文章编号:1004-0609(2012)04-1075-07

锌合金高温变形行为及加工图

许晓庆,李德富,郭胜利,邬小萍,杜 鹏

(北京有色金属研究总院 有色金属加工事业部,北京 100088)

摘 要:在Gleeble-1500D热模拟机上采用等温压缩实验研究Zn-8Cu-0.3Ti锌合金的高温流变行为,获得锌合金在变形温度为230~380 ℃、应变速率为0.01~10 s-1和变形程度为50%条件下的真应力—应变曲线,根据动态材料模型(DMM)建立锌合金的热加工图。结果表明:Zn-8Cu-0.3Ti锌合金在实验条件下具有正的应变速率敏感性,流变应力随着应变速率的增大而增大,随着变形温度的升高而减小,该合金的流变应力行为可用Arrhenius方程来描述。在本研究条件下,Zn-8Cu-0.3Ti锌合金在热变形时存在一个失稳区,即应变速率0.2 s-1以上的区域;在应变速率小于0.001 s-1和340~370 ℃温度范围内,最大功率耗散系数为0.53,该安全区域内合金的变形机制为动态再结晶。

关键词:锌合金;流变应力模型;高温变形;加工图

中图分类号:TG146.1+3 文献标志码:A

High temperature deformation behavior and processing map of Zn-8Cu-0.3Ti Zn alloy

XU Xiao-qing, LI De-fu, GUO Sheng-li, WU Xiao-ping, DU Peng

(Nonferrous Processing Division, General Research Institute for Nonferrous Metals, Beijing 100088, China)

Abstract: The hot compression deformation of Zn-8Cu-0.3Ti alloy was performed on Gleeble-1500D at temperature of 230-380 ℃, strain rate of 0.01-10 s-1, height direction reduction of 50%. The true stress—strain curves under different deformation conditions were obtained and the processing map was developed based on the dynamic material modeling (DMM). The results indicate that the flow stress is sensitive to the strain rate and the deforming temperature. The flow stress increases with increasing the strain rate, and decreases with increasing the deforming temperature, which can be described by a constitutive equation in the form of Arrhenius function. The processing map shows one unsteady zone of high temperature deformation of Zn-8Cu-0.3Ti alloy, which is above strain rate of 0.2 s-1. At the temperature of 340-370 ℃ and below the strain rate of 0.001 s-1, the peak efficiency of power dissipation is 0.53, in which zone the deformation mechanism is dynamics recrystallization (DR).

Key words: zinc alloy; flow stress model; high temperature deformation; processing map

锌合金具有优异的耐磨性、良好的机械性能、低成本和易回收性,因此受到了国内外学者的普遍关注与研究[1]。锌合金被认为是铜合金的理想替代材料[2],且已经成功应用于日常装饰及汽车零部件等民用领 域[3]。锌铜钛是一种变形锌合金,从19世纪40年代起,欧美等国先后申请了一系列不同配比的锌铜钛合金的专利[4],成功应用于社会民生的各个领域。SHARMA和MARTIN[5]研究锌铜合金在200 ℃以下的抗蠕变行为,建立合金抗蠕变强度与铜含量的关系。LI等[6]研究锌铜合金定向凝固过程及其组织演变规律,为锌铜合金的铸造凝固提供了坚实的理论基础。B?Y?KA等[7]研究了铜含量对锌铜合金显微硬度和热物理性能的影响。然而,国内外的文献大多数是关于锌合金凝固过程中组织演变的研究,对于锌合金加工方面的报道却很少、且不够系统,不能够为锌合金塑性加工工艺的制定带来实质性的指导。锌合金为密排六方结构,滑移系少,这使得锌合金的发展受到极大限制,因此有必要对锌合金的高温变形行为进行系统的研究。

材料的流变应力模型是联系材料流变应力与加工工艺参数之间最基本的函数关系,是进行金属塑性成形加工工艺设计的基础。同时建立精确的流变应力模型对金属塑性加工过程的数值模拟以及实际工程应用上具有十分重要的意义[8]。本文作者在Zn-8Cu-0.3Ti锌合金的热模拟压缩实验的基础上,研究变形工艺参数对Zn-8Cu-0.3Ti锌合金高温变形时流变应力的影响,针对Zn-8Cu-0.3Ti锌合金的成形特点,建立该合金高温变形时的流变应力模型,并且采用DMM加工图理论研究锌合金的热加工性,这将为开展锌合金塑性加工过程的数值模拟及加工工艺的制定提供必要的实验基础和理论依据。

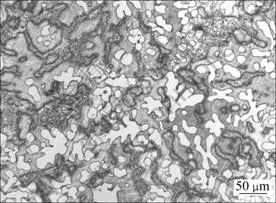

1 实验

实验所用材料为宁波市某公司提供,名义成分为Zn-8Cu-0.3Ti的锌合金铸锭,显微组织如图1所示。由图1可知,铸态组织由三相组成,黑色等轴状组织为初生ε相,白色骨骼状组织为TiZn15相,灰色基体为包晶η相。将铸锭机加工成d 10 mm×15 mm的圆柱试样,在Gleeble-1500D热模拟机上进行热压缩实验。试样采用快速感应加热,压缩过程中由焊接在试样中部的热电偶实时测量温度,通过闭环温控系统实现控温,控温精度为±1 ℃,并在压头与试样两端接触处夹一层石墨片,以减少摩擦对应力与变形状态的影响。压缩实验设定变形温度为230、260、290、320、350、380 ℃;应变速率为0.01、0.1、1、10 s-1;变形程度为50%,实验均在空气中进行。试样以5 ℃/s的速度加热到200 ℃,然后再以3℃/s的速度加热到变形温度,保温3 min后进行压缩,变形后立即水淬,以保留合金压缩结束后的变形组织。采用线切割方法将变形试样沿轴向中线剖开,采用CrO3和Na2SO4配制成的混合溶液进行腐蚀,在Axiovert 200MAT光学显微镜和HITACHI-S4800型扫描电子显微镜上进行组织观察。

图1 Zn-8Cu-0.3Ti合金铸态组织

Fig. 1 Microstructure of as-casted Zn-8Cu-0.3Ti alloy

2 结果与分析

2.1 变形行为分析

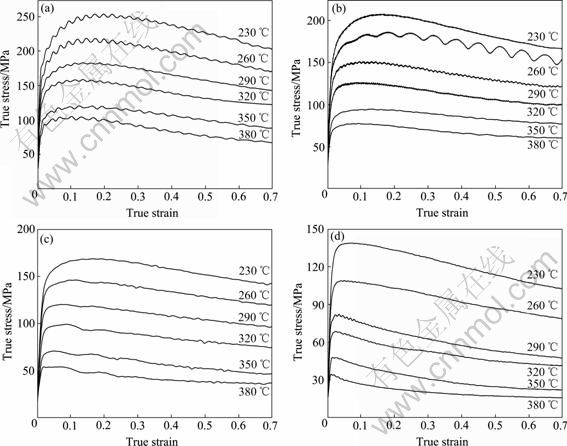

Zn-8Cu-0.3Ti锌合金在不同温度、不同应变速率下的真应力—真应变曲线如图2所示。由图2可以看出,在不同应变速率和不同温度的变形条件下,Zn-8Cu-0.3Ti锌合金的真应力—真应变曲线表现出相似的特征,基本分为3个阶段:流变应力首先随真应变的增加而迅速上升,然后流变应力又稍有下降,最后随着应变的继续增加应力趋于稳态。这是由于在变形初期,位错的湮灭和重组为主要的软化机制,而塑性变形引起大量位错的增值和缠结为主要的硬化机制,此时加工硬化作用远远大于软化作用,因此,造成了流变应力随应变的增大而迅速增大。随着应变量的不断增大,位错密度不断增加,再结晶驱动力不断加大,导致软化作用不断增强,当软化作用超过加工硬化作用时,流变应力减小。随着应变量的继续增加,当位错增殖引起的应变硬化和异号位错之间的销毁与重排引起的软化达到动态平衡时,变形进入稳态变形阶段[9-10]。

当变形温度一定时,流变应力随应变速率的增大而增大,这说明Zn-8Cu-0.3Ti锌合金对应变速率很敏感。这是因为应变速率越大,塑性变形时单位应变的变形时间越短,位错产生的数量越多,流变应力越大;也可能是由于应变速率越大,位错的运动速度越快,导致了流变应力的增大。当应变速率一定时,流变应力随温度的升高而降低,这是因为温度升高,金属原子热振动的振幅增大,原子间的相互作用力减弱,滑移阻力减小,新滑移不断产生,使变形抗力降低。由图2还可以看出,在高应变速率下( 10 s-1)变形时,流变应力曲线出现了锯齿状的流变特征,这很可能是由于动态再结晶的软化与已再结晶晶粒重新变形引起的硬化交替共同作用的结果[11],也可能是由于应变速率太大,导致实验仪器取值不精确造成的。

10 s-1)变形时,流变应力曲线出现了锯齿状的流变特征,这很可能是由于动态再结晶的软化与已再结晶晶粒重新变形引起的硬化交替共同作用的结果[11],也可能是由于应变速率太大,导致实验仪器取值不精确造成的。

图2 Zn-8Cu-0.3Ti锌合金热压缩变形真应力—真应变曲线

Fig. 2 True stress—strain curves for Zn-8Cu-0.3Ti zinc alloy hot-compressed at different temperatures: (a)  =10 s-1; (b)

=10 s-1; (b)  =1 s-1; (c)

=1 s-1; (c)  =0.1 s-1; (d)

=0.1 s-1; (d)  =0.01 s-1

=0.01 s-1

2.2 流变应力模型的建立

常用的流变应力模型有两种,唯象型的流变应力模型和机理型的流变应力模型。由于唯象型的流变应力模型在建立的过程中不涉及微观机制,因此在工程上得到了更广泛的应用[12-13]。Zn-8Cu-0.3Ti锌合金在变形过程中流变应力的大小主要受应变速率、变形温度的影响。在塑性加工过程中,材料的变形抗力是材料内部组织演化过程引起的硬化和软化过程综合作用的结果,所以流变应力模型是非线性的。目前相关研究普遍依据Arrhenius方程对实验数据进行分析、建立流变应力模型[14]。

(1)

(1)

引入Zener-Hollomon参数(Z):

(2)

(2)

式(1)为整个应力范围内的流变应力模型,通过对式(1)进行泰勒级数展开,可得到两个不同应力水平的流变应力模型。

低应力水平时:

(3)

(3)

高应力水平时:

(4)

(4)

式中:A1、A2、n1、n、α、β均为常数,A为结构因子,s-1;n为应力指数;α、β为应力水平参数,MPa-1;α和β、n1之间满足α=β/n1;Q为变形激活能,J/mol,其大小反映了材料热变形的难易程度;R为摩尔气体常数,J/(mol·K)。为了考虑应变对流变应力的影响,本研究假定A、α、n、Q均与应变量相关。

对(3)和(4)两边取对数可得:

(5)

(5)

(6)

(6)

根据真应力—真应变曲线,通过线性回归处理(计算所用应力为峰值应力),由式(5)和(6)可知,温度一定时n1和β分别为 —

— 和

和 —

— 曲线的斜率,根据图3中曲线的斜率求得n1=8.58,β=0.077进而求得α=0.008 96。

曲线的斜率,根据图3中曲线的斜率求得n1=8.58,β=0.077进而求得α=0.008 96。

图3 流变应力与应变速率的关系

Fig. 3 Relationship of ln σ with  (a) and σ with

(a) and σ with  (b)

(b)

假定变形激活能Q与温度T无关,对式(2)两边取对数得:

(7)

(7)

将式(7)整理可得:

(8)

(8)

(9)

(9)

根据式(8)和(9),分别做出不同应变时的 —

— 和

和 —1/T关系曲线,如图4所示。根据

—1/T关系曲线,如图4所示。根据 —

— 和

和 —1/T曲线的斜率可求出n和Q值,根据其截距可计算出lnA值。求得n=6.137,Q=168.517 kJ/mol,A=1.496×1014 s-1。

—1/T曲线的斜率可求出n和Q值,根据其截距可计算出lnA值。求得n=6.137,Q=168.517 kJ/mol,A=1.496×1014 s-1。

图4  与

与 以及

以及 与1/T的关系

与1/T的关系

Fig.4 Relationships of  with

with  at different temperatures (a) and

at different temperatures (a) and  with reciprocal temperature at different strain rates (b)

with reciprocal temperature at different strain rates (b)

对式(1)和(2)进行整理并取对数得:

(10)

(10)

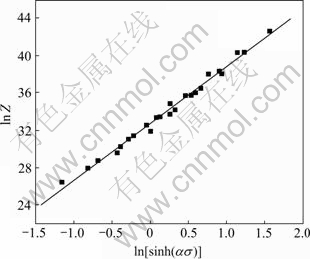

由图5可知: 与lnZ成线性关系,其线性相关系数为99%,这说明可以采用Arrhenius双曲正弦模型来描述Zn-8Cu-0.3Ti锌合金的高温流变行为。

与lnZ成线性关系,其线性相关系数为99%,这说明可以采用Arrhenius双曲正弦模型来描述Zn-8Cu-0.3Ti锌合金的高温流变行为。

综上所述,Zn-8Cu-0.3Ti锌合金的流变应力模型为

(11)

(11)

2.3 动态材料模型加工图

动态材料模型(Dynamic material modeling, DMM)加工图能够反映在各种变形温度和应变速率下,材料高温变形时其内部显微组织的变化,并且可以对材料的可加工性进行评估。进年来,基于动态材料模型的加工图(DMM加工图)越来越多地被应用于设计材料的热加工工艺,如钛合金、铝合金以及高温合金,该模型的理论基础是大塑性流变连续介质力学、物理系统模型和不可逆热力学[15-16]。

图5 Z参数与对数流变应力的关系

Fig. 5 Relationship between parameter Z and logarithm flow stress

在给定的温度和应变速率下,材料的本构关系可表示为

(12)

(12)

式中:K为常数;m为应变速率敏感因子,其表达式为

(13)

(13)

无量纲的功率耗散因子η可以由应变速率敏感因子m表示,它随温度和应变速率的变化构成了功率耗散图。功率耗散图代表了材料显微组织改变时的功率的耗散情况,被称之为微观组织轨迹线[17]。其定义式如下:

(14)

(14)

目前,许多国外学者基于DMM理论发展了几种确定变形稳定区与失稳区的判据,在实际工程应用上,大多数采用Prasad建立的失稳判据[18],表达式如下:

(15)

(15)

满足该判据条件时,材料可能发生流变失稳。

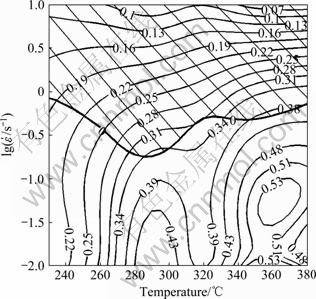

将功率耗散图与失稳图进行叠加就可获得DMM加工图,如图6所示,图中等值线上的数字表示功率耗散系数η,图中的阴影区为流变失稳区。如果Zn-8Cu-0.3Ti锌合金在流变失稳区对应的工艺参数下进行塑性变形,显微组织可能出现缺陷,所以应尽量避免在这个区域内进行热加工。从图6可以看出,应变速率对该合金的加工性能影响很大。该合金在低应变速率( ≤0.2 s-1)时表现出较好的加工性;在高应变速率(

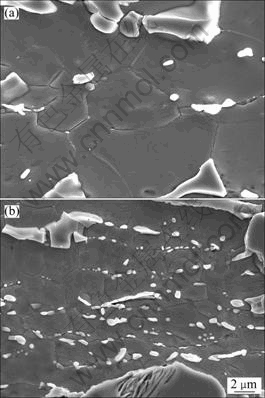

≤0.2 s-1)时表现出较好的加工性;在高应变速率( >0.2 s-1)时容易发生失稳现象,这是由于在高应变速率时,界面滑移所产生的应力集中没有足够的时间通过扩散等途径来释放,因此产生开裂。图7(a)所示为温度为380 ℃应变速率为10 s-1时合金的显微组织。由图7(a)可知,变形过程中基体发生了大量的机械孪生,因此很容易在孪晶与晶界的交接处引发应力集中,产生微裂纹并最终导致在与压缩轴呈45°的方向上产生剪切开裂。图7(b)所示为温度为230 ℃应变速率为1 s-1时合金变形显微组织。由图7(b)可知,在此条件下变形时,在拉长晶粒的晶界上出现了细小的再结晶晶粒,并没有出现高温(380 ℃)时的孪生,因此,在低温高应变速率时材料的局部塑性流动是造成塑性失稳的重要原因。

>0.2 s-1)时容易发生失稳现象,这是由于在高应变速率时,界面滑移所产生的应力集中没有足够的时间通过扩散等途径来释放,因此产生开裂。图7(a)所示为温度为380 ℃应变速率为10 s-1时合金的显微组织。由图7(a)可知,变形过程中基体发生了大量的机械孪生,因此很容易在孪晶与晶界的交接处引发应力集中,产生微裂纹并最终导致在与压缩轴呈45°的方向上产生剪切开裂。图7(b)所示为温度为230 ℃应变速率为1 s-1时合金变形显微组织。由图7(b)可知,在此条件下变形时,在拉长晶粒的晶界上出现了细小的再结晶晶粒,并没有出现高温(380 ℃)时的孪生,因此,在低温高应变速率时材料的局部塑性流动是造成塑性失稳的重要原因。

图6 铸态Zn-8Cu-0.3Ti合金在真应变为0.7时的加工图

Fig. 6 Processing map for as-casted Zn-8Cu-0.3Ti alloy obtained at strain of 0.7

加工图的功率耗散因子较大时,代表着特殊的显微组织或流变失稳机制,可能发生了动态再结晶或回复,也可能发生了局部流变失稳,需要结合变形后的试样组织进一步确认。Zn-8Cu-0.3Ti合金的DMM加工图出现了两个功率耗散因子达到53%的峰值区。峰区1:温度范围在345~370 ℃,应变速率为0.01 s-1,功率耗散因子不小于53%;峰区2:温度范围在350~370 ℃,应变速率范围为0.02~0.1 s-1,功率耗散因子不小于53%。图8(a)和8(b)所示分别为峰1区和峰2区所对应的显微组织。由图8可以看出,该加工图的峰值区的基体已经发生了完全动态再结晶,骨骼状的组织发生明显的球化。锌合金的层错能较高,其动态再结晶的耗散效率高,易发生在低应变速率情况下。这是因为在热加工变形过程中,动态回复已经不能完全消除加工硬化,第二相粒子TiZn15不断地造成局部的位错塞积,致使位错密度不断增大,当变形量继续增大到一定程度时,畸变能累积到了发生动态再结晶所需要的能量,开始发生动态再结晶。由图8(a)和(b)可知,应变速率为0.1 s-1时的晶粒明显比0.01 s-1时的小,这是由于随着应变速率的增大,合金的位错密度增大,储存的畸变能也越来越大,再结晶形核的核心越来越多,导致再结晶的晶粒越细小。因此,峰值区所对应的工艺参数为最佳变形工艺参数。

图7 铸态Zn-8Cu-0.3Ti合金变形后的显微组织

Fig. 7 Microstructures of as-casted Zn-8Cu-0.3Ti alloy after deformation: (a) 380 ℃, 10 s-1; (b) 230 ℃, 1 s-1

图8 铸态Zn-8Cu-0.3Ti合金不同应变速率下的SEM像

Fig. 8 SEM images of as-casted Zn-8Cu-0.3Ti alloy deformed at 350 ℃ and different strain rates: (a) 0.01 s-1; (b) 0.1 s-1

3 结论

1) Zn-8Cu-0.3Ti锌合金的高温压缩变形的流变应力取决于变形温度和应变速率,合金的流变应力随着变形温度的升高或应变速率的降低而增加,该合金是温度和应变速率敏感型材料。

2) 建立Zn-8Cu-0.3Ti锌合金高温变形时的流变应力模型,经拟合证明该模型具有较高的计算精度, 。

。

3) 采用动态材料模型的加工图研究Zn-8Cu-0.3Ti锌合金在230~380 ℃和0.01~10 s-1条件下的热变形行为,并分析高温区与低温区的失稳机制,为制定该材料的热加工工艺提供了理论基础。

REFERENCES

[1] PURCEK G, SARAY O, KUCUKOMEROGLU T, HAOUAOUI M, KARAMAN I. Effect of equal-channel angular extrusion on the mechanical and tribological properties of as-cast Zn-40Al- 2Cu-2Si alloy[J]. Materials Science and Engineering A, 2010, 527: 3480-3488.

[2] KAYA H, ?ADIRLI E, ?LGEN A. Investigation of the effect of composition on microhardness and determination of thermo- physical properties in the Zn-Cu alloys[J]. Materials and Design, 2011, 32: 900-906.

[3] PARK H S, KIMURA T, MURAKAMI T, NAGANO Y, NAKATA K, USHIO M. Microstructures and mechanical properties of friction stir welds of 60% Cu-40% Zn copper alloy[J]. Materials Science and Engineering A, 2004, 371: 160-169.

[4] REDDEN R F. Method of producing zinc alloy. US 3694199[P]. 1972.

[5] SHARMA R C, MARTIN J W. Creep of dilute zinc-copper alloys[J]. Journal of Materials Science, 1974, 9: 1139-1144.

[6] LI Y, NG S C, MA D, JONES H. Observation of lamellar eutectic-like structure in a Zn-rich Zn-3.37wt%Cu peritectic alloy processed by bridgman solidification[J]. Scripta Materialia, 1998, 39: 7-11.

[7] B?Y?KA U, KAYA H, ?ADIRLI E, MARA?LI N, ?LGEN A. Investigation of the effect of solidification processing parameters on microhardness and determination of thermo-physical properties in the Zn-Cu peritectic alloy[J]. Journal of Alloys and Compounds, 2010, 491: 143-148.

[8] 覃银江, 潘清林, 何运斌, 李文斌, 刘晓艳, 范 曦. ZK60镁合金热压缩变形流变应力行为与预测[J]. 金属学报, 2009, 45(7): 887-891.

QIN Yin-jiang, PAN Qing-lin, HE Yun-bin, LI Wen-bin, LIU Xiao-yan, FAN Xi. Hot compression behavior and flow stress predication of ZK60 magnesium alloy[J]. Acta Metallurgica Sinica, 2009, 45(7): 887-891.

[9] 王智祥, 刘雪峰, 谢建新. AZ91镁合金高温变形本构关系[J]. 金属学报, 2008, 44(11): 1378-1383.

WANG Zhi-xiang, LIU Xue-feng, XIE Jian-xin. Constitutive relationship of hot deformation of AZ91 magnesium alloy[J]. Acta Metallurgica Sinica, 2008, 44(11): 1378-1383.

[10] 罗 皎, 李淼泉, 李 宏, 于卫新. TC4钛合金高温变形行为及其流动应力模型[J]. 中国有色金属学报, 2008, 18(8): 1395-1401.

LUO Jiao, LI Miao-quan, LI Hong, YU Wei-xin. High temperature deformation behavior of TC4 titanium alloy and its flow stress model[J]. The Chinese Journal of Nonferrous Metals, 2008, 18(8): 1395-1401.

[11] 王宏伟, 易丹青, 王 斌, 蔡金伶, 钱 锋, 陈缇萦. Mg-6.3Zn-0.7Zr-0.9Y-0.3Nd镁合金的高温塑性变形行为的热压缩模拟[J]. 中国有色金属学报, 2010, 20(3): 378-384.

WANG Hong-wei, YI Dan-qing, WANG Bin, CAI Jin-ling, QIAN Feng, CHEN Ti-ying. Hot compressive deformation simulation of Mg-6.3Zn-0.7Zr-0.9Y-0.3Nd magnesium alloy at elevated temperatures[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(3): 378-384.

[12] 王 斌, 易丹青, 方西亚, 刘会群, 吴春萍. ZK60及ZK60(0.9Y)镁合金高温变形行为的热模拟研究[J]. 稀有金属材料与工程, 2010, 39(1): 106-111.

WANG Bin, YI Dan-qing, FANG Xi-ya, LIU Hui-qun, WU Chun-ping. Thermal simulation on hot deformation behavior of ZK60 and ZK60(0.9Y) magnesium alloys[J]. Rare Metal Materials and Engineering, 2010, 39(1): 106-111.

[13] 赵映辉, 葛 鹏, 赵永庆, 杨冠军, 汶建宏. Ti-1300合金的热变形行为研究[J]. 稀有金属材料与工程, 2009, 38(1): 46-49.

ZHAO Ying-hui, GE Peng, ZHAO Yong-qing, YANG Guan-jun, WEN Jian-hong. Hot deformation behavior of Ti-1300 alloy[J]. Rare Metal Materials and Engineering, 2009, 38(1): 46-49.

[14] SELLARS C M, MCTEGART W J. On the mechanism of hot deformation[J]. Acta Metallurgica, 1966, 14(9): 1136-1138.

[15] 曹兴民, 朱玉斌, 郭富安, 汤玉琼, 向朝建, 杨春秀. Cu-Ti 合金的热变形行为及其组织研究[J]. 稀有金属材料与工程, 2009, 38(S1): 509-514.

CAO Xing-min, ZHU Yu-bin, GUO Fu-an, TANG Yu-qiong, XIANG Chao-jian, YANG Chun-xiu. Hot deformation behavior and microstructure of Cu-Ti alloy[J]. Rare Metal Materials and Engineering, 2009, 38(S1): 509-514.

[16] 闫亮明, 沈 建, 李周兵, 李俊鹏,闫晓东,毛柏平. 基于神经网络的7055铝合金流变应力模型和加工图[J]. 中国有色金属学报, 2010, 20(7): 1296-1301.

YAN Liang-ming, SHEN Jian, LI Zhou-bing, LI Jun-peng, YAN Xiao-dong, MAO Bai-ping. Modelling for flow stress and processing map of 7055 aluminum alloy based on artificial neural networks[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(7):1296-1301.

[17] PRASAD Y V R K, SASTRY D H, DEEVI S C. Processing maps for hot working of a P/M iron aluminide alloy[J]. Intermetallics, 2000, 9/11(8): 1067-1074.

[18] PRASAD Y V R K. Recent advance in the science of mechanical processing[J]. Indian Journal of Technology, 1990, 28(6/8): 435-451.

(编辑 李艳红)

基金项目:“十一五”国家科技支撑计划资助项目(2009BAE71B03)

收稿日期:2011-03-08;修订日期:2011-07-28

通信作者:李德富,教授,博士;电话:010-82241292;E-mail: Lidf@grinm.com