文章编号:1004-0609(2008)03-0476-07

低温烧结型银浆料对半导体芯片贴装性能的影响

甘卫平,刘 妍,甘 梅

(中南大学 材料科学与工程学院,长沙 410083)

摘 要:研究低温烧结型银/玻璃体系浆料的成分配比、制备工艺及其半导体芯片贴装烧结工艺,探讨浆料中银粉、玻璃粉和有机载体的成分对浆料烧结体的微观组织、热导率、线膨胀系数及芯片组装的剪切力之间的影响关系,利用理论模型计算浆料烧结体的热导率和线膨胀系数,分析其理论计算值与实测值差异的影响因素。结果表明:随着玻璃粉含量的增加,浆料烧结体的线膨胀系数及热导率逐渐降低,当银粉和玻璃粉的质量比为7?3,固体混合粉末与有机载体的质量比为8?2时,芯片贴装后可满足热导率和线膨胀系数性能的要求,同时所承受的剪切力最大。

关键词:低温烧结型银浆料;线膨胀系数; 热导率;剪切力

中图分类号:TB 34 文献标识码:A

Effect of low-temperature sintered silver paste on properties of semiconductor chip assembly

GAN Wei-ping, LIU Yan, GAN Mei

(School of Materials Science and Engineering, Central South University, Changsha 410083, China)

Abstract: The composition, preparation and sintering curve of a low-temperature sintered Ag/glass paste were studied. The effects of composition of paste on the microstructure, thermal conductivity, coefficient of thermal expansion (CTE) and shear force were studied. The theoretical models were employed to calculate the CTE and thermal conductivity of Ag/class. The influence factors on the coefficient of thermal expansion and thermal conductivity were analyzed. The results show that the CTE and thermal conductivity of composite decrease apparently with increasing glass content. When the ratio of silver to glass frits is 7?3 and the ratio of solid powder to organic vehicles is 8?2, the semiconductor chip assembly can satisfy the demand of CTE and thermal conductivity, and the optimal shear force can also be obtained.

Key words: low-temperature sintered Ag/glass paste; coefficient of thermal expansion; thermal conductivity; shear force

随着航空、航天和特殊用途的微波电路、微电子器件、半导体集成电路向大功率、小型化、轻量化、高密度组装化、低成本、高性能和高可靠性的方向发展,对集成电路的半导体芯片组装工艺提出更高的要求[1]。由于集成电路的集成度大幅度提高,电子器件发热量急剧上升,容易引起热应力集中而导致芯片扭曲变形,甚至开裂而失效[2-4],因此要求浆料具有低的烧结连接组装温度、良好的导热性和低的线膨胀系数,保护芯片不致受损而失效。以往半导体芯片贴装通常采用昂贵的金-硅共熔焊或导电胶进行贴装,由于金-硅共熔焊组装工艺焊接温度偏高不利于保护芯片,导电胶的易老化和附着力低,不能满足半导体芯片贴装可靠性的要求。针对传统工艺存在的缺陷,国外报道一种新型的半导体芯片组装用的低温烧结型银-玻璃体系浆料[5-7],可解决传统组装工艺中造成的芯片开裂失效和技术不稳定问题,确保半导体芯片贴装的质量和可靠性。本文作者旨在研制一种高热导、低膨胀、低成本的低温烧结型银-玻璃体系的浆料,探讨浆料中银粉、玻璃粉和有机载体的成分对热导率、线膨胀系数及芯片组装的剪切力之间的影响关系,并研究该浆料的组装烧结工艺和应用于芯片贴装工艺的可靠性。

1 实验

1.1 浆料的制备

浆料的成分设计由功能相、粘结相和有机载体这3部分组成。功能相采用银粉,其作用是导热和导电;粘结相采用低融化温度的玻璃粉,它主要通过调整玻璃粉的成分和浆料中的含量,起到低温烧结时的粘结作用,有利于与银导体形成网络状组织,并调节浆料的线膨胀系数,保证半导体芯片与基片贴装时的线膨胀系数相匹配,同时满足芯片与基片粘结强度的要求;有机载体的添加是为了满足半导体芯片与基片的预装配,有机载体的性质、成分和含量将影响浆料的活性、浸润性和流平性。

1.1.1 银粉的制备

银粉的纯度为99.95%,球状银粉平均粒径为3.0 μm。片状银粉的制备[8]采用行星球磨机和氧化锆磨球,球料比为3?1,分散剂为无水乙醇,转速300 r/min,球磨时间为20 h。图1所示为球磨20 h后片状银粉的形貌。片状银粉的粒度由Micro-Plus型激光衍射粒度分析仪测定,其平均粒径为5 μm。然后将制取的片状银粉和球状银粉按质量比9?1进行混合备用。

图1 球磨20 h后片状银粉的形貌

Fig.1 Morphology of flake silver after milling 20 h

1.1.2 玻璃粉的制备

本实验玻璃粉主要成分为PbO,同时含有少量的SiO2和Al2O3,将玻璃粉球磨至平均粒径为5.0 μm,制取的玻璃粉通过Micro-Plus型激光衍射粒度分析仪测定,其粒度分布图和形貌分别如图2和3所示。

图2 玻璃粉的粒度分布图

Fig.2 Particle size distribution of glass frits

图3 球磨后玻璃粉的形貌

Fig.3 Morphology of glass frits after milling

1.1.3 有机载体的制备

本实验所采用的有机载体以松油醇为主要溶剂,加入乙基纤维素、无水乙醇、氢化蓖麻油分别作为流平剂、表面活性剂和触变剂。按照一定配比在80 ℃下进行水浴加热,同时搅拌均匀,密封保存。

1.1.4 浆料的制备

将混合好的银粉与玻璃粉、有机载体按一定的比例进行混合,研磨均匀后制备成浆料。

1.2 实验方法

1.2.1 试样成分及编号

将一定质量的银粉和玻璃粉充分混合,按表1中银粉、玻璃粉和有机载体的不同配比,将试样编号,其中试样1~5为压型烧结试样,用于测定线膨胀系数和热导率,试样6~13为配制浆料后,用于研究不同配比的浆料与芯片和基片组装烧结后各性能之间的关系。

表1 试样成分

Table 1 Component of samples

1.2.2 半导体芯片贴装烧结工艺

采用智能多段式KSX2系列节能快速升温电炉,优化了半导体芯片贴装烧结工艺,其具体工艺如下:首先选择面积为1.69 mm2的FX3026 半导体芯片和JO8S2外壳配对,将芯片置入70~80 ℃的去离子水中进行冲洗,然后在甲苯、丙酮溶液中超声清洗2~3 min,再用无水乙醇清洁2~3 min,最后用热去离子水冲洗干净后,放入烘箱烘干(80±5) ℃;陶瓷基片采用高纯氮气吹洗清洁。组装操作过程是将浆料涂刷在芯片和基片上贴装后静置15 min,然后将样品放入烧舟中,采用有利于有机载体挥发的阶梯式烧结工艺,烧结气氛为大气,升温速率为2 ℃/min,组装烧结从室温开始升温至150 ℃,保温30 min;随后升温至300 ℃和430 ℃时各保温30 min,最后试样随炉冷却。

1.2.3 试样的检测

1) 线膨胀系数

试样要求:d 5 mm×20 mm;处理条件:t≤400 ℃,升温速度100~200 ℃/h;测试仪器采用日本理学差热分析仪TAS100,测量误差±5%。

2) 热导率

试样要求:d10 mm×4 mm。测试设备采用JR-2热物性测试仪,测量误差为±5%。

3) 剪切力

芯片与底座贴装后所承受的剪切力大小可作为它们界面之间附着力的判据。测试试样的剪切力采用HA-10 内引线拉力芯片剪切应力测试仪,该测试仪可对芯片施加近似90度的负载足以能把芯片从固定位置上剪切下来。剪切力实验根据GJB548A—96标准中方法2019A执行。

4) 微观组织观察和能谱分析

利用KYKY-2800型和JSM-5600LV扫描电镜,对样品进行微观组织观察和能谱分析。

2 结果及讨论

2.1 微观组织分析

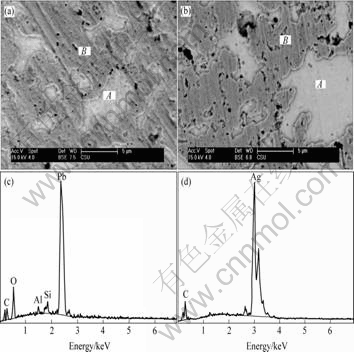

图4所示为银/玻璃烧结体的SEM像和EDS谱,图4(a)和(b)所示分别为试样1和5的SEM像。从图中可明显辨别出银/玻璃烧结体由枝状的白色相A和灰色的基体B组成,其中分布有少量的黑色显微孔洞。由图4(c)和(d)所示的白色相A和基体B的EDS谱可知,枝状的白色相A为玻璃相,灰色的基体B为银导体相,玻璃粉作为烧结体的粘结相经熔融后均匀地分布在导电相周围,使基体与玻璃相之间能够很好的结合在一起,有利于银导体相形成良好的导电网络。从图4(a)和(b)所示的银/玻璃烧结体的SEM形貌可观察到试样1较试样5的微观组织致密,黑色孔洞较少。这是由于试样1的玻璃粉含量为15%,枝状玻璃相相对细小,空隙也逐渐减小,当达到峰值烧结温度时,更多的银粉小颗粒经熔融的玻璃相传递到较大的银粉颗粒上沉淀,使得烧结空隙减少,导致最终的致密度较大;而试样5的玻璃粉含量为35%,由于玻璃融化形成液相,呈粗大枝状分布,改变银粉颗粒的排布,玻璃相已成为一些颗粒的桥,并通过烧结颈的生长而导致银颗粒团进一步收缩融并,在较小的拉应力作用下,可明显观察到银基体中的显微孔洞增多。

图4 银/玻璃烧结体的SEM像和EDS谱

Fig.4 SEM images and EDS patterns of sinter silver and glass: (a) Sample 1, 15% glass; (b) Sample 5, 35% glass; (c) EDS pattern of spot A; (d) EDS pattern of spot B

2.2 线膨胀系数的变化

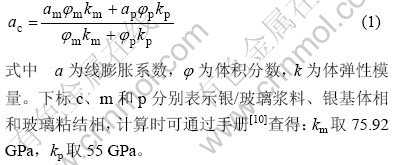

浆料烧结后的线膨胀系数是影响半导体芯片的组装连接的重要因素。银的线膨胀系数高达19.6×10-6/℃,而玻璃粉的线膨胀系数仅为7.2×10-6/℃,因此大量低膨胀玻璃相的加入能有效降低银/玻璃烧结体的线膨胀系数。通常该烧结体的线膨胀系数与材料中玻璃相的含量之间符合混合规则,可用Turner模型反映这一规律[9]:

图5所示为试样1~5的银/玻璃浆料烧结体线膨胀系数计算值和实测值的变化趋势。由图可见,其线膨胀系数随着玻璃粉含量的增加而下降,线膨胀系数的实测值在13.7×10-6~17.0×10-6/℃之间变化。由图5还可以看出,低膨胀玻璃相的加入能有效地抑制基体膨胀,随着玻璃粉质量分数的增加,银/玻璃烧结体的线膨胀系数呈下降趋势。当玻璃粉质量分数为30%时,相应的线膨胀系数为14.5×10-6/℃;当玻璃粉含量继续增大至35%时,其线膨胀系数迅速下降至13.7×10-6/℃。图5中实际测得的热膨胀系数小于理论计算的数值,这一现象可在如下影响因素的分析中得到解释,首先,银基体为延性相,它的分布形态是影响线膨胀系数的另一个重要因素。随着温度的升高,延性相和玻璃脆性相都会发生膨胀,但延性相的线膨胀系数一般较大,且更容易发生塑性变形;当延性相被玻璃脆性相阻断为不连续相时,其变形会受到周围线膨胀系数很小的玻璃相的约束,但当延性相连续分布时这种约束就很小。从图4可以看出,由于玻璃粉含量的增加,材料的延性相减少,且被富集的玻璃相所阻断,因此使烧结体的线膨胀系数下降。其次,残余应力能显著影响线膨胀系数[11]。在浆料烧结过程中,热膨胀

图5 玻璃粉含量与线膨胀系数的关系曲线

Fig.5 Relationship between content of glass and coefficient of thermal expansion

使材料内部产生很复杂的应力,玻璃相中PbO挥发时收缩,导致烧结体内部产生大量残余压应力,制约材料的进一步膨胀,可能使材料发生一定的弹塑性变形。当材料膨胀时,这些残余压应力减小膨胀时的拉应力,从而使得材料的线膨胀系数减小,且玻璃粉含量越大,PbO挥发越多,残余应力越大,线膨胀系数减小越多。此外,烧结体的气孔率对热膨胀性能也有一定的影 响[12],它会降低烧结体的线膨胀系数。随着玻璃粉含量的增加,烧结体的气孔率随之增大,因而线膨胀系数就会逐渐减小。以上分析表明,低温烧结型银/玻璃烧结体中线膨胀系数除受到玻璃粉含量的影响外,还受玻璃相的形状、分布、残余应力以及孔洞等因素的制约,它们都会一定程度的影响到材料的线膨胀系数。

2.3 热导率的变化

浆料作为芯片与基片的组装材料需要有高效导热媒质的功能。在固体中,对能量运载者可以是自由电子、晶格振动波(声子)和电磁辐射(光子)。对纯金属来说,电子导热是主要的导热机制,在绝缘体内,几乎只存在声子导热一种形式;在合金中除了电子导热以外,声子导热也有一定的作用。低温烧结型银/玻璃烧结体实质上是一种以银基体作为连续相,玻璃粘结相作为分散相的复合材料,可以用电子、声子导热的机制来描述其导热行为,则银/玻璃浆料的热导率可简化为Kingery模型[9]:

根据上述理论模型计算和实测得到不同玻璃粉含量与材料热导率的关系曲线如图6所示。

从图6可以看出,银/玻璃烧结体热导率都随着玻璃粉含量的增加而下降,但实测值低于理论值。这是由于银/玻璃烧结体的孔隙和界面热阻两个主要影响因素作用的结果。一方面,低温烧结的银/玻璃烧结体中形成的孔隙使其致密性降低,引起声子的散射而降低热导率;另一方面,在烧结体中存在大量的银基体相与玻璃相的界面,对材料的热导率产生的影响主要是通过界面热阻来起作用的,使声子和自由电子发生一定的散射,降低材料的热导率,界面越多,界面热阻越大,其热导率就会下降越大。如图6所示,随着银/玻璃浆料中玻璃粉含量的增加,体系中气孔率和银基体相与玻璃相的界面逐渐增多,使得材料内部的缺陷增加而导致声子和自由电子发生散射的几率增 加,因此热导率理论值与实验值之间的偏差也逐渐增大。由图6可知,热导率随玻璃粉含量的增加而下降,实测值在145~288 W/(m?K)之间变化。当玻璃粉含量为30%时,相应的热导率为182 W/(m?K),当玻璃粉含量继续增大至35%时,其热导率下降至145 W/(m?K)。

图6 玻璃粉含量与热导率关系曲线

Fig.6 Relationship between content of glass frits and thermal conductivity

2.4 剪切力的变化

剪切力实验按照GJB548A—96标准中方法2019A进行。芯片与底座贴装后所承受的剪切力大小可反映它们界面之间的附着力。通常影响芯片组装附着力大小的主要因素有浆料的玻璃粘结相和有机载体的相对含量。

2.4.1 浆料中玻璃粉含量对附着力的影响试样6~10的玻璃粉含量变化对芯片与底座贴装后剪切力影响如图7所示,其中玻璃粉含量是指玻璃粉占固体混合粉末的质量分数。

在浆料烧成过程中,玻璃料软化呈熔融态,一方面润湿固体银粉,使得片状银粉和球状银粉相互紧密接触,形成良好的导电网络;另一方面熔融的玻璃料润湿陶瓷基板的表面并渗入其晶界,与基板形成机械互锁,将导电膜连接到陶瓷基板上[13-14]。由图7可见,随着玻璃粉含量的增加,剪切力不断提高。玻璃粉含量为30%时,剪切力迅速增加到30 N以上,随后曲线趋于平缓,剪切力增长缓慢,这表明浆料烧结膜附着力增强的首要前提是要有足够的玻璃粘结相,否则不能完全润湿芯片和底座从而影响其附着力。玻璃粉含量达到一定程度后,会使得烧结膜附着力显著的提高,继续增加其含量,附着力虽有增加,但增长缓慢[15]。因此玻璃粉含量在30%时,附着力最大,组装的可靠性最佳,且可满足半导体芯片贴装后线膨胀系数和热导率性能的要求。

图7 浆料中玻璃粉含量对芯片与底座贴装后剪切力的影响

Fig.7 Effect of glass frits content on shear force

2.4.2 有机载体对附着力的影响

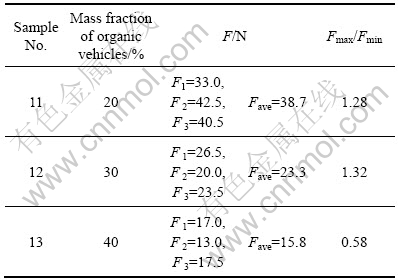

浆料中的有机载体含量一方面直接决定着浆料的粘度,另一方面在浆料烧成过程中有机载体逐渐挥发,影响着浆料烧结时的收缩率,因而成为影响烧结膜附着力的又一因素。浆料中的有机载体包括溶剂、增稠剂、表面活性剂和触变剂等助剂,其功能是将银粉、玻璃粉混合成膏状浆料,使其具有一定的粘稠性,从而很好的粘附在基板表面[16]。如表1所列试样11~13的有机载体含量分别为20%、30%和40%,测试这3个样品与底座贴装后的剪切力(F),其结果列于表2。

表 2 浆料中不同的有机载体含量的剪切力

Table 2 Shear force of chip with various organic vehicles

由表2可知,随着浆料中有机载体含量的增加,剪切力逐渐减小。依据GJB548A—96标准中方法2019A,贴装采用面积为1.69 mm2的芯片时,剪切力为20.6 N,且最大值与最小值的比小于3者为合格,可以得出试样11和12符合标准要求,而试样13的剪切力过小。因此,选用有机载体含量为20%的浆料进行贴装时可获得较为理想的剪切力。

由表2可知,随着浆料中有机载体含量的增加,剪切力逐渐减小。依据GJB548A—96标准中方法2019A,贴装采用面积为1.69 mm2的芯片时,剪切力为20.6 N,且最大值与最小值的比小于3者为合格,可以得出试样11和12符合标准要求,而试样13的剪切力过小。因此,选用有机载体含量为20%的浆料进行贴装时可获得较为理想的剪切力。

3 结论

3 结论

1) 玻璃粉含量对烧结体的组织和性能有较大影响。随玻璃粉含量增加,烧结体中的显微孔洞增多,热膨胀系数和热导率均呈现下降趋势。当银粉与玻璃粉的配比为7?3时,烧结体的线膨胀系数为14.5 ×10-6/℃,热导率为182 W/(m?K),可满足半导体芯片贴装后热膨胀系数和热导率性能的要求。

2) 低温烧结型银浆料中玻璃粉含量为30%,固体粉末与有机载体之比为8?2时,芯片与底座贴装后可承受的剪切力大于30 N,其可靠性最佳;当有机载体含量继续增加时,则剪切力随之下降。

REFERENCES

[1] 蔡菊荣, 刘文俊. 军事应用中的微组装技术[J]. 微电子技术, 1997, 25(4): 1-16.

CAI Ju-rong, LIU Wen-jun. Microelectronic packaging technology applied to military affairs[J]. Microelectronic Technology, 1997, 25(4): 1-16.

[2] GUPTA T K. 厚薄膜混合微电子学手册[M]. 王瑞庭, 朱 征, 等译. 北京: 电子工业出版社, 2005: 1-24.

GUPTA T K. Handbook of thick-and thin-film hybrid microelectronics[M]. WANG Rui-ting, ZHU Zheng, et al transl. Beijing: Electronics Industry Press, 2005: 1-24.

[3] CARL Z. Metal-matrix composites for electronic packaging[J]. Journal of Metals, 1992, 44(7): 15-23.

[4] 刘正春, 王志法, 姜国圣. 金属基电子封装材料进展[J]. 兵器材料科学与工程, 2001, 24(2): 49-52.

LIU Zheng-chun, WANG Zhi-fa, JIANG Guo-sheng. Advance in metal-matrix material for electronic packaging[J]. Ordnance Material Science and Engineerin, 2001, 24(2): 49-52.

[5] NGUYEN M N, BLOCKER M A. Silver-glass pastes[P]. US 5075262, 1991-11-24.

[6] HERRINGTON T L. Silver-glass pastes[P]. US 5084421, 1992-01-28.

[7] NGUYEN M N, LEE C K, HERRINGTON T L. Silver-glass pastes[P]. US 5183784, 1993-02-02.

[8] 甘卫平, 甘 梅, 刘 妍. 高能球磨对片状银粉的改性研究[J]. 材料导报, 2007, 5(21): 325-327.

GAN Wei-ping, GAN Mei, LIU Yan. Study on the modification of flake silver powder by high energy ball milling[J]. Materials Review, 2007, 5(21): 325-327.

[9] 奚同庚. 无机材料热物性学[M]. 上海科学技术出版社, 1981: 208-209.

XI Tong-geng. Thermophysical properties of inorganic material[M]. Shanghai: Shanghai Science and Technology Press, 1981: 208-209.

[10] 徐 灏. 机械设计手册(二)[M]. 北京: 机械工业出版社, 2004: 146.

XU Hao. Machine design handbook (Part Ⅱ)[M]. Beijing: China Machine Press, 2004: 146.

[11] 耿 林, 温丙先, 姚忠凯. 压铸SiCw/Al复合材料的热物理性能研究[J]. 复合材料学报, 1996, 13(3): 48-52.

GEN Lin, WEN Bing-xian, YAO Zhong-gai. Thermal physical properties of squeeze casting SiCw/Al composites[J]. Acta Materiae Compositae Sinica, 1996, 13(3): 48-52.

[12] 王玉金, 周 玉, 宋桂明, 雷廷权. TiCp/W复合材料的热物理性能[J]. 稀有金属材料与工程, 2002, 29(6): 386-389.

WANG Yu-jin, ZHOU Yu, SONG Gui-ming, LEI Ting-quan. Thermophysical properties of TiCp/W composites[J]. Rare Metal Materials and Engineering, 2002, 29(6): 386-389.

[13] 田民波, 何 卫, 李恒德. AlN基片金属化Ag-Pd[J]. 功能材料, 1997, 28(4): 358-359.

TIAN Min-bo, HE Wei, LI Heng-de. Study of Ag-Pd thick film conductor for AlN substrate metallization[J]. Journal of Functional Materials, 1997, 28(4): 358-359.

[14] 陈国华, 刘心宇. 玻璃陶瓷复合材料的制备、微结构和性能[J]. 中国有色金属学报, 2006, 16(5): 818-822.

CHEN Guo-hua, LIU Xin-yu. Preparation,microstructure and preperties of glass/ceramic composites[J]. The Chinese Journal of Nonferrous Metals, 2006, 16(5): 818-822.

[15] 张俊兵, 樊自拴, 孙冬柏, 俞宏英, 孟惠民, 李辉勤. 厚膜镍导电浆料研究[J]. 电子元件与材料, 2004, 7(7): 28-30.

ZHANG Jun-bing, FAN Zi-shuan, SUN Dong-bai, YU Hong-ying, MENG Hui-min, LI Hui-qin. Study on thick-film nickel conductive paste[J]. Electronic Components and Materials, 2004, 7(7): 28-30.

[16] 李世泓. 厚膜金导体浆料[J]. 贵金属, 2001, 22(1): 58-59.

LI Shi-hong. Thick-film gold conductor pastes[J]. Precious Metals, 2001, 22(1): 58-59.

基金项目:国防科工委资助项目(JPPT-115-471)

收稿日期:2007-07-26;修订日期:2007-12-14

通讯作者:甘卫平,教授;电话:0731-8830248;E-mail: gwp@mail.csu.edu.cn

(编辑 龙怀中)