DOI:10.19476/j.ysxb.1004.0609.2017.06.025

N235选择性萃取烟气淋洗液中的铼

王海东,王送荣,甘 敏,范晓慧,邓 琼,郭 慧

(中南大学 资源加工与生物工程学院,长沙 410083)

摘 要:利用N235萃取剂,开展含铼钼精矿焙烧烟气淋洗液中铼和钼分离、提取的研究。结果表明:H+浓度、酸根离子种类和有机相组成都会对钼和铼的萃取率及其分离系数产生较大影响。在硫酸浓度为2.5 moL/L、有机相组成为3% N235+30%仲辛醇+67%煤油(体积分数)条件下,铼的萃取率高、钼铼分离系数大。N235萃取的最优工艺条件为:相比O/A为1:4、萃取平衡时间为2 min、萃取温度为常温。单级逆流萃取铼的萃取率为90.64%,钼的萃取率为10.20%。采用二次三级逆流萃取,铼的总萃取率高达99.41%,而钼的总萃取率仅为11.49%。在此基础上,以氨水为反萃剂,经过浓缩结晶可制得纯度大于99%的高铼酸铵,整个萃取反萃工艺流程铼的综合回收率达到96.04%,实现铼的高效提取。

关键词:N235;萃取;分离;铼;钼

文章编号:1004-0609(2017)-06-1302-08 中图分类号:TF841.8 文献标志码:A

铼是一种稀散金属[1],具有熔点高、耐磨损、耐腐蚀、机械性能稳定等优异性能,还具有优良的催化活性。作为一种重要的战略物资,应用于航空航天、电子、石油化工等领域,其中约78%用于超高温合金领域,20%应用于催化剂[2-4]。铼没有独立的矿物,在地壳中的含量极其稀少,主要分散在辉钼矿和铜铼硫化矿物中[5],2014年全球铼金属的年产量仅48.8t,其中约80%来自开采的铼矿物,且过半数的铼产自智利。近年来,全球对铼的需求以每年5%的速度增长,加剧了铼的供需矛盾,因此尽可能提高一次资源铼的回收率,降低生产成本,对稀贵金属的综合回收利用具有重要意义。

针对含铼溶液中富集并回收铼的方法较多[6-7],主要有沉淀法、离子交换法[8-10]、萃取法[11-17]、液膜法等,其中萃取法和离子交换法应用最为广泛。离子交换法操作简便,选择性较高。林春生等[9]、马红周等[10]用201×7阴离子交换树脂分别对钼精矿焙烧烟气淋洗液和烟尘浸出液中的铼进行分离富集,在溶液pH=9时,可选择性分离富集铼,铼上柱率在87%以上。但离子交换树脂成本高、吸附容量较小、处理时间长,只适合从低含铼溶液中回收铼。萃取法具有萃取容量大、处理时间短、工艺成熟等特点,高志正[15]用N235从净化洗涤污酸中提取金属铼,当铼含量为19.8 mg/L,萃取率为96%。然而,当溶液中钼含量很高时,萃铼的同时会同时萃取钼,还需通过离子交换进一步分离钼和铼,邹振球等[16]采用石灰焙烧钼精矿-酸浸-萃取-离子交换回收钼铼,各工序铼的回收率为:萃取工序97.5%,酸沉工序99.0%,离子交换工序98.6%,可有效分离富集含高浓度钼溶液中的铼,但此法工艺流程较长、生产过程复杂,铼综合回收率较低。若能在萃取过程选择性提取铼,则可缩短工艺流程,减少溶液量。

本文作者通过研究溶液酸度、酸根离子种类和有机相组成对淋洗液中铼和钼分离的影响,确定了适宜的选择性萃取铼的条件和萃取工艺流程,对稀贵金属的综合回收利用具有较大的借鉴意义。

1 实验

1.1 试验原料

试验原料为某含铼钼精矿(Re 0.034%、Mo 39.27%)氧化焙烧的烟气淋洗液,淋洗液的主要成分见表1。从表中可以看出:淋洗液中含铼28.13 mg/L,而溶液中钼含量较高,为3193.58 mg/L,主要杂质为Fe3+、Mg2+、Cu2+、Na+、Al3+、Zn2+、SO42-等。

表1 原料主要化学成分

Table 1 Main chemical compositions of raw materials (mg/L)

本实验选用三烷基叔胺N235(简称R3N)作为萃取剂,试验过程所用试剂均为分析纯,主要有稀释剂磺化煤油、浓盐酸、浓硫酸、浓硝酸、硫酸钠、硝酸钠、氯化钠等,以及浓度>98%的助溶剂仲辛醇。

1.2 实验步骤及分析方法

采用萃取分离法对铼钼进行分离富集:量取一定体积已调配好酸碱度和盐浓度的淋洗液于125 mL分液漏斗中,按设定相比加入有机相,在震荡器上震荡一定时间,静置25 min,直到两相界面清晰后进行分相,检测水相中待测离子浓度。采用PHS-3C型pH计测定pH值,用ICP-MASS测定溶液中的金属浓度,有机相中的金属浓度通过差减法计算得出。对于多级逆流萃取过程采用串级实验来模拟。

萃取过程评价指标主要有钼和铼的萃取率 、

、 ,钼和铼萃取平衡时分配比

,钼和铼萃取平衡时分配比 、

、 ,钼和铼的分离系数E。

,钼和铼的分离系数E。

(1)

(1)

(2)

(2)

(3)

(3)

(4)

(4)

式中:v1、v2 分别为萃取原液、萃余液的体积,L; 、

、 分别为萃取原液、萃余液的钼含量,mg/L;

分别为萃取原液、萃余液的钼含量,mg/L; 、

、 分别为萃取原液、萃余液的铼含量,mg/L;DMo、DRe分别为萃取平衡时钼和铼的分配比;MC、MR分别为有机相中的金属浓度和水相中的金属浓度,mg/L;E表示萃取平衡时铼和钼的分离系数。

分别为萃取原液、萃余液的铼含量,mg/L;DMo、DRe分别为萃取平衡时钼和铼的分配比;MC、MR分别为有机相中的金属浓度和水相中的金属浓度,mg/L;E表示萃取平衡时铼和钼的分离系数。

2 钼和铼选择性萃取分离

2.1 钼存在形态对钼铼萃取率的影响

N235的萃取机理为离子缔合,萃取时N235先结合一个H+,如式(5)所示:

R3N+H+  R3NH+ (5)

R3NH+ (5)

然后再与金属阴离子配对,形成稳定的萃合物进入有机相,钼酸根的聚合状态[18-20]与溶液pH值有关,钼酸在酸化过程中,其主要变化如式(6)所示:

(6)

(6)

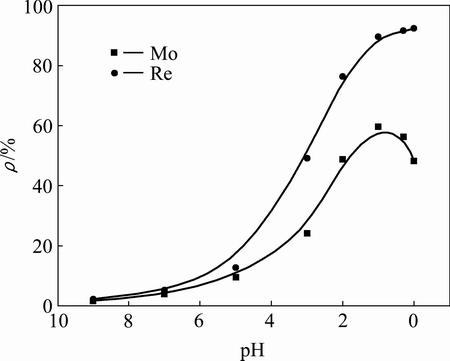

采用NaOH和H2SO4调节淋洗液的H+浓度,研究了淋洗液中H+浓度对钼和铼的萃取率的影响。量取100 mL不同酸度的淋洗液于125 mL分液漏斗中,再加入25 mL组成为3%N235+30%仲辛醇+67%煤油(体积分数)的有机相,在室温、相比(O/A)为1:4条件下震荡摇晃3 min,静置分相25 min,萃取结果如图1所示。

图1 料液酸度对萃取率的影响

Fig. 1 Effect of solution acidity on extractive efficiency

当溶液酸碱度呈中性或碱性时,钼和铼几乎不会被萃取进入有机相。当pH小于3时,钼和铼的萃取率急剧增加;pH=1左右时,钼萃取率达到最大值。这是因为 N235在萃取过程中必须有H+参与反应,萃取率与溶液的酸度相关,少量的酸即可达到较高的萃取率。

继续增加H+浓度,钼萃取率下降,铼萃取率基本不变。当pH<1时,溶液中的钼部分以钼酰阳离子MoO22+存在,N235对钼的萃取率反而会下降,而铼依然以阴离子ReO4- 存在,其萃取率基本保持不变。

2.2 酸根离子对钼铼萃取率的影响

水相中阴离子种类和浓度对萃取率和分配比具有一定影响,为进一步确定用来调节H+浓度的酸的种类对钼和铼分离效率的影响,分别添加硫酸、盐酸、硝酸溶液调节淋洗液的酸度,同时添加相对应的硫酸钠、氯化钠、硝酸钠来调节溶液中SO42-、Cl-和NO3-的浓度至2 mol/L,在相同的实验条件下得到实验结果如图2所示。

图2 H+浓度和阴离子种类对Mo、Re分离系数的影响

Fig. 2 Effect of H+ concentration and types of acid radical ions on separation coefficient of Mo and Re

阴离子半径越大,电荷越少,则水化程度越低,越有利于被交换萃取[13],常见的几种阴离子对萃取影响由大到小依次为SO42-、CO32-、Cl-、NO3-。对比图2可知,在相同酸度和阴离子浓度下,溶液中SO42-存在时,相比于Cl-和NO3-,钼和铼分离系数更高,且随着溶液酸度的提高,钼和铼的分离系数迅速升高。当溶液中H+浓度为5 mol/L,SO42-浓度为2 mol/L时,铼萃取率为91.27%,此时钼萃取率仅为10.27%,钼和铼的分离系数达到85.26。因此,可通过添加硫酸来增加溶液酸度和SO42-浓度,从而提高钼和铼的分离效率。

添加硫酸使溶液中SO42-浓度升高,部分MoO22+会和SO42-结合成MoO2(SO4)22-,硫酸溶液中的钼和铼主要以Mo7O246-、MoO2(SO4)22-、ReO4-等形态存在,因此,吸收液中以ReO4-和MoO2(SO4)22-等阴离子形态存在的铼和钼易被N235选择性萃取而与其他杂质阳离子分离。因此,在一定酸度范围内,添加硫酸可以使Mo(Ⅵ)、Re(Ⅶ)的萃取率都得以提高。其萃取反应式如下:

R3N(O)+H2SO4(W)  R3NH·HSO4(O) (7)

R3NH·HSO4(O) (7)

R3NH·HSO4(O)+HReO4(O)  R3NH·ReO4(O)+H2SO4(W) (8)

R3NH·ReO4(O)+H2SO4(W) (8)

R3NH·HSO4(O)+H2MO2(SO4)2(W)  (R3NH)2MOO2(SO4)(O)+2H2SO4(W) (9)

(R3NH)2MOO2(SO4)(O)+2H2SO4(W) (9)

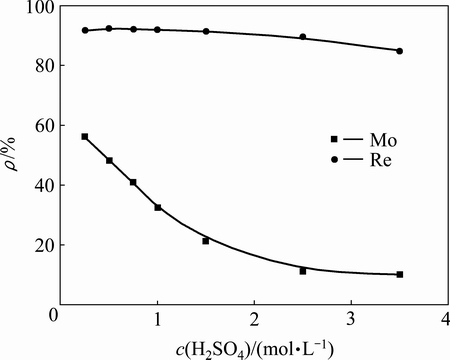

由图3可知,当硫酸添加量增大时,铼的萃取率基本不变,而钼萃取率急剧下降。因为过多的SO42-会和ReO4-、MoO2(SO4)22-形成竞争萃取关系,使有机相中自由的N235浓度降低,同时过多的SO42-也会促进钼萃取平衡式(9)的逆向进行。

综上所述,在H2SO4浓度较低时,SO42-的同离子效应起主导作用,因而钼和铼的分配比随H2SO4浓度的增大而提高;高酸度时,H2SO4的竞争萃取起主导作用,且对MoO2(SO4)22-的抑制效果更强,而对ReO4-的萃取影响较小。料液酸度(酸度N:表示溶液中H+当量浓度,对于1N H2SO4=0.5 mol/L H2SO4)达到5N(即H2SO4浓度为2.5 mol/L)后,随料液酸度的继续提高,铼的萃取率小幅下降,钼萃取率变化幅度很小,由此可以通过添加较多的硫酸来抑制钼的萃取,达到萃取分离钼和铼的目的。从试验现象看,酸度达到5N时,有机相和水相分层的速度较快,此时,铼萃取率达到了90.64%,钼萃取率仅为10.20%,因此,选择5N作为料液酸度进行萃取较为理想。

图3 硫酸添加量对萃取率的影响

Fig. 3 Effect of sulphuric acid amount on extractive efficiency

2.3 有机相组成的影响

加入硫酸调节淋洗液酸度为5N,在控制有机相中仲辛醇体积分数为30%、萃取相比(O/A)为1/4、萃取时间3 min的条件下,研究了有机相中N235浓度(体积分数)对Re、Mo萃取率的影响,结果如图4(a)所示。可知,随着N235浓度的提高,Re和Mo的萃取率逐渐提高后趋于平缓。当N235浓度为2.5%时,钼萃取率仅为7.82%,铼萃取率为77.44%;提高N235体积浓度至3%,铼萃取率达到90.64%,钼萃取率为10.20%;继续提高N235浓度,铼萃取率仍有小幅提升,但钼的萃取率急剧上升;当N235的体积浓度达到35%以上,钼和铼的萃取率均达92%以上。由实验结果可知,ReO4-和MoO2(SO4)22-形成竞争萃取关系,N235对ReO4-比MoO2(SO4)22-有更强的亲和力,能优先被萃取,因此可以采用低浓度N235萃取铼,再用高浓度N235萃取钼,以达到分离、提取铼和钼的目的。因此,最佳的萃取剂N235体积浓度为3%。

图4 有机相组成对铼萃取率的影响

Fig. 4 Effect of organic phase compositions on extractive efficiency

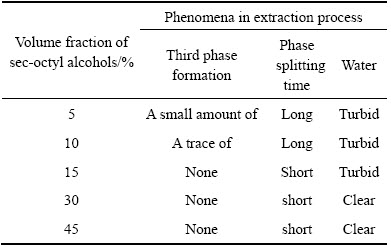

固定有机相中N235体积分数3%,通过改变仲辛醇的浓度和煤油的比例,研究了仲辛醇浓度对 Re、Mo萃取率的影响,结果如表2和图4(b)所示。

表2 仲辛醇含量对萃取过程的影响

Table 2 Effect of sec-octyl alcohols content in extraction process

淋洗液中Fe3+、Mg2+、SiO2、微细气泡和悬浮微粒等可能会导致乳化或第三相的生成,一方面会造成萃取剂的损耗量增加,另一方面会严重影响分相速度,使萃取作业不能正常进行。加入适当的仲辛醇有利于萃取过程中第三相或固相的消除,由表2可知,随着仲辛醇用量的增加,萃取过程的稳定性增强,分相速度加快。这是因为N235在萃取过程中与水相中的ReO4-和MoO2(SO4)22-作用形成亲水性很强的水合络合物,加入仲辛醇后,醇中的羟基能取代络合物中的部分或全部水分子,提高萃合物的疏水性,加速油相和水相的分层。

从图4(b)中可以看出,当仲辛醇体积分数从5%增加到30%时,钼萃取率从41.31%降至10.20%,铼萃取率稍有降低。因此,有机相中的仲辛醇对钼的萃取有抑制作用,对铼的萃取影响相对较小,适当提高有机相中仲辛醇的含量有利于铼的选择性萃取,但仲辛醇的沸点低、易挥发,对环境污染大,用量不宜过高,选用30%作为仲辛醇的添加量进行萃铼较为合适。

3 N235分离钼和铼的工艺优化

3.1 相比、萃取时间、萃取温度等参数的优化

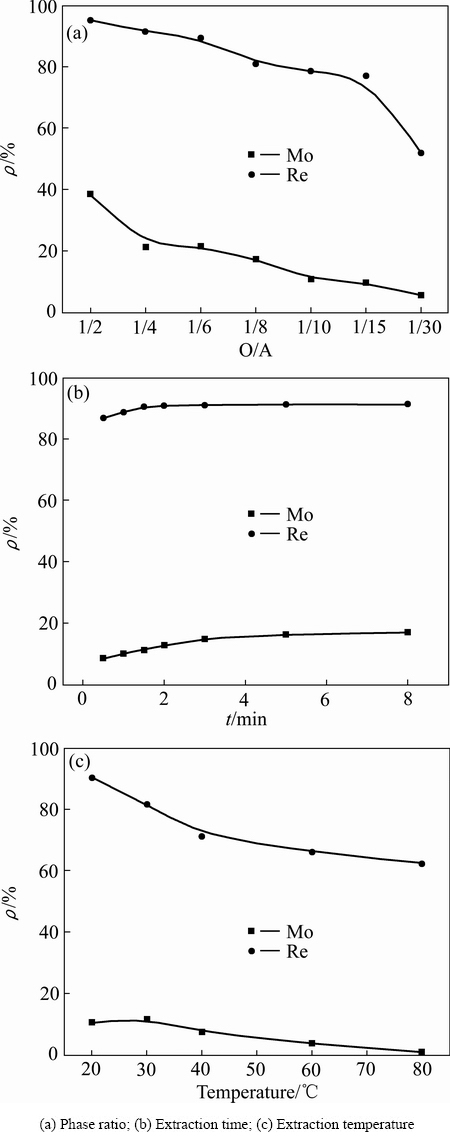

在有机相组成为3% N235+30%仲辛醇+67%煤油、淋洗液酸度为5N的条件下,研究了相比O/A、萃取时间和萃取温度等对Re和Mo萃取率的影响,结果如图5所示。

图5 萃取条件对萃取率的影响

Fig. 5 Effect of extraction conditions on extractive efficiency

从图5(a)可以看出,萃取相比O/A在1/2~1/6之间变化时,铼的萃取率均较高,萃取率可以达到或接近90%;随着有机相相对比例的继续降低,铼的萃取率有较大程度的下降,当O/A相比降低到1/8后,铼的萃取率低于80%;而对于钼的萃取来说,当O/A相比为1/2时,钼的萃取率也较高,达到了20.38%,不利于钼铼的分离;而当O/A相比降低到1/4时,钼的萃取率有较大程度的降低。因此选择相比1/4进行萃取。

铼的萃取平衡时间很短,一般1.5 min左右即可达到萃取平衡,且达到平衡后,随着混合时间的增加,萃取率无明显改变。主要是由于ReO4-的分配系数大,使得萃取平衡的时间很短,因此选用1.5~2 min作为萃取混合时间较为理想。

温度可以改变萃合物的构型,对萃合物在有机相中的溶解度也有较大影响。从图5(c)可以看出,萃取温度对钼和铼的萃取都有较大影响。钼和铼的萃取反应为放热反应,升高温度,钼和铼萃取率都会降低,但铼萃取率降低的速度更快,反而会使铼和钼的分离系数降低,且提高料液温度会消耗大量能量,增加操作流程和操作难度,同时会提高有机物的挥发速率,提高生产成本,因此,在常温下进行萃取比较合适。

综上可知,单级最优选择性萃取铼的条件:有机相组成为3% N235+30%仲辛醇+67%煤油,单级萃取相比O/A为1:4,酸度为5N,萃取平衡时间为2 min,萃取温度为常温。在此条件下,单级萃取萃余液各成分浓度如表3所列。

由表3可得,萃取剂N235基本不萃取金属阳离子,能实现有价金属铼和其他金属阳离子的分离,在最优萃取条件下,钼和铼能达到较好的分离效果。

表3 萃余液主要成分及其萃取率

Table 3 Main chemical compositions and extraction rate of raffinate

3.2 萃取流程的优化

为进一步降低有机相中钼含量及其他杂质含量,分离提纯铼,采用多次多级逆流萃取。研究结果表明,在三级逆流萃取结束时,铼和钼的总萃取率分别为99.41%和10.74%。富铼有机相经过三级逆流反萃,铼和钼的反萃率均达到99%以上,反萃条件为:氨水浓度为7N(质量分数约为15%),反萃相比O/A为4:1,反萃混合时间为2 min,反萃温度为常温。在一次三级逆流萃取-氨水反萃后,通过添加硫酸调节含铼反萃氨水酸度至5N,在上述最佳萃取和反萃条件下再次萃取-反萃,经过二次萃取反萃后,最终得到富铼溶液中含铼2330.5 mg/L,含钼42.54 mg/L,将含铼酸铵的溶液保持在80~85℃条件下浓缩至原体积的1/3,自然冷却至环境温度后,再放置于冰箱中,在-1~4 ℃条件下冷却90 min,-1~4 ℃条件下过滤,得到结晶物质并进行离心脱水处理后,再放置于烘箱中,在60 ℃条件下均匀干燥60 min,即得到粗高铼酸铵晶体,用氨水溶解粗高铼酸铵晶体并再次在相同条件下浓缩结晶得到高纯度高铼酸铵晶体,试验流程如图6所示。

图6 高铼酸铵生产工艺流程图

Fig. 6 Flowsheet of ammonium rhenium production process

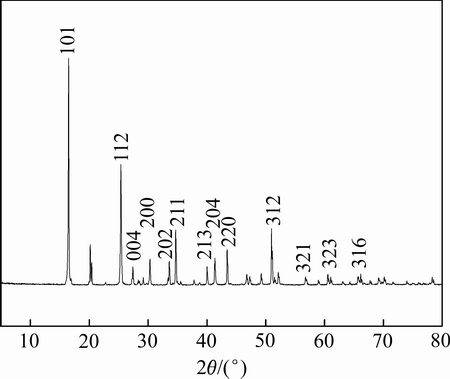

产品为白色晶体粉末,X射线粉末衍射(XRD)分析结果见图7。结果表明,产品晶形规整,与标准图谱对比,所得产品为高铼酸铵(NH4ReO4)。采用ICP-MS测得产品中铼含量为67.80%(质量分数),产品纯度(w[NH4ReO4])为99.5%以上,主要指标达到高铼酸铵产品技术指标【YS/T 894-2013】要求。

图7 高铼酸铵产品的XRD谱

Fig. 7 XRD patterns of ammonium perrhenate product

4 结论

1) 采用N235萃取钼和铼时,溶液中H+浓度和酸根离子种类对钼铼萃取率有较大影响。相比于Cl-和NO3-,添加SO42-可显著提高铼、钼的分离系数。当溶液中H2SO4浓度为2.5 moL/L时,钼萃取率降至10.20%,因此,可通过添加适量的硫酸有效抑制钼的萃取,从而改变钼和铼的萃取率,达到选择性萃取铼的目的。

2) 有机相组成也会对铼的选择性萃取有影响。萃取过程中,由于N235对ReO4-的强亲和力,结合仲辛醇对萃钼的有效抑制可在较低浓度N235条件下通过添加较高浓度的仲辛醇来达到优先萃取Re同时抑制钼萃取的目的,提高铼和钼的分离系数。

3) 对于淋洗回收得到的含铼溶液(Mo 3193.58 mg/L,Re 28.13 mg/L),最优萃取分离富集铼的工艺条件为:硫酸浓度为2.5 moL/L,有机相组成为3% N235+30%仲辛醇+67%煤油,相比O/A为1:4,萃取平衡时间为2 min,萃取温度为常温。采用单级萃取时,钼(Ⅵ)和铼(Ⅶ)萃取率分别为10.20%和90.64%,采用三级逆流萃取时,钼和铼的萃取率分别为10.73%和99.41%,萃取段铼综合回收率为96.04%。该工艺流程短,能选择性地分离富集高钼铼比淋洗液中的铼。

REFERENCES

[1] TAGAMI K,UCHIDA S. Determination of bioavailable rhenium fraction in agricultural soils[J]. Journal of Environmental Radioactivity, 2008, 99(6): 973-980.

[2] 杨尚磊, 陈 艳, 薛小怀, 李仕民, 楼松年. 铼(Re)的性质及应用研究现状[J]. 上海金属, 2005(1): 45-49.

YANG Shang-lei, CHEN Yan, XUE Xiao-huai, LI Shi-min, LOU Song-nian. The property and application research situation of rhenium(Re)[J]. Shanghai Metals, 2005(1): 45-49.

[3] 李红梅, 贺小塘, 赵 雨, 郭俊梅, 韩守礼, 王 欢, 李 勇, 谭明亮. 铼的资源、应用和提取[J]. 贵金属, 2014, 35(2): 77-81.

LI Hong-mei, HE Xiao-tang, ZHAO Yu, GUO Jun-mei, HAN Shou-li, WANG Huan, LI Yong, TAN Ming-liang. Resources, application and extraction status of rhenium[J]. Precious Metals, 2014, 35(2): 77-81.

[4] LEICHTERIED G, SCHNEIBEL J H, HEILMAIER M. Ductility and impact resistance of powder-metallurgical molybdenum- rhenium alloys[J]. Metallurgical and Materials Transactions A, 2006, 37(10): 2955-2961.

[5] 彭 真, 罗明标, 花 榕, 廖桢葳. 从矿石中回收铼的研究进展[J]. 湿法冶金, 2012, 31(2): 76-80.

PENG Zhen, LUO Ming-biao, HUA Rong, LIAO Zhen-wei. Research situation on recovery of rhenium from uranium ore[J]. Hydrometallurgy of China, 2012, 31(2): 76-80.

[6] 邓桂春, 滕洪辉, 刘国杰, 侯松嵋, 张渝阳, 王 鑫, 臧树良. 铼的分离与分析研究进展[J]. 稀有金属, 2004, 28(4): 771-776.

DENG Gui-chun, TENG Hong-hui, LIU Guo-jie, HOU Song-mei, ZHANG Yu-yang, WANG Xin, ZANG Shu-liang. Advance in research on rhenium separation and analysis methods[J]. Chinese Journal of Rare Metals, 2004, 28(4): 771-776.

[7] 钟 宏, 曹占芳, 邱朝辉. 德兴铜矿辉钼矿精矿的选择性电氧化浸出与分离过程[J]. 中国有色金属学报, 2013, 23(8): 2290-2294.

ZHONG Hong, CAO Zhan-fang, QIU Zhao-hui. The selective electric-oxidation leaching and separation of Dexing molybdenite concentrates[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(8): 2290-2294.

[8] 张 俊, 姚 林, 吕改芳, 邓桂春. D-314树脂动态分离钼铼的研究[J]. 稀有金属, 2010, 34(1): 85-89.

ZHANG Jun, YAO Lin,  Gai-fang, DENG Gui-chun. Dynamic separation of molybdenum and rhenium by D-314 resin[J]. Chinese Journal of Rare Metals, 2010, 34(1): 85-89.

Gai-fang, DENG Gui-chun. Dynamic separation of molybdenum and rhenium by D-314 resin[J]. Chinese Journal of Rare Metals, 2010, 34(1): 85-89.

[9] 林春生, 高青松. 用201×7树脂离子交换法回收淋洗液中铼的研究[J]. 中国钼业, 2009, 33(3): 30-31.

LIN Chun-sheng, GAO Qing-song. Research on recovery of rhenium from drip-washing liquid by ion exchange with 201×7 resins[J]. China Molybdenum Industry, 2009, 33(3): 30-31.

[10] 马红周, 王耀宁, 兰新哲. 树脂富集铼的研究[J]. 有色金属(冶炼部分), 2009(6): 43-45.

MA Hong-zhou, WANG Yao-ning, LAN Xin-zhe. Study on the sorption of rhenium by anion exchange resin[J]. Nonferrous Metals (Extractive Metallurgy), 2009(6): 43-45.

[11] 彭 真, 罗明标, 蒋小辉, 花 榕, 廖桢葳. 协同萃取法回收地浸采铀工艺树脂中铼[J]. 稀有金属, 2011(6): 922-927.

PENG Zhen, LUO Ming-biao, JIANG Xiao-hui, HUA Rong, LIAO Zhen-wei. Synergistic extraction of rhenium from In-Situ leach uranium mining technology resin[J]. Chinese Journal of Rare Metals, 2011(6): 922-927.

[12] ALAMDARI E K, DARVISHI D, HAGHSHENAS D F, YOUSEFI N, SADRNEZHAAD S K. Separation of Re and Mo from roasting-dust leach-liquor using solvent extraction technique by TBP[J]. Sep Purif Technol, 2012, 86: 143-148.

[13] 马荣骏. 萃取冶金[M]. 北京: 冶金工业出版社, 2009: 260-293.

MA Rong-jun. Extractive metallurgy[M]. Beijing: Metallurgic Industry Press, 2009: 260-293.

[14] FANG Da-wei, SHAN Wei-jun, YAN Qiang, LI Du, XIA Li-xin, ZANG Shu-liang. Extraction of rhenium from sulphuric acid solution with used amine N235[J]. Fluid Phase Equilibria, 2014(383): 1-4.

[15] 高志正. 从净化洗涤污酸中提取金属铼的试验研究[J]. 中国有色冶金, 2008(6): 68-70.

GAO Zhi-zheng. Experimental researching of extraction rhenium from waste acid washing[J]. China Nonferrous Metallurgy, 2008(6): 68-70.

[16] 邹振球, 周勤俭. 钼精矿石灰焙烧-N235萃取工艺提取钼铼[J]. 矿冶工程, 2002, 22(1): 79-81, 84.

ZOU Zhen-qiu, ZHOU Qin-jian. Recovery of molybdenum and rhenium from molybdenite concentrate in Dexing copper ore by lime roasting N235 extraction method[J]. Mining and Metallurgical Engineering, 2002, 22(1): 79-81, 84.

[17] 林春生. 萃取法从钼、铼溶液中回收铼[J]. 中国钼业, 2005, 29(1): 41-43.

LIN Chun-sheng. Recovery of rhenium from the mixed solution of molybdenum and rhenium by extraction[J]. China Molybdenum Industry, 2005, 29(1): 41-43.

[18] 蒋长俊. 酸性硫酸盐溶液体系中Mo(Ⅵ)的存在形态与其离子交换树脂吸附行为[D]. 长沙: 中南大学, 2014: 42.

JIANG Chang-jun. Existing forms and adsorption behavior on ion exchange resin of Mo(Ⅵ) in acidic sulfate solution[D]. Changsha: Central South University, 2014: 42.

[19] BETKE U, WICKLEDER M S. Sulfates of the refractory metals: Crystal structure and thermal behavior of Nb2O2(SO4)3, MoO2(SO4), WO(SO4)2 and two modifications of Re2O5(SO4)2[J]. Inorganic Chemistry, 2011, 50(3): 858-872.

Selective extraction Re by N235 in eluent of flue gas

WANG Hai-dong, WANG Song-rong, GAN Min, FAN Xiao-hui, DENG Qiong, GUO Hui

(School of Minerals Processing & Bioengineering, Central South University, Changsha 410083, China)

Abstract: The separation and extraction of Re and Mo using N235 from the enrichment of the eluent of the roasted molybdenum concentrate flue gas were investigated. The results show that the concentration of H+, types of acid radical ions and compositions of organic phase could have an significant effect on their extraction rate and separation coefficient of Mo and Re. The separation coefficient between Re and Mo and extraction rate of Re reach the peak value with the concentration of sulphuric acid 2.5 mol/L and the organic phase compositions 3% N235+30% octanol+67% kerosene. The optimal process conditions of N235 extraction process is as following: the ratio of O/A is 1:4 and keep extracted for 2 min at room temperature. Under the optimal conditions, the extraction rate of Re of single stage can reach 90.64%, while the extraction rate of Mo is only 10.20%. Moreover, using multi-stage countercurrent extraction, the extraction rate of Re is enhanced to 99.41% without obvious effect on the extraction rate of Mo which is only 11.49%. On this basis, ammonium perrhenate of purity more than 99% can be prepared using ammonia as stripping agent, and the comprehensive recovery rate of Re reaches 96.04% during the extraction process.

Key words: N235; extractive; separation; rhenium; molybdenum

Foundation item: Project(2013KJJH06) supported by China Nonferrous Metals Group Science and Technology Program

Received date: 2016-04-06; Accepted date: 2016-12-14

Corresponding author: WANG Hai-dong; Tel: +86-13974870583; E-mail: joewhd@126.com

(编辑 王 超)

基金项目:中国有色集团科技项目(2013KJJH06)

收稿日期:2016-04-06;修订日期:2016-12-14

通信作者:王海东,教授,博士;电话:13974870583;E-mail: joewhd@126.com