云南省铅锌冶炼行业二氧化硫排放系数核算

向瑛1,易红宏1,宁平1,杨永宏2,唐晓龙1,李柳琼2,张艳1

(1. 昆明理工大学 环境科学与工程学院,云南 昆明,650500;

2. 云南省环境工程评估中心,云南 昆明,650034)

摘要:根据2009年云南省铅锌冶炼行业的特点以及SO2排放情况,在大量数据收集和实地调研的基础上,采用实测法与物料衡算法相结合核算出云南省铅锌冶炼行业SO2产排污系数,同时给出铅锌冶炼行业不同工艺和规模下的SO2产排污系数。此外,将该研究核算结果与《第一次全国污染源普查工业污染源产排污系数手册》和《主要污染物总量减排核算细则》(试行)中的标准进行比较。研究结果表明:云南省铅冶炼行业SO2产污系数(以粗铅计)为333.04 kg/t,排污系数为63.90~77.49 kg/t;锌冶炼行业SO2产污系数(以电锌计)为570.43 kg/t,排污系数为8.46~19.54 kg/t;造成系数差异的主要原因是全国平均水平与云南省原、辅材料及能源消耗、工艺情况、治理措施不同。

关键词:SO2排放系数;铅锌冶炼行业;云南省

中图分类号:X32 文献标志码:A 文章编号:1672-7207(2013)09-3948-07

Calculation of sulfur dioxide emission factors of lead and zinc smelting industry in Yunnan Province

XIANG Ying1, YI Honghong1, NING Ping1, YANG Yonghong2, TANG Xiaolong1, LI Liuqiong2, ZHANG Yan1

(1. College of Environmental Science and Engineering, Kunming University of Science & Technology, Kunming 650500, China;

2. Environmental Engineering Assessment Center of Yunnan Province, Kunming, 650034, China)

Abstract: Considering the characteristics of lead and zinc smelting industry and SO2 emission of Yunnan Province in 2009, and on the basis of large quantities of investigated data, a measurement method and mass balance were used to calculate SO2 emission factors of lead and zinc smelting industry. The coefficients of SO2 producing and discharging under specific process were also given. Moreover, the emission factors were compared with the discharge coefficients of industrial pollutants in the First National General Survey of Pollution Sources and Total Pollutant Emissions Rules (Trial Implementation). The results show that the coefficient of producing pollution for zinc smelting industry (count by crude lead) is 333.04 kg/t, and the coefficient of discharging pollution is 63.90-77.49 kg/t. For zinc smelting industry, the coefficient of the producing pollution (count by zinc) is 570.43 kg/t, and the coefficient of discharging pollution is 8.46-19.54 kg/t. The cause of coefficients differences are mainly due to the gap between national average level and that of Yunnan Province in the aspect of original and auxiliary materials, resources consumption, process conditions, and control measures.

Key words: SO2 emission factors; lead and zinc smelting industry; Yunnan Province

据统计[1],全国有色金属冶炼及压延加工业2007年排放SO2 122.0×104 t,其中铅锌冶炼行业的SO2排放量为32.5×104 t,占有色金属行业SO2排放量的27%。铅锌冶炼生产原料主要为硫化精矿,含硫量较高,焙烧、烧结、熔炼工序是产生SO2的最主要环节,而SO2排放水平主要取决于冶炼工艺和烟气中硫的利用率[2-3]。由于技术装备水平整体比较落后,目前仅大型冶炼厂的硫利用率较高,多数小型铅冶炼厂的硫利用率很低[4]。未来几年内SO2排放控制和节能减排工作仍然是我国环境保护的重点之一,迫切需要科学依据和技术支持。排放系数(产排污系数)法[5-6]是核算污染物产生量和排放量的基本方法之一,从总体上反映各工业行业环境污染状况。但是,排放系数不仅与原料、燃料本身的特性有关,而且与工艺过程、设备的结构形式、生产及燃烧工况、治理设施等密切相关[7-8]。云南作为我国有色金属大省,铅锌资源储量占全国的20%以上,居全国首位;产量也位于全国前列,铅、锌产量分别占全国总产量9%和17%,因此,针对铅锌冶炼行业,云南省具有一定的代表性。云南省的铅锌冶炼行业无论从原料还是工艺等方面都与全国平均水平存在一定差异,所以,有必要对云南省铅锌冶炼行业的情况进行研究,从而核算出更符合地区特点的排放系数。该研究基于2009年云南省铅锌冶炼行业的原料及工艺等方面的特点,系统分析铅锌冶炼行业的排放现状,收集云南省各州市铅锌冶炼企业生产用原、辅材料及能源消耗、产能、SO2排放量、工艺情况、治理措施等统计数据,在大量基础资料收集和实地调研的基础上,采用物料衡算及实测法核算,最终提出云南省铅锌冶炼行业的SO2排放系数。

1 研究方法

1.1 系数核算方法

排放系数核算方法[9]主要包括物料衡算法和实测法。该研究中用实测法和物料衡算法相结合的方式对个体排放系数进行核算。

实测法因为受技术条件的限制,干扰因素较多,所得结果存在偶然性和不确定性[10-11]。因此,经综合考虑,该研究采用监测部门的资料作为实测值更具有可靠性和权威性。物料衡算法[12-13]是根据物质质量守恒原理,对生产过程中使用的物料变化情况进行定量分析的一种方法。对于SO2产排污系数的核算,原料或燃料中带入的硫分经过生产流程后一般有3个去 向[14]:一是被产品或制酸(脱硫)产物带出;二是残留于灰渣中以灰渣的形式排放;三是以含硫烟气的形式通过烟道排放。其中,以气态形式排入空气中的硫是本文研究的对象。采用容易测定的煤灰、渣、副产物中的固态硫份去推算难测定的烟气中的气态硫分,从而可得出:

(1)

(1)

(2)

(2)

式中:G为烟气中SO2的排放量(kg);M1为含硫原料或燃料的带入量(kg);w1为原料或燃料中硫质量分数(%);M2为产品产量或制酸(脱硫)产物产量(kg);w2为产品或产物中硫质量分数(%);M3为灰渣的排放量(kg);w3为灰渣中的硫质量分数(%);K为SO2原始排放系数,本文以单位产品SO2排放量计(kg/t);M为产品产量(t)。

综合排放系数是按规定的计算方法对个体排污系数进行汇总求取的一种排污系数平均值。在进行产排污系数核算时,综合排放系数可根据个体排放系数进行1次(从技术水平到特定规模)、2次(从规模到特定工艺)、3次(从生产工艺到产品)等汇总计算所得。针对本次研究,综合排放系数是个体排放系数从工艺、规模、SO2治理措施依次所得。

对于物料衡算排污系数中使用到的脱硫效率,本次研究参考了《主要污染物总量减排核算细则》(试行)下的脱硫效率与《第一次全国污染源普查工业污染源产排污系数手册》中给出的制酸效率。结合云南省铅锌冶炼生产的实际情况,采用区间的形式对排污系数进行表示,其中钙法脱硫效率取值为75%~85%;氨酸法脱硫效率取值为70%~85%;两转两吸烟气治理效率为96.0%~98.5%。

1.2 数据来源

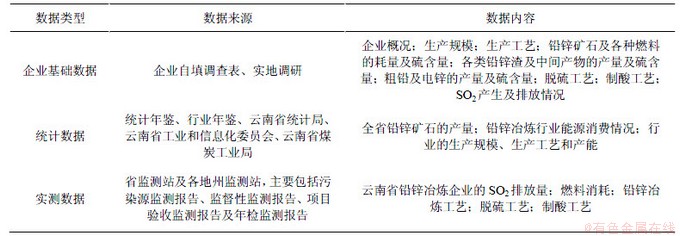

该研究收资渠道主要是通过统计部门及行业协会等途径,收集数据主要有云南省2009年各州市铅锌冶炼企业生产用原、辅材料及能源消耗、产能、SO2排放量、工艺情况、治理措施等统计数据,通过大量基础资料收集和实地调研,确保行业现状分析数据的有效性与时效性,见表1。

1.3 工艺调研情况及产排污节点分析

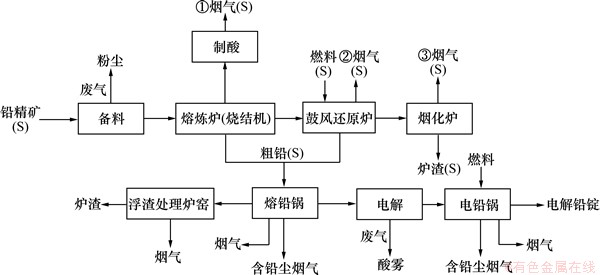

铅冶炼通常分为粗铅冶炼和精炼2个步骤。粗铅冶炼过程是将硫化铅精矿氧化脱硫—还原熔炼—铅渣分离—产出粗铅的过程[15]。根据实际调研得知,云南省大部分铅锌冶炼企业产品为粗铅,炼铅工艺主要有富氧顶吹熔炼(ISA炉)-鼓风炉、水口山法、烧结-鼓风炉工艺。铅冶炼生产过程及主要SO2产排污节点如图1所示。从1可以看出:铅精矿(含硫)经过备料制团,进入烧结机,产生部分制酸后的外排烟气(含硫);再进鼓风还原炉,添加燃料(含硫),产出粗铅(含少量硫)和部分脱硫后的外排烟气(含硫);产物再进烟化炉进行渣的熔炼,产出炉渣(含硫)以及部分烟气(含硫)。烧结工段、还原炉工段和烟化炉工段为主要SO2产污节点,后续电解工段生产电铅的过程主要污染物为硫酸雾,可忽略不计,因此,本次研究以粗铅作为终端产品,以熔炼炉、还原炉、烟化炉产生的SO2为主要产排污节点(如图1中①,②和③号烟气),核算铅冶炼SO2产、排污系数。在物料衡算的过程中,结合图1中的硫平衡关系进行衡算。

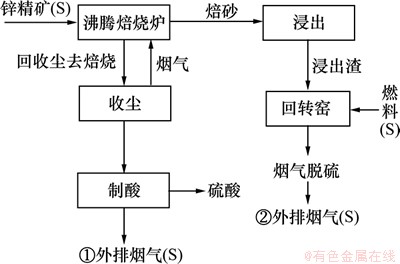

对于锌冶炼行业,由调查结果可知:云南省现有锌冶炼工艺主要为湿法炼锌,采用沸腾炉焙烧硫化矿,焙烧出的焙砂再进行浸出工艺。锌冶炼生产过程及其主要产污环节如图2所示。从图2可知:在炼锌工艺中,SO2排放主要来自于含硫锌精矿沸腾炉焙烧工段,以及回转窑浸出渣处理过程中使用到含有S成分的燃料时释放的SO2。浸出工段及电解工段中仅产生少量硫酸雾,可忽略不计。因此,本次研究以沸腾焙烧炉制酸后的外排烟气和回转窑烟气脱硫后的外排尾气为主要产排污节点(如图2中的①和②号烟气)来核算锌冶炼SO2产、排污系数。在物料衡算的过程中,结合图2中的硫平衡关系来进行衡算。

1.4 分类划分及抽样方案原则

1.4.1 分类划分

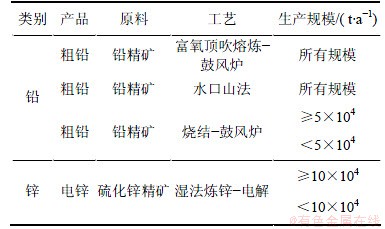

本研究借鉴和参考《第一次全国污染源普查工业污染源产排污系数手册》的研究成果,分类划分原则为:以生产工艺为主要分类因子,生产规模为次要分类因子,同时考虑产品和原材料的不同,参考国家产业政策、行业准入条件等因素进行分类划分。具体划分结果如表2所示。

表1 数据来源情况说明

Table 1 Illustration of data sources

图1 铅冶炼工艺及硫元素平衡示意图

Fig.1 Schematic diagram of lead smelting and balance of sulfur in processes

图2 锌冶炼工艺及硫元素平衡示意图

Fig.2 Schematic diagram of zinc smelting and balance of sulfur in process

表2 云南省铅锌冶炼行业划分原则

Table 2 Classification principles of lead and zinc smelting industry in Yunnan Province

1.4.2 抽样方案

由于行业中企业较多,对所有企业均进行产排污系数的核算存在一定困难,因此,需要进行科学抽样。该研究的抽样方案需考虑以下3个原则:(1) 所调查企业排放的SO2质量分数之和占全行业的75%以上;(2) 所调查企业的产能之和占全行业75%以上;(3) 所调查企业主要原材料消耗量之和占全行业的75%以上。此外,抽样方案还需充分考虑云南省目前铅锌冶炼行业中各种生产工艺及规模的分布情况及覆盖情况。

根据实际调研,云南省铅冶炼行业大部分企业的产品为粗铅,占全省铅产品的90%,电铅所占份额较少,而且后续精炼过程中产生的SO2也较少,对全省SO2排放量的贡献也较小。因此,综合全省情况选取铅精矿为原料,粗铅为产品对本系数进行核算。云南省现行铅冶炼行业生产工艺共3种:ISA炉-鼓风炉工艺、水口山法和烧结-鼓风炉工艺。从工艺情况和资料收集情况,综合选取19家企业作为该次研究的调研对象,所选样本的产品产量占全省铅冶炼行业总产量的84%,SO 2排放量占76%。同样,综合全省锌冶炼情况,湿法炼锌占主导,因此,从统计学研究的角度,针对规模以上的企业,以锌精矿为原料,电锌为产品,以湿法炼锌-电解工艺为主要研究对象,从工艺情况和资料收集情况综合选取7家企业作为该次研究的调研对象,所选样本的产品产量占全省锌冶炼行业总产量的97%,SO 2排放量占88%。

2 结果及比较

2.1 系数核算结果

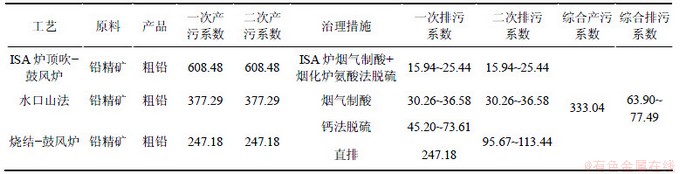

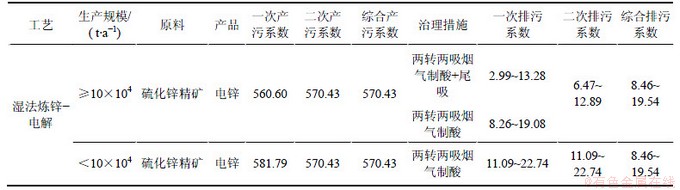

该研究核算所得云南省铅冶炼SO2综合排放系数核算见表3,锌冶炼SO2综合排放系数核算见表4。

从表3可以看出:ISA炉顶吹-鼓风炉、水口山法和烧结-鼓风炉的铅冶炼行业产污系数依次减小,因为ISA炉的硫释放率较高[16],因此产污系数也较大;同时,由于云南省采用ISA炉顶吹-鼓风炉工艺的企业只有1家,其使用的原料铅精矿的硫质量分数(25%以上)明显高于其他工艺下企业的硫质量分数(16%~ 19%),因此,原料的差异也导致产污系数不同。

根据表1和表2可知:云南省铅冶炼行业SO2综合产污系数(以粗铅计)为333.04 kg/t,SO2综合排污系数为63.90~77.49 kg/t;锌冶炼行业SO2综合产污系数(以电锌计)为570.43 kg/t,SO2综合排污系数为8.46~19.54 kg/t。

表3 云南省铅冶炼行业SO2排放系数

Table 3 SO2 emission factors of lead smelting industry in Yunnan Province kg/t

表4 云南省锌冶炼行业SO2排放系数

Table 4 SO2 emission factors of zinc smelting industry in Yunnan province kg/t

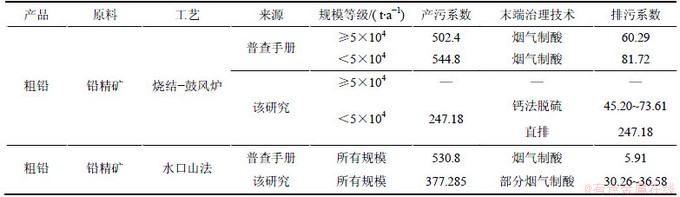

2.2 与第一次全国污染源普查系数的比较

对于铅、锌冶炼行业,选取该研究与《第一次全国污染源普查工业污染源产排污系数手册》(以下简称《手册》)中对应的工艺、产品、原料、规模进行产排污系数比较,分别见表5及表6。

由表5可知:该研究中烧结-鼓风炉工艺产污系数比小于5×104 t/a规模下的产污系数小,也小于《手册》中的产污系数;本文所得水口山工艺在同样规模下的产污系数比《手册》中的小。据《云南能效》(2009年度)[17]得知:2009年全国单位铅冶炼综合能耗为495.45 kg/t,而云南省为440.07 kg/t,可以看出云南省铅冶炼综合能耗比全国的低,因此,该研究的产污系数比《手册》中的低;同时,根据实际调研,云南省铅冶炼行业采用的燃料含硫量较低,如焦炭主要为一级焦炭,而全国为平均水平,还包含了高硫焦炭,因此,燃料的差异也是导致产污系数不同的原因之一。

对于排污系数,在烧结-鼓风炉工艺<5×104 t/a规模、冶炼烟气采用钙法脱硫处理时,该研究排污系数小于《手册》中烟气制酸治理措施的排污系数,主要原因为产污系数及烟气治理措施的差异;该研究在水口山工艺烟气制酸治理措施下排污系数大于《手册》中的烟气制酸下的排污系数。其原因主要是云南省采用水口山工艺的企业只有2家,其中一家企业烟气制酸仅为部分烟气制酸,氧气底吹炉工段的烟气用来制酸,鼓风炉和烟化炉的烟气则属于直排,因此,其排污系数比《手册》中的大。

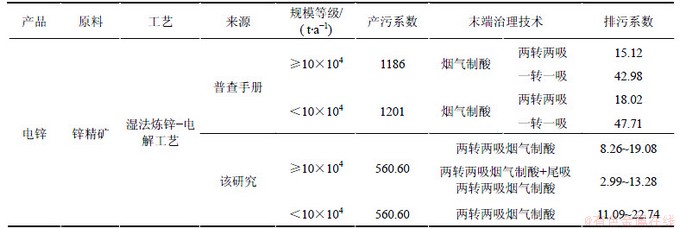

由表6可知:对于湿法炼锌-电解工艺,在生产规模≥10×104 t/a和<10×104 t/a下,该研究的产污系数均比《手册》中的产污系数小,其原因是:(1) 根据《云南能效》(2009年度)[27]的数据,2009年全国单位精锌(电锌)综合能耗为1 071.93 kg/t,而云南省为986.15 kg/t,可以看出云南省锌冶炼综合能耗较低;(2) 原料的差异也是影响产污系数的原因之一。《手册》中的系数处于全国的平均生产水平,矿石品位也是处于全国的平均水平。云南铅锌矿品位高且锌质量分数高于铅质量分数,国外铅锌质量比一般为l:1.2,我国为1:2.5,云南为1:3.4[18],同时全国铅锌矿平均品位只有4.66%,而云南省铅锌矿平均品位较高,其中兰坪矿的矿石含锌品位可达15%~28%[19],因此,云南省的锌矿石资源在全国范围内具有优势[20]。

对于排污系数,在生产规模≥10×104 t/a和<10×104 t/a两转两吸烟气制酸条件下,该研究的系数均比《手册》中的系数小。其原因主要是该规模、工艺下的产污系数就比《手册》中的小,导致排污系数也相应地小,同时,治理效率的差异也可能造成排污系数不同。

2.3 与总量减排核算系数的比较

“十一五”期间,国家对SO2实行排放总量控制计划管理。根据总量核算系数原则,铅冶炼SO2总量核算系数选为85 kg/t,锌冶炼SO2排污系数选为60 kg/t。

该研究核算得到的云南省铅冶炼行业SO2排污系数为63.90~77.49 kg/t,锌冶炼行业SO2排污系数为8.46~19.54 kg/。与总量核算系数85 和60 kg/t相比,云南省SO2排放系数均比国家总量核算系数低。分析其差异原因,除了原料及综合能耗存在差异外,在工艺和治理措施方面也存在以下不同:

(1) 铅冶炼中,云南省范围内采用较先进的ISA炉和水口山法的产能约占云南省总产能的33%,而全国采用新工艺的产能只占总产能的10%~20%;云南省范围内锌冶炼工艺大多采用较先进的湿法炼锌工艺,并且大多采用硫利用率高、制酸或尾吸后尾气中SO2达标的沸腾焙烧炉,这部分产能约占全省锌冶炼行业总产能的80%,而全国锌冶炼先进工艺的产能比例约为60%。可见:云南省铅锌冶炼行业工艺水平优于全国平均水平。

表5 该研究铅冶炼行业SO2产污系数和排污系数与《手册》中的系数对比

Table 5 Comparison of SO2 emission factors of lead smelting industry in this paper and coefficient in manual kg/t

表6 该研究锌冶炼行业SO2产污系数和排污系数与《手册》中的系数对比

Table 6 Comparison of SO2 emission factors of zinc smelting industry in this paper contrast with coefficient in manual kg/t

(2) 云南省铅冶炼行业大部分企业配有尾气治理措施,配有治理措施的企业产能占云南省铅冶炼行业总产能的45%,云南省锌冶炼行业大部分企业配有制酸系统或尾气脱硫设施,配有治理措施的企业产能约占云南省铅冶炼行业总产能的80%。

3 结论

(1) 该研究在基于云南省2009年实际生产水平的基础上,从生产工艺、生产用原辅材料的来源、用量、成分以及各行业烟气治理设施等方面进行实地调研,采用物料衡算法与实测法相结合,根据云南省2009年铅锌冶炼行业的实际情况核算出SO2产排污系数。

(2) 云南省铅冶炼行业SO2综合产、排污系数分别为333.04 kg/t和63.90~77.49 kg/t。其中:ISA炉顶吹-鼓风炉工艺下,产污系数和排污系数分别为608.48 kg/t和15.94~25.44 kg/t;水口山法工艺下,产污系数和排污系数分别为377.29和30.26~36.58 kg/t;烧结-鼓风炉工艺下,产污系数和排污系数分别为247.18 kg/t和95.67~113.44 kg/t。云南省锌冶炼行业SO2综合产污系数和排污系数分别为570.43 kg/t和8.46~19.54 kg/t。其中,湿法炼锌-电解工艺≥10×104 t/a规模下的产污系数和排污系数分别为560.60 kg/t和6.47~12.89 kg/t;在生产规模<10×104 t/a下的产污系数和排污系数分别为581.79 kg/t和11.09~22.74 kg/t。

(3) 铅冶炼行业烧结-鼓风炉工艺(生产规模<5×104 t/)以及水口山工艺下的产污系数均比《手册》中的产污系数。在烧结-鼓风炉工艺(生产规模<5×104 t/a)、冶炼烟气采用钙法脱硫处理时,该研究排污系数也小于《手册》中烟气制酸治理措施的排污系数;对于锌冶炼行业湿法炼锌-电解工艺,在生产规模≥10×104 t/a和<10×104 t/a下,该研究的产污系数、两转两吸烟气制酸条件下的排污系数均比《手册》中的系数小。与总量核算系数85 kg/t和60 kg/t相比,该研究核算得到的云南省铅冶炼、锌冶炼行业的SO2排污系数均低于国家总量核算系数。

(4) 通过本次调研核算云南省铅锌冶炼行业SO2产排污系数工作,建议深入开展对产排污系数开发的理论体系和技术方法的研究。如何验证产排污系数的科学性和合理性即如何进行产排污系数的不确定性评估研究是未来研究的主要方向。

参考文献:

[1] 云南省环境保护厅. 第一次全国污染源普查技术报告[R]. 昆明: 云南省环境保护厅, 2009: 1-10.

Yunnan Environmental Protection Department. The first national census of pollution sources technical report[R]. Kunming: Yunnan Environmental Protection Department, 2009: 1-10.

[2] 陈建民, 酒青霞, 王雪峰. 传统铅冶炼企业污染物排放量的核定[J]. 有色金属, 2008, 60(41): 66-173.

CEN Jianmin, JIU Qingxia, WANG Xuefeng. Pollutant discharge approval for traditional lead smelters[J]. Nonferrous Metals, 2008, 60(41): 66-173.

[3] Hoang J, Reuter M A, Matusewicz R, et al. Top submerged lance direct zinc smelting[J]. Minerals Engineering, 2009, 22(9/10): 742-751.

[4] 王成彦, 郜伟, 尹飞, 等. 铅冶炼技术现状及我国第一台铅闪速熔炼炉试产情况[J]. 有色金属: 冶炼部分, 2010(1): 9-13.

WANG Chengyan, GAO Wei, YIN Fei, et al.Present situation of lead smelting technology and production of the first lead flash smelting the performance of trial furnace in China[J]. Nonferrous Metals: Extractive Metallurgy, 2010(1): 9-13.

[5] CAO Guoliang, ZHANG Xiaoye, GONG Sunling, et al. Investigation on emission factors of particulate matter and gaseous pollutants from crop residue burning[J]. Journal of Environmental Sciences, 2008, 20(1): 50-55.

[6] Faulkner W B, Shaw B W. Review of ammonia emission factors for United States animal agriculture[J]. Atmospheric Environment, 2008, 42(27): 6567-6574.

[7] 段宁, 郭庭政, 孙启宏, 等. 国内外产排污系数开发现状以及启示[J]. 环境科学研究, 2009, 22(5): 622-626.

DUAN Ning, GUO Tingzheng, SUN Qihong, et al. Development and enlightenment of pollutant generation and discharge coefficients at home and abroad[J]. Research of Environmental Sciences, 2009, 22(5): 622-626.

[8] 姚芝茂, 滕云, 李俊, 等. 中小型烟煤层燃炉NOx排放因子的研究[J]. 环境科学研究, 2009, 22(11): 1263-1268.

YAO Zhimao, TENG Yun, LI Jun, et al. NOx emission factors from medium and small layer burning boilers firing soft coal[J]. Research of Environmental Sciences, 2009, 22(11): 1263-1268.

[9] 李维宗, 梅炜, 徐金凤, 等. 大气污染物排放系数及计算方法[J]. 环境科学研究, 1993, 6(4): 34-40.

LI Weizong, MEI Wei, XU Jinfeng, et al. Emission coefficient of air pollution and its calculation method[J]. Research of Environmental Sciences, 1993, 6(4): 34-40.

[10] 易坚, 杨晓松. 铅锌冶炼行业产排污系数核算方法及应用[J]. 有色金属, 2008, 60(3): 124-128.

YI Jian, YANG Xiaosong. Coefficients calculation and application of pollutants producing and emitting in lead and zinc smelting industry[J]. Nonferrous Metals, 2008, 60(3): 124-128.

[11] Karademir A. Evaluation of the potential air pollution from fuel combustion in industrial boilers in Kocaeli, Turkey[J]. Fuel, 2006, 85(12/13): 1894-1903.

[12] Andersen J K, Boldrin A, Christensen T H, et al. Mass balances and life cycle inventory of home composting of organic waste[J]. Waste Management, 2011, 31(9/10): 1934-1942.

[13] Vet R, Ro C U. Contribution of Canada-United States transboundary transport to wet deposition of sulphur and nitrogen oxides-A mass balance approach[J]. Atmospheric Environment, 2008, 42(10): 2518-2529.

[14] 朱法华, 杜维鲁. 燃煤电厂SO2排放量确定方法研究[J]. 电力环境保护, 2009, 25(2): 1-4.

ZHU Fahua, DU Weilu. Study on the calculation method of S02 emission from coal-fired power plants[J]. Electric Power Environmental Protection, 2009, 25(2): 1-4.

[15] 蒋继穆. 我国铅锌冶炼现状与持续发展[J]. 中国有色金属学报, 2004, 14(1): 52-62.

JIANG Jimu. Status and sustainable development of lead and zinc smelting industry in China[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(1): 52-62.

[16] 李炬, 王忠实. 顶吹炼铅及其实践[J]. 有色冶炼, 2001(6): 9-12.

LI Ju, WANG Zhongshi. Top-blown lead smelting and its practice[J]. China Nonferrous Metallurgy, 2001(6): 9-12.

[17] 云南省统计局, 云南省工业和信息化委员会. 云南能效(2009年度)[R]. 昆明: 云南省统计局, 云南省工业和信息化委员会, 2010: 30-42.

Yunnan Bureau of Statistics, Yunnan Provincial Industry & Information Technology Commission. Yunnan energy efficiency (2009)[M]. Kunming: Yunnan Bureau of Statistics, Yunnan Provincial Industry & Information Technology Commission, 2010: 30-42.

[18] 饶天龙. 云南铅锌资源基本特征及超大型铅锌矿床找矿前景[J]. 中国矿业, 2008, 17(3): 107.

RAO Tianlong. Basical characteristics of lead-zinc mineral resources and the vista on geological prospecting of super large scale lead-zinc deposits in Yunnan[J].China Mining Magazine, 2008, 17(3): 107.

[19] 陈世明, 瞿开流. 兰坪氧化锌矿石处理方法探讨[J]. 云南冶金, 1998, 27(5): 31-35.

CHEN Shiming, QU Kailiu. On the treatment of oxidized zinc ore in Lanping[J]. Yunnan Metallurgy, 1998, 27(5): 31-35.

[20] 黄仲权. 因矿制宜发挥云南省铅锌资源优势[J]. 矿产保护和利用, 1992(1): 16-20.

HUANG Zhongquan. Exert the resource advantages of the zinc in Yunnan Province[J]. Conservation and Utilization of Mineral Resources, 1992(1): 16-20.

(编辑 陈灿华)

收稿日期:2012-08-06;修回日期:2012-10-20

基金项目:云南省环境保护厅专项科研项目(KKK0201022137,KKK0201122183)

通信作者:唐晓龙(1977-),男,福建福州人,博士,教授,从事大气污染控制研究;电话:0871-5170905;E-mail: txl-km@163.com