二氧化钌/活性炭复合电极的制备及性能

甘卫平,刘继宇,师响,刘泓,李祥,马贺然

(中南大学 材料科学与工程学院,湖南 长沙,410083)

摘要:为研制低成本、高比容超级电容器的关键复合电极材料,采用涂覆热分解法,以RuCl3·2H2O为前躯体,制备二氧化钌/活性炭复合电极材料。借助扫描电镜、附着力测试、循环伏安、恒流充放电和电化学阻抗谱等检测手段,观察复合薄膜电极材料的表面形貌,分析不同涂覆量的二氧化钌/活性炭复合薄膜电极的性能。研究结果表明:二氧化钌/活性炭复合电极材料具有良好的电化学稳定性,涂覆热分解最佳涂覆数为4次,复合薄膜的比表面积为321.4 m2/g,附着力为11.4 MPa;在H2SO4溶液浓度为0.5 mol/L、扫描速率20 mV/s条件下,复合电极材料的比电容为422 F/g,内阻为0.33 Ω;经300次充放电后,电容量持续为98.8%。

关键词:超级电容器;复合电极;活性炭;二氧化钌

中图分类号:TM53 文献标志码:A 文章编号:1672-7207(2011)02-0336-06

Preparation and performances of RuO2/AC composite electrode materials

GAN Wei-ping, LIU Ji-yu, SHI Xiang, LIU Hong, LI Xiang, MA He-ran

(School of Materials Science and Engineering, Central South University, Changsha 410083, China)

Abstract: To research low-cost, high specific capacitance key composite electrode materials for super-capacitors, ruthenium oxide coated active carbon (RuO2/AC) was prepared by coating and thermal decomposition of ruthenium chloride on AC matrix. The morphology of the composite electrode was investigated by SEM. The performances of RuO2/AC composite membrane electrode at different coating numbers were characterized by adhesion, cyclic voltammetry, constant current charge-discharge and electrochemical impedance spectroscopy analyses. The results show that the best coating number is 4 times, when the composite film has a surface area of 321.4 m2/g, and adhesion of 11.4 MPa. The specific capacitance of RuO2/AC composite electrode is 422 F/g measured at 20 mV/s in 0.5 mol/L H2SO4, and the inner resistance is 0.33 Ω. After 300 cyclic-life, the specific capacitance of RuO2/AC composite electrode is kept at 98.8%, indicating that the composite electrode has a good electrochemical stability and can be used as the electrodes for super-capacitors.

Key words: super-capacitors; composite electrode; active carbon; ruthenium oxide (RuO2)

超级电容器是一种介于充电电池与传统电容器之间的新型能源器件,是一种新型、高效、实用的能量储存装置。与传统的电容器和二次电池相比,超级电容器的功率密度、储存电荷的能力比普通电容器和电池高很多,其容量是传统电容器的200倍以上,功率是二次电池的10倍以上;它充放电速度快、效率高、工作温限宽、电压记忆性好、免维护、对环境无污染、循环寿命长,是一种新型绿色能源;因而在现代航空、航天、兵器、国防科技、移动通讯、电子信息技术、绿色环保能源、电动汽车混合电源等方面有广阔的应用前景[1]。根据电荷的储存机理,超级电容器可分为双电层电容器和法拉第准电容器。双电层电容器采用碳材料作为电极,通过碳电极与电解液界面上电荷分离所产生的双电层电容储存能量;法拉第准电容器一般采用RuO2作为电极,由氧化物电极表面及体相发生的氧化还原反应所产生的法拉第准电容储存能量。电极材料的性能是决定超级电容器质量的关键[2-4]。电极材料必须能够在电极与电解质界面上形成双电层电容或法拉第准电容,并具有一定的化学稳定性和良好的电子及离子导电性。金属氧化物RuO2的比电容高达768 F/g[5],是目前最理想的电极材料。但是,RuO2昂贵的价格限制了它的广泛应用。在复合电极材料的研究中,不少研究者将RuO2和多孔碳材料制成复合电极材料,以减少内阻,提高其功率性能[6],降低生产成本。制备RuO2薄膜的方法很多,如溶胶-凝胶法、化学气相沉积、物理气相沉积、溅射沉积、涂覆热分解、电沉积等[7-11]。目前生产的混合电容器用RuO2薄膜,主要采用涂覆热分解的方法制备[12]。该方法对设备要求低,操作简便,适合规模化生产应用。本文旨在以廉价的活性炭(Active carbon,AC)适当替代部分昂贵的RuO2,研究涂覆热分解工艺,制备高比容的超级电容器用RuO2/AC复合电极,并对该电极材料的形貌、附着力和电化学等性能进行研究。

1 实验过程

1.1 活性炭电极的制备

将活性炭粉末在一定浓度的HNO3溶液中浸泡 24 h,用去离子水超声波洗涤、抽滤、除去杂质和灰分,烘干备用。取一定量预处理过的活性炭,加入20%高导电碳黑作为导电剂,5%聚四氟乙烯乳液作为黏结剂,混合均匀,将其置于钽基上,施加10 MPa压力制成炭电极。

1.2 RuO2/AC活性炭复合电极的制备

配制所使用的涂覆液,其中主要成分的质量比为m(TaCl5):m(RuCl3)·m(2H2O):m(CH3CH(OH)CH3)=1:3:20。将之前压制好的炭电极干燥后,浸入涂覆液中进行涂覆,形成均匀、较薄的液态膜。每次涂覆后的电极置于温度为150 ℃的恒温箱中干燥10 min,取出冷至室温,然后重复涂覆、干燥、冷却,反复1~6次,制得不同RuO2与活性炭质量比的电极,将涂覆好的RuO2/AC复合电极材料在300 ℃下热处理2 h,然后随炉冷却至室温[13]。

1.3 RuO2/AC复合电极的性能测试

1.3.1 形貌观察与比表面积测试

使用FEI-Sirion200扫描电子显微镜观察复合膜的形貌。通过ASAP2020型粒度仪对复合膜进行N2吸附表征,测定膜的N2吸附-脱附等温线,利用BET方法计算复合膜的比表面积。

1.3.2 循环伏安测试

使用CHI660B电化学工作站测试电极材料的电化学性能。三电极系统以铂片电极作为辅助电极,标准氢电极(SHE)作为参比电极,RuO2/AC复合电极作为工作电极,电解液为0.5 mol/ L的H2SO4溶液。经循环伏安特性(CV)测试,并由下式得到电极材料比电容量 。

。

(1)

(1)

式中:i为循环伏安曲线扫描电势范围中点的电流;dv/dt和m分别为电压扫描速率和活性物质的质量。

1.3.3 电化学阻抗谱测试

在上述三电极体系下,施加5 mV的小幅正弦交流信号,信号的频率范围为0.1 Hz至100 kHz,测量复合薄膜电极的阻抗特性。

1.3.4 RuO2/AC膜附着力测试

采用GB5210-82拉开法测试RuO2/AC膜的附着力,将试样黏接在拉力试样夹具上,均匀施加垂直拉力。试样破坏时的负荷为G,试样横截面积为S,则单位面积附着力F=G/S。

2 结果与讨论

2.1 不同涂覆次数对RuO2/AC复合膜形貌的影响

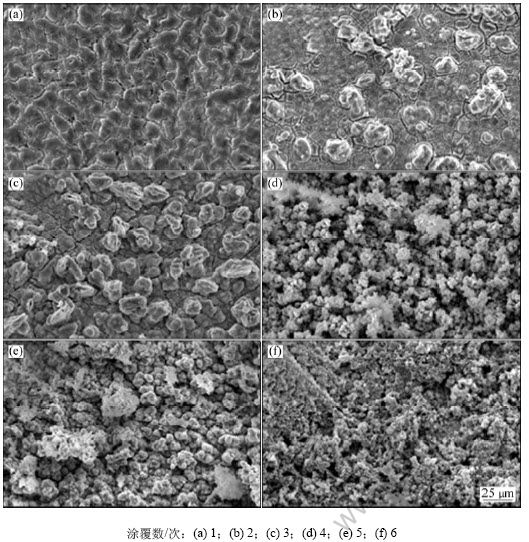

随着涂覆次数的增加,复合电极中RuO2与活性炭质量比也相应增加。每次涂覆后试样的质量增加8.24~10 mg。图1所示为不同涂覆量的RuO2/AC复合膜的SEM照片。

由图1可看出:不同涂覆次数的RuO2/AC复合膜,符合生长型(Volmer-Weber型)膜的形成过程,包括形核、核凝聚成小岛、小岛合并与长大、形成连续的薄膜等阶段[14]。在第1次涂覆热分解时,较薄的液态膜经热处理后紧密覆盖在活性炭电极表面基片上,如图1(a)所示,活性炭颗粒之间的沟壑中也覆盖了涂覆液形成的薄膜;当涂覆热分解到第2次时,新涂覆的液态膜经热处理后在原有涂层上形成凝聚核,如图1(b)所示;随着涂覆热分解量的增加,凝聚核的数量逐渐增加并长大成小岛,如图1(c)所示;当涂覆热分解4次和5次后,随着膜中小岛的生长,相邻小岛彼此结合,如图1(d)与(e)所示。这种结合伴有能量释放,形成具有沟道的颗粒状薄膜,具有较高的比表面积。但是,继续增加涂覆热分解次数后,涂覆液填入颗粒状薄膜的孔洞和沟道,如图1(f)所示。此时,热处理后新生成的小岛也可能填充孔洞和沟道,影响膜的比表面积,使复合膜的整体电容量有所下降。

图1 不同涂覆数时RuO2/AC复合薄膜的SEM图片

Fig.1 SEM photographs of RuO2/AC composite membrane at different coating numbers

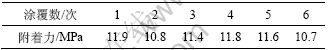

2.2 RuO2/AC复合膜的附着力

不同涂覆次数的复合膜的平均附着力为11.4 MPa(见表1)。拉伸实验的试样破裂面都发生在钽基片与活性炭的接触面上,这说明在RuO2/AC复合膜中,RuO2与活性炭接触面之间为附着力,大于钽基片与活性炭之间的附着力,RuO2/AC复合膜的附着力与涂覆热分解次数并无明显的关联。

表1 不同涂覆数的RuO2/AC复合膜的附着力

Table 1 Adhesion of RuO2/AC composite membrane at different coating numbers

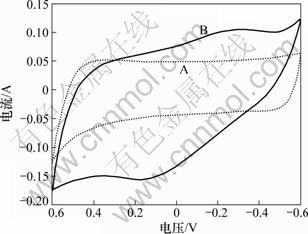

2.3 RuO2/AC复合膜电极的循环伏安特性

图2所示为活性炭电极和涂覆4次的RuO2/AC复合膜电极的循环伏安曲线。从图2可以看出:活性炭电极具有良好的电化学可逆性,在扫描电势范围内无明显的氧化还原峰,电极的电容量几乎完全由双层电容提供。RuO2/AC复合薄膜电极具有显著的电容特性,其比电容与普通活性炭电极的相比明显提高;但其循环伏安曲线已不呈现较规则的四边形,电极反应可逆性有所下降;在0.15 V和-0.3 V附近出现了氧化还原峰,且氧化还原电流较大,这说明复合电极的电容主要基于法拉第氧化还原反应的准电容机制,通过发生在电极表面的二维或准二维法拉第反应存储电荷。经采用ASAP2020粒度仪测定复合薄膜的N2吸附-脱附等温线,并利用BET方法计算出RuO2/AC复合电极材料的比表面积为321.4 m2/g。Raistrick等[15]通过热分解RuCl3制备的RuO2膜涂层的比表面积为130 m2/g,本实验表明多孔活性炭的加入有利于制备大的比表面积的复合电极材料。RuO2/AC复合电极的电容量主要是来自于法拉第氧化还原反应,同时也有少量多孔电极表面双电荷层的贡献[16]。

图2 扫描速度为20 mV/s时活性炭(A)和RuO2/AC复合膜电极(B)的循环伏安曲线

Fig.2 Cycle voltammograms of AC(A) and RuO2/AC composite electrode (B) at scan rate of 20 mV/s

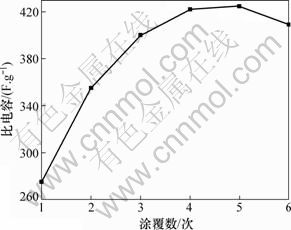

2.4 不同涂覆量对RuO2/AC复合膜电容量的影响

对涂覆热分解1~6次的RuO2/AC复合膜试样作循环伏安测试,所用电解液为0.5 mol/L的H2SO4溶液,扫描速率为20 mV/s,图3所示为RuO2/AC复合膜的比电容性能。

由图3可知,随着涂覆数的增加,RuO2/AC复合膜的比电容也呈增加状态;前4次涂覆热分解后复合膜的比电容增加较快,这一过程是RuO2膜逐步形成到完整覆盖活性炭层的过程;第4次涂覆热分解后,复合膜的比电容达到422 F/g,此时形成具有沟道的颗粒状薄膜,含大量点缺陷,增加了充放电过程中质子进出的自由度,提高了电极材料的电化学活性,有利于与电解液之间的电子和质子的交换,所以,复合薄膜具有较高的比电容。当涂覆热分解超过4次时,复合膜的比电容变化不大,若继续涂覆则仅增加膜的厚度,且增加成本。

图3 复合电极比电容量随涂覆次数的变化曲线

Fig.3 Specific capacitance of composite electrode at different coating numbers

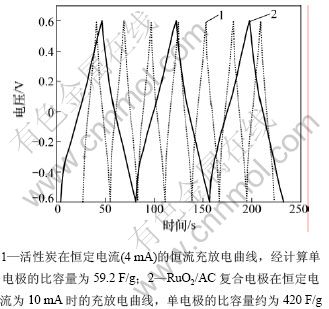

2.5 RuO2/AC复合膜的充放电特性

图4所示为活性炭电极与RuO2/AC复合薄膜电极材料的恒流充放电曲线图。

图4 活性炭(A)和RuO2/AC复合薄膜电极(B)的恒流充放电曲线

Fig.4 Charge-discharge curves of AC(A) and RuO2/AC composite electrode (B)

从图4可以看出:活性炭电极与RuO2/AC复合膜电极呈良好的线形关系,具有典型的电容器的特征。恒电流充放电测试的单电极比电容按下式计算:

(2)

(2)

式中:C为单电极比电容,F/g;I为充放电恒电流,A;ΔV为电位变化,V;Δt为恒电流充(放)电时间,s;m为单电极质量,g。

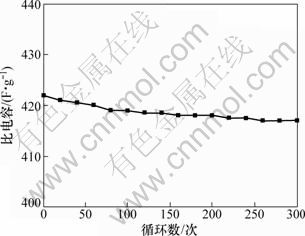

测试结果表明:RuO2/AC复合膜电极材料有良好的充放电效率和较长的循环使用寿命,经过300次充放电循环后,复合电极的比电容量仍保持稳定状态,效率达98.8%,见图5。

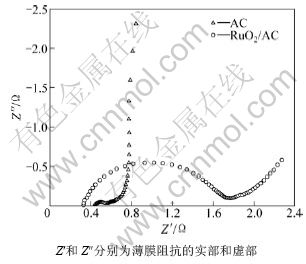

2.6 RuO2/AC复合膜的电化学阻抗特性

图6所示为活性炭和RuO2/AC复合膜的电化学阻抗谱。其中:活性炭电极的阻抗谱由高频区的小圆弧和低频区的一条近似与横轴垂直的直线组成,直线部分明显地体现了双电层电容的特性;RuO2/AC复合电极的阻抗谱由半圆弧部分和1条倾斜的直线组成,高频区的半圆代表了与多孔电极活性物质表面性能有关的电荷传递电阻,低频区与横轴成45°角的直线部分则表明存在Warburg阻抗[17]。曲线与横轴的交点数值代表电极材料的内电阻,主要包括电解液的离子电阻、电极材料的本征阻抗和电极材料与集流体之间的接触电阻。从图6可以得出:RuO2/AC复合电极的内电阻约为0.33 Ω。由于复合膜中的Ru4+和活性炭基体具有较大的比表面积,使得RuO2/AC复合膜产生大量带正电荷的点缺陷,增加了充放电过程中H质子进出自由度和晶体内部的扩散能力,因此,提高了电极电荷传递速度。结合图4可知:RuO2/AC复合膜电极具有良好的功率特性和较低的阻抗,适用作超级电容器的电极材料。

图5 复合电极比电容量随循环数的变化曲线

Fig.5 Cycle-life of composite electrode

图6 活性炭和RuO2/AC复合薄膜的阻抗曲线

Fig.6 Impedance characteristics of AC and RuO2/AC composite electrode

3 结论

(1) 制备RuO2/AC复合电极材料的最佳涂覆热分解次数为4次,最大比电容量为422 F/g,复合膜的比表面积为321.4 m2/g。

(2) RuO2/AC复合膜与钽基片的附着力受控于活性炭与钽基片之间的附着力,涂覆热分解次数对RuO2/AC复合膜的附着力影响不大。RuO2/AC复合膜的平均附着力为11.4 MPa。

(3) RuO2/AC复合电极材料经过300次充放电循环后,比电容量保持98.8%,具有良好的电化学稳定性。RuO2/AC复合电极材料的内电阻为0.33 Ω,是一种理想的超级电容器复合电极材料。

参考文献:

[1] 甘卫平, 师响, 黄波, 等. 超级电容器高比容(RuO2/SnO2)·nH2O复合薄膜的研究[J]. 材料导报, 2009, 23(4): 7-10.

GAN Wei-ping, SHI Xiang, HUANG Bo, et al. Research on high capacitance (RuO2/SnO2)·nH2O composite film as electrode material in super capacitor[J]. Materials Review, 2009, 23(4): 7-10.

[2] Lin C, Ritter J A, Popov B N. Characterization of sol-gel-derives cabalt oxide xerogels as electrochemical capacitors[J]. J Electrochem Soc, 1998, 145(12): 4097-4101.

[3] LIU Kuo-chuan, Marc A. Anderson porous nickeloxide nickel films for electrochemical capacitors[J]. J Electrochem Soc, 1996, 143(1): 124-130.

[4] Ma R Z, Liang J, Wei B Q. Study of electrochemical capacitors utilizing carbon nanotube electrodes[J]. J Power Source, 1999, 84(1): 126-129.

[5] Zheng J P, Cygan T W, Jow T R. Hydrous ruthenium oxide as an elect rode material for electrochemical capacitors[J]. J Electrochem Soc, 1995, 142(8): 2699-2703.

[6] Zheng J P. Ruthenium oxide-carbon composite electrodes for electrochemical capacitors[J]. Electrochemical and Solid-State Letters, 1999, 2(8): 359-361.

[7] Sujit K M, Munichandraiah N. Anodic deposition of porous RuO2 on stainless steel for supercapacitor studies at high current densities[J]. Journal of Power Sources 2008, 175(1): 657-663.

[8] Gujar T P, Shinde V R, Lokhande C D, et al. Spray deposited amorphous RuO2 for an effective use in electrochemical supercapacitor[J]. Electrochemistry Communications, 2007, 9(3): 504-510.

[9] Fachinotti E, Guerrini E, Tavares A C, et al. Electrocatalysis of H2 evolution by thermally prepared ruthenium oxide effect of precursors: nitrate vs. chloride[J]. Journal of Electroanalytical Chemistry, 2007, 600(1): 103-112.

[10] 甘卫平, 覃政辉, 刘泓, 等. 电沉积液初始pH值对电沉积制备钽基RuO2·nH2O薄膜的影响[J]. 材料导报, 2008, 22(5): 143-145.

GAN Wei-ping, QIN Zheng-hui, LIU Hong, et al. Influences of initial pH of electrolyte on electrodeposited RuO2·nH2O films on tantalum substrate[J]. Materials Review, 2008, 22(5):143-145.

[11] 欧定斌, 甘卫平, 何捍卫, 等.电流密度对电沉积制备钽基RuO2·nH2O 薄膜形貌的影响[J]. 材料导报, 2006, 20(3): 144-145.

OU Ding-bing, GAN Wei-ping, HE Han-wei, et al. Effects of current density on adhesion and morphology of tantalum-based RuO2·nH2O film prepared by electrodeposition[J]. Materials Review, 2006, 20(3): 144-145.

[12] David A E. 最小的大容量电容器: Evans 混合电容器[J]. 电子元件与材料,2002, 10(1): 13-16.

David A E. The littlest big capacitor: An evans hybrid[J]. Electronic components & Materials, 2002, 10(1): 13-16.

[13] 甘卫平, 黎晓辉, 欧定斌,等.退火温度对钽基RuO2·nH2O 电沉积薄膜电容性能的影响[J]. 中南大学学报: 自然科学版, 2006, 37(4): 660-664.

GAN Wei-ping, LI Xiao-hui, OU Ding-bing, et al. Effect of annealing temperature on capacitance of ruthenium oxide films deposited on tantalum substrate[J]. J Cent South Univ: Science and Technology, 2006, 37(4): 660-664.

[14] 唐伟忠. 薄膜材料制备原理、技术及应用[M]. 北京: 冶金工业出版社, 2003: 162-163.

TANG Wei-zhong. Preparation of the principle of thin film materials, technology and application[M]. Beijing: Metallurgical Industry Press, 2003: 162-163.

[15] Raistrick I D, Viennet R, Randin J P. Effect of active surface area on the response time of electrochromic and electrolytic displays[J]. J Electrochem Soc, 1982, 129(11): 2451-2453.

[16] 张莉, 宋金岩, 邹积岩. RuO2·xH2O/AC复合电极及混合型超级电容器的性能研究[J]. 无机材料学报, 2005, 20(3): 745-749.

ZHANG Li, SONG Jin-yan, ZOU Ji-yan. Study on properties of Ruthenium oxide/active carbon composite electrode and hybrid super-capacitor[J]. Journal of Inorganic Materials, 2005, 20(3): 745-749.

[17] Zhang S S, Xu K, Jow T R. Electrochemical impedance study on the low temperature of Li-ion batteries[J]. Electrochim Acta, 2004, 49(7): 1057-1061.

(编辑 张曾荣)

收稿日期:2010-05-22;修回日期:2010-07-30

基金项目:国家高技术研究发展计划(“863”计划)项目(2007AA03Z240)

通信作者:甘卫平(1955-),男,湖南桃源人,教授,从事电子及信息功能材料研究;电话:0731-88830248;E-mail:gwp@mail.csu.edu.cn