文章编号: 1004-0609(2005)05-0775-07

氢氧化铝晶粒强度的应力状态分析

李旺兴1, 2, 花书贵1, 尹周澜1, 叶露升1, 刘业翔1

(1. 中南大学 冶金科学与工程学院, 长沙 410083;

2. 郑州轻金属研究院, 郑州 450041)

摘 要: 采用材料力学应力状态分析理论, 通过计算氢氧化铝晶粒叠合面的正应力与剪应力, 研究了叠合面上关键点的应力状态, 建立了叠合方式—应力状态—强度的关系, 并对二段种分氧化铝生产工艺中采用精液分流技术的产品形貌、 结构和强度进行了研究。 结果表明: 氢氧化铝晶粒强度与叠合面承受的应力状态密切相关, 正应力成为强度的关键因素; 各种不同氢氧化铝晶体间叠合方式中, 晶体底面与底面叠合时, 氢氧化铝晶粒强度较高并随两个晶体间叠合面积的减小而减小; 采用精液分流技术生产出的产品氢氧化铝和氧化铝晶粒, 晶体间多为底面与底面叠合且叠合面积较大, 氧化铝强度较高。

关键词: 氢氧化铝; 强度; 晶体叠合; 应力状态 中图分类号: TF821

文献标识码: A

Stress-state analysis on strength of Al(OH)3 grain

LI Wang-xing1, 2, HUA Shu-Gui1, YIN Zhou-lan1,

YE Lu-sheng1, LIU Ye-xiang1

(1. School of Metallurgical Science and Engineering, Central South University,Changsha 410083, China;

2. Zhengzhou Research Institute of Light Metals, Zhengzhou 450041, China)

Abstract: Using stress-state analysis, the stress-state between two overlapped Al(OH)3 crystals was calculated. The relationship between the strength and the way of overlapping of the crystals was obtained. The pattern, structure and strength of the product were studied. The results show that the strength of Al(OH)3 product is closely related to the stress-state of the overlapped Al(OH)3 crystals where the main reason of the shatter on the interface is normal stress. Of all the different ways of overlapping, the strength of two overlapped Al(OH)3 crystals facing to facing is the highest which decreases with the decreasing overlapping area.

Key words: Al(OH)3; strength; crystal overlapping; stress-state

随着环境保护的日益严格, 砂状氧化铝以其粒径粗、 强度高等优良性能成为氧化铝生产的趋势。 国内外对从过饱和铝酸钠溶液中析出氢氧化铝的过程进行了大量的研究[1-3], 但对晶体强度的研究报道不多, 并且这些研究多着重于生产工艺条件对强度的影响[4, 5], 未从本质上寻找氧化铝强度的主要因素, 因此很难为砂状氧化铝生产提供理论指导。

氧化铝强度由其独特的晶体结构决定。 李等[6]发现铝酸钠溶液分解过程氢氧化铝晶体结构是生长基元叠合和化学结晶的直接结果。 谭等[7, 8]研究了具有不同晶体结构的氧化铝的磨损行为, 发现具有镶嵌型结构的氧化铝强度高。 吴等[9, 10]对氢氧化铝晶体面之间的相互作用能进行了量子化学的理论计算, 计算了三水铝石有利生长基元最优结构Al6(OH)18(H2O)6的总能量、 布居数、 原子静电荷等, 结果表明, Al6(OH)18(H2O)6较为有利的成键方位是桥联结OH基团方位。 因此要获得高强度的砂状氧化铝所具有的晶粒结构, 必须控制铝酸钠溶液分解过程氢氧化铝晶体的叠合方式。

任何氢氧化铝晶粒的强度与其在外力作用下的力学行为有关。 氢氧化铝晶粒中存在晶界, 由两个单晶体叠合而成的晶粒的力学行为异于单晶体。 根据晶界两侧晶粒取向的不同, 晶界对整个晶粒力学行为的影响程度也不同。 由晶界面上应变相容性的要求, 晶界直接影响晶粒中各组元晶体的力学行为。 因此研究晶粒的力学行为, 重点在于获得各组元晶体叠合界面的应力状态。 任等[11-13]用三维各向异性有限单元法对3种不同的铜双晶体中晶界附近的弹性应力场和各组元晶体主滑移系上分解切应力进行了计算分析, 结果表明: 同轴双晶体晶界附近的弹性应力场及主滑移系上分解切应力是连续的, 非同轴双晶体晶界附近的弹性应力场主滑移系上分解切应力是不连续的。

本文作者拟运用材料力学应力状态分析方法[14-16], 以两块规则氢氧化铝晶体叠合而成的氢氧化铝晶粒为研究对象, 通过计算在外力作用下不同叠合方式形成的氢氧化铝晶粒的叠合面应力状态, 研究了叠合方式与晶粒强度的关系以及叠合面的破坏方式, 以期建立叠合方式—应力状态—强度的关系, 为氧化铝强度的研究提供理论基础。 同时结合实际生产中的氢氧化铝和氧化铝产品形貌, 进一步说明产品显微结构与强度的关系。

1 物理模型

由于规则氢氧化铝晶体一般为六棱柱形, 为研究不同叠合方式的晶体在重叠界面上的受力情况, 把两个氢氧化铝晶体之间的叠合方式分为底面与顶面叠合, 侧面与侧面叠合以及侧面与底面叠合3种方式[17, 18], 分别如图1所示。

图1 3种不同的叠合方式

Fig.1 Overlapping in different ways

根据材料力学理论[19]和研究对象的实际情况, 为简化计算, 作以下假设。

1) 氢氧化铝晶体为连续均匀介质、 平整且没有内部结构、 具有一定对称性质的正规六棱柱体, 在分析其应力状态和应变时, 忽略其微小变形, 以简化边界条件。

2) 将氢氧化铝晶粒简化为一端固定、 另一端受载荷的固定端杆状模型; 确定氢氧化铝晶粒杆状模型的约束为: 底端3个方向的平动位移和3个方向的转动位移均为零; 在上方氢氧化铝晶体顶面一边中点处施加静载荷, 根据氢氧化铝晶体的材料性能, 忽略应力集中效应。 氢氧化铝(氧化铝)属脆性材料, 因此分析叠合面的应力状态依照“最大拉应力理论”判断其强度以及破坏方式。

在以上约束和载荷条件下, 氢氧化铝晶粒将有发生弯曲变形的趋势。 本文作者重点研究晶体叠合方式与晶粒整体强度的关系, 并分析叠合面的应力状态分布。

2 应力分析方法

现以底面与底面叠合为例来说明在外力作用下,晶体的叠合面所受应力的情况。

假设下方晶体固定不动, 规则氢氧化铝晶体正六边形底面的边长为a, 正六棱柱的高为b。 外力F1沿y轴方向垂直作用在六棱柱底边的中点处,使氢氧化铝晶粒有发生横力弯曲的趋势, 叠合面N-N上产生正应力和剪应力, 过叠合面N-N的形心且与x轴平行的轴称为中性轴, 过叠合面N-N的形心且与y轴平行的轴为叠合面沿y轴的对称轴, 如图2所示。

图2 两晶体完全叠合受力图

Fig.2 Distribution of force on two completely overlapping crystals

由力矩平衡条件, 有

MN-N=F1×b(1)

式中 MN-N为横截面N-N上的弯矩; F1为外力; b为外力F1的作用点到横截面的距离。

由静力平衡条件, 晶体在y轴方向上不发生相对移动, 叠合面上产生剪力F2, 有

F2=F1(2)

3 结果与讨论

3.1 正应力与叠合面积的关系

根据平衡条件, 采用截面法, 对两块晶体在叠合面上的应力分布进行计算, 由于外力F1的作用, 在截面上产生顺时针方向的弯距MN-N。

由力矩平衡方程有

F1×b+MN-N=0(3)

横力弯曲时的正应力为

式中 Ix为叠合面对中性轴的惯性矩, 根据计算公式Ix=∫y2·dA, 得到 , 将它代入式(4)并与式(3)联立可得

, 将它代入式(4)并与式(3)联立可得

式中 σ为距离中性轴y处的正应力, σ对于y轴对称分布。

由式(5)可见, 叠合面的正应力不仅与MN-N有关, 而且与 有关, 亦即与叠合面的形状和尺寸有关。 最大正应力σmax发生于叠合面上离中性轴最远处。 于是由式(4)得

有关, 亦即与叠合面的形状和尺寸有关。 最大正应力σmax发生于叠合面上离中性轴最远处。 于是由式(4)得

当 时,

时,

当两块晶体底面不完全重合时, 即沿y轴方向发生位移, 设位移为c, 受力情况同上, 如图3所示。

图3 两晶体不完全叠合

Fig.3 Uncompletely overlapping of two crystals

当 时,

时,

由式(7)可知, 当两块晶体沿y轴方向位移c增大时, |σmax|将随之增大, 即在晶界承受同等临界应力的强度条件时, 整个晶粒的强度将随界面所发生的位移c的增大(即叠合面积的减小)而减小。

实际中, 外加载荷为F1=10kN(25mm管道中的压强为0.4MPa[20]), a=10μm[21, 22], 代入式(7)计算, 结果如图4所示。

图4 正应力与叠合面积的关系

Fig.4 Relationship between direct stress and overlapping area

3.2 剪应力与叠合面面积的关系

根据平衡条件, 采用截面法, 对两块晶体的叠合面上的剪应力分布进行计算, 由于外力F1的作用, 在截面上产生水平方向的剪力F2。

由静力平衡方程有

F2-F1=0(8)

弯曲剪应力为

将S*x=∫y·dA与 代入式(9)并与式(8)联立, 得

代入式(9)并与式(8)联立, 得

当 时,

时, ; 当

; 当 时, |τ|=0

时, |τ|=0

同理, 当两块晶体底面不完全重合时,  , 有

, 有

将实际参数代入式(10)计算, 结果如图5所示。

图5 剪应力与叠合面积的关系

Fig.5 Relationship between shear stress and overlapping area

由图5可知, 当两块晶体沿y轴方向位移c增大时, 将随之增大。 图4, 5所示分别为不同方式叠合的晶体, 其正应力、 剪应力与叠合面面积的关系, 该关系也适用于晶体侧面与侧面,侧面与底面叠合时的情况。

3.3 叠合面的应力状态分析

两块晶体完全叠合时, 在叠合面上顶边中点处、 形心处、 底边中点处、 叠合面沿y轴的对称轴上距离形心分别为 和

和 处, 分别沿x, y, z轴方向取正方体微小单元进行应力状态分析。 因为在叠合面上x轴两侧应力对称分布, 而且在x轴方向上不产生正应力和剪应力, 因此, 将六面体微元投影到yoz面上, 分析其二向应力状态。

处, 分别沿x, y, z轴方向取正方体微小单元进行应力状态分析。 因为在叠合面上x轴两侧应力对称分布, 而且在x轴方向上不产生正应力和剪应力, 因此, 将六面体微元投影到yoz面上, 分析其二向应力状态。

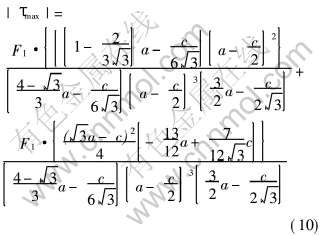

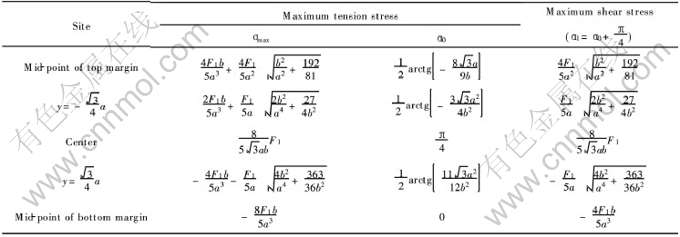

由本文3.1, 3.2节分析计算得, 各处沿z轴的正应力σz和沿y轴的剪应力τzy列于表1。

根据上述不同位置微元的应力计算结果, 应力状态分析结果列于表2, 其中α0, α1分别为最大正应力平面法线和最大剪应力平面法线的与z轴的夹角。

代入相关参数, 由计算得知, 在叠合面上, y轴负方向一侧(即靠近受力点一侧), 正应力较大, 而且距离z轴距离越大正应力越大(图2)。 因此随着载荷的增大, 靠近受力点一侧将首先发生破坏。

由于氢氧化铝晶体属脆性材料, 且叠合面为整块晶粒最为脆弱之处, 尽管在叠合面上主应力分布方位较为复杂, 但其破坏的发生主要是由沿z轴方向上的正应力所决定。

表1 不同位置处的正应力和剪应力

Table 1 Direct stress and shear stress of different sites

3.4 产品氢氧化铝的形貌、 结构与强度

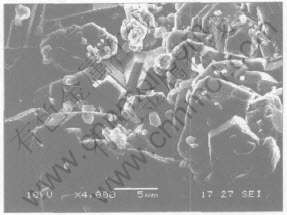

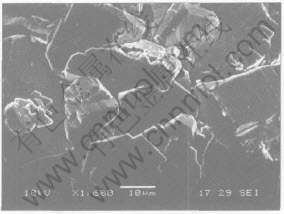

在高浓度二段种分生产氧化铝工艺中, 第一段为附聚段, 第二段为长大段。 当第一段经过附聚后的晶粒随浆液进入第二段后, 由于此时溶液过饱和度已经比较低, 影响产品氧化铝强度。 采用精液分流技术, 使部分精液直接进入长大段, 提高长大段的初始过饱和度, 可以改善产品氧化铝的强度。 图6所示为精液分流产品氢氧化铝晶粒形貌, 图7所示为精液不分流产品氢氧化铝晶粒形貌。 从图中可看出, 精液分流产品晶粒表面氢氧化铝晶体之间的叠合多为底面与底面的相互叠合, 叠合面积较大, 产品强度高, 经小窑焙烧得到的产品氧化铝粒度小于45μm和小于20μm的晶粒分别为8%~11%和2%以下, 磨损指数可以达到20%左右。 而精液不分流产品晶粒的晶体之间较为松散, 底面与侧面, 侧面与侧面的叠合较多, 叠合面积较小, 氢氧化铝整体晶粒的强度相对较小。

图6 精液分流产品氢氧化铝晶粒SEM的形貌

Fig.6 SEM morphology of Al(OH)3 grain produced with

technology of bulk solution distribution

图7 精液不分流产品氢氧化铝晶粒SEM的形貌

Fig.7 SEM morphology of Al(OH)3 grain produced without

technology of bulk solution distribution

表2 不同位置的应力状态

Table 2 Stress-state of different sites

4 结论

1) 通过对晶体叠合方式及受力情况进行分析, 初步建立了晶体的受力模型与叠合方式—应力状态—强度的关系。

2) 通过对叠合面进行应力状态分析, 研究了晶体叠合面应力状态分布, 发现界面破坏主要由于正应力导致, 且界面上靠近受力点一侧正应力较大。 因此随着载荷的增大, 将首先发生破坏, 该位置是决定强度的关键部位。

3) 氢氧化铝晶粒强度与叠合面承受的应力状态密切相关。 各种不同氢氧化铝晶体间叠合方式中, 晶体底面与底面叠合时, 氢氧化铝晶粒强度较高并随两个晶体间叠合面积的减小而减小。

4) 采用精液分流种分技术, 产品晶粒表面氢氧化铝晶体之间的叠合多为底面与底面的相互叠合, 叠合面积较大, 氧化铝强度较高。

REFERENCES

[1]杨重愚. 氧化铝生产工艺学[M]. 北京: 冶金工业出版社, 1993. 119-126.

YANG Zhong-yu. Technology of Alumina Production [M]. Beijing: Metallurgical Industry Press, 1993. 119-126.

[2]周辉放, 杨重愚, 陈光渊, 等. 铝酸钠溶液中晶体附聚机理研究[J]. 有色金属, 1994, 46(4): 54-58.

ZHOU Hui-fang, YANG Chong-yu, CHEN Guang-yuan, et al. Study on agglomeration mechanism in decomposition process of aluminate solution[J]. Nonferrous Metal, 1994, 46(4): 54-58.

[3]Veesler S, Rource S, Boistelle R. Abut supersaturation and growth rates of hydragillite Al(OH)3 in alumina caustic solution[J]. J Crystal Growth, 1993, 130(3-4): 411-415.

[4]Kubota N, Yokota M, Mullin J W. The combined influence of supersaturation and impurity concentration on crystal growth[J]. Journal of Crystal Growth, 2000, 212(3-4): 480-488.

[5]Sang J V. Factors affecting the attrition strength of alumina products[J]. Light Metals, 1987. 121-127.

[6]李洁. 铝酸钠溶液结构与分解机理的研究[D]. 长沙: 中南大学, 2001.

LI Jie. Study on the Structural Characteristics and Decomposition Mechanism of Supersaturated Sodium Aluminate Solution[D]. Changsha: Central South University, 2001.

[7]张櫵青. 对拜耳法高浓度铝酸钠溶液两段分解细晶种附聚的研究[J]. 轻金属, 1994, (4): 5-9.

ZHANG Jiao-qing. Study on the agglomeration in high concentration sodium aluminate solution of two stage Bayer rocess[J]. Light Metal, 1994, (4): 5-9.

[8]陈国辉, 陈启元, 尹周澜, 等. 铝酸钠溶液种分成核和附聚研究进展[J]. 湿法冶金, 2003, 22(1): 14-18.

CHEN Guo-hui, CHEN Qi-yuan, YIN Zhou-lan, et al. Development of nucleation and agglomeration during decomposition of caustic aluminate solutions with seeds[J]. Hydrometallurgy of China, 2003, 22(1): 14-18.

[9]吴争平, 陈启元, 尹周澜, 等. Al6(OH)18(H2O)6的结构及成键方位的从头算法及密度泛函分析(Ⅰ)[J]. 中国稀土学报, 2004, 22(专辑): 283-288.

WU Zheng-ping, CHEN Qi-yuan, YIN Zhou-lan, et al. Ab initio and studies on the structure and bonding orientation of the favorable growth unit Al6(OH)18(H2O)6 of Al(OH)3 crystals precipitating (Ⅰ)[J]. Journal of The Chinese Rare Earth Society, 2004, 22(Special Issue): 283-288.

[10]吴争平, 陈启元, 尹周澜, 等. Al6(OH)18(H2O)6的结构及成键方位的从头算法及密度泛函分析(Ⅱ)[J]. 中国稀土学报, 2004, 22(专辑): 289-293.

WU Zheng-ping, CHEN Qi-yuan, YIN Zhou-lan, et al. Ab initio and studies on the structure and bonding orientation of the favorable growth unit Al6(OH)18(H2O)6 of Al(OH)3 crystals precipitating (Ⅱ)[J]. Journal of The Chinese Rare Earth Society, 2004, 22(Special Issue): 289-293.

[11]任德斌, 彭兆行, 李守新, 等. 双晶体弹性应力场和在滑移上分解的切应力分析[J]. 东北大学学报(自然科学版), 2000, 21(1): 34-37.

REN De-bin, PENG Zhao-xing, LI Shou-xin, et al. Analysis of elastic stress field and resolved shear stress in primary slip system of bicrystal[J]. Journal of Northeastern University(Natural Science), 2000, 21(1): 34-37.

[12]任德斌, 彭兆行, 李守新, 等. Cu三晶体中各晶粒滑移系上切应力分析[J]. 沈阳工学院学报, 1999, 18(3): 50-54.

REN De-bin, PENG Zhao-xing, LI Shou-xin, et al. Analysis of copper tricrystal on slip system of each grain[J]. Journal of Shenyang Institute of Technology, 1999, 18(3): 50-54.

[13]任德斌, 李守新, 王中光, 等. Cu三晶交点应力集中特征的分析[J]. 沈阳工学院学报, 1998, 17(2): 45-49.

REN De-bin, LI Shou-xin, WANG Zhong-guang, et al. Analysis of stress concentration for triple junction in Cu tricrystal[J]. Journal of Shenyang Institute of Technology, 1998, 17(2): 45-49.

[14]陈肖虎, 程立, 赵莉. 砂状氧化铝生产分解过程实验研究[J]. 贵州工学院学报, 1994, 23(6): 65-70.

CHEN Xiao-hu, CHENG Li, ZHAO Li. Experimental study of the precipitation in sandy alumina production [J]. Journal of Guizhou Institute of Technology, 1994, 23(6): 65-70.

[15]刘宝琛, 曹秋良. 大晶粒多晶铝试样细观变形测量[J]. 清华大学学报(自然科学版), 1994, 34(5): 26-31.

LIU Bao-chen, CAO Qiu-liang. Measurement of mesodeformation for polycrystal specimen[J]. Journal of Tsinghua University, 1994, 34(5): 26-31.

[16]张广平, 王中光. 晶体取向Ni3Al合金单晶体疲劳行为的影响[J]. 金属学报, 1997, 33(10): 1009-1013.

ZHANG Guang-ping, WANG Zhong-guang. Effects of crystal orientation and load mode on fatigue behavior in Ni3Al alloy single crystals[J]. Acta Metallurgica Sinica, 1997, 33(10): 1009-1013.

[17]Malkin A J, Kuznetsor Y G, Mepherson A. Defect structure of macromolecular crystals[J]. Joural of Structural Biology, 1996, 117(2): 124-137.

[18]Yasuhisa A. Lowering friction coefficient under low loads by minimizing effects of adhesion force and viscous resistance[J]. Wear, 2003, 254(10): 965-973.

[19]刘鸿文. 材料力学[M]. 北京: 高等教育出版社, 1992. 173-191.

LIU Hong-wen. Material Mechanics[M]. Beijing: Higher Education Press, 1992. 173-191.

[20]Seyssiecq I, Veesler S, Boistelle R, et al. Agglomeration of gibbsite Al(OH)3 crystals in Bayer liquors, influence of the process parameters[J]. Chemical Engineering Science, 1998, 53(12): 2177-2185.

[21]YS/T 438.2-2001. 砂状氧化铝物理性能测定方法—磨损指数的测定[S].

YS/T 438.2-2001. Methods for Physical Performance Determination of Sandy Alumina—Determination of the Attrition index[S].

[22]李旺兴, 张江峰, 尹周澜, 等. 铝酸钠溶液晶种分解附聚过程研究[J]. 中国稀土学报, 2004, 22(专辑): 223-226.

LI Wang-xing, ZHANG Jiang-feng, YIN Zhou-lan, et al. Study of agglomeration during the precipitation of sodium aluminate solution[J]. Journal of Rare Earths, 2004, 22(S): 223-226.

基金项目: 国家自然科学基金资助项目(50374097)

收稿日期: 2004-12-22; 修订日期: 2005-04-04

作者简介: 李旺兴(1962-), 男, 教授.

通讯作者: 花书贵, 电话: 0731-8877364; E-mail: laohua9920765@sina.com.cn

(编辑陈爱华)