文章编号:1004-0609(2009)02-0339-07

5 kA级惰性阳极铝电解槽热平衡仿真

李 劼,王志刚,张红亮,赖延清,徐宇杰

(中南大学 冶金科学与工程学院,长沙 410083)

摘 要:使用有限元软件Ansys仿真计算5 kA级惰性阳极铝电解槽的槽膛内形及热平衡情况。结果表明:过热度和侧部炭块类型对槽膛内形产生显著影响,过热度增加10 ℃,槽帮厚度减少约50%,伸腿宽度减少约30%;侧部炭块散热性越好,槽帮厚度和伸腿宽度越大;半石墨质类型的侧部炭块能够在保证形成满足要求的槽膛内形时降低热量损失,建议采用这类侧部炭块;采取一定措施后,采用半石墨质阴极和石墨化阴极的电解槽均能实现热平衡,石墨化阴极电解槽比普通阴极电解槽所需能量约多9%,但在热平衡时阴极底部等温线分布更合理。

关键词:铝电解;惰性阳极;电解槽;热平衡;数值模拟

中图分类号:TF 821; O 441.4 文献标识码:A

Simulation of heat balance in 5 kA grade aluminum reduction cell with inert anodes

LI Jie, WANG Zhi-gang, ZHANG Hong-liang, LAI Yan-qing, XU Yu-jie

(School of Metallurgical Science and Engineering, Central South University, Changsha 410083, China)

Abstract: The cell profile and heat balance of 5 kA grade aluminum reduction cell with inert anodes were calculated and simulated by finite element software Ansys. The results show that the superheat temperature and type of side carbon block have great influence on the cell profile. When the superheat temperature increases 10 ℃, the ledge thickness is reduced by about 50%, the ledge width is reduced by about 30%. The better the heat dissipation capability of side carbon block is, the thicker the cell ledge is. The semi graphitic side carbon block is advised because it can not only assure the required cell profile but also reduce the heat dissipation. The heat balance calculation shows that both the cell with semi graphitic cathode and graphitized cathode can achieve heat balance by taking some measures, while the cell with graphitized cathode needs about 9% more energy input than the cell with semi graphitic cathode, but it can assure more reasonable temperature distribution in the cathodes.

Key words: aluminum electrolysis; inert anode; reduction cell; heat balance; numerical simulation

工业铝电解过程一直采用炭作为阳极,由此产生如能耗高、污染大等许多问题。惰性阳极及其电解新工艺因能解决使用炭阳极时产生的问题,而成为国际铝业界和材料界的关注焦点和研究热点[1?3]。使用惰性阳极的优点包括降低劳动强度和减轻温室效应,因为阳极的气体产物为氧气而不是二氧化碳。氧气还可以作为副产品,估计回收的氧可能是原铝产品价值的3%[4]。目前研究的重点主要集中在阳极材料的制备工艺[5?7]及电解腐蚀性能[8],而对惰性阳极电解槽的设计研究的较少。ANTILLE等[9]数值模拟了25 kA惰性阳极铝电解槽的各个物理场,表明电解槽的物理场分布合理,通过合理的设计,能够保证电解槽的稳定运行,在此基础上他们还对阳极结构进行了相应的改进。小容量电解槽的成功运行可以为更大容量电解槽的设计提供参考,然而,容量小容量的电解槽由于热收入比较少,加上惰性阳极在电解时的理论能耗要比使用炭阳极的高[10],因此,这种小的惰性阳极电解槽更难实现热平衡。本文作者运用大型商用有限元软件Ansys建立5 kA级惰性阳极铝电解槽槽膛内形和热平衡计算模型,考查过热度和侧部炭块类型对槽膛内形的影响,并分别计算底部采用普通阴极炭块(半石墨质)和石墨化阴极炭块时的热平衡情况。其设计思路可以为其他同类型槽的建立和操作提供指导和建议。

1 5 kA级惰性阳极铝电解槽的基本参数

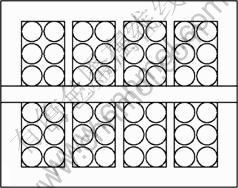

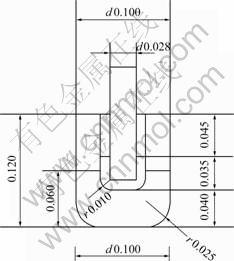

根据本课题组关于惰性阳极铝电解槽的设计经验,5 kA级惰性阳极铝电解槽应用如图1所示的阳极布置,采用6根阳极组成一个阳极组,电解槽两侧各布置4组阳极,共计48根阳极,阳极组外形尺寸为320 mm×210 mm。阳极为课题组自行研制的深杯状NiFe2O4基金属陶瓷惰性阳极,其截面尺寸如图2所示,电解槽的其他结构及工艺参数见表1。

图1 电解槽阳极布置示意图

Fig.1 Schematic diagram of anode configuration in cell

图2 惰性阳极截面尺寸示意图

Fig.2 Schematic diagram of section dimension for inert anode (m)

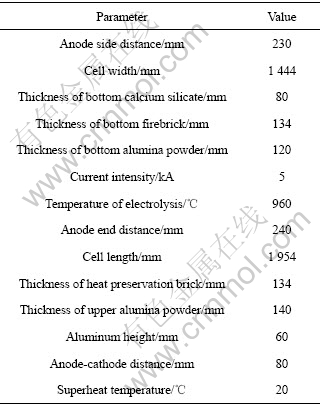

表1 电解槽基本结构及工艺参数

Table 1 Basic structural and technical parameters of cell

2 仿真研究方法

2.1 电热控制方程

铝电解槽内的电传递和热传递分别服从拉普拉斯方程和带有内热源的泊松方程[11]:

2.2 槽膛内形计算方法

本文作者在前人工作的基础上,采用简化的二维模型计算槽膛内形,有限元模型如图3所示。计算时,忽略电解质和铝液的存在,并忽略槽膛内形在电解槽长轴方向的差异,具体计算步骤如下。

图3 槽膛内形计算模型

Fig.3 Cell profile of calculation model

1) 施加边界条件,计算模型的温度分布,获得结壳表面各点的温度分布,并选择若干个代表点作为迭代的计算点。

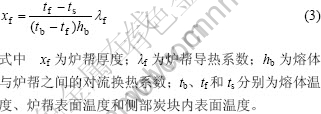

2) 根据代表点的温度以一维传热模型计算理论的结壳厚度并与实际结壳厚度相比较,若误差在指定的范围内则停止计算,否则进入下一步。一维传热理论公式为[12]

式中 xf为炉帮厚度;λf为炉帮导热系数;hb为熔体与炉帮之间的对流换热系数;tb、tf和ts分别为熔体温度、炉帮表面温度和侧部炭块内表面温度。

3) 根据理论结壳厚度与实际结壳厚度的差值确定结壳表面点的移动方向,输入更新后的代表点坐标,建立新的槽膛内形。

4) 重复1)~3)步,直到结壳表面代表点计算的理论结壳厚度与实际结壳厚度的差值在指定的范围之内则终止程序,输出槽膛内形的计算结果。

2.3 热平衡计算方法

假定阳极气体的显热为零并忽略母线部分的热损失,以电解槽整体作为计算体系和电解温度作为计算基础,则输入铝电解槽的电能分配在以下3个方面: 1) 电化学反应能耗;2) 将物料加热到反应温度所需要的能量;3) 理论上的热量损失。前两部分能量可以由电化学反应计算出来,输入电解槽的总电能可以由电流强度与电压的乘积得到,则电解槽的理论热损失可以求得。电解槽的实际热量损失可以由有限元法计算出来,判断电解槽是否达到热平衡即判断理论热损失与实际热损失之间的差距,如果两者差距在5%以 内[13],就认为电解槽的热量是平衡的,否则就应采取相应的措施直到实现热平衡,具体措施包括强化电流、增加极距和加强保温。

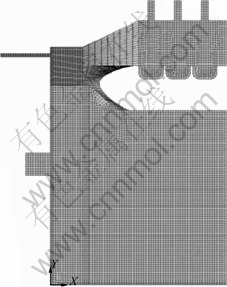

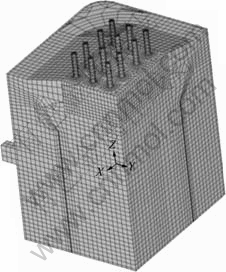

为了准确计算电解槽的电压降,在模型中考虑了阴极与钢棒及阴极与铝液之间的电接触,以TARGE170单元划分目标面,以CONTA173单元划分接触面,并保证接触面与目标面的法线方向相对,接触电导率取自文献值[14?15],模型网格划分如图4所示。

图4 热平衡计算模型示意图

Fig.4 Schematic diagram of heat balance calculation model

2.4 计算方法验证

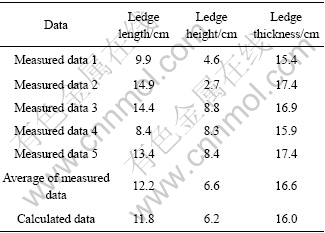

采用同样的计算方法计算了某厂200 kA大型预焙阳极铝电解槽的槽膛内形,计算结果与实测结果对比如表2所列。

从表2可以看出,槽膛内形计算值与实测平均值吻合较好,证明本模拟选取的计算方法正确、可行。此外,也应用了热平衡的计算方法对大型槽的热平衡情况进行研究,计算结果与实测结果相吻合。

表2 槽膛内形计算值与实测值对比

Table 2 Comparison of calculated and measured cell profile

3 结果分析

3.1 槽膛内形计算结果

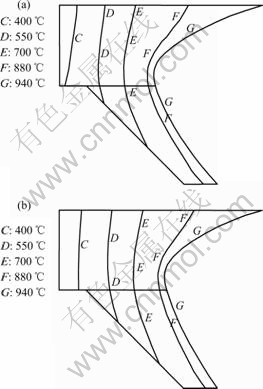

图5~7所示为电解槽在不同过热度和不同类型侧部炭块下的槽膛内形图,表3所示为具体的槽膛内形计算结果。

图5 过热度为15 ℃时的槽膛内形

Fig.5 Cell profile with superheat temperature of 15 ℃: (a) Common side carbon block; (b) SiN/SiC side carbon block

图6 过热度为20 ℃时的槽膛内形

Fig.6 Cell profile with superheat temperature of 20 ℃: (a) Common side carbon block; (b) SiN/SiC side carbon block

图7 过热度为25 ℃时的槽膛内形

Fig.7 Cell profile with superheat temperature of 25 ℃: (a) Common side carbon block; (b) SiN/SiC side carbon block

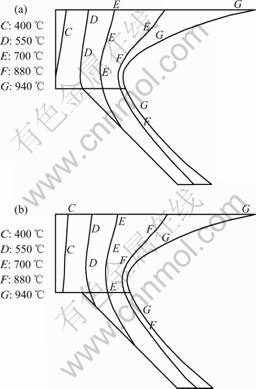

表3 槽膛内形计算结果

Table 3 Calculated results of cell profile

从图5~7及表3可以看出,电解质过热度和侧部炭块的类型对电解槽的槽膛内形产生显著影响。当过热度从15 ℃增加到25 ℃时,侧部采用普通阴极炭块的电解槽伸腿宽度降低14 mm,槽帮厚度由165 mm减少到83 mm,厚度减少82 mm。而采用SiN/SiC侧部炭块时,当过热度由15 ℃增加到25 ℃时,伸腿宽度降低15 mm,槽帮厚度降低92 mm,由此可以看出,过热度的变化对采用SiN/SiC侧部炭块的电解槽影响更大。当采用SiN/SiC侧部炭块时,由于其导热系数更高,侧部散热量必然更大,因此,在相同的电解质过热度下,无论是伸腿宽度还是槽帮厚度都要比采用普通阴极类型的侧部炭块要大一些。但从表3可知,侧部炭块类型变化所引起的伸腿宽度变化并不显著,而槽帮厚度本身比较大,能够适应一定的过热度变化,因此,考虑到采用普通阴极类型的侧部炭块时电解槽散热量更小,更有利于实现热平衡,建议5 kA级惰性阳极铝电解槽采用普通阴极类型的侧部炭块。

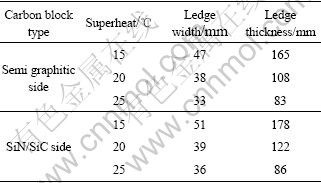

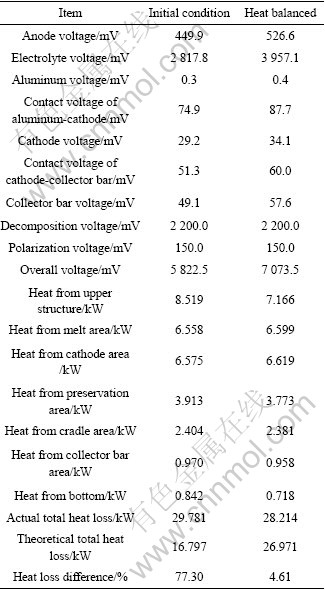

3.2 普通阴极电解槽热平衡分析

当电解槽采用普通阴极类型的侧部炭块,底部也采用普通的半石墨质阴极时,在初始的结构及工艺参数下,电解槽的电热平衡计算情况如表4所列。由表4可知,在初始参数下电解槽未能达到热平衡,通过改变部分条件并反复计算发现,当电流强化到5.7 kA,极距增加到9 cm,上部氧化铝粉厚度增至200 mm时,电解槽达到热平衡。电解槽的理论热量损失数值很小,而实际热量损失相对较大,电解槽远没有达到热平衡,这说明电解槽提供的热量不足以维持电解反应的温度,因此,一方面需要增加电解槽的能量输入,另一方面需要降低电解槽的能量损失。在电压分布中,电解质电压及分解电压是电压组成中最重要的两部分,而接触电压也占据一定的比例,不能忽略。

表4 普通阴极电解槽的电热平衡

Table 4 Thermo-electric balance of cell with common cathodes

为了准确计算出电解槽的电压降,必须合理将电接触考虑在内。电解槽由于尺寸及容量较小,总体散热量远比大型预焙阳极铝电解槽的小,槽上部、熔体区及阴极区向外散热是热量损失的主要来源,分别约占总散热量的30%,22%和22%。强化电流、增加极距和加强保温以后,阳极部分电压、电解质电压、铝液电压、接触电压、阴极电压和钢棒电压均有一定程度的增加,其中电解质电压增加最多,主要是由于极距有所增加,因此,电解槽的总电压由5 850.7 mV增加至6 662.4 mV。电解槽的理论热损失量由于热收入的增加而明显增加,由16.938 kW增加至23.936 kW,增加41.3%,各部分实际热量损失由于加强了槽体保温而都有一定程度的下降,总热量损失由26.732 kW降至25.072 kW。

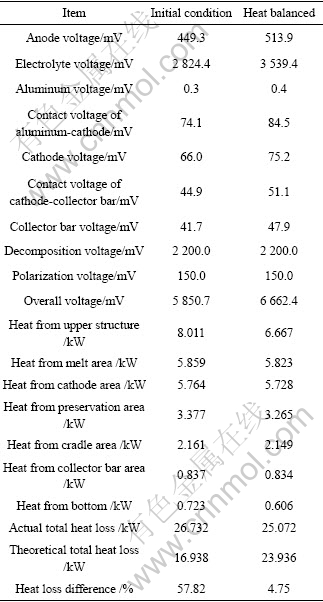

3.3 石墨化阴极电解槽热平衡分析

当电解槽侧部采用普通阴极类型的炭块,底部采用石墨化阴极时,按上述的计算方法计算得到的电热平衡情况如表5所示,对应的热平衡条件为:电流强度5.85 kA,极距10 cm,上部氧化铝粉厚度200 mm。

表5 石墨化阴极电解槽的电热平衡

Table 5 Thermo-electric balance of cell with graphitized cathodes

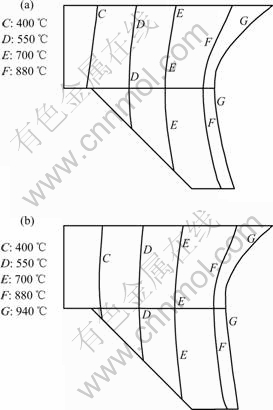

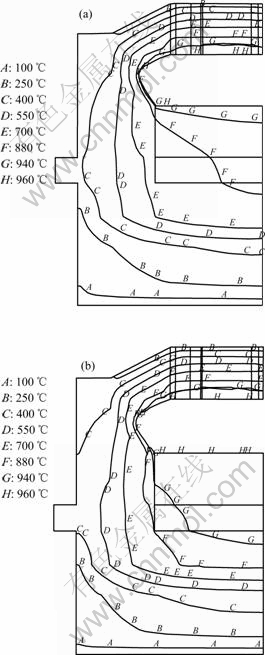

从表5可知,电解槽采用石墨化阴极时,由于电阻率更低,阴极电压降更小,在初始参数下总体压降必然低于普通阴极的电解槽压降,加上石墨化阴极导热系数高,阴极区的散热量必然更大,因此,在初始条件下,理论热量损失更低,实际热量损失更高,即电解槽需要比普通阴极电解槽更为“苛刻”的条件才能实现热平衡,计算得到的热平衡条件也正说明了这一点。电解槽电流为5.85 kA,电压为7 073.5 mV,均大于普通阴极电解槽热平衡时的相应数值,即需要更大的能量输入才能维持电解槽的热平衡。图8所示为采用普通阴极和石墨化阴极的电解槽截面等温线分布图。

从图8可以看出,虽然电解槽都达到热平衡,但阴极内的温度分布还是有很大差别的,图8(a)中电解质凝固等温线(G线)在阴极炭块以内,阴极底部及阴极端部温度较低,这将缩短阴极以及电解槽的寿命,电解质容易在阴极内凝固结晶从而给阴极带来一定的破损。图8(b)中电解质凝固等温线在阴极炭块以下,

图8 电解槽截面等温线对比

Fig.8 Temperature distribution comparison of cell section: (a) Common cathode; (b) Graphitized cathode

除阴极端部小部分区域以外,阴极的温度分布是比较合理的,即采用石墨化阴极能够在一定程度上延长阴极及电解槽的使用寿命。电解槽阴极结构的改变会使电解工艺及电解槽结构都发生相应的改变,加上电解槽物理场之间复杂的耦合关系,具体使用何种阴极结构应根据实际情况及综合考虑其他物理场的计算结果进行选择。

4 结论

1) 槽膛内形的计算值与实测值吻合较好,证明计算方法正确;过热度和侧部炭块类型对槽膛内形影响显著,过热度越大,炉帮和伸腿厚度越小;侧部炭块散热性能越好,炉帮和伸腿厚度越大。采用普通阴极类型的侧部炭块既能够形成满足要求的槽膛内形,又有利于降低能量损失,建议5 kA级惰性阳极铝电解槽采用这类侧部炭块;

2) 采用普通阴极和石墨化阴极的惰性阳极电解槽在初始条件下都不能达到热平衡,采取相应措施以后电解槽能够实现热平衡,石墨化阴极电解槽在热平衡时阴极底部的温度分布更为合理,但需要更大的能量输入。

REFERENCES

[1] 刘业翔. 铝电解惰性阳极与可湿润性阴极的研究与开发进展[J]. 轻金属, 2001(5): 26?29.

LIU Ye-xiang. Advance on the research and development of inert anode and wettable cathode in the aluminum electrolysis[J]. Light Metals, 2001(5): 26?29.

[2] PAWLEK R P. Inert anodes: an update[C]// SCHNEIDER W. Light Metals 2002. Seattle, WA: TMS, 2002: 449?456.

[3] DE NORA V. Aluminium electrowinning: The future[J]. Aluminium, 2000, 76(12): 998?999.

[4] 王志刚, 黄 蔚, 赖延清. 铝电解惰性阳极材料研究新进展[J]. 轻金属, 2007(2): 27?30.

WANG Zhi-gang, HUANG Wei, LAI Yan-qing. New progress of inert anode materials for aluminum electrolysis[J]. Light Metals, 2007(2): 27?30.

[5] 张 雷, 周科朝, 李志友, 张晓泳. 气氛对NiFe2O4陶瓷烧结致密化的影响[J]. 中国有色金属学报, 2004, 14(6): 1002?1006.

ZHANG Lei, ZHOU Ke-chao, LI Zhi-you, ZHANG Xiao-yong. Effect of atmosphere on densification in sintering nickel ferrite ceramic for aluminum electrolysis[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(6): 1002?1006.

[6] 张 刚, 赖延清, 田忠良, 秦庆伟, 李 劼, 黎文献. 铝电解用NiFe2O4基金属陶瓷的制备[J]. 材料科学与工程学报, 2003, 21(4): 510?513.

ZHANG Gang, LAI Yan-qing, TIAN Zhong-liang, QIN Qing-wei, LI Jie, LI Wen-xian. Preparation of nickel ferrite based cermets for aluminum electrolysis[J]. Journal of Materials Science & Engineering, 2003, 21(4): 510?513.

[7] 田忠良, 赖延清, 张 刚, 秦庆伟, 王剑峰, 李 劼, 刘业翔. 铝电解用NiFe2O4-Cu金属陶瓷惰性阳极的制备[J]. 中国有色金属学报, 2003, 13(6): 1540?1545.

TIAN Zhong-liang, LAI Yan-qing, ZHANG Gang, QIN Qing-wei, WANG Jian-feng, LI Jie, LIU Ye-xiang. Preparation of NiFe2O4-Cu based cermet inert anodes in aluminum electrolysis[J]. The Chinese Journal of Nonferrous Metals, 2003, 13(6): 1540?1545.

[8] LAI Yan-qing, LI Jie, TIAN Zhong-liang, YE Shao-long, DUAN Hua-nan, LIU Ye-xiang. On the corrosion behaviour of NiFe2O4-NiO based cermets as inert anodes in aluminum electrolysis[C]// GALLOWAY T J. Light Metals 2006. San Antonio, TX: TMS, 2006: 495?500.

[9] ANTILLE J, KLINGER L, VON KAENEL R, DE NORA V. Modeling of a 25kA de NORA inert metallic anode test cell[C]// GALLOWAY T J. Light Metals 2006. San Antonio, TX: TMS, 2006: 391?396.

[10] 李德祥. 惰性阳极铝电解的理论能耗和理论能耗电压[J]. 轻金属, 2006(2): 31?32.

LI De-xiang. Theoretical energy consumption and theoretical energy consumption voltage for aluminium electrolysis with inert anode[J]. Light Metals, 2006(2): 31?32.

[11] 郭宽良, 孔祥谦, 陈善年. 计算传热学[M]. 合肥: 中国科学技术大学出版社, 1989: 4?9.

GUO Kuan-liang, KONG Xiang-qian, CHEN Shan-nian. Theory of calculating heat transfer[M]. Hefei: University of Science and Technology of China Press, 1989: 4?9.

[12] LIU Wei, LI Jie, LAI Yan-qing, LIU Ye-xiang. 2D finite element analysis of thermal balance for drained aluminum reduction cells[J]. Journal of Central South University of Technology, 2007, 14(6): 783?787.

[13] 李相鹏. 75kA导流型铝电解槽物理场仿真与优化[D]. 长沙: 中南大学, 2004: 66?67.

LI Xiang-peng. Physical fields simulation and optimization of the 75kA drained aluminum reduction cells[D]. Changsha: Central South University, 2004: 66?67.

[14] RICHARD B. An analytical model for cathode voltage drop in aluminum reduction cell[C]// CREPEAU P N. Light Metals 2003. San Diego, CA: TMS, 2003: 241?245.

[15] LI Jie, LIU Wei, LAI Yan-qing, WANG Zhi-gang, LIU Ye-xiang. Analysis of cathode voltage drop in aluminum electrolysis cells with an electric contact model[C]// SORLIE M. Light Metals 2007. Orlando, FL: TMS, 2007: 465?470.

基金项目:国家重点基础研究发展计划资助项目(2005CB623703);国家高技术研究发展计划资助项目(2008AA30504);国家自然科学基金资助项目(50874120)

收稿日期:2008-03-19;修订日期:2008-06-10

通讯作者:李 劼,教授;电话:0731-8876454;E-mail: wzg03@163.com

(编辑 龙怀中)