DOI:10.19476/j.ysxb.1004.0609.2018.10.11

稀土Ce掺杂Ti基IrMn复合涂层电极的制备与性能

白茂金1, 2,周 键1, 2,王三反1, 2,赵小云1, 2

(1. 兰州交通大学 环境与市政工程学院,兰州 730070;

2. 寒旱区水资源综合利用教育部工程研究中心,兰州 730070)

摘 要:采用溶胶凝胶法在400 ℃条件下制备不同Ce含量的Ti/IrO2+MnO2+CeO2电极,并运用SEM、循环伏安、析氧极化曲线、交流阻抗实验分析Ce掺杂量对Ti/IrO2+MnO2+CeO2电极的微观结构和电化学性能的影响。结果表明:各涂层表面都是由带有裂纹的低洼区和致密的高隆区组成,当涂层中Ce含量为10%时,可以明显改善涂层电极的表面形貌与结构,增加比表面积。在电化学性能方面,相比不含Ce的IrMn电极,适量CeO2可以提高Ti/IrO2+MnO2+CeO2电极的电催化性能,并在10%的Ce含量时,Ti/IrO2+MnO2+CeO2电极的电化学活性达到最大。

关键词:Ti/IrO2+MnO2+CeO2;溶胶凝胶法;钛阳极;电化学活性

文章编号:1004-0609(2018)-10-2043-07 中图分类号:TG178 文献标志码:A

钛基金属氧化物(DSA)被广泛用于消毒、氯碱工业、电化学阳极氧化、废水处理等现代工业中[1-3]。随着重金属废水对环境的污染和对人体健康造成的损害越来越大,利用有效的方法回收治理重金属废水就变得很有必要,而采用电沉积法回收重金属废水中的重金属离子符合国家绿色环保政策导向—废水、废物资源化再利用。在利用电沉积法回收重金属废水中的重金属离子的研究中,钛阳极设计和制备是它的核心内容,电解槽电压、电能消耗、电流效率等都与钛阳极的性能有密切的联系。因此,研制寻找一种具有较低析氧过电位、稳定良好的阳极材料来减小能耗,提高回收金属质量。氧化铱具有良好的导电性、电催化性和稳定性,是理想电极的活性组分之一。YE等[4-5]通过热分解的方法制备了Ti/IrO2+MnO2涂层,研究发现该电极显示出优良的电催化性能和较高的稳定性。稀土元素以其特有的4f电子层结构,较高的催化性能而在化学催化中得到了广泛的应用[6-9]。娄长影等[10]研究了退火温度对Ti/IrO2-CeO2电极组织 结构与电容性能的影响,结果表明,CeO2可以抑制IrO2晶化的作用,在380 ℃退火温度下的电极具有良好的循环稳定性和最小的容抗。鉴于适量的CeO2和MnO2都对Ti/IrO2电极有很好的促进作用,本文作者采用溶胶凝胶法制备了Ce掺杂IrMn复合涂层电极,研究了Ce的掺杂量对电极表面形貌、组成及电化学性质的影响。

1 实验

1.1 钛基板的预处理

以工业纯钛为基体,大小为5 mm×1 mm。将钛板先后用360号和600号的砂纸打磨,使之呈银白色金属光泽,蒸馏水洗后浸泡在10%的NaOH溶液中,在80 ℃的条件下碱洗1 h,接着在10%(质量分数)的草酸溶液中微沸加热2 h使得表面呈现出麻面,最后清洗并放在酒精中待用。

1.2 涂层的制备

采用溶胶凝胶法制备电极涂层。将柠檬酸与乙二醇按3:14的摩尔比溶于定量的无水乙醇中,用超声波使之搅拌均匀。取氯铱酸、硝酸锰和硝酸铈溶于等量的无水乙醇中,其中n(Ir):n(Mn):n(Ce)=0.7:(0.3-x):x (x=0,5%,10%,15%,20%,25%,30%),超声波震荡4 h,之后将柠檬酸和乙二醇的混合溶液滴入各自之中,并加入少量的盐酸和蒸馏水得到胶体溶液(金属离子的总浓度固定在0.2 mol/L)。超声波震荡2 h使之均匀混合,静置38 h后即可用于涂膜。将上述胶液用软毛刷涂敷在预处理后的钛片上,然后在100 ℃的烘箱中干燥10 min,取出后立即放入400 ℃的马弗炉中,煅烧10 min后,取出在空气中冷却。反复涂覆、烘干、煅烧、空冷共10次,最后一次在马弗炉中烧结1 h,使得涂层彻底氧化。

1.3 电极结构及性能测试

采用德国蔡司公司的ZeissUltra Plus型场发射扫描电镜观察分析电极的表面形貌。 电化学测试在瑞士万通AUTOLAB-PGSTAT128N电化学工作站上进行。采用经典三电极体系,制备的涂层电极试样为工作电极,2 cm×2 cm的铂片作为辅助电极,参比电极为饱和甘汞电极,电解液为0.5 mol/L的H2SO4溶液。析氧极化曲线的电位测试范围为0.6~1.5 V,扫描速率为10 mV/s;循环伏安曲线的电位测试范围为0.2~1.1 V,扫描速率为20 mV/s,循环扫描5次,取最后一次的伏安曲线用于计算;电化学阻抗谱的频率测试范围为10 mHz~100 kHz,测试电位为1.30 V,使用Nova软件对阻抗谱进行拟合,在所有测试过程中保持电解液的温度为(25±1) ℃。

2 结果与分析

2.1 涂层表面形貌分析

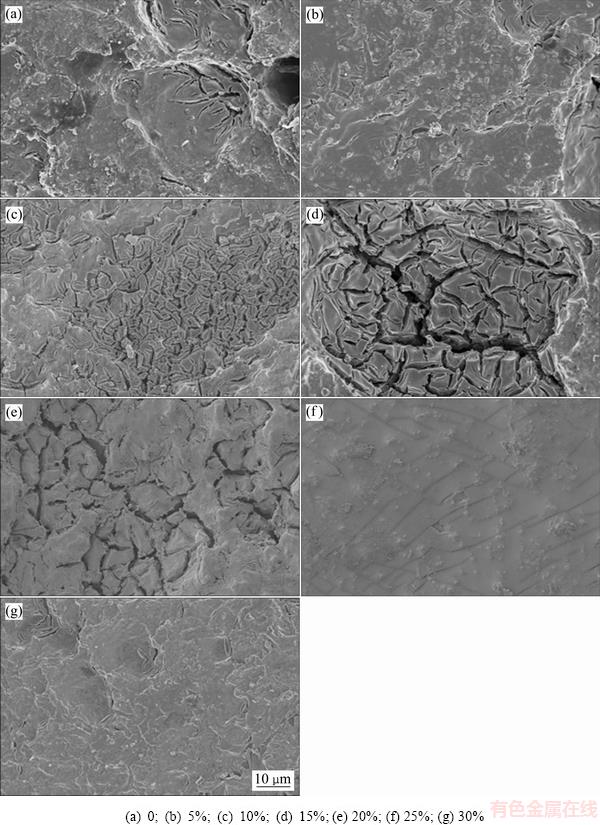

图1所示为不同Ce含量的Ti/IrO2+MnO2+CeO2氧化物阳极表面形貌的SEM像。由图1可以看出,不同Ce掺杂量改性对电极表面形貌产生的影响明显不同,但各涂层表面都是由带有裂纹的低洼区和致密的高隆区组成,裂纹的形成主要是由钛基体和涂层的热膨胀系数不同,在涂层和基体之间产生了热应力,导致了裂纹的形成。未掺杂的Ti/IrO2+MnO2电极表面很不均匀,有孔洞且有凹凸感,掺杂Ce后的电极表面相对平整均匀,凹凸感变小,且增加了裂纹数量,但当Ce过量时,电极涂层表面又变得致密,裂纹快速减少。这说明适量的Ce掺杂能改善电极的表面形貌,龟裂度减少,镀层结构变得更加致密,增加了比表面积,这一方面其致密的表层结构有利于阻碍电极在使用过程中活性氧穿过电极表层向内部扩散,从而延长电极的使用寿命;另一方面比表面积的增大又可以增加活性点的数目,提高电催化活性。分析导致这种现象的原因可能是因为添加的稀土元素Ce改善了镀层表面的微观电流分布,使结晶应力分散,颗粒变小,电极表面结构更加优良,有利于界面的电子转移,电极的电化学反应电阻大为降低。

2.2 循环伏安曲线分析

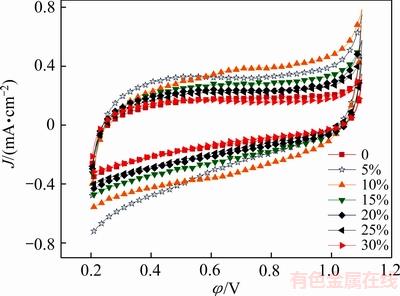

循环伏安法可以被认为是理想的“原位”测量技术,因为它可以通过循环伏安曲线来研究电极的表面敏感行为,可以深入探讨电催化活性的来源,它是电化学测量方法中应用最广的一种。图2所示为不同Ce含量的Ti/IrO2+MnO2+CeO2电极的循环伏安曲线,它们的形状基本相似,没有看到明显的氧化还原峰。但各曲线的对称性较好,说明电极具有较好的可逆性和稳定性。在低点位时(低于0.3 V)都出现了阴极峰,这对应于原子氢吸收到氧化物晶格和晶界中[11]。添加了CeO2的Ti/IrO2+MnO2+CeO2电极的伏安曲线面积都大于没有掺杂CeO2电极的伏安曲线面积,这在一定程度上说明CeO2提高了Ti/IrO2+MnO2+CeO2电极的电催化活性。

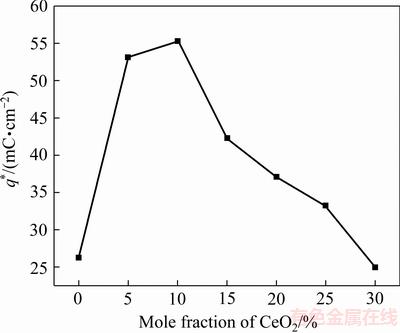

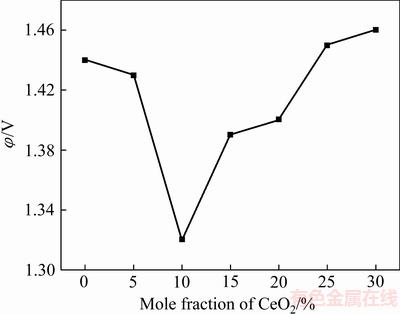

电化学活性位点的数量通常可以通过伏安电荷q*来描述,因此可以通过在一定电位范围内测得伏安曲线的积分电荷量q*来描述涂层阳极的活性表面积的大小[12]。Ti/IrO2+MnO2+CeO2电极的伏安电荷量q*随Ce掺杂量的变化规律如图3所示。随CeO2含量的增加,伏安电荷量q*先逐渐增大,在Ce含量为10%时达到最大。随着Ce含量的进一步增加,q*值突然下降。因此可以得出,含有10%Ce含量的Ti/IrO2+MnO2+CeO2电极具有最大的伏安电荷量q*,表明该电极在0.5 mol/L的H2SO4溶液中具有最优异的电催化活性。分析这一规律出现的原因可能是因为在活性涂层中添加的稀土Ce元素具有特殊的4f电子结构,极易因极化而发生变形,它以填隙或者置换的方式进入IrO2晶格内部,适量Ce的添加可以增加涂层内部活性中心的分散程度,使有效活性点的数目增加,在Ce含量为10%时这种分散达到了极限,因而会在此时电极具有最高的电催化活性。而过量的Ce会改变涂层的结构,影响电极的电子传导性质,降低在电极涂层/电解质界面积聚电荷的能力,从而减少了活性点的数量。这与图1中的SEM像有很好的一致性,在Ce含量为10%时的涂层表面具有较多的细小裂纹,大大增加了它的比表面积,当Ce过量时电极表面又变得致密,活性点开始减少。

2.3 析氧极化曲线分析

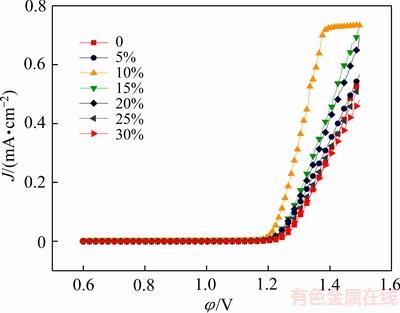

析氧极化曲线的极化电位可以间接地反应涂层电极的催化活性(当涂层的极化电位下降100 mV,催化活性能够提高10倍)。在电流密度相同的条件下,电极电位负移量越多,说明该电极的电子转移量越多,转移速度越快,从而可以得出它的催化活性越高[13]。预示着利用该电极电解时,槽电压较低,能够节省电耗。对各试样的析氧极化曲线做出了测试,如图4所示。

图1 不同Ce含量Ti/IrO2+MnO2+CeO2阳极涂层的SEM像

Fig. 1 SEM images of Ti/IrO2+MnO2+ CeO2 anodes prepared with different Ce contents

图2 不同Ce含量的Ti/IrO2+MnO2+CeO2阳极的循环伏安曲线

Fig. 2 Cyclic voltammetry curves of Ti/IrO2+MnO2+CeO2 anodes with different Ce contents

图3 Ce含量对伏安电荷量的影响

Fig. 3 Effect of Ce contents on voltammetric charge

图4 不同Ce含量的Ti/IrO2+MnO2+CeO2阳极的析氧极化曲线

Fig. 4 Oxygen evoluton polarization curves of Ti/IrO2+ MnO2+CeO2 anodes with different Ce contents

以电流密度为0.4 A/cm2时为例,各电极涂层的极化电位如图5所示。不同Ce含量阳极的极化电位亦随Ce掺杂量的大小而呈现出一定的变化规律。结合图4和5可以看出,适量的CeO2的掺杂在一定程度上降低了电极的极化电位,且随着CeO2含量的增加,Ti/IrO2+MnO2+CeO2电极的极化电位呈现出先快速减小后逐渐增加的趋势。在CeO2含量为10%时,该电极具有最低的极化电位,比传统的Ti/IrO2+MnO2电极负移量达到了130 mV,电催化性能大幅度提高。这一规律从电极过程动力学中也可以得到解释,极化电位越低,交换电流密度也就越大,则所需的过电位越小,反应速率越快,说明电极的电催化活性越高。

图5 同等电流密度下Ce含量对极化电位的影响

Fig. 5 Effect of Ce contents on polarization potential under same current density

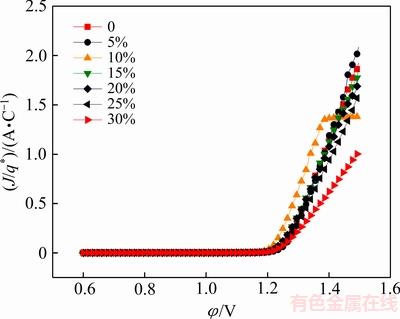

虽然从极化曲线可以表明加入CeO2后,极化电位降低,析氧更加容易。但是,无法区分真正的电催化效应和表面活性大小[14]。因此,使用电流密度和伏安电荷的比率J/q*来将活性归一化到每个活性位点,如图6所示,通过这种归一化,发现x(Ir):x(Mn): x(Ce)=7:2:1电极的每个活性位点显示出最高的活性。x(Ir):x(Mn)=7:3电极表现出比Ce含量超过10%的电极更高的性能。结合前面的循环伏安结果可以表明,虽然在IrMn涂层中掺杂Ce情况下,活性位点的数量增加,但当Ce含量超过10%时,电极涂层每个活性位点的电催化性质和固有效率会降低。这表明掺杂Ce改性的IrMnCe电极的电催化活性的提高更可能是几何效应的结果。

图6 不同Ce含量Ti/IrO2+MnO2+CeO2阳极的析氧电流归一化曲线

Fig. 6 Normalization curves of oxygen evolution current of Ti/IrO2+MnO 2+CeO2 anodes with different Ce contents

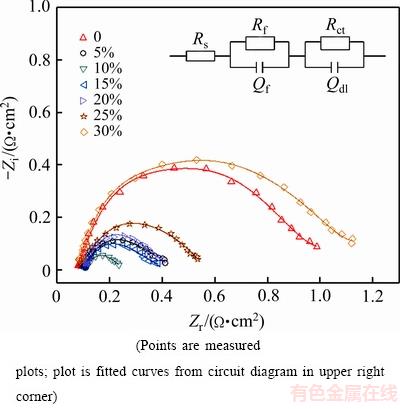

2.4 交流阻抗分析

图7所示为不同Ce含量的涂层电极在0.5 mol/L的H2SO4溶液中于1.30 V下测得的实验和拟合的EIS图。图7中不同组成的分布曲线非常相似,表明析氧的反应机理并没有随着涂层中CeO2含量的变化而发生变化。实轴Zre反映电极的阻抗性质,虚轴Zim反映电极反应过程中的容抗性质[15]。在整个频域的复平面呈现出不明显的两个直径不同的容抗弧,分别对应低频区和中高频区的阻抗数据。一般认为,低频容抗弧对应在氧化物层和溶液之间的界面处的电化学反应,中高频容抗弧与氧化物电极的多孔结构的物理响应有关。

图7 不同Ce含量的Ti/IrO2+MnO2+CeO2阳极的阻抗复数平面图

Fig. 7 Impedance multiple plane diagram of Ti/IrO2+MnO2+ CeO2 anodes with different Ce contents

等效电路EEC可以表征为Rs(RfQf)(RctQdl)(见图7插图)[16-17]。Rf是氧化物层的电阻,Qf是氧化物层的电容。(RfQf)组合与在中频和高频域观察到的氧化物电极的多孔结构的物理响应有关,而与反应电位无关。(RctQdl)组合代表涂层与溶液界面间的阻抗,与低频环路中O2析出的电化学反应有关。Rct是O2析出反应的响应电阻,Qdl是表面双电层电容。Rs表示无补偿电阻,其包括溶液电阻和由Ti衬底的氧化形成的界面绝缘TiO2膜的电阻。

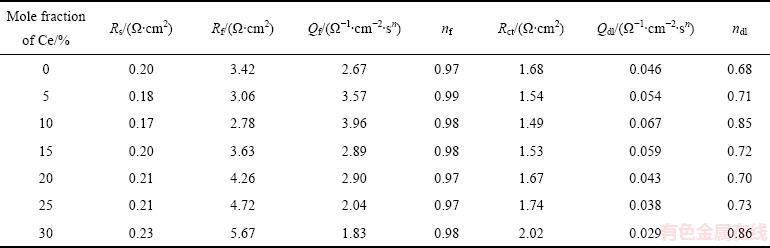

图7中的实线图是使用Rs(RfQf)(RctQdl)的EEC拟合出的阻抗谱。由图7可以看出,测量值与拟合值符合的很好(x2<1×10-3),说明图7中的等效电路可以用来代表此涂层阳极的电化学系统。将拟合电路的各参数值列于表1。

如表1所列,表1中的nf和ndl分别是常相位元件Qf和Qdl的弥散指数。ndl经常用于反应粗糙电极的不均一性和孔隙度。当涂层中的Ce含量等于10%时,ndl为0.85;随着Ce含量的增加,其大致保持在0.7左右,而当Ce含量为30%时,ndl又增加到0.86,这表明Ce含量为10%和30%的氧化物层具有较高均匀度和较低的孔隙率,这与样品的致密表面形态有很好的一致性如SEM所示,但Ce含量为30%的涂层表面太过密实而大大减小了电极的活性点。由表1可以看出,随着CeO2含量的增加,Rs和Rf值逐渐下降,当CeO2含量等于10%时,Rs和Rf值同时达到最小,但是随着CeO2含量的进一步增加,Rs和Rf值又逐步增大。Rct的变化也出现同样的规律,在CeO2含量为10%时达到最小,这有助于对电子和质子的迁移,表明在该电势范围内,在金属氧化物的表面处更容易发生反应。但CeO2含量的进一步增加,会阻碍了电子在导电IrO2颗粒间的传递,从而增大电阻。在表1中很明显,随着CeO2含量的增加,Qf和Qdl值逐渐增加,当CeO2含量等于10%,Qf和Qdl值同步达到最大值。相反,随着CeO2含量的进一步增加,Qf和Qdl值降低。最大的Qf和Qdl值表明10%CeO2含量的Ti/IrO2+ MnO2+CeO2阳极具有比其他CeO2含量的Ti/IrO2+ MnO2+CeO2阳极更优异的电催化活性。这是因为稀土元素拥有独特的电子结构,4f空轨道能占据5d的轨道,使其变成价电子,这使得稀土氧化物也能作为电催化活性点,适量的稀土铈加入可以进一步增强电极与溶液之间的电子传递[18],增加电极的电催化活性。

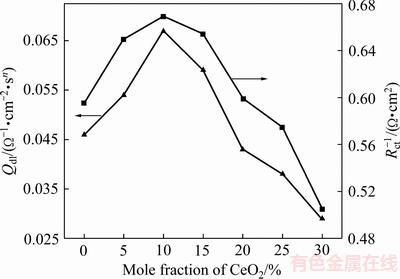

1/Rct和Qdl可以可靠地评估和解释氧化物电极的电催化活性的大小。图8作出了在400 ℃下制备的Ti/IrO2+MnO2+CeO2电极在0.5 mol/LH2SO4溶液中的Qdl和1/Rct随CeO2含量的函数。1/Rct和Qdl随着涂层中CeO2含量的增加而先增加后减小,这与图3中的循环伏安电荷量q*数据的变化趋势一致。这表明在测量氧化物电极的电化学活性时这3个参数的高度可靠性。

表1 不同Ce含量的Ti/IrO2+MnO2+CeO2阳极的电化学阻抗谱拟合后的各参数值

Table 1 Summary of fitted EIS data for the Ti/IrO2+MnO2+CeO2 anodes with different Ce contents

图8 Ce含量对Ti/IrO2+MnO2+CeO2阳极的1/Rct和Qdl的影响

Fig. 8 Effect of Ce contents on 1/Rct and Qdl values of Ti/IrO2+MnO2+CeO2 anodes

3 结论

1) 对不同Ce含量的涂层进行 SEM 分析,发现在添加Ce元素后,涂层表面形貌变得相对平整均匀,在Ce含量为10%时,涂层表面具有最多的细小裂纹,大大增加比表面积;但当Ce含量超过20%后,涂层变得致密,裂纹快速减少,活性点数目迅速降低。

2) 通过对涂层电极的电化学性能分析,可知适量Ce的掺杂可以提高Ti/IrO2+MnO2+CeO2电极的电催化活性,降低析氧电位。当涂层中Ce含量为10%时,涂层电阻和响应电阻达到最小,电催化活性达到最大,但随着Ce含量的进一步增加时,涂层的催化活性又开始降低。

REFERENCES

[1] 宁慧利, 辛永磊, 许立坤, 杜爱玲. 含石墨烯IrO2-Ta2O5涂层钛阳极性能改进研究[J]. 稀有金属材料与工程, 2016, 45(4): 946-951.

NING Hui-li, XIN Yong-lei, XU Li-kun, DU Ai-ling. Improvement of the performance of titanium anodes containing graphene IrO2-Ta2O5 coating[J]. Rare Metal Materials and Engineering, 2016, 45(4): 946-951.

[2] CHEN X, GUO H J, LUO S L, WANG Z X, LI Xin-hai. Effect of SnO2 intermediate layer on performance of Ti/SnO2 /MnO2 electrode during electrolytic-manganese process[J]. Transactions of Nonferrous Metals Society of China, 2017, 27(6): 1417-1422.

[3] 闫镇威, 孟惠民, 金 莹. Ti基氮化处理对IrO2-Ta2O5涂层阳极服役性能的影响[J]. 中国有色金属学报, 2012, 22(12): 3495-3503.

YAN Zhen-wei, MENG Hui-min, JIN Ying. Effects of Ti-based nitriding on service performance of IrO2-Ta2O5 coatings[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(12): 3495-3503.

[4] YE Z G, HUANG G B, LIU G W, DONGY H, QIAOG J. Influence of preparation process on electrocatalytic activity of Ti/IrO2+MnO2 anodes for oxygen evolution in 0 - 5 M Na2SO4 solution[J]. Materials Research Innovations, 2014, 18(S2): 440-446.

[5] ZHOU X L, YE Z G, HUA X Z, ZOUA H, DONG Y H. Electrocatalytic activity and stability of Ti/IrO2+MnO2, anode in 0.5M NaCl solution[J]. Journal of Solid State Electrochemistry, 2010, 14(7): 1213-1219.

[6] 邵艳群, 伊昭宇, 娄长影, 朱君秋, 马晓磊, 唐 电. Ti/IrO2-SnO2-CeO2电极的电容特性[J]. 中国有色金属学报, 2014(10): 2553-2558.

SHAO Yan-qun, YI Shao-yu, LOU Chang-ying, ZHU Jun-qiu, MA Xiao-lei, TANG Dian. Capacitance characteristics of Ti/IrO2-SnO2-CeO2 electrode[J]. The Chinese Journal of Nonferrous Metals, 2014(10): 2553-2558.

[7] NETO A O, WATANABE A Y, BRANDALISE M, MARCELO M T, RITA M S R, MARCELO L, ESTEVAM V S, CHRISTINA A L G O F. Preparation and characterization of Pt-rare earth/C electrocatalysts using an alcohol reduction process for methanol electro-oxidation[J]. Journal of Alloys & Compounds, 2009, 476(1/2): 288-291.

[8] WU H, QIN R, LI L, WANG B. Characterization and electrocatalytic properties of titanium-based Ru0.3Co0.7-xCex, mixed oxide electrodes for oxygen evolution in alkaline solution[J]. Journal of Nanomaterials, 2011(2): 1-7.

[9] LI Q Z, ZUO Y, ZHAO J M. The preparation and corrosion resistance of Ce and Nd modified anodic films on aluminum[J]. Anti-Corrosion Methods and Materials, 2010, 57(5): 238-243.

[10] 娄长影, 朱君秋, 邵艳群, 马晓磊, 唐 电. 退火温度Ti/IrO2-CeO2电极组织结构与电容性能的影响[J]. 中国稀土学报, 2014, 32(2): 205-212.

LOU Chang-ying, ZHU Jun-qiu, SHAO Yan-qun, MA Xiao-lei, TANG Dian. Annealing temperature Ti/IrO2-CeO2 electrode structure and capacitance performance[J]. Chinese Journal of Rare Earths, 2014, 32(2): 205-212.

[11] AUDICHON T, MORISSET S, NAPPORN T W, KOKOH K B, COMMINGES C, MORAIS C. Effect of adding CeO2 to RuO2-IrO2 mixed nanocatalysts: Activity towards the oxygen evolution reaction and stability in acidic media[J]. Chemelectrochem, 2015, 2(8): 1128-1137.

[12] XU L, XIN Y, WANG J. A comparative study on IrO-TaO coated titanium electrodes prepared with different methods[J]. Electrochimica Acta, 2009, 54(6): 1820-1825.

[13] 范农杰, 竺培显, 韩朝辉, 周生刚. 稀土La对RuO2-TiO2涂层钛阳极表面结构和性能的影响[J]. 材料热处理学报, 2015, 36(7): 217-221.

FAN Long-jie, ZHU Pei-xian, HAN Chao-hui, ZHOU Sheng-gang. Effect of rare earth La on the surface structure and properties of RuO2-TiO2 coating titanium anode[J]. Journal of Materials Heat Treatment, 2015, 36(7): 217-221.

[14] ZHANG J J, HU J M, ZHANG J Q, CAO C N. IrO2-SiO2 binary oxide films: Geometric or kinetic interpretation of the improved electrocatalytic activity for the oxygen evolution reaction[J]. International Journal of Hydrogen Energy, 2011, 36(9): 5218-5226.

[15] JANG J H, OH S M. Complex capacitance analysis of porous carbon electrodes for electric double-layer capacitors[J]. Journal of the Electrochemical Society, 2004, 151(4): 571-577.

[16] SHIEH D T, HWANG B J. ChemInform abstract: Morphology and electrochemical activity of Ru-Ti-Sn ternary-oxide electrodes in 1 M NaCl solution[J]. Cheminform, 2010, 24(50): 256-262.

[17] LASSALI T A F, BOODTS J F C, BULHOES L O S. Charging processes and electrocatalytic properties of IrO2/TiO/SnO2, oxide films investigated by in situ AC impedance measurements[J]. Electrochimica Acta, 1999, 44(24): 4203-4216.

[18] 徐 迈, 王凤武, 梁 铣, 魏亦军, 方文彦, 朱传高, 胡云虎. Pr-PVP掺杂Ti/PbO2电极制备及其在有机物降解中的应用[J]. 电化学, 2017(3): 340-346.

XU Mai, WANG Feng-wu, LIANG Xian, WEI Yi-jun, FANG Wen-yan, ZHU Chuan-gao, HU Yun-hu. Pr-PVP doped Ti/PbO2 electrode preparation and its application in organic degradation[J]. Electrochemical, 2017(3): 340-346.

Preparation and performance of Ti-based IrMn composite coating electrode doped rare-earth Ce

BAI Mao-jin1, 2, ZHOU Jian1, 2, WANG San-fan1, 2, ZHAO Xiao-yun1, 2

(1. School of Environmental and Municipal Engineering, Lanzhou Jiaotong University, Lanzhou 730070, China;

2. Engineering Research Center for Cold and Arid Regions Water Resource Comprehensive Utilization, Ministry of Education, Lanzhou 730070, China)

Abstract: Ti/IrO2+MnO2+CeO2 electrodes with different Ce contents were prepared by sol-gel method at 400 ℃. The effects of the Ce content to Ti/IrO2+MnO2+CeO2 electrode on microstructure and electrochemical properties was analyzed by SEM, cyclic voltammetry, oxygen evolution polarization curve and AC impedance test. The results show that the surface of each coating is composed of cracked low-lying areas and dense high-long areas, when the content of Ce in the coating is 10%, the surface morphology and structure of the coated electrode can be significantly improved, and the specific surface area increases. In terms of electrochemical performance, moderate CeO2 can increase the electro-catalytic performance of Ti/IrO2+MnO2+CeO2 electrode compared to the Ce-free IrMn electrode, and the Ti/IrO2+MnO2+CeO2 electrode with the Ce content of 10% has the highest electrochemical activity.

Key words: Ti/IrO2+MnO2+CeO2; sol-gel method; titanium anode; electrochemical activity

Foundation item: Project(201606) supported by Lanzhou Jiaotong University Excellent Platform Fund, China; Project (21466019) supported by the National Natural Science Foundation of China; Project(17JR5RA088) supported by Gansu Provincial Youth Science and Technology Fund Plan, China

Received date: 2018-03-27; Accepted date: 2018-07-25

Corresponding author: ZHOU Jian; Tel: +86-13609344897; E-mail: 2700355584@qq.com

(编辑 王 超)

基金项目:兰州交通大学优秀平台基金Lzjtu支撑(201606);国家自然科学基金资助项目(21466019);甘肃省省青年科技基金计划(17JR5RA088)

收稿日期:2018-03-27;修订日期:2018-07-25

通信作者:周 键,副教授,博士;电话:13609344897;E-mail: 2700355584@qq.com