文章编号:1004-0609(2013)S1-s0437-04

固溶处理对Ti65高温钛合金组织与性能的影响

王 旭,李四清,李臻熙,黄 旭,刘晶南

(北京航空材料研究院,北京 100095)

摘 要:研究Ti65高温钛合金的固溶处理工艺,分析不同固溶处理的Ti65高温钛合金的金相组织,测试Ti65高温钛合金的力学性能。结果表明:随着固溶温度的提高,Ti65高温钛合金初生α相的尺寸与含量减少,拉伸性能降低,蠕变性能提高;随冷却速率的提高,合金次生α相尺寸变小,长宽比增大,拉伸强度和蠕变性能提高,塑性和持久性能降低。

关键词:Ti65合金;固溶处理;显微组织;力学性能;热稳定性

中图分类号:TG145.21 文献标志码:A

Effects of solution treatment on microstructures and properties of Ti65 high-temperature titanium alloy

WANG Xu, LI Si-qing, LI Zhen-xi, HUANG Xu, LIU Jing-nan

(Beijing Institute of Aeronautical Materials, Beijing 100095, China)

Abstract: The solution treatment process of Ti65 high-temperature tianium alloy was studied. The microstructure of Ti65 alloy was analyzed by optical mircoscopy. The mechanical properties of the alloy were tested. The results show that, with the solution temperature increasing, both the size and content of the primary α phase of the alloy and the tensile properties decrease, but the creep properties improve. With the increase of cooling rate, the size of secondary α phase, plasticity and stress rupture life of the alloy decrease, but the tensile properties improve.

Key words: Ti65 high-temperature titanium alloy; solution treatment; microstructure; mechanical property; thermal stability

高温钛合金是一类主要用于航空发动机风扇轮盘和叶片等部位,使用温度在400 ℃以上的钛合金。使用高温钛合金取代高温合金,可以显著地减小发动机质量,提高发动机的推重比。目前,已使用的高温钛合金的服役温度最高达到600 ℃,包括英国的IMI834合金和美国的Ti-1100合金等[1-3],各国也做了很多的相关工作[4-8]。但随着航空发动机推重比的不断提高,对高温钛合金提出了越来越苛刻的使用要求,新设计的高推重比航空发动机高压压气机后段的工作温度将超过600 ℃。600 ℃高温钛合金已经不能满足其设计要求,迫切需要开发出高比强度、高比模量和使用温度高于600 ℃的高温钛合金以替代镍基高温合金,制成发动机的结构件。为不断满足航空发动机对高温钛合金的要求,国内在600 ℃钛合金的基础上自行研发了最高使用温度达到650 ℃的高温钛合金(简称为Ti65合金)[9-10]。为了满足高推重比航空发动机对高温钛合金的性能要求,北京航空材料研究院开展了对Ti65合金的性能优化研究。本文作者主要通过调节固溶处理参数控制合金的组织和力学性能,最终优化固溶处理参数,以期使锻件获得良好的热强性与热稳定性匹配。

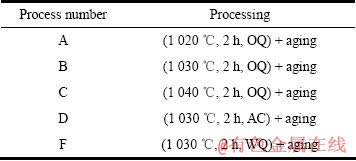

1 实验

实验使用3次真空自耗熔炼Ti65高温钛合金,名义成分(质量分数,%)为Ti-6.5A1-2Sn-4Zr-2.5Mo- 1.4W-0.2Si。试样坯料取自经过预制坯锻造,热模锻制备的航空锻件。为研究固溶处理对合金组织和性能的影响,本实验将试样毛坯分别进行1 020、1 030和1 040 ℃固溶保温2 h,按空冷(AC)、油冷(OQ)和水冷(WQ) 3种冷却方式冷却,然后进行700 ℃保温5 h后空冷的时效处理。工艺如表1所列。

表1 固溶处理工艺

Table 1 Solution treatment processes

将不同固溶处理后的材料加工成拉伸、持久、蠕变和金相试样。其中热稳定性拉伸试样为固溶时效处理后的毛坯料进行650 ℃热暴露100 h后按照标准加工成的室温拉伸试样。

2 结果与讨论

2.1 固溶温度对Ti65合金组织与性能的影响

2.1.1 固溶温度对力学性能的影响

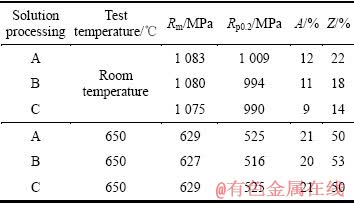

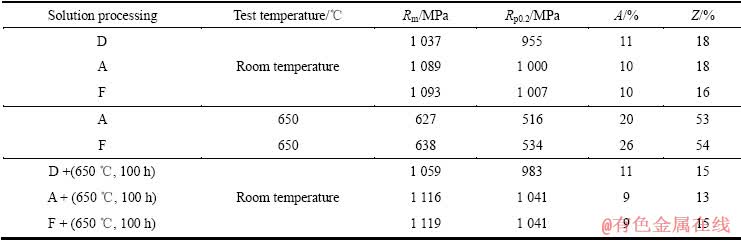

固溶温度对Ti65合金拉伸性能的影响如表2所列。从表2可以看出,Ti65合金的室温拉伸强度和650 ℃高温拉伸强度对固溶温度的变化不敏感;而随着固溶温度升高,Ti65合金的塑性均有一定程度的降低。固溶温度对Ti65高温钛合金650 ℃蠕变性能的影响如表3所列。由表3可知,Ti65高温钛合金的高温蠕变性能随着固溶温度的提高有显著的提高。

表2 固溶温度对Ti65合金力学性能的影响

Table 2 Effects of solution treatment temperature on tensile properties of Ti65 alloy

表3 固溶温度对Ti65合金蠕变性能的影响

Table 3 Effects of solution treatment temperature on creep properties of Ti65 alloy

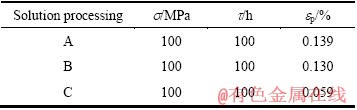

2.1.2 固溶温度对合金显微组织的影响

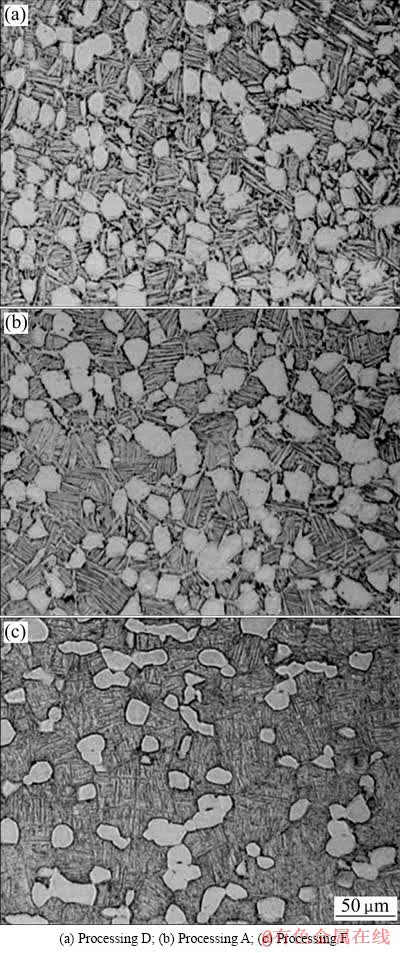

固溶温度对Ti65合金显微组织的影响如图1所示。由图1可知,Ti65合金在3种固溶温度下的显微组织均由初生α相和β转变组织组成,但是其含量和尺寸差异较大。随着固溶温度的升高,合金中初生α相的体积分数逐渐降低,而β转变组织体积分数逐渐增加、尺寸增大。这与Ti65合金在表2和3中表现出的力学性能相吻合,这是由于初生α相含量降低,初生α相与β转变组织之间的协调性差,对合金的拉伸塑性不利;而初生α相含量越少,β转变组织越多,相界面越少,越有利于提高高温蠕变性能。

图1 不同固溶处理的Ti65合金的微观组织

Fig. 1 Microstructures of Ti65 alloy by different solution processes

表4 冷却方式对Ti65合金力学性能和热稳定性能的影响

Table 4 Effects of cooling method on tensile properties and thermal stability of Ti65 alloy

2.2 固溶后冷却方式对Ti65合金组织与性能的影响

2.2.1 固溶后冷却方式对合金力学性能的影响

冷却方式对Ti65合金室温、650 ℃拉伸性能以及毛坯热稳定性的影响如表4所列。随冷却速率的提高,合金的室温和650 ℃高温拉伸强度均有一定程度的提高,而合金塑性有少量降低。Ti65合金毛坯经过650 ℃热暴露试验后,其室温拉伸性能与未经热暴露的毛坯数据相比,强度有一定的提高,塑性有少许降低。说明Ti65合金具有良好的650 ℃毛坯热稳定性。

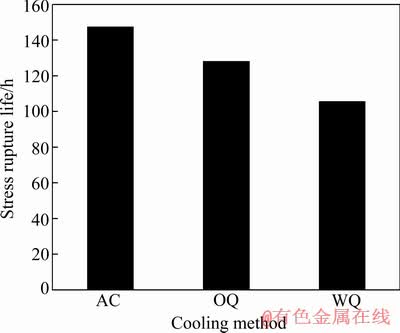

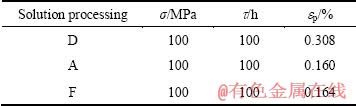

冷却方式对650 ℃持久和蠕变性能的影响分别见图2和表5。可见,随冷却速率的提高,Ti65合金的持久性能有一定程度的降低,而蠕变性能却有所提高。

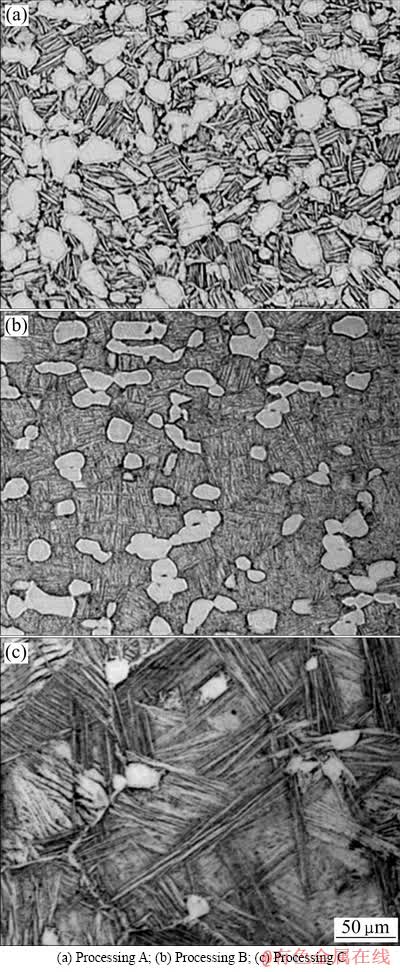

2.2.2 固溶后冷却方式对合金显微组织的影响

Ti65合金在固溶后不同冷却方式处理后的显微组织如图3所示。由图3可知,固溶后冷速对Ti65合金初生a相的形貌影响不大,但对次生a相的影响较显著,随着固溶后冷却速度的增加,合金中次生a相的尺寸逐步变小,而长宽比则逐步增大。

3 结论

1) 固溶温度对Ti65合金显微组织的初生α相的含量和尺寸影响较大,固溶温度越低初生α相的体积越大,尺寸越大。

图2 冷却方式对Ti65合金在650 ℃和240 MPa下的持久性能的影响

Fig. 2 Effects of cooling method on stress rupture properties of Ti65 alloy at 650 ℃ and 240 MPa

表5 冷却方式对Ti65合金在650 ℃的蠕变性能的影响

Table 5 Effects of cooling method on creep properties of Ti65 alloy at 650 ℃

2) 固溶后冷却方式对对初生α相的影响不大,但对次生α相影响显著。

3) 随着固溶温度升高,拉伸塑性均降低,高温蠕变等性能则有显著的提高;随冷却速率的提高,合金在室温和650 ℃高温下的拉伸强度均有一定程度的提高,塑性和持久性能有一定程度的降低,蠕变性能有所提高。

图3 不同冷却方式下的Ti65合金的微观组织

Fig. 3 Microstructures of Ti65 alloy by different cooling processes

REFERENCES

[1] 蔡建明, 李臻熙, 马济民, 黄 旭, 曹春晓. 航空发动机用600 ℃高温钛合金的研究与发展[J]. 材料导报, 2005, 19(1): 50-53.

CAI Jian-ming, LI Zhen-xi, MA Ji-min, HUANG Xu, CAO Chun-xiao. Research and development of 600 ℃ high temperature titanium alloys for aeroengine [J]. Materials Review, 2005,19(1): 50-53.

[2] 付艳艳, 宋月请, 惠松骁, 米绪军. 航空用钛合金的研究与应用进展[J]. 稀有金属, 2006, 30(6): 850-856.

FU Yan-yan, SONG Yue-qing, HUI Song-xiao, MI Xu-jun. Research and application of typical aerospace titanium alloys [J]. Chinese Journal of Rare Metals, 2006, 30(6): 850-856.

[3] 曾立英, 赵永庆, 洪 权, 毛小南, 戚运莲. 600 ℃高温钛合金的研发[J]. 钛工业进展, 2012, 29(5): 1-5.

ZENG Li-ying, ZHAO Yong-qing, HONG Quan, MAO Xiao-nan, QI Yun-lian. Research and development of high temperature titanium alloys at 600 ℃ [J]. Titanium Industry Progress, 2012, 29(5): 1-5.

[4] MESHRAM S D, MOHANDAS T. Influence of matrix microstructure on aging response of near alpha titanium alloy (IMI 834) parent metal and welds on toughness [J]. Materials Science & Technology, 2011, 27(1): 235-239.

[5] WANJARA P, JAHAZI M, MONAJATI H, YUE S, IMMARIGEON J P. Hot working behavior of near-α alloy IMI834 [J]. Material Science and Engineering A, 2005, 396(1/2): 50-60.

[6] GERHARD B, MARK E, HANS J M. Influence of environment on fatigue mechanisms in high-temperature titanium alloy IMI834 [J]. International Journal of Fatigue, 2005, 27(10/12): 1485-1493.

[7] KARTIK P, VIKAS K. Effect of temperature and hold time on internal hardening behavior of a near α titanium alloy under cyclic deformation [J]. Materials and Design, 2010, 31(6): 2716-2724.

[8] VO P, JAHAZI M, YUE S. Recrystallization during thermomechanical processing of IMI834 [J]. Metallurgical and Transactions A, 2008, 39(12): 2965-2980.

[9] 卢 斌, 杨 锐. 热处理对650 ℃短时用Ti650板材显微组织和力学性能的影响[J]. 宇航材料工艺, 2007, 37(6): 77-81.

LU Bin, YANG Rui. Heat treatment on microstructure and mechanical properties of Ti650 alloy sheet for short-term use at 650 ℃ [J]. Aerospace Materials & Technology, 2007, 37(6): 77-81.

[10] 王 永, 卢 斌, 杨 锐. 热处理对Ti650钛合金显微组织和相组成的影响[J]. 稀有金属材料与工程, 2008, 37(S3): 704-707.

WANG Yong, LU Bin, YANG Rui. Effects of heat treatment on the microstructure and phase evolution of Ti650 titanium alloy [J]. Rare Metal Materials and Engineering, 2008, 37(S3): 704-707.

(编辑 何学锋)

收稿日期:2013-07-28;修订日期:2013-10-10

通信作者:王旭,助理工程师,硕士;电话:010-62496630;传真:010-62496640;E-mail:wangxu621@gmail.com