间的交互作用比Cu原子更强,所以在基体中将首先形成Mg-Mg原子的聚集区域,之后才会形成Cu-Cu及其Cu-Mg原子团簇。因此,对于m(Cu)/m(Mg)=6.78的2A14铝合金,θ′相和S′相在合金中的出现概率是接近的,时效条件是主要影响因素。

根据沉淀相的聚集长大公式[19]:

式中: 和

和 分别为沉淀相粒子在聚集前、后的平均半径;V为粒子中原子的平均体积;γ为沉淀相与基体间的界面张力;c为界面为平面时基体的平衡浓度;D为溶质在基体中扩散系数;T为温度;t为时间;M为常数。基于以上公式并结合合金固溶态和不同时效态的TEM组织可看出,在较低温度时效时,合金中析出相的形核数量较多,溶质扩散系数较低;而在较高时效时,合金中析出相的形核数量较少,但溶质扩散系数较高,因而在相同时效时间内,高温时效获得的析出相尺寸会明显大于较低温度时效的,从而合金硬度降低。由图3和5可见,合金时效到达峰值以后,随着时效时间的延长,合金的硬度降低。

分别为沉淀相粒子在聚集前、后的平均半径;V为粒子中原子的平均体积;γ为沉淀相与基体间的界面张力;c为界面为平面时基体的平衡浓度;D为溶质在基体中扩散系数;T为温度;t为时间;M为常数。基于以上公式并结合合金固溶态和不同时效态的TEM组织可看出,在较低温度时效时,合金中析出相的形核数量较多,溶质扩散系数较低;而在较高时效时,合金中析出相的形核数量较少,但溶质扩散系数较高,因而在相同时效时间内,高温时效获得的析出相尺寸会明显大于较低温度时效的,从而合金硬度降低。由图3和5可见,合金时效到达峰值以后,随着时效时间的延长,合金的硬度降低。

结合以上现象说明,2A14合金的电导率和硬度主要取决于两方面的因素:1) Cu原子在基体中的固溶程度;2) 合金中析出相的大小和弥散分布状况。从图2可以看到,H112状态的合金硬度最低,而电导率最高。这是因为在热加工过程中,合金元素主要以尺寸较大的金属间化合物存在,没有固溶强化和时效强化,所以合金硬度低,而这些金属间化合物同时对电子运动的阻碍较弱,因此,合金具有较高的电导率,可以达到49.3%。合金充分固溶后,硬度急剧升高而电导率急剧降低,这是因为固溶处理后铸态第二相中的Cu原子固溶到基体中后,引起基体晶格发生畸变,使位错的运动受到阻碍,增大了合金的硬度,同时,固溶体中晶格畸变程度变大,进而使得基体点阵电子散射源的数量和密度增大,阻碍了自由电子的运动,导致电导率大幅度降低[20-21]。

由图2和3可见,随着时效温度的升高和时效时间的延长,合金的电导率逐渐升高,这是由于溶质原子Cu随着时效的进行在基体中逐渐减少,固溶体中晶格畸变程度变小,进而使得基体点阵电子散射源的数量和密度减小,最终导致电导率升高。而电导率的增加速率与时效过程中Cu-Mg原子团簇和析出相对电子的散射能力有关[11]。当合金处于由Cu-Mg原子团簇开始大量向S″相和S'相转变过程时,电导率的增加相对比较缓慢,这是因为Cu-Mg原子团簇、S″相和S'相尺寸小分布广,且与基体保持共格和半共格关系,使周围基体晶格发生较大畸变,增加了对电子的散射,因此,合金电导率增长缓慢;而合金处于由S″相和S'相开始向S相转变时,由于电子运动自由程减小,增加了电子的散射,电子运动阻力增大,电导率增加速率变大;在时效后期,因析出相的粗化使析出相在合金中的体积分数增加,电导率减小,当两者达到平衡时,合金的电导率不再增加,基本保持稳定[22-23]。合金在120~140 ℃保温12 h后,电导率变化不大,正是因为低于140 ℃的合金在时效过程尚处于时效初级状态,刚好形成Cu-Mg原子团簇和少量S″相。当时效温度大于160 ℃后,同样保温12 h时,随着时效温度的升高,合金电导率逐渐升高。合金在160~220 ℃时效保温12 h后,电导率明显增大,因为此时合金处于由S″相和S'相开始向S相转变的峰值时效和过时效阶段。

4 结论

1) 经160 ℃、12 h时效的2A14铝合金具有较好的综合力学性,其抗拉强度和屈服强度分别达到509 MPa和452 MPa,伸长率为10.1%,合金主要强化相为S'相;当合金在低于160 ℃条件下时效时,对m(Cu)/m(Mg)=6.78的合金,其原子的扩散驱动力低,时效效果差;当合金在高于180 ℃条件下时效时,对m(Cu)/m(Mg)=6.78的合金,其原子的扩散驱动力增大,时效行为受时间影响明显,较短时间性能发生明显变化;当合金在160 ℃附近条件下时效时,合金在较宽时间范围内的抗拉强度、屈服强度、伸长率变化不明显,电导率变化明显适用于工业化生产和产品质量控制。

2) 固溶态合金中存在大量与Al6Mn粒子晶体结构相近的Al12(MnCu)3Si2粒子位于晶界处,并可有效钉扎对晶界,阻碍其运动,因此,在适当的晶体学条件下,Al12(MnCu)3Si2粒子也可以抑制再结晶过程中基体晶粒的长大。

REFERANCES

[1] CHEN J Z, ZHEN L Z, YANG S J, SHAO W Z, DAI S L. Investigation of precipitation behavior and related hardening in AA7055 aluminum alloy[J]. Materials Science and Engineering A, 2009, 500(1/2): 34-42.

[2] 王 涛, 尹志民. 高强变形铝合金的研究现状和发展趋势[J]. 稀有金属, 2006, 30(2): 197-202.

WANG Tao, YIN Zhi-min. Research status and development trend of ultra-high strength aluminum alloys[J]. Chinese Journal of Rare Metals, 2006, 30(2): 197-202.

[3] 李慧中, 梁霄鹏, 郭菲菲, 李 洲, 焦 岩, 张新明. 预时效温度对2519铝合金力学性能和电导率的影响[J]. 中国有色金属学报, 2009, 19(1): 21-25.

LI Hui-zhong, LIANG Xiao-peng, GUO Fei-fei, LI Zhou, JIAO Yan, ZHANG Xin-ming. Effect of pre-ageing temperature on mechanical properties and electrical conductivity of 2519 aluminum alloy[J]. The Chinese Journal of Nonferrous Metals, 2009, 19(1): 21-25.

[4] 熊柏青, 李锡武, 张永安, 李志辉, 朱宝宏, 王 锋, 刘红伟. 新型高强韧低淬火敏感性Al-7.5Zn-1.65Mg-1.4Cu-0.12Zr合金[J]. 中国有色金属学报, 2009, 19(9): 1539-1547.

XIONG Bai-qing, LI Xi-wu, ZHANG Yong-an, LI Zhi-hui, ZHU Bao-hong, WANG Feng, LIU Hong-wei. Novel Al-7.5Zn-1.65Mg-1.4Cu-0.12Zr alloys with high strength high toughness and low quench sensitivity[J]. The Chinese Journal of Nonferrous Metals, 2009, 19(9): 1539-1547.

[5] 王 丽. 2A14-T6铝合金大规格棒材时效制度的研究[J]. 轻金属, 2004(2): 50-52.

WANG Li. Study of age treatment system of 2A14-T6 large sized aluminum alloy bars[J]. Light Metals, 2004(2): 50-52.

[6] MENG X Y, DEREK O N. A TEM study of precipitates in an Al-Mn-Si alloy[J]. Metallography, 1998, 21(3): 293-315.

[7] RIOS P R, FONSECA G S. Grain boundary pinning by Al6Mn precipitates in an Al-1wt%Mn alloy[J]. Scripta Materialia, 2004, 50(1): 71-75.

[8] 刘志义, 李云涛, 刘延斌, 夏卿坤. Al-Cu-Mg-Ag合金析出相的研究进展[J]. 中国有色金属学报, 2007, 17(12): 1905-1915.

LIU Zhi-yi, LI Yun-tao, LIU Yan-bin, XIA Qing-kun. Development of Al-Cu-Mg-Ag alloys[J]. The Chinese Journal of Nonferrous Metals, 2007, 17(12): 1905-1915.

[9] VILLARS P, PRINCE A, OKAMOTO H. Handbook of ternary alloy phase diagrams[M]. Gloucester: ASM International, 1994: 295-297.

[10] QUAN Guo-zheng, WANG Feng-biao, LIU Ying-ying, SHI Yu, ZHOU Jie. Evaluation of varying ductile fracture criterion for 7075 aluminum alloy[J]. Transactions of Nonferrous Metals Society of China, 2013, 23(2): 749-755.

[11] 叶凌英, 吴懿萍, 贾寓真, 张新明, 吴高龙. 二次时效对2519A 铝合金组织与性能的影响[J]. 中国有色金属学报, 2014, 24(3): 624-630.

YE Ling-ying, WU Yi-ping, JIA Yu-zhen, ZHANG Xin-ming, WU Gao-long. Effects of secondary aging on microstructure and properties of 2519A aluminum alloy[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(3): 624-630.

[12] FENG Di, ZHANG Xin-ming, LIU Sheng-dan, WU Ze-zheng, TAN Qi. Rate controlling mechanisms in hot deformation of 7A55 aluminum alloy[J]. Transactions of Nonferrous Metals Society of China, 2014, 24(1): 28-35.

[13] MARLAUD T, MALKI B, HENON C, DESCHAMPS A, BAROUX B. Relationship between alloy composition, microstructure and exfoliation corrosion in Al-Zn-Mg-Cu alloys[J]. Corrosion Science, 2011, 53(10): 3139-3149.

[14] 韩小磊, 熊柏青, 张永安, 李志辉, 朱宝宏, 王 锋. 欠时效态7150 合金的高温回归时效行为[J]. 中国有色金属学报, 2011, 21(1): 80-87.

HAN Xiao-lei, XIONG Bai-qing, ZHANG Yong-an, LI Zhi-hui, ZHU Bao-hong, WANG Feng. High-temperature retrogression behavior of under-aged 7150 aluminum alloy[J]. The Chinese Journal of Nonferrous Metals, 2011, 21(1): 80-87.

[15] 李国峰, 张新明, 李鹏辉. 7055合金在回归加热过程中组织演变[J]. 稀有金属材料与工程, 2011, 40(7): 1295-1299.

LI Guo-feng, ZHANG Xin-ming, LI Peng-hui. Microstructure evolution rules for aluminum alloy 7050 during retrogression heating up[J]. Rare Metal Materials and Engineering, 2011, 40(7): 1295-1299.

[16] CINA B. Reducing the susceptility of alloys, particularly aluminium alloys, to stress cracking: USA, 3856584[P]. 1974-12-24.

[17] BAKAVOSA D, PRANGNELLA P B, BESB B, EBERL F. The effect of silver on microstructural evolution in two 2xxx series Al-alloys with a high Cu:Mg ratio during ageing to a T8 temper[J]. Materials Science and Engineering A, 2008, 491: 214-223.

[18] 胡赓祥, 钱苗根. 金属学[M]. 上海: 上海科学技术出版社, 1980.

HU Geng-xiang, QIAN Miao-geng. Metal science[M]. Shanghai: Shanghai Science and Technology Press, 1980.

[19] 张新明, 刘文军, 刘胜胆, 袁玉宝, 邓运来. 7050 铝合金的TTP曲线[J]. 中国有色金属学报, 2009, 19(5): 861-868.

ZHANG Xin-ming, LIU Wen-jun, LIU Sheng-dan, YUAN Yu-bao, DENG Yun-lai. TTP curve of aluminum alloy 7050[J]. The Chinese Journal of Nonferrous Metals, 2009, 19(5): 861-868.

[20]  N, GABLE B M, SHIFLET G J, STARKE E A. The effect of cold work on the precipitation of θ′ and Ω in a ternary Al-Cu-Mg alloy[J]. Metallurgical and Materials Transactions A, 2003, 34(12): 2757-2769.

N, GABLE B M, SHIFLET G J, STARKE E A. The effect of cold work on the precipitation of θ′ and Ω in a ternary Al-Cu-Mg alloy[J]. Metallurgical and Materials Transactions A, 2003, 34(12): 2757-2769.

[21] PARK J K, ARDELL A J. Effect of retrogression and reaging treatments on the microstructure of Al-7075-T651[J]. Metallurgical and Materials Transactions A, 1984, 15(8): 1531-1543.

[22] 刘胜胆, 张新明, 游江海, 黄振宝, 张 翀, 张小艳. 7055铝合金的TTP曲线及其应用[J]. 中国有色金属学报, 2006, 16(12): 2034-2039.

LIU Sheng-dan, ZHANG Xin-ming, YOU Jiang-hai, HUANG Zhen-bao, ZHANG Chong, ZHANG Xiao-yan. TTP curve of 7055 aluminum alloy and its application[J]. The Chinese Journal of Nonferrous Metals, 2006, 16(12): 2034-2039.

[23] LI Luo-xing, WANG Guan, LIU Jie, YAO Zai-qi. Flow softening behavior and microstructure evolution of Al-5Zn-2Mg aluminum alloy during dynamic recovery[J]. Transactions of Nonferrous Metals Society of China, 2014, 24(1): 42-48.

(编辑 李艳红)

收稿日期:2014-03-03;修订日期:2014-07-13

通信作者:孙进宝,工程师;电话:010-62497157;传真:010-62496407;E-mail: jinbao621@163.com