DOI:10.19476/j.ysxb.1004.0609.2019.06.20

响应曲面法优化废催化剂中微波浸出钒的工艺

马致远1, 2, 3,刘 勇1, 2, 3,周吉奎1, 2, 3,刘牡丹1, 2, 3,刘珍珍1, 2, 3

(1. 广东省科学院 广东省资源综合利用研究所,广州 510650;

2. 广东省科学院 稀有金属分离与综合利用国家重点实验室,广州 510650;

3. 广东省科学院 广东省矿产资源开发和综合利用重点实验室,广州 510650)

摘 要:采用响应曲面法对废石化催化剂微波辅助碱性浸出工艺进行优化研究,建立微波功率、反应时间和NaOH浓度及三者间交互作用对钒浸出率影响的二次多项式回归模型。结果表明:反应时间对钒浸出率的影响最显著;反应时间与NaOH浓度、微波功率与NaOH浓度的交互作用对钒浸出率具有显著性影响。最佳工艺条件为微波功率648 W,反应时间13.50 min,NaOH浓度87.51 g/L。此条件下,钒浸出率为97.55% ± 0.18%,与模型预测值吻合度较高。微波浸出机理研究结果表明:微波条件下,钒的浸出率能够得到明显提高,这与固体和液体之间的温度差和矿物表面裂缝的产生有密切关系。

关键词:废催化剂;响应曲面法;钒;微波;交互作用

文章编号:1004-0609(2019)-06-1308-08 中图分类号:TF19 文献标志码:A

据统计,90%以上的石油化学反应需添加相应的催化剂,钼系催化剂是石油炼制工业中使用数量较多的一种催化剂,大致包括钼-钒、钼-镍(钴)、钼-钒-镍几大类型,对于催化裂化反应具有良好的效果,因此,被广泛应用于石油化工领域[1-2]。随着催化剂使用时间的不断增长,容易发生热老化现象,并且有机物和Ni、Cr、Cu等重金属会沉积在催化剂表面或剂孔中,少量的Na、P、As等元素也常存在于废催化剂中,使其失去活性,因此,随着国内外石油化工业的迅速发展,每年全球产生大量的废石化催化剂。废石化催化剂富含V、Mo、Al、Ni、Co等有价金属,有些甚至远高于某些贫矿中的相应组分的含量,同时,也含有As、Cr等有害元素,是一种具有重要经济价值的危固二次资源,其成分复杂,处理难度较大,如不经无害化处理而随意堆放,不仅占用土地资源,而且造成环境污染,因此,在当前矿物资源日趋减少及生态环境破坏日益恶化的严峻现实下,开展废催化剂综合回收利用的研究,具有环境和经济的双重效益[3-5]。废石化催化剂中回收钒的工艺可分为3种:传统火法工艺,即氧化焙烧法、升华法和氯化物挥发法等;传统湿法工艺,即酸浸法、碱浸法等;火法-湿法联合工艺,即氧化焙烧-碱浸法、加碱焙烧-水浸法等[6]。废石化催化剂的传统火法和火法-湿法联合工艺是成熟工艺,该工艺对原料适应性强,钒的回收率高;但同时也存在环境污染、能耗高等问题。与传统火法工艺相比,湿法工艺具有能耗低、有利于环境保护等诸多优点,已在国内外迅速推广,但传统湿法流程同时也存在耗时长、原料适应性差、金属较分散等缺点,因此,废石化催化剂的湿法处理工艺的创新与发展十分有必要[7-10]。近年来,微波加热作为一种绿色环保的特殊加热技术,在矿物处理、湿法冶金等领域取得较好的发展[11-13]。相对于传统的冶金加热技术,微波浸出工艺具有加热均匀、能耗低、加热速度快等优点,是一种绿色环保高效的新型冶金技术。

本文作者提出了微波辅助浸出废石化催化剂的工艺,并采用响应曲面法,研究了各个工艺参数对实验影响的主次关系以及各参数之间的相互作用,优化了工艺条件。废石化催化剂的微波辅助浸出工艺,能够快速有效地回收钒,使得其他有价金属富集在浸出渣中,简化了废石化催化剂的处理工艺,降低了工艺能耗和成本,对于废石化催化剂中回收钒工艺的发展具有一定的指导作用。

1 实验

1.1 实验材料

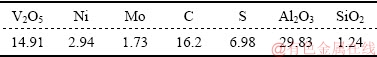

实验采用的原料为国内某石化企业提供的已经过脱油处理的废石化催化剂,含有Al、V、Ni、Mo、C、S等元素,其主要成分见表1。废催化剂主要含有的稀有金属为钒和钼,重金属为镍,轻金属为铝,还含有碳、硫、硅等非金属物质。图1所示为废催化剂的XRD谱。由图1可以看出,废催化剂中含有的物相有NiSO4·6H2O、C6H14N2O3、SiO2、VO2、ZnS、Al2O3、MoO3等,物相复杂,处理难度较大。

表1 废石化催化剂的主要化学组分

Table 1 Main elements and composition of spent petrochemical catalyst (mass fraction, %)

图1 废催化剂的XRD谱

Fig. 1 XRD pattern of spent catalyst

1.2 实验方法

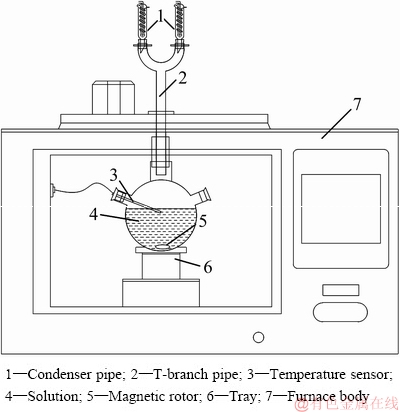

图2所示为微波浸出实验装置图,微波实验设备型号为XH-200A (北京祥鹄科技发展有限公司生产,2450 MHz,1000 W)。浸出实验在微波设备专用三口球形烧瓶(250 mL)中进行,向废催化剂加入一定浓度的NaOH溶液进行调浆,控制浆料固液比为0.20 g/mL,置于微波反应器中,设置微波功率、时间、目标温度等参数,进行搅拌,搅拌速率为400 r/min,目标温度设定为90 ℃。浸出结束后,采用真空过滤的方法进行固液分离,浸出渣用去离子水进行洗涤,然后烘干。浸出渣和浸出液中的V含量采用ICP分析方法测定。

图2 微波浸出实验装置图

Fig. 2 Schematic diagram of experimental installation

响应曲面法是一种结合数学和统计学的优化方法,主要是采用回归法将多因子实验中的因素与响应值的关系函数化,依次对各影响因素及其交互作用进行评估,从而确定最佳因素水平,使响应值达到最优化[14-15]。针对机理复杂的废石化催化剂微波辅助浸出钒的工艺,采用响应曲面法可快速准确地确定反应的最优条件。

实验采用Design-Expert.8.05软件进行优化分析,结合前阶段的研究结果,选取了对钒浸出率影响较显著的微波功率(W)、反应时间(min)和NaOH浓度(g/L)3个工艺参数来进行优化分析,分别用X1、X2、X3表示,选择钒浸出率作为评价指标,实验因素水平和编码见表2。

表2 响应曲面设计的不同因素值和水平编码

Table 2 Independent variables and their levels used for response surface methodology

2 结果与讨论

2.1 优化实验研究

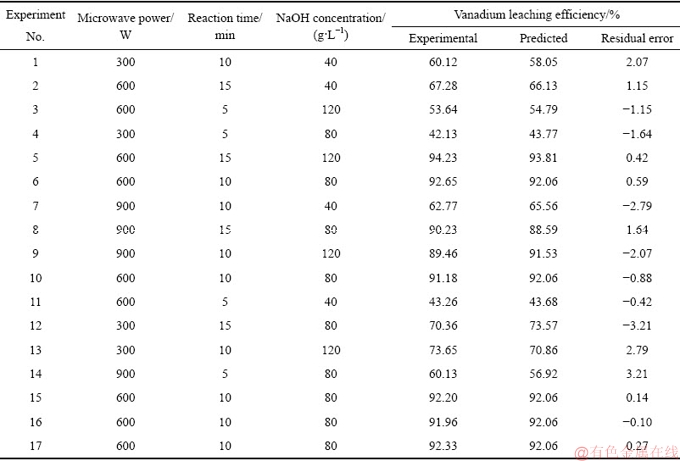

根据Box-Behnken优化方法,设计了3因素3水平,共17个实验点的实验方案[16],实验结果见表3。钒浸出率的响应范围为42.13%~94.23%。

表3 Box-Behnken设计实验结果

Table 3 Box-Behnken experimental design matrix and results

为了选取适合本实验的模型,对不同模型进行了数据分析,模型分析表如表4所列,2FI模型为方差来源与x12、x22和x32无关的模型,根据表中数据比较,钒浸出率模型建议采用响应曲面二阶模型。

表4 不同响应曲面模型分析表

Table 4 Analysis of different response surface models

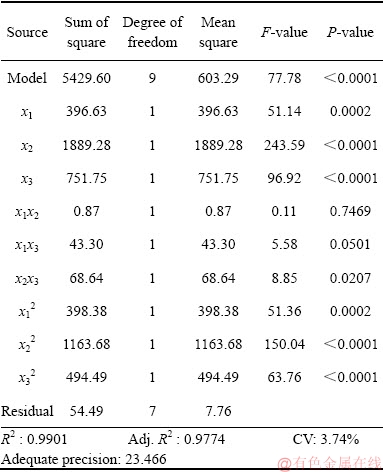

回归模型的方差分析(ANOVA)如表5所列。由表5可以明显看出:模型p<0.0001,呈极显著性,精确度高;复相关系数(R2)和修正决定系数(Adj.R2)分别为0.9901和0.9774,说明97.74%的钒浸出率响应值的变化可采用此模型解释,模型与实际情况拟合程度较高,误差小;变异系数和信噪比都能够说明模型精确度的问题,变异系数越低、信噪比越高都表明实验的准确度越好,变异系数CV为3.74%,信噪比为23.466,表明二次模型的准确度高[17]。综上所述,可采用此模型对废催化剂微波浸出钒的工艺进行优化分析。

表5 响应曲面二阶模型的方差分析

Table 5 Analysis of variance for response surface quadratic model

钒浸出率模型采用响应曲面二次模型,回归方程可由式(1)描述:

(1)

(1)

式中:Y为预测值;θ0为常数项;θi、θii、θij分别为一次、二次、交互项的回归系数;xa、xb为自变量;k为误差。

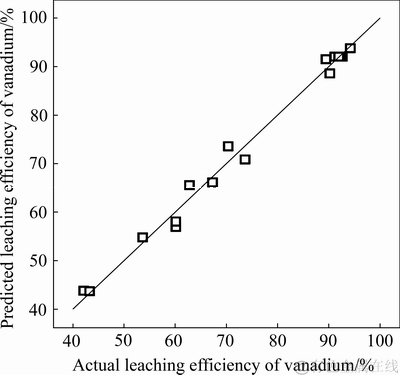

通过对实验结果进行多项回归拟合分析,得模型回归方程,见式(2),可描述响应值与影响因子之间的函数关系。图3所示为废石化催化剂微波浸出模型预期值和实际值的对比图,实际值均匀分布在标准线的两侧,说明实际值和预期值的契合度高,模型准确度好。

(2)

(2)

式中:x1、x2、x3分别表示微波功率、反应时间、NaOH浓度的编码值,各回归系数的绝对值表示各因素影响程度,系数的正负表示各因素对响应值的正负影响。

图3 钒浸出模型预期值和实际值的对比

Fig. 3 Comparison of vanadium leaching model prediction with experimental data

模型的响应曲面和等高线图如图4所示,响应曲面和等高线的形状能够反映出实验因素的影响大小和因素间交互作用的显著性。曲面越陡,因素的影响越显著,反之则表明因素的影响越不明显;等高线的形状和曲面的曲率可用于判断因素间交互作用的显著性,等高线形状为椭圆形或曲面曲率越大时,因素之间的交互作用越明显,而等高线圆形或者曲率较小时,交互作用越不显著[17-18]。

如图4(a)、4(b)所示,在一定区间内,V浸出率随着微波功率的增大和时间的增加呈升高趋势,并且时间的影响较微波功率显著,继续增大功率或者增加时间,V浸出率反而下降,表明存在一个微波功率与时间区域,该区域可使浸出的协同作用效果达到最优。等高线的轮廓和曲面的曲率表明,微波功率与时间的交互作用不显著。

图4(c)~4(f)得出的结论与图4(a)和(b)相似,V浸出率随着NaOH浓度的增加而增加,当超过一定区域时,反而下降,说明在本实验设计区间内,必然存在一个最优参数组合,使得V浸出率达到最大。通过观察曲面和等高线的形状,表明微波功率和NaOH浓度、反应时间和NaOH浓度之间的交互作用较显著。

综上所述,结合方差分析结果,X1X3、X2X3的交互作用较X1X2的显著,3个因素中对V浸出率影响最大的是反应时间,其次是NaOH浓度,而微波功率影响最小。

2.2 验证实验

通过Design-Expert软件分析,获得此模型的最优条件:微波功率648.15 W,反应时间13.51 min,NaOH浓度87.51 g/L,最优条件和对应的预测值如表6所示。为了验证预测条件的准确性,进行验证实验。由于设备的原因,微波功率648.15 W和反应时间13.51 min不能够设定至小数点后两位,对最优条件进行了相应调整,调整后的条件:微波功率648 W,反应时间13.50 min,NaOH浓度87.51 g/L,V浸出率为97.55%±0.18%,实际结果与预测结果基本一致,说明采用响应曲面法对废石化催化剂微波辅助浸出钒的工艺条件进行优化是合理可行的。

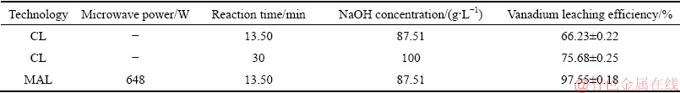

2.3 对比实验

传统浸出与微波辅助浸出实验条件:固液比0.20 g/mL,温度90 ℃,搅拌速率400 r/min。表7所列为传统浸出与微波辅助浸出的对比结果。可以明显看出,微波辅助浸出的效果明显高于传统浸出,V浸出率的提高十分明显,在相同反应时间条件下,V浸出率提高了31.32%;同时延长传统浸出的反应时间和提高反应剂的浓度,钒的浸出率仍然低于微波辅助浸出的,这与微波的作用密切相关。

2.4 机理讨论

2.4.1 微波场下温度变化

图4 钒浸出率的响应曲面和等高线图

Fig. 4 Response surface and contour plots for vanadium leaching efficiency

表6 响应曲面法的验证结果

Table 6 Verification result of RSM

表7 废催化剂传统浸出与微波辅助浸出的对比实验

Table 7 Comparison between conventional(CL) and microwave assisted leaching(MAL) of spent petrochemical catalyst

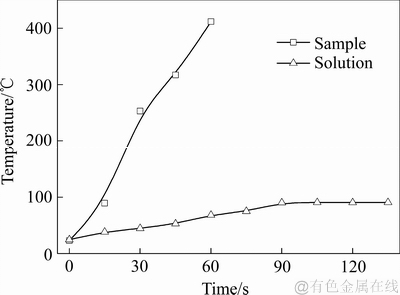

图5 废催化剂与溶液在微波场下的温度变化

Fig. 5 Temperature variation of spent catalyst and leaching solution in microwave field

图5所示为废催化剂与液体在微波场下的温度变化曲线图。实验条件:微波功率648 W,NaOH浓度87.51 g/L,搅拌速率400 r/min,溶液体积为100 mL。可以看出,在微波场下,废石化催化剂的温度随着加热时间的增长而迅速升高,时间为60 s时,温度由23.1 ℃迅速上升至411.6 ℃,说明废石化催化剂具有良好的微波吸收性能。废催化剂在微波场下升温速率明显高于液体的升温速率,固体与液体之间存在明显的温度梯度,能够产生强烈的热流,对于清除反应表面产生的产物层十分有效,使得溶液与内部的矿物能够充分反应[19]。

2.4.2 微波场下矿物扫描电镜分析

对原料与微波直接照射处理后的废催化剂进行了扫描电镜分析(见图6),实验条件:微波功率648 W,照射时间13.50 min,可以明显看出,原料中钒的氧化物被载体氧化铝包裹(见图6(a)),采用传统的工艺处理难度较大;而采用微波处理后,矿物表面形成明显裂缝(见图6(b)),这是由于微波的特殊性质,原料中氧化铝和钒的氧化物具有不同的吸波性能,升温速率也不同,组分间因热膨胀系数不同而产生相应的热应力,矿物之间的界面上能够产生裂缝,裂缝的产生能够促使矿物的解离,增加矿物反应表面积,有效提高工艺的效率[20]。

图6 废催化剂的SEM像

Fig. 6 SEM images of spent catalyst (1—Vanadium oxide; 2—Aluminium oxide)

3 结论

1) 采用微波辅助浸出的方法处理废石化催化剂,可实现快速有效地浸出V,V浸出率达到97.55%。

2) 通过响应曲面法研究微波功率、反应时间和NaOH浓度对V浸出率的影响。利用模型的响应曲面及等高线对实验因素及交互作用进行探讨,获得最优化条件:微波功率648 W,反应时间13.50 min,NaOH浓度87.51 g/L。在此条件下进行验证性实验,钒浸出率为97.55%±0.18%,实际结果与预测结果基本一致,说明采用响应曲面法对废石化催化剂微波辅助浸出V的工艺条件进行优化是合理可行的。

3) 通过对比实验和机理研究,发现微波辅助浸出的效果明显高于传统浸出的效果,钒浸出率能够得到明显提高,这与固体和液体之间的温度差和矿物表面裂缝的产生有着密切的关系。

REFERENCES

[1] 刘 健, 邱兆富, 杨 骥, 曹礼梅, 张 巍. 我国石油化工废催化剂的综合利用[J]. 中国资源综合利用, 2015, 33(6): 38-42.

LIU Jian, QIU Zhao-fu, YANG Ji, CAO Li-mei, ZHANG Wei. The comprehensive utilization of spent petrochemical catalysts in China[J]. China Resources Comprehensive Utilization, 2015, 33(6): 38-42.

[2] AKCIL A, VEGLIO F, FERELLA F, OKUDAN M D, TUNCUK A. A review of metal recovery from spent petroleum catalysts and ash[J]. Waste Management, 2015, 45: 420-433.

[3] LI Z, CHEN M, ZHANG Q, LIU X, SAITO F. Mechanochemical processing of molybdenum and vanadium sulfides for metal recovery from spent catalysts wastes[J]. Waste Management, 2015, 60: 734-738.

[4] PINTO I S S, SOARES H M V M. Selective leaching of molybdenum from spent hydrodesulphurisation catalysts using ultrasound and microwave methods[J]. Hydrometallurgy, 2012, 129/130: 19-25.

[5] PINTO I S S, SOARES H M V M. Microwave-assisted selective leaching of nickel from spent hydrodesulphurization catalyst: A comparative study between sulphuric and organic acids[J]. Hydrometallurgy, 2013, 140: 20-27.

[6] 郝喜才, 胡斌杰. 用N-263从废钒催化剂中回收钒的工艺研究[J]. 化学世界, 2014, 55(4): 193-196.

HAO Xi-cai, HU Bin-jie. Study on recovery technology of vanadium oxide from waste catalyst by using N-263[J]. Chemical World, 2014, 55(4): 193-196.

[7] PARK K H, REDDY B R, MOHAPATRA D, NAM C W. Hydrometallurgical processing and recovery of molybdenum trioxide from spent catalyst[J]. International Journal of Mineral Processing, 2006, 79(2): 261-265.

[8] HAVLIK T, ORAC D, PETRANIKOVA M, MISKUFOVA A, KUKURUGYA F, TAKACOVA Z. Leaching of copper and tin from used printed circuit boards after thermal treatment[J]. Journal of Hazardous Materials, 2010, 183(1/3): 866-873.

[9] MYMRIN V, PEDROSO A M, PONTE H A, PONTE M J J, ALEKSEEV K, EVANIKI D, PAN R C Y. Thermal engineering method application for hazardous spent petrochemical catalyst neutralization[J]. Applied Thermal Engineering, 2017, 110: 1428-1436.

[10] GORBATOVA L D, GODOVYKH Y N, SHTUKINA A A, ISKHAKOVA G R, KARPOV Y A. Specific features of application of different methods of analytical control of spent catalysts of the petrochemical industry[J]. Inorganic Materials, 2017, 53(14): 1442-1447.

[11] GUO S H, CHEN G, PENG J H, CHEN J, LI D B, LIU L J. Microwave assisted grinding of ilmenite ore[J]. Transactions of Nonferrous Metals Society of China, 2011, 21(9): 2122-2126.

[12] 马致远, 杨洪英, 陈国宝, 吕 阳, 佟琳琳. 基于田口法的铜阳极泥微波浸出工艺[J]. 中国有色金属学报, 2014, 24(8): 2152-2157.

MA Zhi-yuan, YANG Hong-ying, CHEN Guo-bao, Lü Yang, TONG Lin-lin. Microwave assisted leaching of copper anode slime based on Taguchi methods[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(8): 2152-2157.

[13] TURAN M D, SARI Z A, MILLER J D. Leaching of blended copper slag in microwave oven[J]. Transactions of Nonferrous Metals Society of China, 2017, 27(6): 1404-1410.

[14] MAKADIA A J, NANAVATI J I. Optimisation of machining parameters for turning operations based on response surface methodology[J]. Measurement, 2013, 46(4): 1521-1529.

[15] LIU B G, PENG J H, WAN R D, ZHANG L B, GUO S H, ZHANG S M. Optimization of preparing V2O5 by calcination from ammonium metavanadate using response surface methodology[J]. Transactions of Nonferrous Metals Society of China, 2011, 21(3): 673-678.

[16] YANG S, LI Y, JIA D, YAO K, LIU W. The synergy of Box-Behnken designs on the optimization of polysaccharide extraction from mulberry leaves[J]. Industrial Crops & Products, 2017, 99: 70-78.

[17] 马致远, 杨洪英. 响应曲面法优化铜阳极泥微波浸出硒工艺[J]. 中南大学学报(自然科学版), 2015, 46(7): 2391-2397.

MA Zhi-yuan, YANG Hong-ying. Microwave assisted leaching of selenium from copper anode slime optimized by response surface methodology[J]. Journal of Central South University (Science and Technology), 2015, 46(7): 2391-2397.

[18] CIFUENTES B, FIGUEREDO M, COBO M. Response surface methodology and aspen plus integration for the simulation of the catalytic steam reforming of ethanol[J]. Catalysts, 2017, 7(1): 15-34.

[19] MA Z Y, YANG H Y, HUANG S T, Lü Y, XIONG L. Ultra fast microwave-assisted leaching for the recovery of copper and tellurium from copper anode slime[J]. International Journal of Minerals Metallurgy and Materials, 2015, 22(6): 582-588.

[20] AMANKWAH R K, OFORI-SARPONG G. Microwave heating of gold ores for enhanced grindability and cyanide amenability[J]. Minerals Engineering, 2011, 24(6): 541-544.

Optimization of microwave assisted leaching of vanadium from spent catalyst based on response surface methodology

MA Zhi-yuan1, 2, 3, LIU Yong1, 2, 3, ZHOU Ji-kui1, 2, 3, LIU Mu-dan1, 2, 3, LIU Zhen-zhen1, 2, 3

(1. Guangdong Institute of Resources Comprehensive Utilization, Guangdong Academy of Sciences, Guangzhou 510650, China;

2. State Key Laboratory of Separation and Comprehensive Utilization of Rare Metals, Guangdong Academy of Sciences, Guangzhou 510650, China;

3. Guangdong Provincial Key Laboratory of Development and Comprehensive Utilization of Mineral Resources, Guangdong Academy of Sciences, Guangzhou 510650, China)

Abstract: The microwave assisted alkaline leaching of spent petrochemical catalyst was optimized using response surface methodology (RSM). The quadratic polynomial regression model charactering effect factors, such as microwave power, reaction time and NaOH concentration, and their interactions on the vanadium leaching efficiency were established. The results show that the effect of reaction time on the vanadium leaching efficiency is the most significant. The interactions of reaction time and NaOH concentration, microwave power and NaOH concentration have significant impacts on the vanadium leaching efficiency. The optimum conditions of microwave assisted leaching process are as follows: microwave power of 648 W, reaction time of 13.50 min and NaOH concentration of 87.51 g/L. Under the optimized conditions, the vanadium leaching efficiency of 97.55% ± 0.18% is obtained, which are well agree with the values predicted by the model. The mechanism of microwave-assisted leaching systems was studied. The enhancement on the leaching efficiency of vanadium is attributed to the temperature gradient between solid and liquid and generation of cracks on mineral surface.

Key words: spent catalyst; response surface methodology; vanadium; microwave; interaction

Foundation item: Project(2017GDASCX-0841) supported by the High-degree Talent Introduction Program of Guangdong Academy of Sciences, China; Project(U1608254) supported by the National Natural Science Foundation of China; Project(201607020021) supported by the Science and Technology Program of Guangzhou, China; Project(201806010016) supported by the Pearl River Nova Program of Guangzhou, China

Received date: 2018-05-30; Accepted date: 2018-11-12

Corresponding author: MA Zhi-yuan; Tel: +86-20-61086452; E-mail: mzy1988@163.com

(编辑 李艳红)

基金项目:广东省科学院专项资金项目(2017GDASCX-0841);国家自然科学基金资助项目(U1608254);广州市科技计划重点项目(201607020021);广州市珠江科技新星项目(201806010016)

收稿日期:2018-05-30;修订日期:2018-11-12

通信作者:马致远,工程师,博士;电话:020-61086452;E-mail:mzy1988@163.com