TiN涂层刀具对20CrMo钢的干切削性能的影响及磨损机理

韩文强1,何辉波1,李华英1,冉春华2,杨俊1

(1. 西南大学 工程技术学院,重庆,400715;

2. 西南大学 材料科学与工程学院,重庆,400715)

摘要:为了研究TiN涂层的摩擦性能及TiN涂层刀具对金属切削性能的影响,采用电弧离子镀工艺在45号钢基体和可转位硬质合金车刀YG6上沉积TiN涂层。采用球-盘式摩擦磨损实验仪对45号钢基体和TiN薄膜的干式摩擦学行为进行研究,用TiN涂层和未涂层的YG6车刀在CA6140A普通车床上对20CrMo钢进行干切削,对2种刀具切削过程中的切削力、工件表面质量及刀具磨损程度进行研究。研究结果表明:TiN薄膜和45号钢基体的平均摩擦因数为0.25和0.29;与未涂层刀具相比,TiN涂层刀具切削20CrMo钢时的主切削力可减小20%~40%,刀具耐磨性能约提高45%,寿命提高2倍左右,加工表面质量也明显提高;TiN涂层刀具前刀面的主要磨损机理是磨粒磨损,附带有黏结磨损、氧化磨损和扩散磨损。

关键词:TiN涂层刀具;干切削;切削力;刀具磨损

中图分类号:TH161 文献标志码:A 文章编号:1672-7207(2014)01-0064-07

Effect of TiN coated tools on machinability and wear mechanism in dry turning of 20CrMo steel

HAN Wenqiang1, HE Huibo1, LI Huaying1, RAN Chunhua2, YANG Jun1

(1. College of Engineering and Technology, Southwest University, Chongqing 400715, China;

2. College of Material Science and Engineering, Southwest University, Chongqing 400715, China)

Abstract: In order to explore the tribological properties of TiN films and the cutting performance of TiN coated carbide tools, TiN films were deposited on No.45 steel and YG6 indexable turning tools by Arc Ion Plating technique. The dry tribological behavior of the substrate and TiN films were tested in a ball-on-disk tribometer. The dry turning tests of 20CrMo steel were carried out with TiN coated and uncoated carbide tools on the CA6140A lathe. The effect of the two kinds of tools on cutting forces, surface qualities and tool wear was investigated to assess the performance of TiN coated tools. The results show that the friction coefficients of coatings and substrate are 0.25 and 0.29, respectively. In contrast to the uncoated YG6 tool, the cutting forces of coated tool are decreased by 20%-40%, and the flank wear resistance enhances by 45%, and life is improved by 200%. The coated cutting tools obviously outperform those uncoated tools in surface finish. The wear mechanisms of TiN coated tool in dry machining of 20CrMo steel is mainly abrasive wear, accompanied with adhesive, diffusion and oxidation wear.

Key words: TiN coated tools; dry turning; cutting forces; tool wear

干切削技术自20世纪90年代以来迅速发展,由于其不使用切削液,不会对环境产生污染,降低了生产成本,切削干净易于回收处理,正逐渐成为现代切削加工的主要方式[1-2]。在干切削钢类工件时,刀具材料的切削性能及刀具的寿命、磨损机理是一个重要问题[3]。王西彬[4]的研究表明:与湿式切削相比,干切削会使刀具与工件的摩擦因数变大,直接的加工能耗增大,切削温度显著升高,加工表面质量易于恶化,刀具磨损情况加剧。因此,常规的刀具材料及相关设计和工艺已不再适用于干切削,选择合适的刀具材料和设计刀具的表层特性成为近年来研究的热点。其中一个主要方法是在刀具上涂覆一层或多层硬度高、耐磨性好的金属或非金属氧化物薄膜,制成涂层刀具。涂层刀具与未涂层刀具相比,具有明显的优越性,如TiN涂层作为较早应用于刀具的保护涂层,具有良好的耐磨性能,可显著改善刀具的切削性能,减轻刃边材料的附着,降低切削力,维持切削几何的稳定,改善工件的表面质量,增大进刀量,提高加工精度和切削效率,是低速切削工具理想的涂层材料[5-6]。根据Grzesik[7]的研究,目前80%的机械加工采用了涂层刀具。20CrMo钢属于低碳合金结构钢,渗碳淬火处理后,机械性能优良,综合力学性能较好,是目前机械制造行业使用较为广泛的钢材之一,主要用于制作各种机械的重要部件如齿轮轴、轴套、连杆等[8]。根据金属切削理论,提高工件的切削速度可以减小切削力,但过高的切削速度会引起切削温度的剧增,使刀尖磨损加剧,工件加工表面层硬化。根据相关文献,铝的切削速度可达8 000 m/min,钛合金和铬镍铁合金的适宜切削速度为250 m/min左右,奥氏体不锈钢的适宜切削速度为150~350 m/min[9]。而目前人们对于20CrMo钢切削速度对切削力影响的研究较少。20CrMo含碳量较低,可切削加工性不如45号钢,因此,利用20CrMo钢作为工件材料来研究其切削加工性能显得十分必要。本文作者用TiN涂层刀具(基体为YG6硬质合金)和未涂层的YG6硬质合金刀具对20CrMo钢在不同切削速度下进行了干切削试验,分别对切削过程中的切削力进行监测,将工件表面质量和2种刀具的磨损程度及寿命进行对比,分析TiN涂层刀具的主要磨损机理。

1 试验设备与试验方法

1.1 试验设备

工件:20CrMo钢,基本尺寸(直径×长度)为46mm×450 mm,热处理状况正火,20CrMo钢的化学成分见表1[10]。

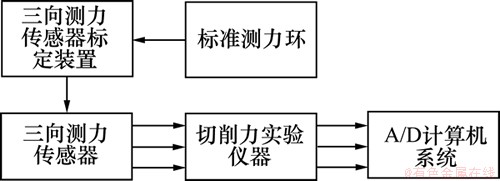

机床为沈阳第一机床厂生产的普通车床CA6140A×1000,主电机功率为7.5 kW,最大加工长度为900 mm,最大加工直径为400 mm,主轴转速范围为10~1 400 r/min。2种刀具分别为TiN涂层和未涂层的YG6硬质合金可转位车刀,型号均为T31605F。刀具几何参数见表2。采用重庆迪佳科技有限公司生产的SDC-L3M型应变式三向车削测力传感器和DJ-CL-1型三向力高精度放大器来完成切削力的采集和测量。切削力测力仪硬件系统简图见图1。摩擦磨损测量仪为瑞士CSM公司生产的球—盘式微动摩擦磨损试验仪。刀具磨损程度观察仪器为蔡斯金相显微镜和日本电子公司生产的JSM-6510型扫描电子显微镜。

表1 20CrMo钢的化学成分(质量分数)

Table 1 Chemical constituent of 20CrMo steel %

表2 刀具几何参数

Table 2 Geometric parameters of cutting tools (°)

图1 切削测力仪硬件系统简图

Fig. 1 Diagram of cutting dynamometer experiential hardware

1.2 试验方法

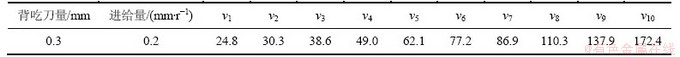

采用单因素测量法对20CrMo钢进行干切削,即保持背吃刀量ap=0.3 mm和进给量f=0.2 mm/r不变,只改变切削速度v。切削工艺参数设计如表3所示。

表3 切削工艺参数

Table 3 Parameters of cutting technology m/min

2 试验结果与分析

2.1 TiN薄膜的摩擦性能分析

本试验以45号钢为基体,基本尺寸(直径×厚度)为30 mm×3 mm,来研究TiN薄膜的摩擦性能。采用电弧离子镀工艺在基体上沉积TiN薄膜,以瑞士CSM公司生产的球—盘式微动摩擦磨损试验仪的往复运动式测量方法来测量其摩擦因数,方式为干摩擦,环境温度为25 ℃,载荷为P=1 N,滑行速度为0.1 m/s,测量距离为100 m,结果如图2所示。

由图2可以看出:在摩擦过程中TiN薄膜的摩擦因数共经历4个阶段的变化:首先在开始时处于较低状态;然后逐渐增大到1个峰值,约为0.225;第3阶段是降低到波谷,约为0.21;最后逐渐增大到稳定阶段,约为0.25。原因是在摩擦初期,薄膜的表面吸附有油、灰尘等一些杂质,形成一层较薄的有机薄膜,因此,开始时,摩擦因数比较低;随着摩擦的继续,表层的有机物质被逐渐除去,实际接触面积增大,同时产生磨粒和犁沟,摩擦因数迅速增大到峰值;当磨粒增加到一定程度时,形成第三体[11],使小球与薄膜的接触面积减小,摩擦因数下降;最后,产生的磨粒与离开摩擦表面的磨粒达到动态平衡,摩擦因数逐渐稳定。

图2 TiN薄膜和基体的摩擦因数

Fig. 2 Friction coefficient of TiN coating and substrate

TiN薄膜的摩擦因数的平均值为0.25,45钢基体的平均值为0.29,说明沉积了一层TiN薄膜的试样摩擦因数降低约13.8%, TiN膜层具有比45钢基体更优异的减摩性能。当摩擦距离大于60 m时,基体的摩擦因数表现出较大的波动,TiN薄膜继续保持稳定,说明TiN薄膜保持摩擦稳定阶段的时间要比基体更长,TiN涂层刀具相比未涂层刀具能更长时间保持稳定的摩擦状态,这对于减少刀具磨损,增加刀具使用寿命都有重要意义。

2.2 切削力分析

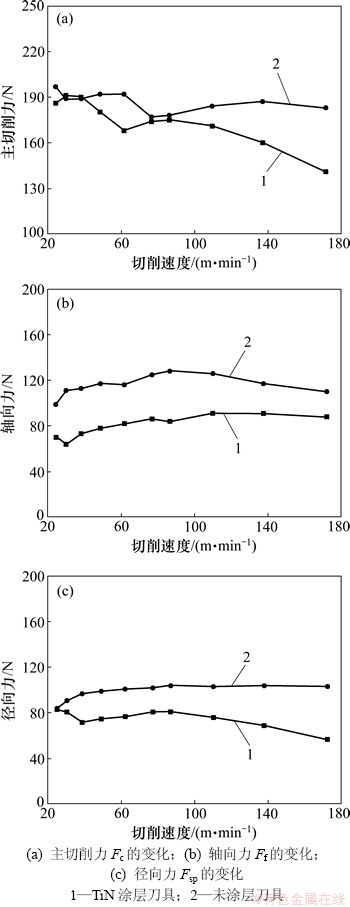

采用表3所示的切削工艺分别用TiN涂层和未涂层的YG6刀具对20CrMo进行干切削,三向切削力的变化如图3所示。

图3 切削速度对切削力的影响

Fig. 3 Effect of cutting speeds on cutting forces

从图3(a)可以看出:主切削力随切削速度的变化趋势是减小、增大、减小,并逐渐趋于稳定。这是由于20CrMo钢在低速干切削时,会产生积削瘤,导致刀具实际前角增大,切削变形减小,切削力减小。进一步提高切削速度,积削瘤消失,切削力增大。在中高速区,随着切削速度的增大,刀具和工件的温度急剧上升[9],导致摩擦因数μ降低,切削变形减小,切削力降低,并逐渐趋于稳定。轴向力的变化趋势是先增大后减小,原因是当切削速度较低时,工件表面质量很差,呈现明显的螺纹状,残留的金属对刀具副后刀面的圆弧处产生挤压,与切削层金属、切屑对刀具的挤压方向相反,两者可以相互抵消,使轴向力较小。随着切削速度的增大,工件表面质量逐渐提高,表面逐渐光滑,残留的金属对刀具副后刀面的圆弧处产生挤压力减小,使轴向力逐渐增大。切削速度大于120 m/min时,切削温度急剧上升,工件与刀具的摩擦因数逐渐减小,导致轴向力逐渐减小。

TiN涂层刀具的切削力明显小于未涂层刀具的切削力,尤其是当切削速度大于100 m/min时,未涂层刀具的主切削力变化逐渐变缓,而TiN涂层刀具的主切削力则迅速降低。说明TiN涂层减小了刀具前、后刀面与切屑、工件之间的摩擦因数;当切削速度大于100 m/min时,切削过程中产生的切削热急剧增加,由于TiN涂层热导率较低,大量的切削热被碎屑带走,从而有效防止了刀具和工件的快速升温,减轻了刀具的黏接磨损和化学磨损[12],从而使其切削力大大低于未涂层刀具。与未涂层刀具相比,TiN涂层刀具的切削力降低20%~40%。

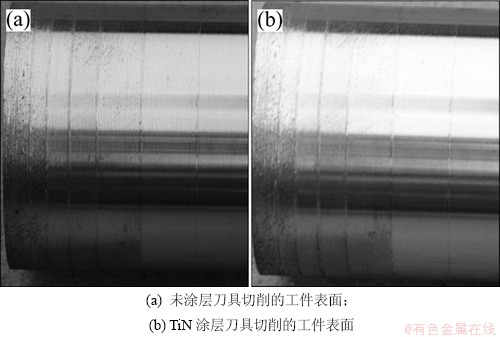

2.3 工件表面质量分析

图4所示为未涂层刀具和TiN涂层刀具以不同速度切削过的工件表面。从图4可以看出:在速度较低时,2个工件的表面质量均较差。对于未涂层刀具,当切削速度v5=62.1 m/min时,图4(a)中的工件表面开始逐渐光滑;当切削速度v10=172.4 m/min时,工件表面开始出现了一些黑色的切屑黏着小颗粒,原因是随着切削速度的增加,由于接触表面产生的摩擦热增多,刀刃刃口会出现切屑黏接,同时在工件的接触表面产生热应力和黏着磨损而影响加工表面质量的稳定性。对于TiN涂层刀具,当切削速度v4=49 m/min时,工件表面开始逐渐光滑,随着切削速度v的增大,工件表面质量逐渐提高,没有出现黑色小颗粒,原因是TiN涂层热导率较低,大量的切削热被碎屑带走,显著地降低了切削速度对表面粗糙度的影响。

图4 工件表面质量对比

Fig. 4 Comparison of workpieces surface quality

2.4 刀具磨损程度分析

实践证明,对于连续切削形式,若合理选择各切削工艺参数,则磨损仍是涂层刀具的主要失效形式,因此,研究其磨损具有十分重要的现实意义[13]。

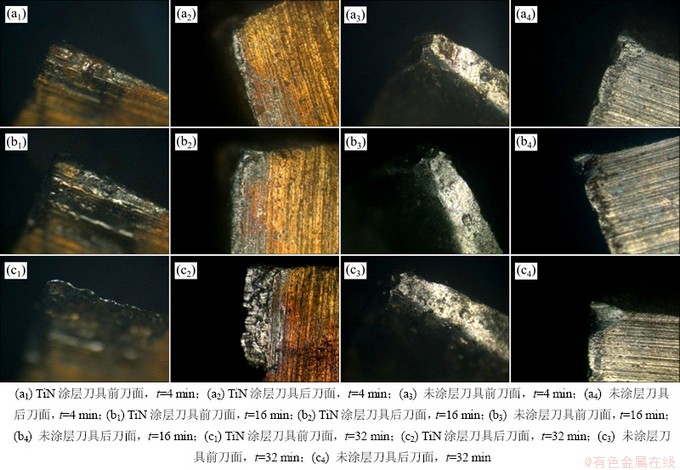

保持切削速度v=53.2 m/min,背吃刀量ap=0.5 mm,进给量f=0.08 mm/r不变,分别用TiN涂层刀具和未涂层刀具连续干切削20CrMo钢的时间为4,8,16和32 min,用蔡斯金相显微镜放大100倍观察刀具的磨损程度,并测量刀具后刀面的磨损量VB,以VB≥0.6 mm为其刀具失效标准,得到结果如图5和图6所示。

从图5(a1)~(a4)可以看出:当切削时间t=4 min时,涂层刀具前刀面和后刀面的磨损VB均较小,磨痕浅细,前后刀面的涂层均未受到严重破坏,仅有轻微擦伤,原因是新刃磨的刀具后刀面存在粗糙不平之处以及显微裂纹、氧化等缺陷,而且刀具刃口锋利,与工件接触面积小。根据相关定义[11],此阶段属于初期轻微机械磨损。未涂层刀具磨损VB较大,磨痕较深,为梳状犁沟状磨损带,前刀面出现了明显的剥落,后刀面主要是黏接磨损和磨粒磨损,并伴有微崩刃。

从图5(b1)~(b4)可以看出:当切削时间t=16 min时,前刀面的TiN涂层特别是主切削刃附近的涂层出现了明显的剥落,刀刃附近有与切屑方向一致的沟纹,后刀面可以观察到明显的磨粒磨损现象,由于TiN涂层刀具的涂层与工件间的摩擦因数较小,所以,磨损从涂层的破坏开始[14]。切削时,刀具主切削刃比较锋利,单位面积所承受的机械载荷比较大,而主切削刃处不是圆角过渡,而是45°倒角,故此处涂层与基体的结合力是整个刀片上最薄弱之处,涂层容易受到破坏,在热应力及机械应力和黏接磨损的作用下出现明显的剥落。未涂层刀具磨损较为严重,刀尖处出现了明显的崩塌,主切削刃崩刃现象进一步加剧,刀具失效。

从图5(c1)~(c4)可以看出:当切削时间t=32 min时,TiN涂层刀具的刃口处产生了微崩刃,涂层剥落较为严重,后刀面上可见有黏接物附着。根据相关研究,虽然TiN涂层的熔点较高,但在空气中温度达到550~600 ℃时,涂层便会发生氧化成疏松的TiO2[15],此氧化物可以加剧前刀面的磨粒磨损。涂层材料剥落后,切屑与刀具基体材料发生直接接触,切削温度迅速升高,刀具表面硬度持续降低,刀具切削条件下降,刀具迅速磨损,但还没达到未涂层刀具同期磨损率,此时涂层虽部分被磨穿,但仍起着缓和磨损的作用。

图5 刀具磨损对比(×100)

Fig. 5 Comparison of tools wear

从图6中刀具后刀面的磨损量随切削时间的变化曲线可以看出:在相同的切削条件下,与未涂层刀具相比,TiN涂层刀具后刀面的磨损量明显较小,耐磨性能约提高45%。未涂层刀具的寿命约为16 min,而TiN涂层刀具的寿命可保持到32 min以上,涂层刀具寿命约提高2倍。

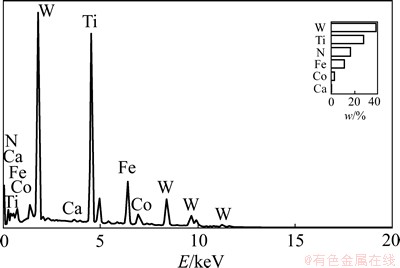

3 TiN涂层刀具前刀面磨损机理分析

图7所示为切削32 min后TiN涂层刀具前刀面磨损的SEM照片。从图7可以看出:刀具表面的擦伤较严重,出现了很深的沟痕和严重的磨粒磨损,特别是靠近刀尖部分更为明显。这是因为此处是切削区域切削温度最高处[16],刀具不但受到硬质磨粒的磨损,同时还有扩散磨损和氧化磨损。远离刀尖部分出现了平行划痕,此划痕较宽、较平,没有可见黏着物,说明该部分主要是磨粒磨损,划痕两侧还保留有TiN涂层,还能起到一定的抗磨作用。图8所示为TiN涂层刀具切削32 min后的前刀面磨损部分的EDS分析。从图8可见:此时Ti的质量分数约为28.4%,小于正常情况下的72%,说明TiN涂层出现了较严重的剥落。Co和W的质量分数分别约为3.2%和39.2%。根据文献[17],YG6基体应含有的Co和W质量分数的正常值分别为6.0%和86.1%。此时,Co和W的质量分数偏低,原因有2个方面:一是TiN涂层剥落后,随着温度的升高,硬质合金中的Co迅速扩散到了切屑、工件中,WC分解为W和C扩散到钢中,说明TiN涂层刀具发生了较为严重的扩散磨损;二是在切削温度较高时,刀具材料中的WC,Co和TiN等会与空气中的O2化合成低硬度的WO3,CoO和TiO2等氧化物,较软的氧化物容易被切屑或工件磨掉,形成氧化磨损。同时Fe的质量分数明显上升,说明工件和切屑中的Fe扩散到了硬质合金中,这会导致硬质相的黏结强度降低,刀具强度下降。

图6 TiN涂层和未涂层刀具后刀面的磨损量随切削时间的变化

Fig. 6 Flank wear of TiN coated and uncoated carbide tools in dry turning of 20CrMo steel with cutting time

图7 t=32 min时前刀面磨损的SEM照片

Fig. 7 SEM micrograph of wear modes on rake face when t=32 min

图8 t=32 min时TiN涂层刀具前刀面EDS分析结果

Fig. 8 EDS results of rake face of TiN coated tool when t=32 min

4 结论

(1) 在干摩擦环境下,TiN薄膜和基体的摩擦因数分别为0.25和0.29,薄膜保持摩擦稳定阶段的时间要比基体的更长。

(2) 与未涂层刀具相比,TiN涂层刀具切削20CrMo钢时的切削力可减小20%~40%,尤其是当切削速度大于100 m/min时,切削力减小更为明显。

(3) TiN涂层刀具切削20CrMo钢时,刀具的主要磨损机理为磨粒磨损,附带有黏接磨损、扩散磨损和氧化磨损。在切削32 min后,出现了轻微的崩刃现象。

(4) 与未涂层刀具相比,在相同的切削条件下,TiN涂层刀具的磨粒磨损与黏接磨损较轻,耐磨性能约提高45%,刀具寿命约提高2倍。

(5) 涂层质量对刀具的切削性能有较大影响,涂层剥落后,刀具基体直接与工件接触,刀具磨损加剧,因此,应该尽量避免涂层的剥落,可以通过多元复合和梯度涂层体系来改善涂层与基体的附着性。

参考文献:

[1] 熊良山, 严晓光, 张福润. 机械制造技术基础[M]. 武汉: 华中科技大学出版社, 2007: 129-131.

XIONG Liangshan, YAN Xiaoguang, ZHANG Furun. Fundamentals of machine manufacturing technology[M]. Wuhan: Huazhong University of Science and Technology Press, 2007: 129-131.

[2] Ashok K S, Bidyadhar S. Experimental investigations on machinability aspects in finish hard turning of AISI 4340 steel using uncoated and multilayer coated carbide inserts[J]. Measurement, 2012, 45(8): 2153-2165.

[3] 黄树涛, 贾春德, 姜增辉, 等. TiN涂层刀具高速车铣切削性能及磨损机理[J]. 哈尔滨工业大学学报, 2008, 40(9): 1501-1502.

HUANG Shutao, JIA Chunde, JIANG Zenghui, et al. Cutting performance and wear mechanism of TiN coat cutter in high speed turn-milling[J]. Journal of Harbin Institute of Technology, 2008, 40(9): 1501-1502.

[4] 王西彬. 绿色切削加工技术的研究[J]. 机械工程学报, 2000, 36(8): 6-9.

WANG Xibin. Research of green machining[J]. Journal of Mechanical Engineering, 2000, 36(8): 6-9.

[5] 徐银超, 陈康华, 王社权, 等. TiN和TiAlN涂层硬质合金的氧化和切削性能[J]. 粉末冶金材料科学与工程, 2011, 16(3): 425-430.

XU Yinchao, CHEN Kanghua, WANG Shequan, et al. Oxidation and cutting properties of TiN and TiAlN coated cemented carbide[J]. Materials Science and Engineering of Powder Metallurgy, 2011, 16(3): 425-430.

[6] 何玉定, 胡社军, 谢光荣. TiN涂层应用及研究进展[J]. 广东工业大学学报, 2005, 22(2): 31-35.

HE Yuding, HU Shejun, XIE Guangrong. Application and research development of TiN coating[J]. Journal of Guangdong University of Technology, 2005, 22(2): 31-35.

[7] Grzesik W. The role of coatings in controlling the cutting process when turning with coated indexable inserts[J]. Journal of Materials Processing Technology, 1998, 79(1): 133-143.

[8] 黄永建, 赵勇战, 严国安. 转炉冶炼20CrMo钢的生产实践[J]. 炼钢, 2003, 19(5): 4-6.

HUANG Yongjian, ZHAO Yongzhan, YAN Guoan. Practice on smelting 20CrMo steel in BOF[J]. Steelmaking, 2003, 19(5): 4-6.

[9] Fernández-Abia A I, Barreiro J, López de Lacalle L N, et al. Effect of very high cutting speeds on shearing, cutting forces and roughness in dry turning of austenitic stainless steels[J]. The International Journal of Advanced Manufacturing Technology, 2011, 51: 61-71.

[10] 孙维连, 魏凤兰. 工程材料[M]. 北京: 中国农业大学出版社, 2007: 138-141.

SUN Weilian, Wei Fenglan. Engineering materials[M]. Beijing: China Agricultural University Press, 2007: 138-141.

[11] 谢红梅, 聂朝胤. 不同测试条件下TiN 薄膜的摩擦学特性研究[J]. 真空, 2009, 46(4): 32-35.

XIE Hongmei, NIE Chaoyin. Tribological properties of TiN films under different testing conditions[J]. Vacuum, 2009, 46(4): 32-35.

[12] 吕明. 机械制造技术基础[M]. 武汉: 武汉理工大学出版社, 2010: 63-64.

L Ming. Fundamentals of machine manufacturing technology[M]. Wuhan: Wuhan University of Technology Press, 2010: 63-64.

Ming. Fundamentals of machine manufacturing technology[M]. Wuhan: Wuhan University of Technology Press, 2010: 63-64.

[13] 樊宁, 艾兴, 邓建新. 陶瓷刀具的磨损寿命可靠性[J]. 机械工程学报, 2002, 38(4): 30-35.

FAN Ning, AI Xing, DENG Jianxin. Reliability of ceramic cutting tool life by wear[J]. Journal of Mechanical Engineering, 2002, 38(4): 30-35.

[14] 宋海潮. Ti(C,N)涂层刀切削磨损分析及应对措施[J]. 航空制造技术, 2011(23/24): 93-95.

SONG Haichao. Wear analysis and improvement measure of Ti(C,N) coated tool in machining[J]. Aeronautical Manufacturing Technology, 2011(23/24): 93-95.

[15] Chim Y C, Ding X Z, Zeng X T. Oxidation resistance of TiN, CrN, TiAlN and CrAlN coatings deposited by lateral rotating cathode arc[J]. Thin Solid Films, 2009, 517(17): 4845-4849.

[16] Abhijeet S M, JIANG Wenping, Brown W D, et al. Tool wear and machining performance of cBN-TiN coated carbide inserts and PCBN compact inserts in turning AISI 4340 hardened steel[J]. Journal of Materials Processing Technology, 2006, 180(1/2/3): 253-262.

[17] 李一楠. 硬质合金刀具扩散磨损的数值模拟及成分优化设计[D]. 哈尔滨: 哈尔滨理工大学材料科学与工程学院, 2006: 27-28.

LI Yinan. Numerical simulation of diffusion failure of cemented carbide and optimized design of cutting tools composition[D]. Harbin: Harbin University of Science and Technology. College of Material Science and Engineering, 2006: 27-28.

(编辑 杨幼平)

收稿日期:2012-12-05;修回日期:2013-05-02

基金项目:重庆市自然科学基金资助项目(CSTC2011BB4013);中央高校基本科研业务费专项资金资助项目(XDJK2012C002,XDJK2013D015);国家留学基金委西部地区人才培养特别项目(201208505038)

通信作者:何辉波(1972-),男,四川仪陇人,博士,副教授,硕士生导师,从事机械工程设计研究;电话:023-68251265;E-mail: hehuibo@126.com