J. Cent. South Univ. (2017) 24: 1019-1026

DOI: 10.1007/s11771-017-3504-y

Application of nano silica to improve self-healing of asphalt mixes

Ganjei Mohamad Amin, Aflaki Esmail

Department of Civil and Environmental Engineering, Amirkabir University of Technology, Tehran, Iran

Central South University Press and Springer-Verlag Berlin Heidelberg 2017

Central South University Press and Springer-Verlag Berlin Heidelberg 2017

Abstract: Nano silica due to its spherical shape, tiny size and higher density compared to bitumen, may have an inherent potential to improve hot mix asphalt (HMA) self-healing. In this research scanning electron microscopy (SEM) images were used to investigate size, morphology and dispersion of nano silica particles. Additionally, HMA self-healing mechanism was also examined by SEM. Furthermore, dynamic indirect tensile test (IDT) was used to evaluate HMA self-healing index. The SEM results indicated that bitumen mortar flowing into micro cracks may be one of the most important mechanisms of HMA self-healing. The experiment results also showed that modification of bitumen by nano silica promotes the ability of the HMA self-healing.

Key words: nano silica; healing index; Taguchi method; hot mix asphalt

1 Introduction

Fatigue damage caused by repeated traffic loads is one of the most destructive distresses in asphalt pavements [1-6]. Fatigue damage in asphalt mixture manifests itself in the form of micro-cracks. However, the fatigue process is viewed as the result of the competing processes of crack growth and crack healing [5]. During a rest period, given a minimal (nearly zero) applied stress and nearly virgin strain state, a healing process can be driven by locally available heat or other internal energy and residual viscoelastic stresses [2,5]. WOOL [7] described the repair of cracks and microscopic damage in terms of the following stages: (a) surface rearrangement; (b) surface approach; (c) wetting; (d) diffusion and (e) randomization, and he concluded that in healing process, temperature should be higher than glass transition temperature (Tg). BHASIN et al [8] also stated that temperature can affect the self-healing of asphalt mixtures drastically. TANG et al [9] proposed that optimal self-healing property to heal fatigue damage is softening point temperature of asphalt binder. Moreover, self-healing rate of asphalt binder and mixture increases with the extension of the rest periods. It can be understood that both healing time and healing temperature can substantially affect the self-healing of the material.

Nowadays, nano particles due to their unique chemical and physical inherent properties, such as high specific area, structure and reactions, are used in a wide range of applications [3,10-12]. Researchers have modified asphalt binder with nano particles to promote their fatigue resistance, rutting resistance and aging sensitivity to temperature [11,12]. YAO et al [13] studied the properties of asphalt binders and mixtures modified with nano silica particles. Their results obtained from binder tests showed that nano silica enhanced anti-aging property, rutting resistance and fatigue cracking performance of asphalt binders. Moreover, they concluded that addition of nano silica to asphalt mixture significantly improved the dynamic modulus, flow number and rutting resistance. MOJTABA et al [14] studied the effect of nano silica modification of bitumen on moisture susceptibility of asphalt mixture using modified Lottman test. They concluded that tensile strength ratio was improved with increasing nano silica content.

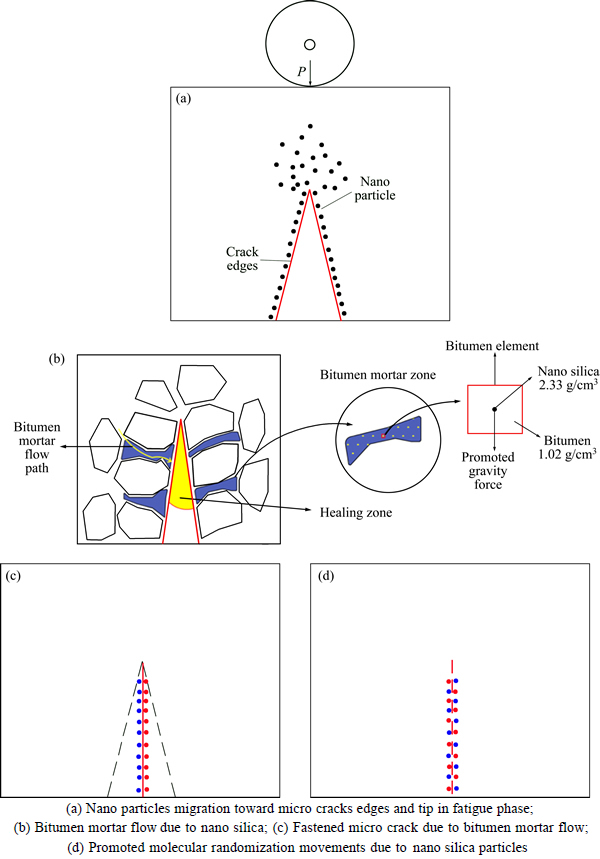

GUPTA et al [15] suggested that nano particles possessed an inherent potential to improve self-healing of polymers, since nano particles can diffuse faster than the larger particles. When modified with nano particles, micro-cracks of polymers may heal faster during rest periods because during the cracking period, the nano particles migrated preferentially to the micro cracks surface and in the rest periods molecular random movements occurred and the micro cracks healed [15]. Due to its spherical shape, higher density (2.33 g/cm3, in comparison to bitumen) and very tiny size, the nano silica possesses an inherent potential to promote the ability of HMA self-healing. It can be hypothesized that adding nano particles to bitumen would enhance surface approach and molecular randomization, and accelerate the diffusion, which may generally lead to faster healing of micro-cracks.

Despite extensive researches on the effect of nano silica modification on the performance of related properties of asphalt binders and mixtures, less attention has been paid to the investigation of the behavior of nano silica particles during micro-crack formation and their healing process. Thus, it is necessary to carry out more experiments to investigate the effect of nano silica on HMA self-healing mechanism and the process by which healing capability of hot mix asphalt may be promoted. The main objective of this study is to investigate the effect of nano silica on HMA self-healing index and its mechanism. In addition, the effects of aggregate type, bitumen content and air voids on healing index (HI) were investigated using Taguchi design of experiment (DOE).

2 Materials and method

2.1 Materials

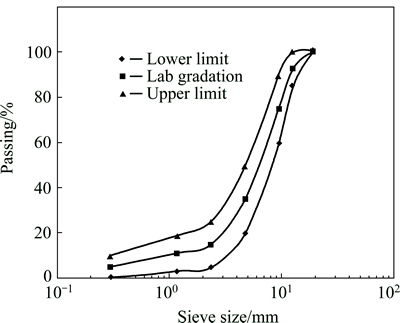

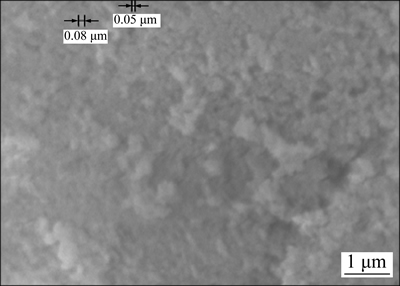

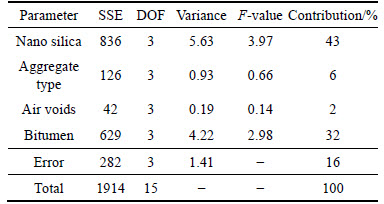

The following materials were used to prepare the modified bitumen and HMA samples: 1) PG 64-22 bitumen with density of 1.02 g/cm3; 2) Natural, crushed limestone and granite gravel were used as coarse and fine aggregate obtained from Joshaghan mine in Isfahan, Iran with a maximum size of 19 mm and specific densities of 2600 and 2610 kg/m3, respectively. The aggregate gradation was densely graded, compatible with the Iranian Highway Asphalt Paving Code 2011 (Fig. 1); 3) Nano silica was used with an average particle size of 60 nm and a particle density of 2.33 g/cm3 and spherical structure morphology (Fig. 2).

Fig. 1 Aggregate gradation

To obtain modified bitumen, the pure bitumen and nano silica were mixed together with adjusted levels using an ultrasonic high shear mixer at 120 °C for 1 h. The HMA specimens were prepared in accordance to the procedure given by the Asphalt Institute (MS-2).

The optimum pure bitumen content was obtained 5.5% of the mass of mixture. The HMA slabs were made by mixing modified bitumen and the aggregates at 150 °C and compacted with a press-box shear compactor. The compactor was adjusted by changing the apparent density in order to obtain air voids between 4% and 13% (based on experimental design levels) and the maximum specific density of 2520 kg/m3.

Fig. 2 SEM image of nano silica particles

The dimensions of the slabs were 45 cm × 15 cm × 17 cm. After cooling to room temperature for three days, with coring and sawing from each slab, 6 IDT samples with diameter of 15 cm and thickness of 4.2 cm were obtained. Brass gauge points were glued to each specimen face. The samples were placed for at least 3 h in the environmental chamber at the test temperature (25 °C) before starting the test to assure temperature uniformity.

2.2 Methodology

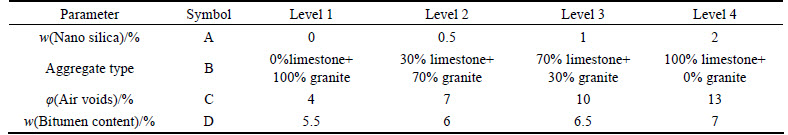

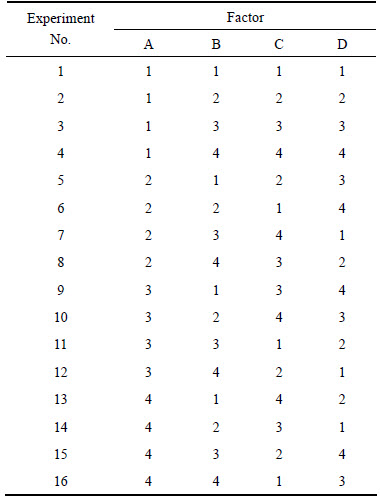

The Taguchi design of experiment (DOE) method was chosen to investigate the effect of each parameter and find the optimum combination which promotes the HMA self-healing using the minimum number of required samples [16]. Tables 1 and 2 show four levels of each dependent variable, the Taguchi method L16 orthogonal array and all different combinations. Each test was repeated four times to ensure the repeatability of the results. Minitab Release 17 was used for statistical

analysis of obtained healing indices.

Table 1 Parameters and levels of Taguchi design

Table 2 L16 orthogonal array based on Taguchi method

Calculation of modified brittleness index (IMB), selection of the applied stress (σ), and the HI computation were conducted according to guideline of ROQUE et al [17]. Indirect tensile (IDT) tests were carried out to obtain strength and strain at failure to measure IMB. IMB for all specimens was less than one, indicating ductile property. Thus, the applied stress in fatigue IDT test (at 25 °C) was chosen as 37% of the failure stress. The relationships are as follows [17,18]:

(1)

(1)

(2)

(2)

(3)

(3)

(4)

(4)

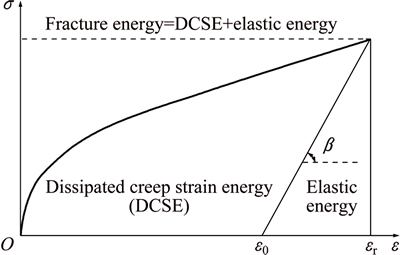

where Papplied is applied force in each fatigue cycle; σfail is stress at fail; εr is resilient strain; β is angle shown in Fig. 3; D is sample diameter; T is sample thickness; L is strain gauge length; A is percentage of strength (37% of failure stress in strength test); is Poisson ratio from the strength test; CSX is correction factor; εfail is strain at fail; △r is the horizontal resilient displacement in each cycle (obtained from strain gauges).

is Poisson ratio from the strength test; CSX is correction factor; εfail is strain at fail; △r is the horizontal resilient displacement in each cycle (obtained from strain gauges).

Figure 3 shows dissipated creep strain energy concept (DCSE) and MR in each cycle. The obtained MR was used in measuring the healing index.

As mentioned in the introduction part, both healing temperature and healing time can affect the healing index. These two factors were evaluated extensively by ROQUE et al [17] and TANG et al [9]. Nevertheless, in this study, these two factors were chosen as constant (temperature = 25 °C and healing time = 1 h) since the effect of nano silica modification was to be solely evaluated.

Fig. 3 Dissipated creep strain energy concept, tan β=MR [17,18]

The healing index (HI) was calculated based on the guideline of ROQUE et al [17] given by Eq. (5).

(5)

(5)

where MR(0) is resilient modulus at the start of damage phase (undamaged); MR(AF) is resilient modulus at the end of damage phase (after fatigue); MR(AH) is resilient modulus at the end of healing phase (after healing).

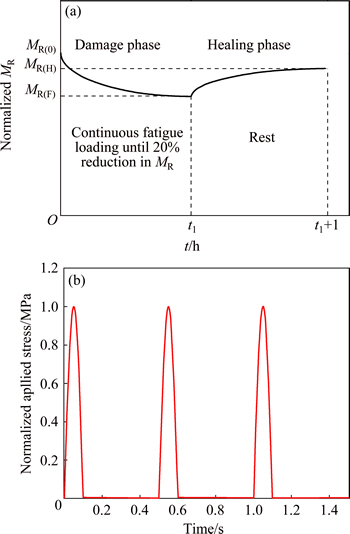

The schematic diagram of MR variation during the fatigue damage and the healing phases is shown in Fig. 4.

2.3 Testing procedure

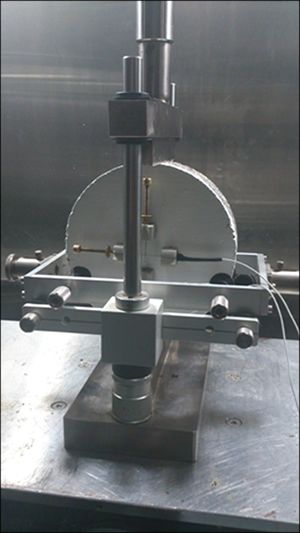

In this study, dynamic indirect tensile test (IDT) was used to evaluate the self-healing of asphalt mixtures. Figure 5 shows set up and devices of IDT samples.

Fatigue and healing phase are induced based on Fig. 4(a) in order to compare the self-healing indices of all specimens. The loading phase was continued until each sample reached to a certain level of damage (80% of undamaged MR). It was found that after reaching approximately 80% of undamaged MR, visible micro cracks could be observed. Beyond this limit it will result in unhealable macro-crack formation. Furthermore, SEM images captured from HMA samples at this damage level showed that cracks size is in nano and micro scale range. Thus, by setting the damage level to 20% decrease in MR, micro cracks were controlled to be roughly the same between samples.

The loading phase consisting of repeated haversine loads with 0.1 s loading and 0.4 s rest period and was continued until achieving 80% of MR-undamaged. It should be mentioned that the maximum repetitive load amplitude was 37% of the load at failure for each specimen.

Fig. 4 Schematic diagram of MR reduction in damage phase and MR recovery in healing phase used in this study (a) and fatigue loading shape (b)

Fig. 5 Set up and device of IDT sample

Data were acquired at a rate of 100 samples per cycle during the loading cycles. Then, the samples were unloaded for the healing phase for 1 h. During the healing phase, in order to measure the resilient modulus recovery, 6 cycles of repeated haversine load were applied with only 5% of the load level with 0.1 s loading and 0.4 s rest. The reduction of the load level to 5% was to limit the damage induction during the healing period. The loads were applied 16 times during the 1 h healing period.

3 Results and discussion

3.1 Healing index results

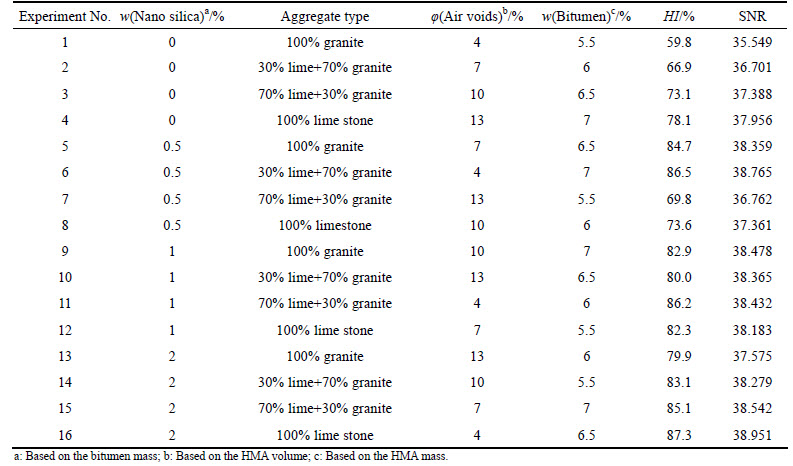

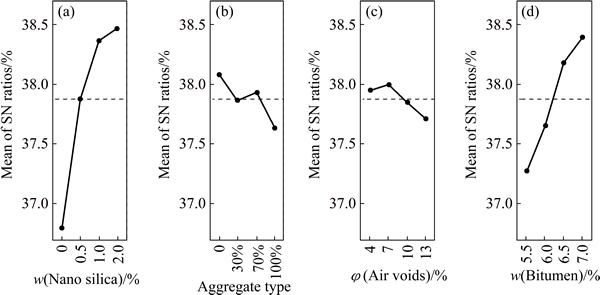

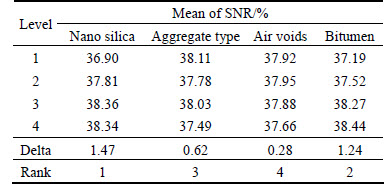

As described before, the specimens were prepared based on the Taguchi design of experiment (DOE) and the healing index was calculated for each sample. The signal to noise ratios, known as SNRs, which were calculated for average of four results are shown in Table 3 with the option of “larger is better”. Therefore, the desired response holds higher SNR. The obtained results are presented in Table 4 and Fig. 6. Moreover, in order to quantify the influence of each parameter on the HI, the analysis of variance (ANOVA) was performed using Qualitek4 software and the results are presented in Table 5. Figure 6 shows the mean effects of SNR for all parameters. In this figure, positive and sharper slope indicates increasing and stronger parameter effect. Table 4 shows ranking of each parameter obtained from delta (difference between the high and low level response of each parameter). In this table the highest delta has the first rank. Table 5 shows the ANOVA of the experiment, in which, each parameter contribution can be observed.

As shown in Fig. 6 and Tables 4 and 5, the effects of increasing nano silica and bitumen content are positive and significant. The most effective parameter on the HI is the content of nano silica, followed by bitumen content, the aggregate type and air voids. The first step of adding nano silica to HMA considerably promotes its healing index, but as can be seen in Fig. 6, the slope of the diagram slows down with increasing the nano silica amount. Moreover, increasing bitumen content leads to a thicker bitumen film surrounding aggregates and makes asphalt mixture more healable. As can be observed in Tables 4 and 5, the aggregate type and air voids in the selected levels are not very effective on HI. The optimum combination (experiment No. 16) based on the mentioned materials and method consisted of 2% nano silica, 4% air voids, 6.5% bitumen content with limestone aggregates.

Table 3 Combination of levels and results

Fig. 6 Mean effects of SNR for HI (four parameters)

Table 4 Ranking of effective parameters

3.2 SEM images investigation

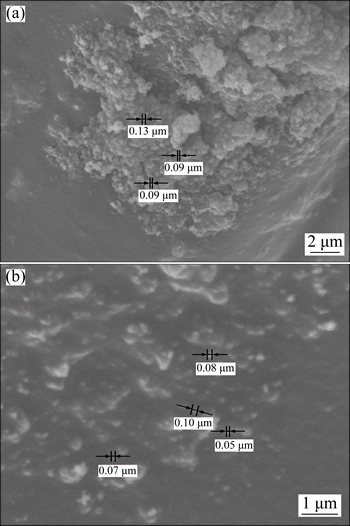

First, nano silica and pure bitumen, were mixed at 120 °C with conventional high shear mixer at 3600 (revolutions per minute) for 1 h to produce the modified bitumen. Then a tiny film of the modified binder was coated with a thin layer of gold and finally SEM images were captured to evaluate the dispersion degree. But these images showed that due to the fact that nano silica particles have a high tendency to be clustered (Fig. 7(a)), the dispersion wasn't successful. In contrast, SEM images captured from modified bitumen showed that mixing bitumen and nano silica with a high shear ultra-sonic mixer (for 1 h at 120 °C) was successful to disperse nano silica in the bitumen. Figure 7(b) shows that nano particles dispersed very well in the modified bitumen and a low amount of clusters existed. Mixing nano particles at ultra-sonic shear rates with asphalt binder may not be applicable in asphalt plant; however, other methods such as surface treatment may be used to avoid agglomeration of the nano particles [19,20].

Table 5 ANOVA for Taguchi DOE results

Fig. 7 SEM images of nano silica clusters left in bitumen by mixing with conventional mixer (a) and nano silica dispersed in modified bitumen by high shear ultra-sonic mixer (b)

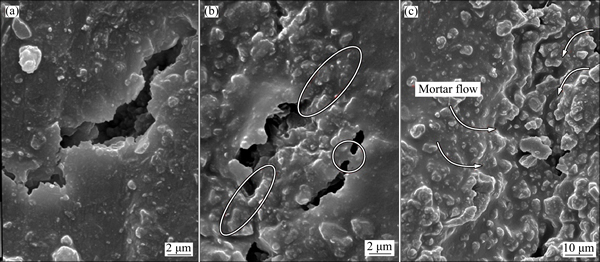

After inducing fatigue micro cracks into HMA specimens in dynamic IDT tests, the damaged specimens were seen from the middle of the sample (IDT damage zone). Then, the surface was cleaned with high pressure air and coated with a thin layer of gold to be prepared for the scanning electron microscopy. Figure 8 shows the prepared HMA sample for microscopy. Then, SEM images of damaged specimens, after 1 h and 1 week of healing were captured.

Fig. 8 Prepared HMA sample for SEM

Figure 9(a) shows SEM image of damaged HMA sample. In this image nano silica particles around micro crack edges have been observed. Figures 9(b) and (c) show under healing and healed HMA samples. In these images, bitumen mortar flow paths were pointed out, indicating that one of the HMA healing mechanisms is the migration of bitumen mortar into the micro cracks.

It can be concluded that each parameter which accelerates bitumen mortar flow, would promote HI of HMA. Nano silica particles due to their higher density

compared to bitumen (2.33 g/cm3 compared to 1.02 g/cm3) and their very tiny size act like spherical metal balls in bitumen mortar matrix and facilitate bitumen mortar flow under the gravity force. The micro cracks are filled with bitumen mortar flow (in the stage of surface rearrangement and surface approach). Then, because of very tiny size of nano silica particles, faster molecular randomization movements occur, which is the reason of micro cracks becoming healed. This process has been described schematically in Fig. 10.

Fig. 9 SEM images of damaged HMA specimen (a), under healing HMA sample due to bitumen mortar flow (b) and healed HMA specimen (c)

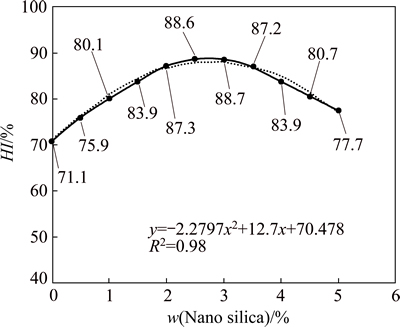

As described before, the addition of nano silica to asphalt binder improves the HI of HMA with sharp slope (Fig. 6), but this slope decreases with increasing nano silica content. To further investigate the nano effect based on the obtained optimum levels in mentioned experiments (Table 3, No. 16), 11 HMA slabs were made with the different amounts of nano silica (0 to 5% by step of 0.5%) and the obtained results are presented in Fig. 11.

Figure 11 shows that at the small nano silica content the HI rises with increasing nano silica. This growth is stopped at 3% of nano silica. This phenomen

might be explained by the fact that at the first step of adding nano silica, diffusion and molecular randomization of bitumen mortar are improved but higher percentage of nano silica could lead to huge bitumen absorption by nano silica particles due to high specific area which thickens the bitumen mortar and restricts its mobility. As a result, the process of crack repair and healing is restricted.

Fig. 10 Schematic picture:

Fig. 11 Variation of HI with nano silica

4 Conclusions

1) Adding 3% nano silica to the bitumen by ultrasonic high shear mixer, 6.5% bitumen, 4% air voids with limestone aggregate resulted in the highest HI.

2) The SEM images captured from the modified bitumen showed that described process of mixing nano silica and bitumen successfully disperses nano silica into bitumen.

3) SEM images captured from damaged, under healing and healed micro-cracks of HMA samples, showed that the bitumen mortar flow is an important mechanism that contributes to self-healing of asphalt mixture.

4) Increasing nano silica content improves HI; however, this improvement is limited up to 3% of nano silica. Beyond this content, with increasing nano silica, the HI decreases. It can be concluded that higher quantity of nano silica absorbs larger amount of binder due to its high specific area and thickens the modified bitumen and restricts its mobility which prohibits the crack healing process.

References

[1] LU X. Investigation of the fracture healing and mechanism of asphalt binders [D]. Pullman: Washington State University, 2013.

[2] BHASIN A, PARTHASARTHY A S, LITTLE D N. Laboratory investigation of a novel method to accelerate healing in asphalt mixtures using thermal treatment [R]. Southwest Region University Transportation Center, Center for Transpotation Reserch, University of Texas at Austin, 2009.

[3] FANG C, YU R, LIU S, LI Y. Nanomaterials applied in asphalt modification: A review [J]. Journal of Materials Science & Technology, 2013, 29(7): 589-594.

[4] KRINGOS N, SCHMETS A, SCARPAS A, PAULI T. Towards an understanding of the self-healing capacity of asphaltic mixtures [J]. Heron, 2011, 56(1,2): 45-74.

[5] LITTLE D N, BHASIN A. Exploring mechanism of healing in asphalt mixtures and quantifying its impact, in self healing materials [M]//van der ZWAAG S. An Alternative Approach to 20 Centuries of Materials Science. Dordrecht: Springer, 2007: 205-218.

[6] QIU J. Self healing of asphalt mixtures: Towards a better understanding of the mechanism [D]. TU Delft: Delft University of Technology, 2012.

[7] WOOL R P. Self-healing materials: A review [J]. Soft Matter, 2008, 4(3): 400-418.

[8] BHASIN A, PALVADI S, LITTLE D. Influence of aging and temperature on intrinsic healing of asphalt binders [J]. Transportation Research Record: Journal of the Transportation Research Board, 2011, 2207: 70-78.

[9] TANG J, LIU Q, WU S, YE Q, SUN Y, SCHLANGEN E. Investigation of the optimal self-healing temperatures and healing time of asphalt binders [J]. Construction and Building Materials, 2016, 113: 1029-1033.

[10] YOU Z, MILLS-BEALE J, FOLEY J M, ROY S, ODEGARD G M, DAI Q, GOH S W. Nanoclay-modified asphalt materials: Preparation and characterization [J]. Construction and Building Materials, 2011, 25(2): 1072-1078.

[11] YANG J, TIGHE S. A review of advances of nanotechnology in asphalt mixtures [J]. Procedia - Social and Behavioral Sciences, 2013, 96: 1269-1276.

[12] PARTL M N, GUBLER R, HUGENER M. Nano-science and -technology for asphalt pavements [M]. The Royal Society of Chemistry, 2004: 343-355.

[13] YAO H, YOU Z, LI L, LEE C, WINGARD D, YAP Y, SHI X, GOH S. Rheological properties and chemical bonding of asphalt modified with nanosilica [J]. Journal of Materials in Civil Engineering, 2012, 25(11): 1619-1630.

[14] MOJTABA G, MORTEZA M S, MAJID T, JALAL K R, REZA T. Modification of stone matrix asphalt with nano-SiO2 [J]. J Basic Appl Sci Res, 2012, 2(2): 1338-1344.

[15] GUPTA S, ZHANG Q, EMRICK T, BALAZS A C, RUSSELL T P. Entropy-driven segregation of nanoparticles to cracks in multi layered composite polymer structures [J]. Nat Mater, 2006, 5(3): 229-233.

[16] TAGUCHI G, CHOWDHURY S, TAGUCHI S. Robust engineering [M]. McGraw-Hill Professional, 2000.

[17] ROQUE R, SIMMS R, CHEN Y, KOH C, LOPP G. Development of a test method that will allow evaluation and quantification of the effects of healing on asphalt mixture [R]. Department of Cicil and Coastal Engineering, University of Florida, 2012.

[18] KIM B, ROQUE R. Evaluation of healing property of asphalt mixtures [J]. Transportation Research Record: Journal of the Transportation Research Board, 2006, 1970: 84-91.

[19] LU S N, XIE N, FENG L C, ZHONG J. Applications of nano structured carbon materials in constructions: The state of the art [J]. J Nano Materials, 2015, 2015: 807416.

[20] ZHANG H, ZHU C, YU J, SHI C, ZHANG D. Influence of surface modification on physical and ultraviolet aging resistance of bitumen containing inorganic nanoparticles [J]. Construction and Building Materials, 2015, 98: 735-740.

(Edited by YANG Hua)

Cite this article as: Ganjei Mohamad Amin, Aflaki Esmail. Application of nano silica to improve self-healing of asphalt mixes [J]. Journal of Central South University, 2017, 24(5): 1019-1026. DOI: 10.1007/s11771-017-3504-y

Received date: 2016-02-26; Accepted date: 2016-05-19

Corresponding author: Aflaki Esmail, Associate Professor; Tel: +98-21-64543005; E-mail: eaflaki@aut.ac.ir