DOI:10.19476/j.ysxb.1004.0609.2019.07.01

Al-Cu-Li合金蠕变时效过程的性能演变及显微组织分析

谭 佳1,张 劲1, 3,邓运来2, 3,张新明2, 3

(1. 中南大学 轻合金研究院,长沙 410083;

2. 中南大学 材料科学与工程学院,长沙 410083;

3. 中南大学 高性能与复杂制造国家重点实验室,长沙 410083)

摘 要:采用光学显微及透射电子显微、拉伸力学性能、维氏硬度等测试技术,研究Al-Cu-Li合金在蠕变时效过程中拉伸性能演变规律与微观组织特征。结果表明:在蠕变时效过程中,合金的硬度和强度呈现先升高,到达峰值之后再缓慢下降的趋势。其中CA2试样(2%预变形再进行蠕变时效)在16 h达到了蠕变时效硬度与强度峰值,比CA1试样(不预变形直接进行蠕变时效)提前了4 h,且CA2试样的峰值区域更为明显。相比于CA1试样,CA2试样的硬度和强度提高,伸长率降低。在峰值蠕变时效状态下,CA1试样最大晶间腐蚀深度为180.6 μm,腐蚀等级为4级;CA2试样最大晶间腐蚀深度为92.0 μm,腐蚀等级为3级。TEM结果表明:CA1试样中以细小致密的θ′相为主,晶内可见少量T1相;CA2试样由于T1相在蠕变时效初期时存在析出优势,晶内析出大量T1相的同时,伴随着细小的θ′相,且CA2试样T1相在亚晶界处的富集程度要低于CA1试样的。

关键词:AL-Cu-Li合金;蠕变时效;力学性能;晶间腐蚀;T1相

文章编号:1004-0609(2019)-07-1341-07 中图分类号:TG146.2 文献标志码:A

20世纪90年代初研发的第三代铝锂合金属于典型的可时效强化型合金,它具有密度低、比强度和比刚度高、抗腐蚀性能良好等特点[1-2]。在铝合金中每添加1%(质量分数)的锂,合金的密度可降低3%,弹性模量提高6%[3-4]。与传统铝合金相比,第三代铝锂合金密度低2%~8%,在航空航天结构具有明显减轻质量的效果。其中,作为综合性能较好的Al-Cu-Li系2195铝锂合金,已成功应用于1998年首飞的航天飞机超轻贮箱上,经过设计改进后使得贮箱质量减轻了3175 kg,显著提高了航天飞机往返国际空间站的性能[5]。其低密度、高强度以及良好的塑性等特点无疑对于航空航天领域,尤其是运载火箭、直升机和卫星都很有价值,被视为航空航天工业中最具有应用前景的轻质高强结构材料之一[6-7]。

蠕变时效(Creep aging,CA)是指材料在高温和低于材料宏观屈服极限应力下发生缓慢塑性变形的时效过程,与人工时效不同的是它在一定温度环境下还受到恒定载荷作用力,对材料内部位错、析出相分布等微观组织有着重要的影响[8-9]。2195铝锂合金时效过程中的强化机制主要为沉淀强化,它的主要强化相有惯习面为{100}的θ′(Al2Cu)相以及惯习面为{111}的T1(Al2CuLi)相,其中T1相为密排六方结构,它能够有效阻止共面滑移,强化效果高于θ′相,是Al-Cu-Li合金中强化效果最佳的析出相[10-11]。他们之间的竞争析出动力学受时效制度、预变形时效工艺等影响,而析出相的种类、体积分数、分布形态很大程度上决定了合金的力学性能[12-14]。此外,2xxx系铝合金极易发生局部腐蚀,主要形式有晶间腐蚀和剥蚀等,预拉伸在促进基体沉淀相析出的同时,某种程度上还可以抑制晶界相析出,降低亚晶界的腐蚀程度[15]。因此,本文针对2195铝锂合金不同初始状态在蠕变时效过程中,合金的力学性能演变、微观析出相特征以及抗晶间腐蚀性能进行研究。

1 实验

1.1 实验材料

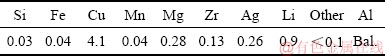

本研究所采用的材料为法国Constellium公司进口2195-O铝锂合金板材,厚度为12.7 mm,用铣床将板材上下表面各铣掉1 mm后取样进行实验,其化学成分如表1所列。

表1 2195铝锂合金板材化学成分

Table 1 Chemical composition of 2195 aluminum-lithium alloy profile (mass fraction, %)

1.2 实验方法

按GB/T 2039-2012标准[16]从轧制板材上截取蠕变拉伸试样,在电阻加热炉中进行固溶处理,固溶温度510 ℃,保温60 min后立即进行水淬,一组水淬后直接进行蠕变时效(CA1),另一组则进行2%预变形再进入蠕变时效(CA2)。在RWS50型电子蠕变松弛实验机上进行蠕变时效(CA)试验,试样安装于加热炉中心,将热电偶分别放置试样的上、中、下位置,且热电偶结点必须置于炉内空气中不能接触炉壁或者试样表面,以确保炉内温度为设定温度,紧闭炉门,炉子上下孔隙处用石棉塞紧以防空气对流影响炉温。蠕变时效温度为170 ℃,应力200 MPa。

晶间腐蚀试验按照GB/T 7998-2005标准[17]进行。先用酒精洗净样品表面,随后将其放入氢氧化钠溶液中碱洗5~15 min,取出试样后用水洗净,再放入硝酸溶液中酸洗至表面光洁,取出试样水洗。用密封胶封住非腐蚀面,放入腐蚀液(57 g NaCl+10 mL H2O2)中浸泡6 h,实验温度保持在(35±2) ℃,试样腐蚀面积与腐蚀液容积比小于20 mm2/mL,试样与容器及试样之间避免相互接触。将经腐蚀的试样在垂直主变形方向切去5 mm,切后的截面按金相试样制备方法研磨与抛光,在电子显微镜下放大200倍观察。晶间腐蚀评定标准如下:最大腐蚀深度不超过10 μm为1级;深度在10~30 μm之间为2级;介于30~100 μm之间为3级;100~300 μm之间为4级;大于300 μm为5级。

取不同时效时间的蠕变时效试样,分别进行力学性能与微观组织测试。硬度测试在HV-5型维氏硬度计下进行,试验力为29.4 N,保持时间为15 s。采用D60K型数字涡流电导率测量仪测试试验的电导率。在CSS44100电子拉伸实验机上进行室温拉伸测试,夹头移动速度为2 mm/min。在Sirion200场发射扫描电镜下进行扫描电子显微分析。TEM样品磨至80 μm厚进行电解双喷减薄,双喷液采用硝酸与甲醇(硝酸和甲醇的体积比为3:7)溶液,使用TECNAIG220型透射电镜观察试样的显微组织。

2 结果与分析

2.1 时效硬化曲线

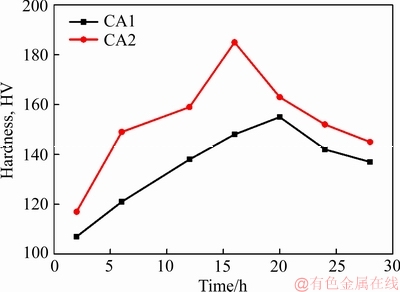

2195铝锂合金试样经510 ℃固溶1 h后水淬,在170 ℃温度、200 MPa应力下进行蠕变时效试验,图1所示为蠕变时效后的硬度曲线。从图1中可以看出,该合金为典型的时效强化型合金。蠕变时效初期,硬度值快速上升,随着时效时间的延长,合金的硬度增加缓慢,直至达到峰值,之后进入过时效状态,硬度曲线呈下降趋势。与固溶淬火后直接蠕变时效的试样(CA1)相比,2%预变形后进行蠕变时效的试样(CA2)不仅提高了合金的硬度,还缩短了合金达到峰值时效的时间;CA1试样的硬度较低,硬度在20 h达到峰值,峰值硬度值为155 HV。CA2试样硬度峰值时间明显提前,在16 h时达到最高硬度185 HV。

图1 2195铝锂合金的蠕变时效硬化曲线

Fig. 1 Creep aging hardness curves of test 2195 Al-Li alloy

2.2 室温拉伸性能

图2所示为2195铝锂合金两种不同初始状态在蠕变时效过程中拉伸性能的演变。由图2可知,在蠕变时效初期,随着时效时间的延长,合金的抗拉强度(σb)和屈服强度(δ)显著升高,到达峰值强度之后,进入过时效状态,强度开始缓慢下降,曲线趋于平缓。其中,经过2%预变形的CA2试样的抗拉强度与屈服强度明显高于淬火后直接蠕变时效CA1试样的,CA2试样在16 h达到了强度峰值,较CA1试样峰值时效时间20 h提前了4 h,且CA2试样峰值区域更为明显。在峰值蠕变时效时间下,CA2试样的屈服强度为546 MPa,相比于CA1试样的峰值屈服强度(324 MPa),上升了68.52%;CA2试样的抗拉强度为585 MPa,也比CA1试样峰值抗拉强度470 MPa有所上升,上升了24.47%。从图2(c)中可以看出,伸长率(η)在时效初期呈迅速下降趋势,下降至最低值之后略有上升,随着时效时间的延长,伸长率基本保持稳定。不难发现两种试样都在其峰值蠕变时效时间伸长率达到了最低,CA1试样最低伸长率为20%,CA2试样为10%。表2所列为两种不同初始状态试样的峰值蠕变时效拉伸性能表。

图2 不同初始状态蠕变时效过程中2195铝锂合金拉伸性能演变

Fig. 2 Tensile properties evolution during creep aging under different initial conditions

表2 2195铝锂合金不同初始状态蠕变峰值时效的拉伸性能

Table 2 Tensile properties of 2195 Al-Li alloy at different initial state of creep peak aging

取峰值蠕变时效试样的拉伸断口做断口扫描,如图3所示。从图3中可以看出,CA1与CA2试样峰值蠕变时效的断口形貌有明显差别。CA1试样断口处呈现出大量韧窝,这些韧窝比较浅,尺寸相差不大,且断口形貌出现少量的平滑带,断裂方式呈现为韧窝型穿晶断裂与沿晶断裂混合的混合型断裂方式。而CA2试样的拉伸断口,韧窝数量明显减少,断口表面有明显的分层特征,出现大量平滑带与撕裂棱,断裂方式以沿晶断裂为主。

图3 不同初始状态2195铝锂合金蠕变峰值时效时间断口形貌

Fig. 3 Tensile fracture surface morphologies of 2195 Al-Li alloy during creep peak aging under different initial conditions

2.3 晶间腐蚀性能

取蠕变峰值时效状态下的CA1与CA2试样做晶间腐蚀测试,在光学金相电子显微镜下拍摄其腐蚀形貌,其结果如图4所示。由图4可以看出,CA1试样与CA2试样的晶间腐蚀程度有较大的差别。未经预变形的CA1试样发生了严重的晶间腐蚀,腐蚀已经沿着晶界深入到试样内部相当深的地方,且腐蚀范围也相当广泛,经过测量,其最大腐蚀深度达到了180.6 μm,按晶间腐蚀等级评定标准其腐蚀等级为4级;CA2试样腐蚀程度相对来说明显降低,最大腐蚀深度为92.0 μm,腐蚀等级为3级。表3所列为蠕变峰值时效下晶间腐蚀等级评定结果。

图4 不同初始状态2195铝锂合金蠕变峰值时效晶间腐蚀

Fig. 4 Intergranular corrosion of peak creep aging for 2195 Al-Li alloy under different initial conditions

表3 不同初始状态2195铝锂合金蠕变峰值时效晶间腐蚀等级评定结果

Table 3 Evaluation results of intergranular corrosion grades of creep peak aging of 2195 Al-Li alloy at different initial states

2.4 显微组织

Al-Cu-Li合金在时效过程中析出相的种类、数量以及分布很大程度上取决于Cu和Li的质量比[18]。JO等[19]总结Al-Cu-Li三元系合金体系的析出相反应,并构建了与m(Cu)/m(Li)的关系,对于m(Cu)/m(Li)>4的合金中,时效过程中的析出序列为:α(ss)→GP区→θ″→θ′。图5所示为CA1与CA2试样在蠕变时效2 h的TEM像及[110]轴选区电子衍射斑点(SAED)。CA1试样内分布着大量由GP区转变的细小θ′相,几乎未见T1相析出;而CA2试样内在分布着细小θ′相的同时,在位错线位置聚集析出了部分T1相,从图5(b)中的衍射斑点也隐约可见T1相的茫线。根据研究[20],在基体位错分裂为位错1/6<112>时,会形成有利于片状相的生长界面,T1相则易于在此形核并生长。显然2%预变形的引入给T1相提供了优先形核的位置,相比于CA1试样,CA2试样中T1相在蠕变时效初期时存在析出优势。

图6所示为CA1试样与CA2试样在蠕变峰值时效时间下,晶内以及亚晶界的TEM像及[110]轴选区电子衍射斑点(SAED)。由图6(a)和(b)可以看到,CA1试样与CA2试样晶内析出相的组成与分布明显不同。CA1试样中以大量细小致密的θ′相为主,晶内可见少量T1相;而CA2试样中明显析出了大量的T1相,同时伴随着细小的θ′相。晶内析出相的组成和分布直接影响合金的强度,结合图5中的TEM像与表2中蠕变峰值时效的强度分析,经2%预变形的蠕变试样在时效开始前向基体内引入了大量位错,为早期T1相的形核提供了有利场所,随着蠕变时效的进行,进入蠕变峰值时效阶段,由于塑性变形引起合金内位错增殖,T1相析出数量明显增多,且伴随着时效初期由GP区转变过来的θ′相,其中T1相的强化占主导作用,这两种强化相的组合,提高了合金的硬度和强度[21];而未经预变形的CA1试样在蠕变时效过程中,没有具备有利于T1相在析出竞争中优先形核的条件,使得θ′相的析出明显占据优势,T1相只能在蠕变时效过程中少量析出,其强化效果远远低于CA2试样的。

图6(c)和(d)分别为CA1试样与CA2试样在亚晶界出析出相析出分布情况的TEM像。由图可知,CA2试样中T1相在亚晶界的富集程度要低于CA1试样的。而合金的抗晶间腐蚀性能与亚晶界处析出相的大小、分布等密切相关,亚晶界处析出相分布较多,在晶间腐蚀过程中表现为阳极相,阳极性的亚晶界构成物与晶格本体的腐蚀电位差异形成电偶腐蚀,进而发生晶间腐蚀[22-23]。CA2试样由于初始预变形的引入,晶内析出相增多且均匀,而亚晶界T1相富集程度相对降低,所以晶间腐蚀抗力有所增强,晶间腐蚀程度减缓。

图5 不同初始状态2195铝锂合金蠕变时效2 h的TEM像及[110]Al的SAED谱

Fig. 5 TEM images of 2195 Al-Li alloy creep-aging for 2 h and SAED spectra of [110]Al

图6 不同初始状态2195铝锂合金蠕变峰值时效的TEM像及[110]Al的SAED谱

Fig. 6 TEM images of 2195 Al-Li alloy after creep peak age and SAED spectra of [110]Al

3 结论

1) 在蠕变时效过程中,合金的硬度和强度呈现先升高,到达峰值之后再缓慢下降的趋势。其中,CA2试样在16 h达到了蠕变时效硬度与强度峰值,较CA1试样提前了4 h,且CA2试样峰值区域更为明显。相比于CA1试样,CA2试样硬度和强度明显提高,伸长率降低。CA1试样在蠕变峰值时效状态下的抗拉强度、屈服强度和伸长率分别为470 MPa、324 MPa和20%;CA2试样在蠕变峰值时效状态下的抗拉强度、屈服强度和伸长率分别为585 MPa、546 MPa和10%。

2) 蠕变峰值时效状态下,CA2试样的抗晶间腐蚀能力比CA1试样高。CA1试样发生了严重的晶间腐蚀,最大腐蚀深度达到了180.6 μm,按晶间腐蚀等级评定标准其腐蚀等级为4级;CA2试样最大腐蚀深度为92.0 μm,腐蚀等级为3级。

3) CA1试样与CA2试样在蠕变峰值时效时,T1相的分布有明显差异。CA1试样晶内析出相以大量细小致密的θ′相为主,可见少量T1相。CA2试样晶内则在析出细小θ′相的同时,析出了大量的T1相。且CA2试样中T1相在亚晶界的富集程度要低于CA1试样的。

REFERENCES

[1] RIOJA R J, LIU J. The evolution of Al-Li base products for aerospace and space applications[J]. Metallurgical and Materials Transactions A, 2012, 43(9): 3325-3337.

[2] WARNER T. Recently-developed aluminium solutions for aerospace applications[J]. Materials Science Forum, 2006, 519/521: 1271-1278.

[3] HALES S J, TAYON W A. Heat treatment of a friction-stir-welded and spin-formed Al-Li alloy[J]. Procedia Engineering, 2011, 10(7): 2496-2501.

[4] JIANG N, GAO X, ZHENG Z Q. Microstructure evolution of aluminium-lithium alloy 2195 undergoing commercial production[J]. Transactions of nonferrous metals society of China, 2010, 20(5): 740-745.

[5] PRASAD N E, GOKHALE A, WANHILL R J H. Aluminum-lithium alloys: Processing, properties, and applications[M]. Oxford: Butterworth-Heinemann, 2013: 3-19.

[6] NAYAN N, MURTY S N, JHA A K, PANTB, SHARMA S, GEORGE K M, SASTRY G. Mechanical properties of aluminium-copper-lithium alloy AA2195 at cryogenic temperatures[J]. Materials & Design, 2014, 58: 445-450.

[7] HATAMLEH O, HILL M, FORTH S, GARCIAD. Fatigue crack growth performance of peened friction stir welded 2195 aluminum alloy joints at elevated and cryogenic temperatures[J]. Materials Science and Engineering A, 2009, 519(1/2): 61-69.

[8] ZHAN L H, LIN J G, DEAN T A. A review of the development of creep age forming: Experimentation, modeling and applications[J]. International Journal of Machine Tools and Manufacture, 2011, 51(1): 1-17.

[9] ZHU A W, JR E A S. Stress aging of Al-xCu alloys: Experiments[J]. Acta Materialia, 2001, 49(12): 2285-2295.

[10] AHMADI S, ARABI H, SHOKUHFAR A. Formation mechanisms of precipitates in an Al-Cu-Li-Zr alloy and their effects on strength and electrical resistance of the alloy[J]. Journal of Alloys and Compounds, 2009, 484(1/2): 90-94.

[11] DONNADIEU P, SHAO Y, GEUSERF D, BOTTON G A, LAZAR S, CHEYNET M, BOISSIEU M, DESCHAMPS A. Atomic structure of T1 precipitates in Al-Li-Cu alloys revisited with HAADF-STEM imaging and small-angle X-ray scattering[J]. Acta Materialia, 2011, 59(2): 462-472.

[12] 程 彬, 郑子樵, 范春平, 钟继发, 韩 烨, 孙景峰. 时效制度对新型 Al-Cu-Li 合金组织与性能的影响[J]. 中国有色金属学报, 2014, 24(4): 926-933.

CHENG Bin, ZHENG Zi-qiao, FAN Chun-ping, ZHONG Ji-fa, HAN Ye, SUN Jing-feng. Effect of aging treatments on microstructures and properties of new Al-Cu-Li alloy[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(4): 926-933.

[13] 张 健, 朱瑞华, 李劲风, 马云龙, 刘德博, 郑子樵. 时效前处理对新型 Al-Cu-Li-X 合金力学性能和显微组织的影响[J]. 中国有色金属学报, 2015, 25(12): 3300-3308.

ZHANG Jian, ZHU Rui-hua, LI Jin-feng, MA Yun-long, LIU De-bo, ZHENG Zi-qiao. Effect of heat treatment before aging on tensile properties and microstructures of new Al-Cu-Li-X alloy[J]. The Chinese Journal of Nonferrous Metals, 2015, 25(12): 3300-3308.

[14] 李红英, 张孝军, 张建飞, 郑子樵. 分级时效对新型 Al-Cu-Li 合金组织与性能的影响[J]. 中国有色金属学报, 2008, 18(3): 426-432.

LI Hong-ying, ZHANG Xiao-jun, ZHANG Jian-fei, ZHENG Zi-qiao. Effect of multi-stage aging treatments on microstructures and mechanical properties of new-type Al-Cu-Li alloy[J]. The Chinese Journal of Nonferrous Metals, 2008, 18(3): 426-432.

[15] 李劲风, 张 昭, 程英亮,曹发和, 张鉴清, 曹楚南. 时效状态对Al-Cu-Li-Mg-Ag-Zr合金在3.0%NaCl溶液中局部腐蚀的影响[J]. 中国有色金属学报, 2002, 12(5): 967-971.

LI Jing-feng, ZHANG Zhao, CHENG Ying-liang, CAO Fa-he, ZHANG Jian-qing, CAO Chu-nan. Effect of aging state on localized corrosion behavior of Al-4.0Cu-1.0Li- 0.4Mg-0.4Ag-0.14Zr alloy in 3.0% NaCl solution[J]. The Chinese Journal of Nonferrous Metals, 2002, 12(5): 967-971.

[16] GB/2039-2012. 金属材料单轴拉伸蠕变试验方法[S].

GB/2039-2012. Metallic materials—Uniaxial creep testing method in tension[S].

[17] GB/7998-2005. 铝合金晶间腐蚀测定方法[S].

GB/7998-2005. Test method for intergranular corrosion of aluminium alloy[S].

[18] DECREUS B, DESCHAMPS A, DE GEUSER F, DONNADIEU P, SIGLI C, WEYLAND M. The influence of Cu/Li ratio on precipitation in Al-Cu-Li-X alloys[J]. Acta Materialia, 2013, 61(6): 2207-2218.

[19] JO H H, HIRANO K I. Precipitation processes in Al-Cu-Li alloy studied by DSC[J]. Materials Science Forum, 1987, 13/14: 377-382.

[20] CASSADA W A, SHIFLET G J, STARKE E A. Mechanism of Al2CuLi (T1) nucleation and growth[J]. Metallurgical and Materials Transactions A, 1991, 22(2): 287-297.

[21] ZHU A W, CSONTOS A, JR E A S. Computer experiment on superposition of strengthening effects of different particles[J]. Acta Materialia, 1999, 47(6):1713-1721.

[22] MAITRA S, ENGLISH G C. Mechanism of localized corrosion of 7075 alloy plate[J]. Metallurgical Transactions A, 1981, 12(3): 535-541.

[23] BUCHHEIT R G, MORAN J P, STONER G E. Electrochemical behavior of the T1(Al2CuLi) intermetallic compound and its role in localized corrosion of Al-2% Li-3% Cu alloys[J]. Corrosion, 1994, 50(2): 120-130.

Properties evolution and microstructure analysis of creep aging process in Al-Cu-Li alloy

TAN Jia1, ZHANG Jin1, 3, DENG Yun-lai2, 3, ZHANG Xin-ming2, 3

(1. Light Alloy Research Institute, Central South University, Changsha 410083, China;

2. School of Materials Science and Engineering, Central South University, Changsha 410083, China;

3. State Key Laboratory of High Performance and Complex Manufacturing, Central South University, Changsha 410083, China)

Abstract: The tensile properties and microstructure characteristics of Al-Cu-Li alloy during creep aging were studied by optical microscopy and transmission electron microscopy, tensile mechanical properties and Vickers hardness. The results show that the hardness and tensile strength increase gradually to the maximum, and then decrease slowly during creep aging. The maximum hardness and tensile strength are obtained after the CA2 sample (creep aging after 2% pre-stretching) creep aging for 16 h, which reaches the maximum values than CA1 sample (creep aging without pre-stretching) earlier about 4 h. When compared with CA1 samples in the creep aging, the peak value is sharper in the CA2 samples and possess higher hardness and tensile strength, but lower elongation. Under the condition of peak creep aging, the maximum intergranular corrosion depth of CA1 specimen is 180.6 μm, and the corrosion level is 4. The maximum intergranular corrosion depth of the CA2 specimen is 92.0 μm and the corrosion level is 3. TEM results show that the CA1 sample is dominated by small, dense θ′ phases, and a small amount of T1 phases can be seen in the crystal. For the sake with a precipitation advantage at the initial stage in the CA2 sample, a large number of T1 phases are precipitated in the crystal accompanying with a small θ′ phase, and the enrichment of precipitated T1 at the sub-crystal boundary is lower than that in the CA1 sample.

Key words: Al-Cu-Li alloy; creep aging; mechanical property; intergranular corrosion; T1 phase

Foundation item: Project(2017YFB0306301) supported by the National Basic Research Development Program of China; Project(51705539) supported by the National Natural Science Foundation of China; Project (ZZYJKT2016-01) supported by State Key Laboratory of High Performance Complex Manufacturing Independent Subject, China

Received date: 2018-06-28; Accepted date: 2018-12-30

Corresponding author: ZHANG Jin; Tel: +86-731-88876913; E-mail: zhangjinlari@csu.edu.cn

(编辑 李艳红)

基金项目:国家重点研发计划重点专项项目(2017YFB0306301);国家自然科学基金资助项目(51705539);高性能复杂制造国家重点实验室自主课题(ZZYJKT2016-01)

收稿日期:2018-06-28;修订日期:2018-12-30

通信作者:张 劲,副教授,博士;电话:0731-88876913;E-mail:zhangjinlari@csu.edu.cn