文章编号:1004-0609(2013)S1-s0662-05

W对高铌TiAl合金组织和力学性能的影响

韩建超1, 2,徐丽娟1,肖树龙1, 2,陈玉勇1, 2,王致彬3

(1. 哈尔滨工业大学 材料科学与工程学院,哈尔滨 150001;

2. 哈尔滨工业大学 金属精密热加工国家级重点实验室,哈尔滨 150001;

3. 重庆长安汽车股份有限公司,重庆 404100)

摘 要:研究分别添加0.3%、0.7%、1.0%W(摩尔分数)对高铌TiAl合金组织和力学性能的影响。结果表明:W的添加不改变合金的凝固路径,不影响合金的室温相组成;随W添加量的增加,合金中Nb和Al的元素偏析程度提高,添加1.0%W时,Al元素偏析明显;W的添加提高TiAl合金的显微硬度,W含量的变化对显微硬度的影响较小;适量的添加W可提高合金的室温压缩强度,添加0.7%W合金的强度达到最大,为1821 MPa,压缩率为24.47%,过量的W(1.0%)将导致合金组织偏析严重,恶化合金的性能。

关键词:TiAl合金;钨;显微组织;力学性能

中图分类号:TG146.2+3 文献标志码:A

Effect of W addition on microstructure and mechanical properties of high-Nb TiAl alloy

HAN Jian-chao1,2, XU Li-juan1, XIAO Shu-long1,2, CHEN Yu-yong1,2, WANG Zhi-bin3

(1. School of Materials Science and Engineering, Harbin Institute of Technology, Harbin 150001, China;

2. National Key Laboratory for Precision Hot Processing of Metals, Harbin Institute of Technology, Harbin 150001, China;

3. Chongqing Changan Automobile Co., Ltd., Chongqing 404100, China)

Abstract: The effects of the addition of 0.3%, 0.7%, 1.0%W (mole fraction) on the microstructure and mechanical properties of high-Nb TiAl alloy were studied. The results show that the W alloying doesn’t change the alloy solidification path, has no effect on the room temperature phase composition of high-Nb TiAl alloy. With the increase of W content, the segregation degree of Nb and Al element is enhanced, and the macrosegregation of Al turns striking with 1.0% W addition. Tungsten alloying boosts the microhardness of TiAl alloy, while this boost does not rely on the W content variation. Appropriate W addition can facilitate the room temperature compression strength, the strength achieves maximum value as 1821MPa and the compressibility reaches 24.47% with 0.7% W addition. Nevertheless, excessive W addition (1.0%) will deteriorate the mechanical property owing to severe segregation of Nb, W and Al.

Key words: TiAl alloy; W; microstructure; mechanical property

高铌TiAl合金作为重要的新型高温结构材料之一,由于其低密度、优异的高温强度以及良好的高温抗氧化性等优点,极具应用前景与发展潜力[1-3]。然而,高铌TiAl合金具有铸态组织粗大、室温塑性及加工性差、室温与高温性能之间匹配性不良等缺 点,制约了其应用。研究表明[4-6],W对TiAl基合金具有很强的固溶强化作用以及钉扎1/6<112>孪生位 错、提高合金强度;同时W是β相稳定元素[7-10],可以抑制α2相长大,细化晶粒进而提高其综合性能。在此,本文作者对4种不同W含量的高铌TiAl合金铸态显微组织及其力学性能之间的关系进行了讨论。

1 实验

实验用原材料为海绵钛(99.9%,质量分数)、高纯铝(99.9%)、铝铌中间合金(铌含量52.59%)和高纯钨(99.9%)。合金名义成分Ti-45Al-7Nb-xW (x=0、0.3%、0.7%、1.0%,摩尔分数),采用DHL-400型真空非自耗电弧炉熔炼成合金锭,合金锭经LZ-5离心铸钛机浇铸为d10 mm×40 mm的铸锭。压缩试样为d 3 mm×5 mm柱状,试样由铸锭心部线切割而成。压缩试验在Instron-5500万能材料试验机上进行,测试温度为室温,压缩应变速率为1 mm/min。采用CLEMEX全自动显微硬度计测试试样的显微硬度值,加载载荷0.98 N,加载时间15 s。

采用OLYMPUS-TH3光学显微镜、S-4700型扫描电镜观察试样金相组织和压缩试样的断口形貌。利用D/max-B型旋转阳极X射线衍射仪进行X射线衍射(XRD)分析试样的相组成,衍射范围20°~100°,步长0.02°,每步0.5 s。

2 实验结果

2.1 合金的相组成

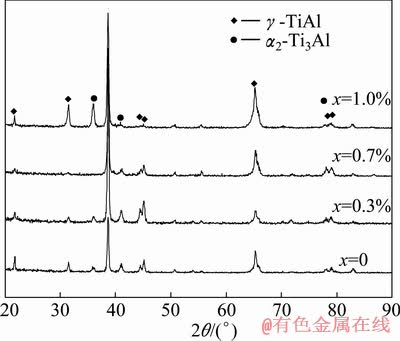

图1所示为不同W含量TiAl合金的XRD谱。从图1可知,Ti-45Al-7Nb-xW合金组织均由γ相和α2相组成,未发现B2相,这可能是由于B2相的含量较少,未能检测出。

图1 Ti-45Al-7Nb-xW合金XRD谱

Fig.1 XRD patterns of Ti-45Al-7Nb-xW alloys

2.2 合金的显微组织

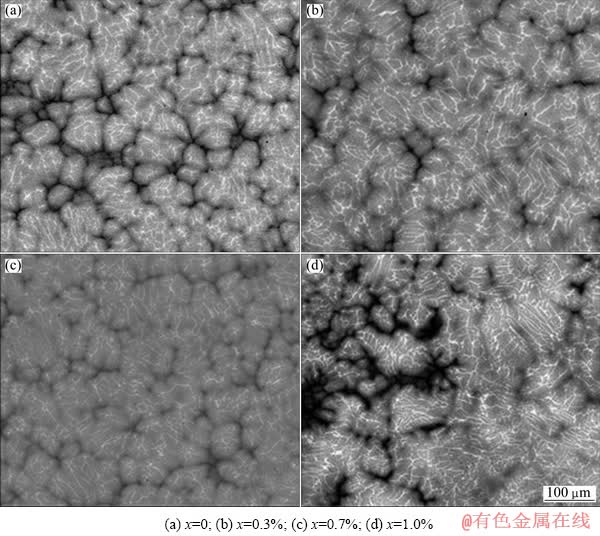

图2所示为不同W含量TiAl合金的背散射SEM像。从图2可以发现,除了W、Nb等重元素偏析外,未见其他化合物,因此可以判定,W和Nb在合金中固溶于α2基体,在非平衡铸态组织中偏聚于枝晶间。图2(a)所示合金中不含W,但其背散射图像中依然有白色的网状组织,说明其是金属Nb的枝晶间偏析。随W含量的增加,4种合金中的偏析情况越来越严重,在图2(d)中有条状物交叉,可能是合金在凝固过程中由于W含量较高,枝晶偏析程度大,枝晶发达,相互交叉的结果。

图2 Ti-45Al-7Nb-xW合金的BSE像

Fig.2 BSE images of Ti-45Al-7Nb-xW alloys

2.3 合金的力学性能

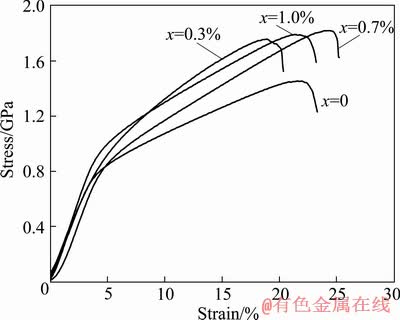

合金的室温压缩试验结果如图3所示。由图3可知,合金在屈服到断裂的过程中,抗压强度和应变量均显著增加。Ti-45Al-7Nb的抗压强度为1460 MPa,当添加W后,抗压强度逐渐增加,Ti-45Al-7Nb-0.7W的抗压强度最大,达到1821 MPa。Ti-45Al-7Nb压缩率为21.82%,添加W后合金压缩率并无规律性变化,当合金成分为Ti-45Al-7Nb-0.7W时,压缩率增加到最大,达到24.47%。

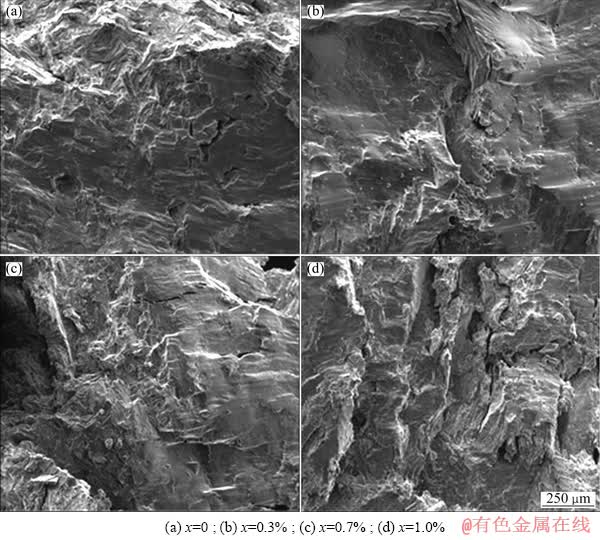

图4所示为Ti-45Al-7Nb-xW合金的压缩断口形貌。从图4可以看出,4种合金的试样断裂面均未出现塑性变形痕迹,失效形式既有穿层片断裂,又有沿层片断裂,断裂类型为脆性断裂,W的添加对合金断口形貌和断裂方式影响不大。

图3 Ti-45Al-7Nb-xW合金的室温压缩应力—应变曲线

Fig.3 Room temperature compression stress—strain curves of Ti-45Al-7Nb-xW alloys

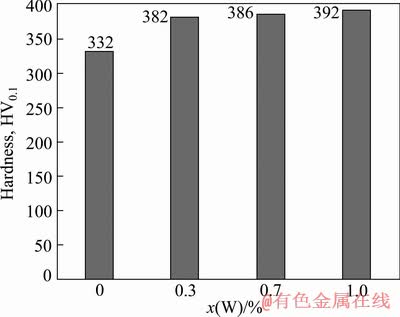

图5所示为Ti-45Al-7Nb-xW合金的显微硬度随W含量的变化。在本试验中,测试了每种合金6个不同位置的显微硬度,最后取其平均值。从图5中可以看出,Ti-45Al-7Nb合金的显微硬度最小,为332HV;当添加W后,显微硬度值上升;随着W含量的继续增多,显微硬度值逐渐增加,Ti-45Al-7Nb-1.0W的显微硬度为392HV,达到最大值。

图4 Ti-45Al-7Nb-xW合金的断口形貌

Fig.4 Fracture morphologies of Ti-45Al-7Nb-xW alloys

图5 Ti-45Al-7Nb-xW合金的显微硬度

Fig.5 Microhardness of Ti-45Al-7Nb-xW alloys

3 分析与讨论

3.1 W对组织的影响

由图1可知,W元素的添加对Ti-45Al-7Nb合金的室温相组成无影响,图2所示的4种合金的BSE像,表明W的添加提高了合金中的元素偏析程度。据能谱分析可知,图中亮白色网络状区域Nb和W含量较多,暗黑色区域为富Al区。众所周知,β相稳定元素Nb和W的加入,扩大了β相区的范围[11-13]。据实验结果分析,W的添加不影响合金的凝固过程,Ti-45Al-7Nb-xW合金沿着β相凝固路线:L→L+β。在析出的β相枝晶中Al元素贫乏而β相稳定元素(如Nb和W)富集,因此,β相的析出势必将多余的Al原子通过固液界面向液相中排出,同时液相中的Nb原子和W原子也通过固液界面向β相扩散并析出新的β相。随着β相的不断析出,液相中Al元素越来越富集,Nb元素和W元素越来越贫乏,最后,在β枝晶间区域残留的液相中Al元素富集、Nb元素贫乏。

随着温度的继续降低,合金在凝固过程中通过β+α双相区,凝固后的β枝晶通过L+β→α包晶反应转变为α相。包晶反应会首先发生在β枝晶与液相接触的区域。这部分区域Al元素富集,随后转变成γ相,在BSE像中表现为黑色的组织。在L+β→α转变过程中,Al向α相扩散,β相稳定元素Nb和W沿着相反方向扩散,这个趋势导致了β和α晶粒的界面处Nb和W富集而Al贫乏。随着包晶反应的进行,反应界面不断从枝晶间区域向枝晶臂推进,最后在β相枝晶臂中Al贫乏而Nb和W富集 ,随后转变为B2相,在BSE像中表现为白色的网状组织。α晶粒在随后的冷却过程中,转变成α2/γ层片组织,在BSE图像中表现为灰色的层片组织。结合图2可以看出,随着W含量的增加,BSE像中白色组织的亮度在不断增加。这是因为W的存在促进了Nb的偏析,同时Nb和W都是β相稳定元素, Nb和W很容易在β相中富集。

3.2 W对力学性能的影响

晶粒粗大的TiAl合金中,由于位错运动困难,变形过程中易形成位错缠结及位错塞积,导致合金过早解理断裂而失效。TiAl合金的屈服强度和晶粒尺寸间符合Hall-Petch公式,因此,细化晶粒能达到改善延展性和提高强度的目的。有研究表明[9,14-16],适量添加可提高Ti-Al-Nb合金的室温和高温强度,但W的添加将导致显微组织偏析,使塑性恶化,同时枝晶组织的存在可诱发裂纹萌生,导致合金的过早失效。

由图3压缩曲线可知,适量添加W可提高合金的强度,在W含量为0.7%时,强度达到最大值,这是由于W的固溶强化提高晶内和片层内位错运动的阻力。固溶强化效果正比于溶质与溶剂原子半径差,而W原子和Ti、Al的原子半径差约为5.7%,因此,W原子可与1/6<112>孪生位错及1/2<110>普通位错发生强烈的交互作用而使其可动性大幅度降低,从而提高合金的强度。随W含量增加,合金性能反而下降,这与文献[14,16]中的报道结果一致。

4 结论

1) W元素的添加不影响合金的室温相组成,不改变高铌TiAl合金的凝固路径,W含量的增加促进了合金中Nb、Al元素的偏析。

2) 随W含量的增加,合金的室温强度呈上升趋势,0.7%时达到最值,为1821 MPa,压缩率亦为最大,达到24.47%;W的添加提高了合金的显微硬度,W含量的变化对显微硬度的影响较小。

3) 适量的W含量可以提高合金的强度,过量的W将会恶化合金性能,W含量为1.0%时,合金的偏析程度最大,枝晶粗大,影响了合金的强度。

REFERENCES

[1] ZGHAL S, THOMAS M, NAKA S, FINEL A, COURET A. Phase transformations in TiAl based alloys[J]. Acta Materialia, 2005, 53(9): 2653-2664.

[2] 王 刚, 徐 磊, 崔玉友, 杨 锐. Ti-47Al-2Cr-2Nb-0.2W- 0.15B 合金板材的制备及其拉伸性能[J]. 中国有色金属学报, 2010, 20(S1): s274-s279.

WANG Gang, XU Lei, CUI Yu-You, YANG Rui. Fabrication and tensile property of Ti-47Al-2Cr-2Nb-0.2W-0.15B alloy sheets[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(S1): s274-s279.

[3] 肖树龙, 于宏宝, 韩杰才, 徐丽娟, 陈玉勇. 机械合金化与放电等离子烧结制备Ti-45Al-5.5 (Cr, Nb, B, Ta)合金[J]. 中国有色金属学报, 2010, 20(S1): s309-s314.

XIAO Shu-Long, YU Hong-Bao, HAN Jie-Cai, XU Li-Juan, CHEN Yu-Yong. Preparation of Ti-45Al-5.5(Cr, Nb, B, Ta) alloy by mechanical milling and spark plasma sintering [J]. The Chinese Journal of Nonferrous Metals, 2010, 20(S1): s309-s314.

[4] 彭超群, 黄伯云, 贺跃辉. 双温循环热处理对铸造TiAl基合金显微组织的影响[J]. 中国有色金属学报, 1999, 9(1): 15-18.

PENG Chao-Qun, HUNAG Bai-Yun, HE Yue-Hui. Effects of double temperature cyclic heat treatment on microstructures of TiAl-based alloys[J]. The Chinese Journal of Nonferrous Metals, 1999, 9(1): 15-18.

[5] 郑瑞廷, 张永刚, 陈昌麒. 循环热处理工艺对于双态复相TiAl基合金室温拉伸性能的影响[J]. 稀有金属材料与工程, 2002, 31(6): 472-475.

ZHENG Rui-ting, ZHANG Yong-gang, CHEN Chang-qi. The effect of circle heat treatment on room temperature mechanical properties of γ-TiAl alloys with duplex microstructure[J]. Rare Metal Materials and Engineering, 2002, 31(6): 472-475.

[6] BEDDOES J, ZHAO L, WALLANCE W. High temperature compression behaviour of near γ-titanium aluminides containing additions of chromium or tungsten[J]. Materials Science and Engineering A, 1994, 184: L11.

[7] MAZISAZ P J, RAMANUJAN R V, LIU C T. Effects of B and W alloying additions on the formation and stability of lamellar structures in two-phase γ-TiAl[J]. Intermetallics, 1997, 5(2): 83-95.

[8] LARSON D J, MILLER M K. Precipitation and segregation in α2+γ titanium aluminides[J]. Materials Science and Engineering A, 1998, 250: 65-71.

[9] 刘自成, 林均品, 陈国良. 添加W 对高铌TiAl 合金组织和力学性能的影响[J] . 材料热处理学报, 2001, 22(1): 7-13.

LIU Zi-Cheng, LIN Jun-Pin, CHEN Guo-Liang. Effect of the addition W on the micro structure and mechanical proper ties for high-Nb TiAl alloy [J]. Transaction of Materials and heat Treatment, 2001, 22(1): 7-13.

[10] MIZUHARA Y, HASHIMOTO K, MASAHASHI N. Microstructure and phase stability of TiAl-W ternary alloy[J] . Intermetallics, 2003, 11(8): 807-816.

[11] ARREL D, FLOWER H M, WEST D R F. Effect of Si on microstructure of Ti3Al alloys containing niobium[J]. Journal of Materials Science & Technology, 1996, 12(8): 617-622.

[12] TERNER M, BIAMINO S. UGUES D, SABBADINI S, FINO P, PAVESE M, BADINI C. Phase transitions assessment on gamma-TiAl by thermo mechanical analysis[J]. Intermetallics, 2013, 37: 7-10.

[13] YANG F, ZHANG L Q, LIN J P, LIANG Y F, HE Y H, SHANG S L, LIU Z K. Pore structure and gas permeability of high Nb-containing TiAl porous alloys by elemental powder metallurgy for microfiltration application[J]. Intermetallics, 2013, 33: 2-7.

[14] LARSON D J, LIU C T, MILLER M K. Tungsten segregation in α2+γ titanium aluminides[J]. Intermetallics, 1997, 5(7): 497-500.

[15] GABRISCH H, STARK A, SCHIMANSKY F P, WANG L, SCHELL N, LORENZ U, PYCZAK F. Investigation of carbides in Ti-45Al-5Nb-xC alloys (0≤x≤1) by transmission electron microscopy and high energy-XRD[J]. Intermetallics, 2013, 33: 44-53.

[16] SUN H F, LI X W, FENG J, FANG W B. Characterization of TiAl-based alloy with high-content Nb by powder metallurgy[J]. Transactions of Nonferrous Metals Society of China, 2012, 22(S2): s491-s495.

(编辑 龙怀中)

基金项目:国家自然科学基金资助项目(51001040, 51371064);国家重点基础研究发展计划资助项目(2011CB605502)

收稿日期:2013-07-28;修订日期:2013-10-10

通信作者:徐丽娟,工程师,博士;电话:0451-86402451;E-mail:xljuan@hit.edu.cn