DOI: 10.11817/j.issn.1672-7207.2015.12.008

滑动速度对织构化表面润滑状态的影响

万轶1,李建亮2,熊党生2

(1. 南京航空航天大学 金城学院机电工程系,江苏 南京,211156;

2. 南京理工大学 材料科学与工程学院,江苏 南京,210094)

摘要:为了研究滑动速度对织构化摩擦副的润滑状态的影响,采用Nd:YAG固体脉冲激光对GCr15钢盘表面进行织构化处理,形成直径约150 μm、深度约30~40 μm的环形排列的微孔。在摩擦试验机上对Al2O3陶瓷球/GCr15钢盘进行摩擦学性能测试,并基于Stribeck曲线和弹流理论研究滑动速度对织构化表面润滑状态的影响。研究结果表明:在油润滑条件下,试样的摩擦因数随滑动速度的增大而减小。当滑动速度大于2 m/s,润滑状态从混合润滑逐渐进入到流体润滑区域;而经过织构化处理的配副能在较低的速度下实现由混合润滑向流体润滑状态过渡。根据磨损形貌比对可以看出:在流体润滑状态下,织构可以增加摩擦配副间的润滑膜厚度,使流体产生额外动压,提高油膜承载能力,减少磨痕宽度。

关键词:表面织构;滑动速度;膜厚比;润滑状态

中图分类号:TH117 文献标志码:A 文章编号:1672-7207(2015)12-4442-06

Influence of sliding velocity on lubrication state of surface texturing

WAN Yi1, LI Jianliang2, XIONG Dangsheng2

(1. Department of Electromechanical Engineering, Jincheng College,

Nanjing University of Aeronautics and Astronautics, Nanjing 211156, China;

2. School of Material Science and Engineering,

Nanjing University of Science and Technology, Nanjing 210094, China)

Abstract: In order to study the influence of sliding velocity on the texturing of the lubrication state, the dimples with about 150 μm in diameter and 30-40 μm in depth arranged circularly were formed on GCr15 steel with Nd:YAG solid-state pulsed laser. The testing of tribological performance was investigated on the friction tester for Al2O3 ball/GCr15 disc and the influence of sliding velocity on lubrication state was analysed based on Stribeck curve and elasto-hydrodynamic lubrication. The results show that the friction coefficient is decreased with the increase sliding speed under the oil lubrication. When the sliding velocity is over 2 m/s, the lubrication state changes from the mixed lubrication to the fluid lubrication gradually, and the texturing pairs can be achieved at a low speed by mixed lubrication to fluid lubrication transition. According to the wear morphology comparison, the surface texturing can increase the lubricant film thickness to add the additional fluid dynamic pressure, increase the capacity of oil film and reduce the wear scar width in fluid lubrication.

Key words: surface texturing; sliding velocity; film thickness ratio; lubrication state

机械中各相对运动副之间的摩擦磨损和润滑性能对机械系统的功能、效率和使用寿命等有着直接的影响。近年来的大量研究结果表明[1-3],摩擦接触面之间并非越光滑其抗磨减摩性就越好,反而具有一定非光滑形貌的表面具有更好的摩擦学特性。通过激光表面微造型工艺可加工出具有一定直径、深度、密度和排列的凹坑等微图案[4-6],已被国内外众多学者证明具有有效的减摩效果,并已广泛应用于轴承和密封及发动机等机械领域[7-9]。Hamilton等[10]提出表面微凸起可以产生附加动压润滑效果的想法,并从理论上验证了具有一定表面粗糙度的摩擦副能够产生额外的流体动压承载。Etsion等[11-13]在研究中发现,在流体润滑状态下,织构的存在能够使摩擦副2个表面间隙间的润滑剂流场产生非对称的压力分布,从而形成额外的净压增加油膜承载能力,通过建立相应的理论模型,计算得出经过激光织构化后的密封端面可以产生流体动压效应,产生具有一定刚度的流体膜,使密封面形成非接触,从而减小了摩擦副的摩擦力矩、表面温升和磨损率。汪家道等[14]采用雷诺方程探究了不同摩擦副间隙下对应的织构深度最优值,并通过试验验证了仿真结果,但他们没有对结果给出详细的理论解释与分析。目前对表面织构的研究大部分都是对比性试验,研究结果之间分散性很大,尚未形成具有指导意义的表面织构设计方法和理论,因此,此领域的研究还需进一步加强。本文作者利用球/盘式摩擦试验机研究织构化摩擦副在油润滑下的摩擦性能,基于弹性流体润滑理论和Stribeck曲线,讨论润滑膜厚度和粗糙度之间的关系以及接触状态等方面进行微织构的减摩机理,研究不同滑动速度对表面织构润滑状态的影响。

1 试验部分

1.1 激光表面织构化

试验选用尺寸为48 mm×8 mm(直径×高)的GCr15钢盘为基体材料,先将其研磨抛光至表面粗糙度低于0.1 μm,然后将钢盘在丙酮中超声清洗后进行激光织构化处理。激光参数为:脉冲激光波长为1 064 μm;脉冲宽度为450 ns;脉冲频率为10 kHz;脉冲循环为6次。加工完成后对试样进行抛光以去除微孔边缘形成的毛刺。图1所示为GCr15钢盘表面微孔的环形排列,径向间距约为500 μm,周向间距约为300 μm。

图2所示为6个脉冲形成的单个微孔的三维轮廓图。材料表面未经过抛光处理,微孔呈圆锥状,周围有明显的凸起毛刺和溅射物,微孔直径约为150 μm,深度约为30~40 μm。

图1 GCr15钢盘表面微孔的环形排列

Fig. 1 Circular distribution of dimple on GCr15 steel disc

图2 6个脉冲在盘表面形成的微孔形貌

Fig. 2 Morphology of micro-dimple on disc surface with six pulses laser

1.2 摩擦磨损试验

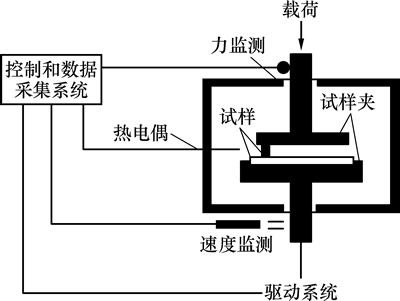

采用MG-2000型球/盘式摩擦试验机进行摩擦学性能试验,如图3所示。配副材料为Al2O3陶瓷球/织构化GCr15钢盘,陶瓷球固定在上方的保持架上,垂直加载于下方织构化盘表面,钢盘用电机驱动旋转,摩擦轨道直径约40 mm。油润滑试验开始前,所有试样都用丙酮超声清洗3 min,将润滑剂(黏度为0.013 6 Pa·s)涂抹在接触表面间,并预先以100 r/min的转速旋转1 min,去摩擦副之间多余的润滑剂,保持一层油膜在接触面。

图3 球/盘式摩擦试验机示意图

Fig. 3 Schematic diagram of ball-on-disc tribological tester

2 结果与讨论

2.1 滑动速度与膜厚比的关系

根据Stribeck曲线可以得到摩擦因数μ与载荷FN、摩擦表面对润滑油的综合速度v及润滑油的动力黏度η的关系。Stribeck曲线如图4所示。为了消除黏度和温度关系的影响,将测量结果都换算成25 ℃ 的常温条件。根据膜厚比λ=hmin/R,可将润滑类型分为流体润滑、混合润滑和边界润滑。其中:hmin为平均油膜厚度, ,

, 和

和 分别为2个摩擦表面相应的粗糙度。在Stribeck曲线上可以分为3种润滑机制:边界润滑、混合润滑和流体润滑。

分别为2个摩擦表面相应的粗糙度。在Stribeck曲线上可以分为3种润滑机制:边界润滑、混合润滑和流体润滑。

图4 Stribeck曲线

Fig. 4 Stribeck curve

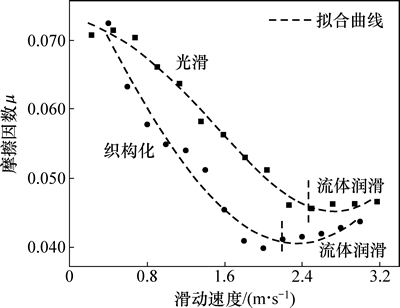

图5所示为Al2O3陶瓷球/织构化GCr15盘配副的摩擦因数随速度变化的曲线。试验条件为:载荷为 100 N,初始滑动速度为0.2 m/s,每滑动2 000 r后速度增幅为0.2 m/s,直至3 m/s。图5中每个点为不同速度下的摩擦因数,虚线为原始数值经过高斯拟合后得到的平滑曲线。从图5可以看出:在初始磨合期,织构和光滑配副的摩擦因数都比较大,而光滑配副的表面粗糙度较小,对摩擦因数的不利影响较低,因此磨合初期的摩擦因数较织构化配副小。随着滑动速度的增大,上下配副表面逐渐匹配,表面织构开始发挥存储部分润滑油的作用,并且随着油膜厚度逐渐增大,光滑和织构配副平均的摩擦因数随速度增大而降低。当速度增大到一定值,摩擦因数又开始缓慢增加,当滑动速度大于2 m/s后,2种配副的润滑状态都从混合润滑逐渐进入到流体润滑区域,而经过织构化处理的配副能在较低的速度下实现由混合润滑向流体润滑状态过渡。

图5 光滑和织构化Al2O3陶瓷球/GCr15盘配副的摩擦因数随滑动速度变化的曲线

Fig. 5 Curves of friction coefficient of smooth and texturing Al2O3 ball / GCr15 disc with changing velocity

对比图4和图5可知:织构表面在摩擦过程中可以产生动压润滑作用,能形成额外的净压增加膜厚比,将2个摩擦表面分离,并且膜厚比随滑动速度的增加而增大。从图5可以看出:摩擦因素呈现先减小后增大的趋势,原因是当动压润滑稳定后,这时再进一步增大速度,摩擦面之间的热量会使润滑油黏度下降,降低油膜厚度,油膜厚度相对较小其摩擦因数则相对较大,从而可以推导出油膜厚度与摩擦因数的关系成反比。

对表面织构的研究绝大部分假定摩擦副表面是绝对光滑的,没有考虑表面粗糙度参数对织构润滑区域的影响。这一假定在织构表面处于全膜流体润滑状态(即表面粗糙度尺寸远小于织构和油膜厚度尺寸)时是可以接受的。但在工程应用中,当油膜厚度尺寸较小时,织构表面将处于部分膜流体润滑状态,其上的粗糙峰产生直接接触并承担一部分载荷,此时粗糙度对油膜润滑性能有着决定性的影响[3]。

根据弹性流体润滑理论,Dowson[15]得到点接触时润滑界面间的最小接触膜厚度的计算公式为

(1)

(1)

其中:R为当量曲率半径, ;F为载荷;Ra为综合表面粗糙度;v为滑动速度;E′为当量弹性模量,

;F为载荷;Ra为综合表面粗糙度;v为滑动速度;E′为当量弹性模量, ,接触材料的弹性模量分别为E1和E2,泊松比分别为

,接触材料的弹性模量分别为E1和E2,泊松比分别为 和

和 。

。

本试验中,采用Al2O3陶瓷球/GCr15钢盘的摩擦配副,润滑剂黏度η=0.013 6 Pa·s,载荷F=100 N;滑动速度v=0.3~3 m/s。Al2O3陶瓷球的弹性模量E1=400 GPa;泊松比 =0.25;表面粗糙度Ra1<0.01 μm;球半径为R=6.5 mm;GCr15钢的弹性模量E2=210 GPa;泊松比

=0.25;表面粗糙度Ra1<0.01 μm;球半径为R=6.5 mm;GCr15钢的弹性模量E2=210 GPa;泊松比 =0.3;表面粗糙度Ra2=0.04 μm。计算得出:当量曲率半径R=R1=6.5 mm;E′=300 GPa;综合表面粗糙度Ra=Ra2=0.04 μm。

=0.3;表面粗糙度Ra2=0.04 μm。计算得出:当量曲率半径R=R1=6.5 mm;E′=300 GPa;综合表面粗糙度Ra=Ra2=0.04 μm。

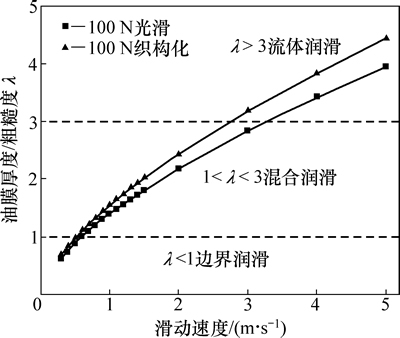

根据润滑界面间的最小润滑膜厚比计算式(1),计算出光滑和织构化配副的膜厚比随速度变化的关系曲线,如图6所示。试验中采用贫油润滑,在低速v≤0.5 m/s下,大多数摩擦配副处于边界润滑状态。在相同载荷下,织构化配副接触面间的膜厚比大于光滑配副,并随着滑动速度的增大而增大;但增大趋势变缓慢。如:当滑动速度v=3 m/s、载荷为100 N时,织构化摩擦配副的润滑状态已经开始进入流体润滑状态,说明织构化配副可以在高载低速下由混合/边界润滑状态进入流体润滑状态。

图6 光滑和织构化配副的膜厚比随速度变化的曲线

Fig. 6 Curves of film thickness ratio of smooth and texturing mates with changing velocity

摩擦副表面最理想的润滑方式是液膜润滑,即摩擦副表面在运动时完全被液体或液体膜隔开,因此大多数的摩擦工况是在混合/边界润滑下。边界润滑条件下的摩擦面可以看成是许多小的干摩擦区和流体润滑区的组合,运动摩擦副的接触状态不断变化,接触表面的干摩擦区域和流体润滑区域也随之不断变化。

2.2 磨损形貌分析

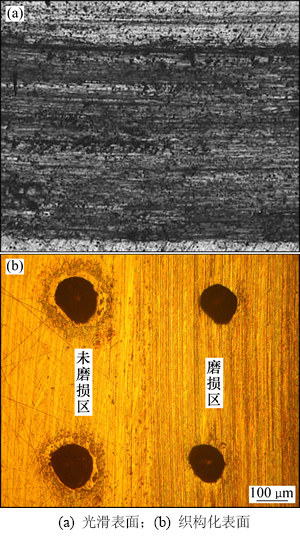

图7所示为2种GCr15钢盘随载荷变化的磨损表面形貌。试验条件为:载荷为100 N;滑动速度为1 m/s;滑行距离为2 000 r。从图7可以看出:光滑试样表面的磨痕较深,犁沟较多,并由于速度增大使接触面温度上升,部分区域发生粘着;而在织构化试样的磨损表面磨痕较浅,微孔在摩擦过程中,直径和深度相比原始状态都有所减小。

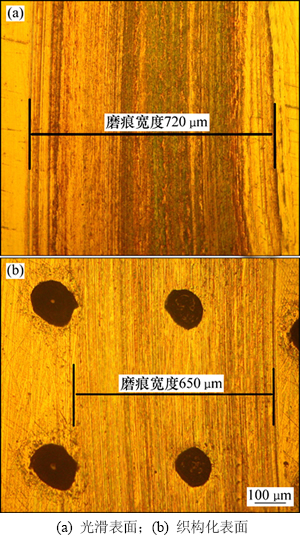

图8所示为油润滑下2种配副磨损后的磨痕宽度。从图8可以看出:织构化配副的磨痕宽约为650 μm,小于光滑配副的磨痕宽度720 μm,磨痕宽度的减小说明了接触面间的膜厚比增大,增大了流体动压效应。

图7 2种GCr15钢盘随载荷变化的磨损表面形貌

Fig. 7 Morphologies of worn surfaces of two GCr15 steel discs with changing loading

图8 GCr15盘与陶瓷球对磨的磨痕宽度

Fig. 8 Wear scar width of milling between GCr15 steel disc and ceramic ball

2.3 流体动压效应

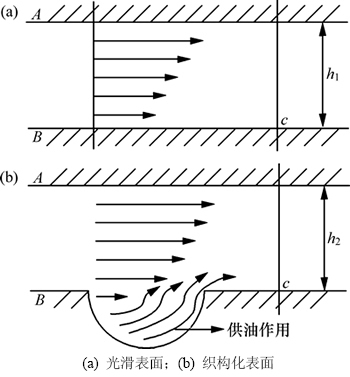

流体动压润滑的工作原理是利用端面旋转时的流体楔升压作用,把流体介质挤入端面之间,使两端面分离而获得一层动压流体膜。当摩擦副之间发生相对旋转时,由于表面织构化引起的粗糙度变化,形成很小的润滑楔,增大了接触面间的膜厚比,如图9所示。图9(a)所示为光滑配副的接触面,AB接触面之间存在润滑膜,B静止,A在B上滑动,液体内部的黏滞阻力使得每层油膜之间存在速度梯度,摩擦稳定时的油膜厚度为h1;图9(b)所示为织构化配副的接触面,当发生相对滑动时,表面微孔内部预先存储的润滑油被带出,经过相同截面c的液体通量增大,对A表面产生一个附加的支撑力,相对光滑表面之间油膜的厚度有所增加,h2>h1,在受热、振动后使2个摩擦副接触,产生流体动压效应,尤其是在较高转速的工况下,该效应更为明显。

图9 织构化对膜厚比的影响示意图

Fig. 9 Sketch of influence of film thickness ratio on texturing

3 结论

1) 利用激光对GCr15钢表面进行织构化处理,形成直径约为150 μm,深度约为30~40 μm的微孔;织构化配副可以在较低速下由混合/边界润滑状态进入流体润滑状态。

2) 根据弹流理论计算出光滑和织构化配副的膜厚比随速度变化的关系曲线,油膜厚度与摩擦因数成反比,并且膜厚比在一定速度范围内随滑动速度的增加而增大。

3) 表面织构化配副的磨痕宽度较光滑配副减小,说明了织构化能形成额外的净压增加膜厚比,增大了流体动压效应,从而提高油膜承载能力,达到抗磨减摩的作用。

参考文献:

[1] 马晨波, 朱华, 孙见君. 椭圆形截面织构的最优参数设计模型[J]. 中南大学学报(自然科学版), 2012, 43(3): 953-969.

MA Chenbo, ZHU Hua, SUN Jianjun. Optimal design model of surface texture with elliptical shape[J]. Journal of Central South University (Science and Technology), 2012, 43(3): 953-969.

[2] Gandra J, Krohn H, Miranda R M, et al. Friction surfacing: A review[J]. Journal of Materials Processing Technology, 2014, 214(5): 1062-1093.

[3] Siripuram R B, Stephens L S. Effect of deterministic asperity geometry on hydrodynamic lubrication[J]. ASME Journal of Tribology, 2004, 126(3): 527-534.

[4] Ibatan T, Uddin M S, Chowdhury M A K. Recent development on surface texturing in enhancing tribological performance of bearing sliders[J]. Surface and Coatings Technology, 2015, 272: 102-120.

[5] Hilgenberg K, Steinhoff K. Texturing of skin-pass rolls by pulsed laser dispersing[J]. Journal of Materials Processing Technology, 2015, 225: 84-92.

[6] WAN Yi, XIONG Dangsheng. The effect of laser surface texturing on frictional performance of face seal[J]. Journal of Materials Processing Technology, 2008, 197(1/2/3): 96-100.

[7] 万轶, 熊党生. 激光表面织构化改善摩擦学性能的研究进展[J]. 摩擦学学报, 2006, 26(6): 603-607.

WAN Yi, XIONG Dangsheng. Study of Laser Surface texturing for improving tribological properties[J]. Tribology, 2006, 26(6): 603-607.

[8] Grabon W, Koszela W, Pawlus P, et al. Improving tribological behaviour of piston ring–cylinder liner frictional pair by liner surface texturing[J]. Tribology International, 2013, 61: 102-108.

[9] WAN Yi, XIONG Dangsheng. Influence of laser surface texturing on tribological performance of mechanical components[J]. Journal of Central South University, 2007: 14(S2): 79-84.

[10] Hamilton D B, Walowit J A, Allen C M. A theory of lubrication by micro irregularities[J]. Journal of Fluids Engineering, 1966, 88(1): 177-185.

[11] Etsion I. State of the art in laser surface texturing [J]. ASME Journal of Tribology, 2005, 127(1): 248-253.

[12] Kligerman Y, Shinkarenko A, Etsion I. Improving tribological performance of piston rings by partial surface texturing[J]. Journal of Tribology, 2005, 127(3): 632-638.

[13] Shinkarenko A, Kligerman Y, Etsion I. The effect of surface texturing in soft elasto-hydrodynamic lubrication[J]. Tribology International, 2009, 42(2): 284-292.

[14] 汪家道, 陈大融, 孔宪梅. 规则凹坑表面形貌润滑研究[J]. 摩擦学学报, 2003, 23(1): 52-55.

WANG Jiangdao, CHEN Darong, KONG Xianmei. Study on lubrication of regular concave surface[J]. Tribology, 2003, 23(1): 52-55.

[15] Dowson D. Thin Films in tribology[J]. Tribology Series, 1993, 25: 3-12.

(编辑 罗金花)

收稿日期:2014-12-21;修回日期:2015-02-21

基金项目(Foundation item):国家自然科学基金资助项目(51041001, 51101087);江苏省自然科学基金资助项目(BK2011708)(Projects (51041001, 51101087) supported by the National Natural Science Foundation of China; Project (BK2011708) supported by the Natural Science Foundation of Jiangsu Province of China)

通信作者:万轶,博士,副教授,从事表面织构及涂层的摩擦学方向的研究;E-mail:wan2721@163.com