DOI:10.19476/j.ysxb.1004.0609.2019.05.07

铝/钢表面预置粉末激光焊接头的组织与性能

周惦武,姜德福,刘金水,周来沁,潘井春

(湖南大学 汽车车身先进设计制造国家重点实验室,长沙 410082)

摘 要:针对铝/钢焊接的技术难点,采用铝表面预置AlSi12Mg1.5粉、铝/钢层间预置Sn粉的方法,对1.2 mm厚6016铝合金和1.4 mm厚DP590双相钢进行铝上钢下搭接、铝/钢表面同时预置粉末的光纤激光焊接试验,分析接头成形、连接界面显微组织及力学性能;利用ANSYS有限元软件,建立铝/钢激光焊接瞬态有限元模型,计算接头温度场分布;利用基于密度泛函理论的第一性原理方法,计算预置粉末新形成物相FeSn、Fe3Sn及FeAl3、Fe2Al5等化合物的模量和热力学性能。结果表明:在激光头沿焊接方向偏转10°、激光功率2750 W、焊接速度32 mm/s、离焦量 -2 mm、Ar保护气体流量20 L/min条件下,铝/钢表面同时预置粉末可实现6016铝合金与DP590双相钢有效连接,无明显气孔、裂纹等缺陷,接头平均线载荷54.16 N/mm,与铝表面预置AlSi12Mg1.5粉、铝/钢层间未预置Sn粉相比,接头性能提高1.6倍;铝表面预置AlSi12Mg1.5粉,焊接元素光谱相对强度和等离子体的电子密度增大,预置AlSi12Mg1.5粉增加上层铝对激光的吸收率,改善焊缝表面成形;当铝/钢层间预置Sn粉时,铝、钢均达到熔化状态,上层铝液和下层钢液的熔合宽度加大,铝/钢横向结合面积增加,焊合率提高;此外,焊缝区晶粒细小,接头界面Fe-Al化合物的层厚度减少,生成高温下结构稳定的FeSn和Fe3Sn等延性新相,因而同时预置粉末获得了较好的铝/钢接头性能。

关键词:激光焊接;铝/钢;预置粉末;Fe-Al化合物

文章编号:1004-0609(2019)-05-0942-12 中图分类号:TG454 文献标志码:A

采用铝/钢结构件替代单一钢结构件,可获得良好的轻质效果,是实现车辆结构轻量化的有效途径,因而在现代交通运输工具中有广泛应用前景[1-5]。然 而铝/钢存在热物理性能及晶体结构方面的差异,熔化焊条件下铝液和钢液混合,Fe与Al易反应生成脆性Fe-Al化合物,恶化接头力学性能,因此,实现铝/钢优质连接十分困难[6-7]。目前,铝/钢的连接方法主要有粘接、机械连接和焊接[8]。粘接得到连接接头的机械强度有限,只在一些强度要求较低的场合应用;机械连接虽得到强度较高的连接接头,但接头质量大,气密性无法保证;焊接是解决构件同时满足多方面性能要求的有效途径,但常规熔焊方法难以实现铝/钢连接。钎焊焊接周期长、焊接柔性差、接头性能不高。压焊受工件形状和尺寸影响,需要工艺装备配合,焊接效率低,难以满足大批量生产需求。激光具有优良单色性、良好相干性和方向性,作为一种焊接能量,它的能量密度高,可调性好,激光焊成为铝/钢连接的重要方法[9]。从铝/钢激光焊现有研究来看,影响接头性能的因素主要有气孔、飞溅、裂纹、焊接接头的组织特征等,这些因素中,脆性Fe-Al化合物是影响接头性能的关键因素。为改善铝/钢接头性能,主要通过优化焊接工艺参数,减少铝/钢界面Fe-Al化合物的层厚度以及利用添加材料(如中间夹层、粉末),改变铝/钢界面Fe-Al化合物的相组成[10-15]。

针对铝/钢焊接的技术难点,本文选取车身广泛应用的DP590双相钢与6016铝合金作为研究对象,采用铝表面预置AlSi12Mg1.5粉、铝/钢层间预置Sn粉的方法,通过铝上钢下的搭接形式,利用光纤激光器作为焊接热源,实现铝/钢之间的有效连接,分析激光焊接头成形、焊接光谱、等离子体的电子密度、连接界面显微组织及力学性能;利用ANSYS有限元软件,建立铝/钢激光焊接瞬态有限元模型,计算接头温度场分布;利用基于密度泛函理论的第一性原理方法,计算预置粉末新形成物相FeSn、Fe3Sn及FeAl3、Fe2Al5等化合物的模量和热力学性能。本文研究结果期望为丰富和完善异种金属焊接成形理论,并为发展铝/钢结构件激光焊接的推广应用提供新思路和理论依据。

1 实验与计算方法

焊接材料采用6016铝合金、DP590双相钢,6016铝合金的成分(质量分数,%):Si 1.0~1.5,Cu 0.2, Mn 0.2, Mg 0.25~0.6, Fe 0.5, Al余量;双相钢的成分:C 0.15, Si 0.60, Mn 2.50, S 0.015, P 0.04, Fe余量。6016铝合金和DP590双相钢的平板尺寸分别为1.2 mm × 100 mm×30 mm和1.4 mm×100 mm×30 mm。采用砂纸打磨去除铝合金表面氧化层,用丙酮清洗试样去除表面油污。加入丙酮使AlSi12Mg1.5粉以糊状形式均匀涂敷铝合金待焊部位表面,单位面积涂敷量25~27 mg/cm2。加入丙酮使Sn粉以糊状形式均匀涂 敷钢板表面,粉末粒度<0.05 mm,Sn粉含量(质量分数):Pb≤0.03%,Fe≤0.005%,As≤0.0002%,Zn≤0.005%,Sb≤0.01%,Bi≤0.005%,Sn≥99.0%;涂敷钢板表面糊状Sn粉即为铝/钢层间预置的中间层粉末,Sn粉涂敷量30~40 mg/cm2,待其干燥后,与铝合金组合成铝上钢下的搭接接头,激光焊示意如图1所示。

图1 铝/钢激光搭接焊示意图

Fig. 1 Principle map of aluminum /steel laser lap welding

焊接实验采用YLS-4000-CL型光纤激光器作为焊接热源,最大输出功率4000W,激光波长1070 nm,连续输出激光模式TEM00;焦点光斑直径0.4 mm,光束发散角α<0.15 rad,焦距镜长200 mm。为获得较佳接头质量,优化有无预置粉末焊接工艺参数为:激光功率2750 W,焊接速度32 mm/s,离焦量-2 mm,氩气保护气体流量20 L/min,激光头沿焊接方向偏转10°;焊接光谱试验采用HR2000+型光谱仪,将光纤探测头借助固定装置水平固定在一定位置,光纤探测头离观测位置的距离约0.3 m,保证光纤探测头能准确 接收等离子体信号,而光纤探测头和光谱仪通过光纤相连,在取放和使用光纤时不超过其弯曲半径,以防止光纤遭到损坏。焊后线切割取样,经砂纸粗磨细磨,机械抛光,4%硝酸酒精溶液腐蚀制备金相试样;EBSD试样机械抛光后用5%高氯酸酒精溶液室温下电解抛光35~45 s。利用卧式金相显微镜观察铝/钢焊缝显微组织;采用配有能谱仪(EDS)和电子背散射衍射(EBSD)探头FEI Quanta200 扫描电镜观察断口形貌,分析界面主要物相分布及含量和晶粒大小;采用D500X射线衍射仪(XRD)分析焊接接头主要物相;利用Css-225型电子万能试验机测试焊接试样的平均线载荷,测试时,加载速度0.5 mm/min,焊接试样每组取3个,以计算焊件的平均剪切力,其中线载荷为单位长度上承受剪切力的大小。

利用ANSYS 有限元软件,考虑材料温度相关性、初始条件、边界条件等因素,建立铝/钢激光焊接瞬态有限元模型,使用高斯面-体组合热源对激光焊接头温度场进行数值模拟;计算预置粉末新形成物相FeSn、Fe3Sn以及FeAl3、Fe2Al5等化合物的模量时,采用基于密度泛函理论的Castep程序软件包[16],其总能量包括动能、静电能和交换关联能3部分。交换关联能采用广义梯度近似(GGA)中的Perdew-Burke- Ernzerhof形式[17],计算在最小化的快速傅立叶变换(Fast-tourier-transform, FFT)网格上进行,采用对正则条件进行驰豫的超软赝势[18]作为平面波基集。采用自洽迭代(SCF)方法进行计算,采用结合Broyden- Flecher-Goldfarb-Shanno(BFGS)共轭梯度方法的Pulay密度混合方案[19-21]处理电子驰豫;热力学性能计算采用Dmol程序包中的Dynamics模块,选取宏观正则系综(NVT),电子交换能函数采用GGA近似的BLYP形式势函数取全电子位势,电子波函数采用带d轨道的双数值基(DNP)函数。

2 结果与分析

2.1 焊缝成形与元素特征谱线

图2所示为铝/钢激光焊接头焊缝的表面形貌。由图2可知:铝上钢下搭接、未预置粉末时,焊缝成形不连续且焊缝发皱(见图2(a)),这可能是上层铝合金板在激光的作用下,铝对激光的反射率大,难以吸收激光能量,导致焊接过程不稳定;铝表面预置AlSi12Mg1.5粉,焊缝成形性得到改善,但存在少量飞溅现象(见图2(b));而铝表面预置AlSi12Mg1.5粉、同时铝/钢层间预置Sn粉,发现焊缝表面均匀连续,且具有规则的鱼鳞状花纹,无明显飞溅、裂纹等缺陷(见图2(c))。

图2 不同焊接工艺条件下铝/钢焊缝表面形貌

Fig. 2 Weld surface morphologies of aluminum /steel

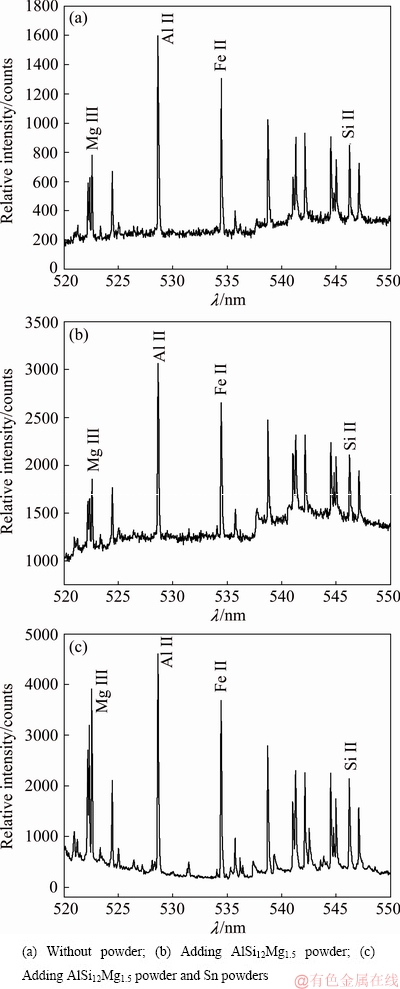

图3所示为铝/钢激光焊接时的元素特征谱线图。发现主要为Al、Fe元素和少量Mg、Si元素,其中光谱相对强度最高为AlⅡ528.61,其他为MgⅢ522.55、FeⅡ534.42和SiⅡ546.2。观察波峰峰值,发现铝表面预置AlSi12Mg1.5粉,相对未预置粉末,焊接元素光谱相对强度明显增大;而对铝/钢层间预置Sn粉时,Mg元素谱线相对强度增加较显著。以元素特征谱线为中心,通过Lorentzian函数对其进行拟合,拟合时选取一定时间间隔的5组试验数据取平均值,铝/钢激光焊接过程中等离子体电子密度的计算结果如表1所列。分析发现:相对未预置粉末,铝表面预置AlSi12Mg1.5粉,由于增加上层铝对激光的吸收率,因而导致激光焊接等离子体增加。

2.2 接头显微组织

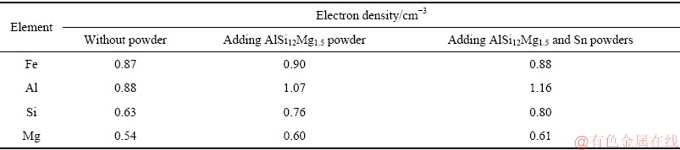

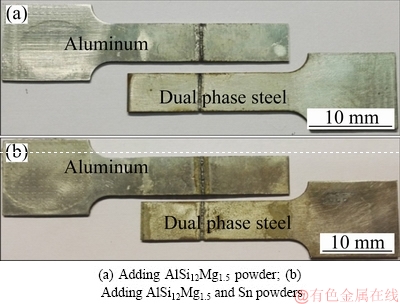

图4所示为铝表面预置AlSi12Mg1.5粉、铝/钢层间有无预置Sn粉激光焊接头的金相组织。发现铝/钢层间未预置Sn粉,焊缝熔深与熔宽分别为2.08 mm和0.76 mm(见图4(a)),熔池左侧与双相钢结合处存在微裂纹(见图4(b));而铝/钢层间同时预置Sn粉,焊缝熔深变化不大,但熔宽增大到0.85 mm(见图4(c)),并且焊缝组织较均匀,无明显气孔和裂纹等缺陷(见图4(d))。

图3 不同焊接工艺条件下铝/钢激光焊接元素特征谱线

Fig. 3 Element feature line of aluminium/steel laser welding

表1 铝/钢激光焊接元素等离子体的电子密度

Table 1 Electron density of plasma for aluminium/steel laser welding

图4 不同焊接工艺条件下铝/钢激光焊接头金相组织

Fig. 4 Microstructures of aluminium/steel laser welding joints

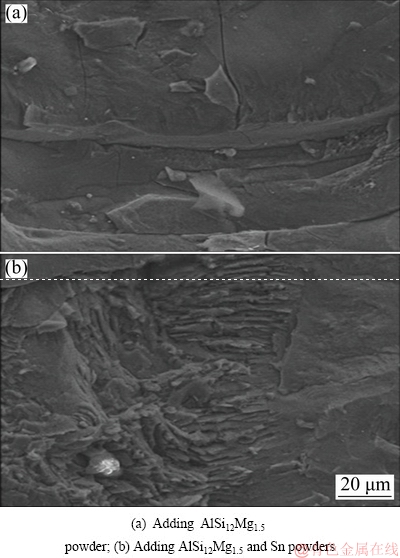

图5所示为铝表面预置AlSi12Mg1.5粉、铝/钢层间未预置Sn粉的接头界面的SEM像。发现界面层底部存在少量微裂纹。对图5(a)所示界面层Q1区、Q2区和Q3区进行放大,观察结果如图5(b)~(d)所示。将界面层Q1区划分为A1、B1、C1、D1、E1 5个区域,Q3区划分为G1、H1 2个区域,以及F1区域,并进行能谱分析,其结果如表2所列。可见A1区域主要为Fe,E1和H1区域主要为Al元素;B1和F1区域的Fe和Al的摩尔比接近2:5,从Fe-Al相图推测来看,B1和F1区域为Fe2Al5化合物;而C1、D1和G1区域的Fe和Al的摩尔比接近1:3,表明生成FeAl3化合物。综合上述可知,铝/钢层间未预置Sn粉,整个铝/钢界面层主要为Fe-Al化合物,其厚度大约50~100 μm。

图6所示为铝表面预置AlSi12Mg1.5粉、铝/钢层间预置Sn粉的接头界面的SEM像。发现界面层金属融合良好、结合紧密。对图6(a)所示界面层Q4区、Q5区和Q6区进行放大,观察结果如图6(b)~(d)所示。与未预置Sn粉相比,界面层厚度明显减小,约10~20 μm,熔池内部弥散分布较多白色颗粒组织(见图6(b))。对Q4区中的A2~D2,Q5区中的E2,Q6区中的F2、G2进行能谱分析,结果见表3。A2区域主要为Fe,C2区域主要为Al;B2和E2区域中的Fe和Al的摩尔比接近2:5,推测生成Fe2Al5化合物;D2和F2区域中的Fe和Al的摩尔比接近1:3,推测生成FeAl3化合物;G2区域中的Fe和Al的摩尔比接近3:1,推测生成Fe3Al化合物。

图5 预置AlSi12Mg1.5粉激光焊接头界面SEM像

Fig. 5 SEM images of laser welding joint adding AlSi12Mg1.5 powder

表2 预置AlSi12Mg1.5粉激光焊接头的界面EDS分析

Table 2 EDS analysis of laser welding joint adding AlSi12Mg1.5 powder

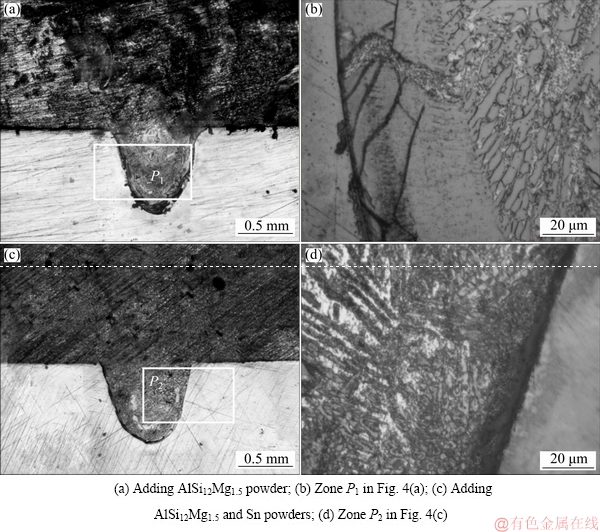

为进一步确定化合物的相结构类型,对焊接试样进行XRD分析,结果如图7所示。发现铝表面预置AlSi12Mg1.5粉、铝/钢层间未预置Sn粉时,焊缝界面生成FeAl3和Fe2Al5等化合物(见图7(a)),而铝/钢层间预置Sn粉,接头界面生成Fe3Al、FeAl3、Fe2Al5、FeSn和Fe3Sn(见图7(b)),与上述铝/钢激光焊接头界面层的能谱分析结果基本一致。

图8所示为铝表面预置AlSi12Mg1.5粉、铝/钢层间有无预置Sn粉条件下铝/钢接头不同区域相的分布及相对含量。发现接头相组成主要是铁素体(F)、马氏体(M)和微量奥氏体(A)。由图8(a)可知,双相钢母材由72.2%(面积分数)铁素体、27.4%马氏体及0.4%奥氏体组成。从图8(b)可知,末预置Sn粉时,双相钢热影响区的马氏体含量(17.6%,摩尔分数)比母材组织的马氏体含量减少9.8%,但铁素体(81.8%)及奥氏体(0.5%)含量均有所上升。从图8(c)可知,预置Sn粉时,双相钢热影响区相分布及相对含量中,铁素体占75.5%,马氏体含量占23.2%,奥氏体占1.3%,与母材各相对应含量相差不大。

图6 预置AlSi12Mg1.5粉和Sn粉激光焊接头界面SEM像

Fig. 6 SEM images of laser welding joint adding AlSi12Mg1.5 and Sn powders

表3 预置AlSi12Mg1.5粉和Sn粉激光焊接头界面EDS分析

Table 3 EDS analysis of laser welding joint adding AlSi12Mg1.5 and Sn powders

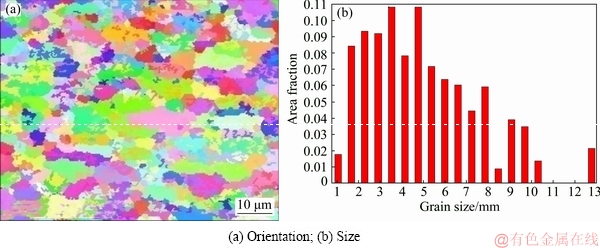

为研究铝/钢层间预置Sn粉对焊缝晶粒尺寸的影响,分析预置粉末前后双相钢热影响区晶粒取向分布和晶粒尺寸分布。双相钢母材晶粒取向分布和尺寸如图9所示。发现组织晶粒尺寸分布相对均匀,平均晶粒尺寸约为4.99 μm,晶粒大小主要分布在1~10 μm范围内。图10所示为铝/钢层间有无预置Sn粉时双相钢热影响区的晶粒分布情况。发现未预置Sn粉时,热影响区平均晶粒尺寸约7.75 μm,晶粒大小主要分布在1~15 μm范围内,最大晶粒尺寸高达21 μm。预置Sn粉时,发现双相钢热影响区的平均晶粒尺寸小于母材,且尺寸大小更集中,其平均晶粒尺寸约3.92 μm,晶粒大小主要集中在2~5 μm范围内。

图7 铝/钢激光焊接头的XRD谱

Fig. 7 XRD patterns of aluminum/steel laser welding joints

图8 铝/钢激光焊接头的相分布及相对含量

Fig. 8 Distribution and relative content of aluminum/steel laser welding joints

2.3 接头力学性能与断口形貌

室温条件下对铝表面预置AlSi12Mg1.5粉、铝/钢层间有无预置Sn粉的铝/钢激光焊接头试样进行剪切性能测试,焊接接头的载荷-位移曲线如图11所示。发现铝/钢层间未预置Sn粉时,接头平均线载荷为33.67 N/mm;而铝/钢层间预置Sn粉时,接头平均线载荷54.16 N/mm。与未预置Sn粉相比,相同焊接工艺参数条件下,铝/钢接头的剪切性能提高1.6倍。

图12所示为剪切试样的断裂位置。发现铝/钢层间有无预置Sn粉时,焊接试样均从焊缝界面处剥离。未预置Sn粉的铝/钢激光焊接头微观断口形貌如图13(a)所示。发现高低各异的台阶区和尖锐的撕裂棱,为典型的解理断裂特征;图13(b)所示为预置Sn粉后的微观断口形貌,发现除撕裂棱外,还含有韧窝,表现为混合断裂特征。

2.4 接头温度场分析

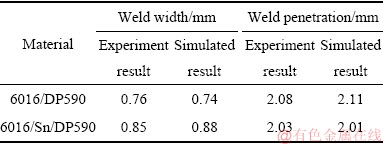

为从热量传递角度分析铝表面预置AlSi12Mg1.5粉、铝/钢层间预置Sn粉获得较好铝/钢接头性能,本部分对铝/钢激光焊接头的温度场模拟结果进行分析。表4所示为铝/钢层间有无预置Sn粉激光焊实际焊缝尺寸与模拟熔池尺寸的对比结果。发现模拟熔池尺寸与实验焊缝尺寸基本接近,可见采用高斯面-体组合热源对激光焊接头温度场进行数值模拟是合理的。

图9 双相钢母材晶粒分布

Fig. 9 Grain distribution of dual phase steel base material

图10 双相钢热影响区晶粒分布

Fig. 10 Grain distribution of dual phase steel thermal influence zone adding AlSi12Mg1.5 powder

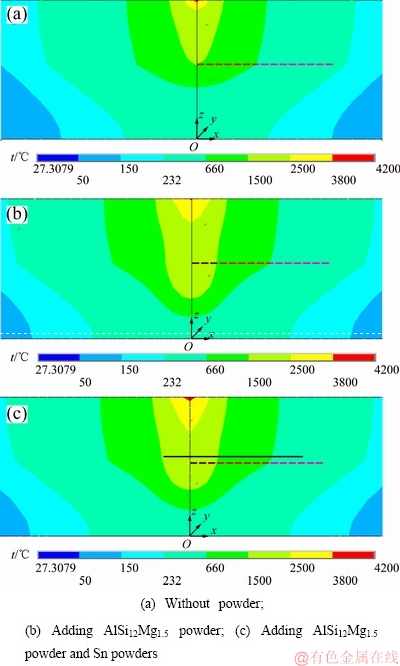

图14所示为不同工艺条件下铝/钢激光焊接头横截面的温度场分布。从图14(a)可以发现,铝/钢表面未预置粉末时,铝上钢下搭接时,上层铝合金熔化,但下层钢板未熔化,熔池上部铝液与下部钢液的混合程度低。在相同焊接参数条件下,铝表面预置AlSi12Mg1.5粉,熔池温度场分布如图14(b)所示。可以发现,铝和钢均达到熔化状态,熔宽和熔深明显增加,钢侧存在较大的温度梯度。可见,铝表面预置AlSi12Mg1.5粉、铝上钢下搭接时,上层铝对激光的吸收率增加,与2.1节中观察铝/钢激光焊接时元素特征谱线分析等离子体增加的结果一致。进一步分析铝表面预置AlSi12Mg1.5粉,铝/钢层间预置Sn粉的接头温度场,发现铝和钢均达到熔化状态(见图14(c)),相对铝/钢层间未预置Sn粉,熔深虽然变化不大,但熔宽明显增加。可见预置Sn粉,改变了接头熔池的温度场分布,增加上层铝液和下层钢液的熔合宽度,为铝/钢激光焊接头的冶金反应创造有利条件。

图11 焊接接头的载荷-位移曲线

Fig. 11 Load-displacement curves of welded joint

图12 铝/钢激光焊接头剪切试样断裂位置

Fig. 12 Shearing specimen fracture position of aluminium/ steel laser welding joints

图13 铝/钢激光焊接头剪切试样微观断口形貌

Fig. 13 Shear specimen microfracture morphologies of aluminium/steel laser welding joints

表4 实验熔池熔合尺寸与模拟结果对比

Table 4 Comparison of size of real weld pool and simulated results

图14 不同工艺条件下铝/钢激光焊接头横截面温度场分布

Fig. 14 Cross section temperature field distribution of aluminium/steel laser welding joints

2.5 力学性质与相结构的稳定性

研究本文中XRD谱与能谱的分析结果发现,在铝表面预置AlSi12Mg1.5粉、铝/钢层间预置Sn粉条件下,铝/钢激光焊试样生成FeAl3、Fe2Al5等Fe-Al化合物以及FeSn、Fe3Sn等新相。铝表面预置AlSi12Mg1.5粉、铝/钢层间预置Sn粉均可获得较好的铝/钢接头性能,为从冶金学角度分析其原因,本部分计算了Fe-Al化合物以及FeSn、Fe3Sn等新相的模量和热力学性能,比较了FeAl3、Fe2Al5、FeSn以及Fe3Sn的延、脆性与高温下的相结构稳定性。FeAl3、Fe2Al5、FeSn以及Fe3Sn弹性常数的计算结果如表5所列。在此基础上,采用如下公式进行计算[22]:

(1)

(1)

(2)

(2)

计算FeAl3、Fe2Al5、FeSn以及Fe3Sn等化合物的体模量B、剪切模量G以及剪切模量与体模量的比值G/B值,结果也列入表5。通常G/B可预测材料的脆性与延性等本征力学性质[23-24],即当G/B<0.5时,材料表现为延性,否则呈脆性。从表5所示结果来看,FeAl3和Fe2Al5的G/B值分别为0.627和0.656,大于0.5,表明FeAl3和Fe2Al5化合物为脆性相;FeSn和Fe3Sn的G/B值分别为0.437和0.329,小于0.5,表明FeSn和Fe3Sn为延性相。

FeAl3、Fe2Al5、FeSn以及Fe3Sn等化合物在不同温度下的焓(H)与Gibbs自由能(G1),分析采用如下公式进行计算:

(3)

(3)

(4)

(4)

式中:T为温度;cp是该温度下的定压比热容;U为0 K、1.01×105 Pa时的形成热:S为对应温度下的熵。

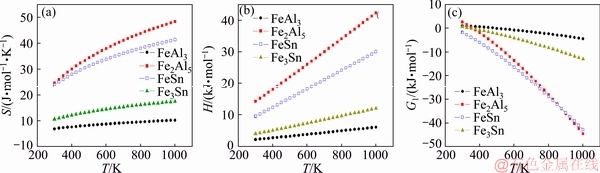

图15所列为FeAl3、Fe2Al5、FeSn以及Fe3Sn等化合物的熵、焓与Gibbs自由能等热力学性能的计算结果。发现随着温度的升高,上述化合物的熵和焓值均呈现上升趋势,而Gibbs自由能下降,表明上述化合物的结构稳定性随温度升高而下降。进一步分析发现,在298~875K温度范围内,FeSn的Gibbs自由能小于Fe2Al5的,Fe3Sn的Gibbs自由能小于FeAl3的,通常Gibbs自由能越低,表明体系相结构稳定性越好,所以该温度范围内FeSn最稳定,其次是Fe2Al5、Fe3Sn和FeAl3。

表5 FeAl3、Fe2Al5、FeSn和Fe3Sn的弹性参数

Table 5 Elastic parameter of FeAl3, Fe2Al5, FeSn and Fe3Sn

图15 FeAl3、Fe2Al5、FeSn和Fe3Sn在不同温度下的热力学性能

Fig. 15 Entropy S (a), enthalpy H (b) and Gibbs free energy G1 (c) of FeAl3,Fe2Al5,FeSn and Fe3Sn phases at different temperatures

3 结论

1) 激光头沿焊接方向偏转10°,激光功率2750 W,焊接速度32 mm/s,离焦量-2 mm,Ar保护气体流量20 L/min工艺条件下,铝/钢表面同时预置粉末可实现6016铝合金与DP590双相钢的有效连接,无明显气孔、裂纹等缺陷,接头平均线载荷54.16 N/mm,与铝表面预置AlSi12Mg1.5粉、铝/钢层间未预置粉末相比,接头性能提高1.6倍。

2) 铝表面预置AlSi12Mg1.5粉,元素光谱相对强度和等离子体的电子密度增大,预置AlSi12Mg1.5粉增加上层铝对激光的吸收率,改善焊缝表面成形;当铝/钢层间预置Sn粉时,铝和钢均达到熔化状态,上层铝液和下层钢液的熔合宽度加大,铝/钢横向结合面积增加,焊合率提高,此外,焊缝区晶粒细小,接头界面Fe-Al化合物的层厚度减少,生成高温下结构稳定的FeSn、Fe3Sn等延性新相,因而同时预置粉末获得了较好的铝/钢接头性能。

REFERENCES

[1] 范子杰, 桂良进, 苏瑞意. 汽车轻量化技术的研究及进展[J]. 汽车安全与节能学报, 2014, 5(1): 1-16.

FAN Zi-jie, GUI Liang-jin, SU Rui-yi. Research and progress of vehicle lightweight technology[J]. Journal of Automotive Safety and Energy Saving, 2014, 5(1): 1-16.

[2] 周惦武, 李宁宁, 徐少华. 双相钢/铝合金激光胶接焊胶层作用分析[J]. 机械工程学报, 2016, 52(14): 25-30.

ZHOU Dian-wu, LI Ning-ning, XU Shao-hua. Analysis of the adhesive layer of laser weld bonding joints in dual phase steel/aluminum alloy[J]. Journal of Mechanical Engineering, 2016, 52(14): 25-30.

[3] 卢源志, 刘金水, 周惦武, 谭 哲, 贾 骁, 胡林西. 双相钢/铝合金激光搭接焊添加Mn粉的作用[J]. 中国有色金属学报, 2016, 26(8):1632-1640.

LU Yuan-zhi, LIU Jin-shui, ZHOU Dian-wu, TAN Zhe, JAI Xiao, HU Lin-xi. Laser lap welding joints in dual phase steel/aluminum alloy with Mn powder addition[J]. The Chinese Journal of Nonferrous Metals, 2016, 26(8): 1632-1640.

[4] 周惦武, 刘元利, 李宁宁, 徐少华, 刘金水. 添加Sn-5%Zr 粉末对激光焊接钢/铝显微组织和性能影响[J]. 中国激光, 2015, 42(5): 0503004-1-0503004-9.

ZHOU Dian-wu, LIU Yuan-li, LI Ning-ning, XU Shao-hua, LIU Jin-shui. Effect of Sn-5%Zr powder addition on microstructure and mechanical property of steel/Al laser welding[J]. Chinese Journal of Lasers, 2015, 42(5): 0503004-1-0503004-9.

[5] 周惦武, 彭 艳, 徐少华, 刘金水. 添加Sn粉激光焊钢/铝异种金属的显微组织与性能[J]. 金属学报, 2013, 49(8): 959-968.

ZHOU Dian-wu, PENG Yan, XU Shao-hua, LIU Jin-shui. Microstructure and mechanical properties of steel/Al alloy laser welding with Sn powder addition[J]. Acta Metall Sin, 2013, 49(8): 959-968.

[6] SIERRA G, PEYRE P, DESCHAUX-BEAUME F. Steel to aluminium key-hole laser welding[J]. Materials Science and Engineering A, 2007, 447(1/2):197-208.

[7] TORKAMANY M J, TAHAMTAN S, SABBAGHZADEH J. Dissimilar welding of carbon steel to 5754 aluminum alloy by Nd:YAG pulsed laser[J]. Materials & Design, 2010, 31(1): 458-465.

[8] LEI H Y, LI Y B, CARLSON B E, LIN Z Q. Cold metal transfer spot joining of AA6061-T6 to galvanized DP590 under different modes[J]. Journal of Manufacturing Science and Engineering, 2015, 137(5): 051028-1-051028-10.

[9] WANG P F, CHEN X Z, PAN Q H, MADIGAN B, LONG J Q. Laser welding dissimilar materials of aluminum to steel: An overview[J]. The International Journal of Advanced Manufacturing Technology, 2016, 87(9): 3081-3090.

[10] FAN J, THOMY C, VOLLERTSEN F. Effect of thermal cycle on the formation of intermetallic compounds in laser welding of aluminum-steel overlap joints[J]. Physics Procedia, 2011, 12:134-141.

[11] SHI Y, ZHANG H, TAKEHIRO W, TANG J. CW/PW duel-beam YAG laser welding of steel/aluminum alloy sheets[J]. Optics and Lasers in Engineering, 2010, 48(1/2): 732-736.

[12] CHEN H, PINKERTON A, LI L, LIU Z, MISTRY A. Gap-free fibre laser welding of Zn-coated steel on Al alloy for light-weight automotive applications[J]. Materials & Design, 2011, 32(1/2): 495-504.

[13] MA J, HAROONI M, CARLSON B, KOVACEVIC R. Dissimilar joining of galvanized high-strength steel to aluminum alloy in a zero-gap lap joint configuration by two-pass laser welding[J]. Materials & Design, 2014, 58(1/2): 390-401.

[14] CHEN S H, HUANG J H, MA K, ZHAO X K, VIVEK A. Microstructures and mechanical properties of laser penetration welding joint with/without Ni-foil in an overlap steel-on-aluminum configuration[J]. Metallurgical and Materials Transactions A, 2014, 45(7): 3064-3073.

[15] ZHOU D W, XU S H, PENG L, LIU J S. Laser lap welding quality of steel/aluminum dissimilar metal joint and its electronic simulations[J]. The International Journal of Advanced Manufacturing Technology, 2016, 86(5): 2231-2242.

[16] SEGALL M D, LINDAN P L D, PROBERT M J, PICKARD C J, HASNIP P J, CLARK S J, PAYNE M C. First- principles simulation: Ideas, illustrations and the CASTEP code[J]. J Phys (Condens Matter), 2002, 14(11): 2717-2743.

[17] MARLO M, MILMAN V. Density-functional study of bulk and surface properties of titanium nitride using different exchange-correlation functionals[J]. Phys Rev B, 2000, 62(4): 2899-2907.

[18] VANDERBILT D. Soft self-consistent pseudopotentitals in a generalized eigenvalue formalism[J]. Phys Rev B, 1990, 41(11): 7892-7895.

[19] HAMMER B, HANSEN L B, NORKOV J K. Improved adsorption energetics with an density-functional theory using revised Perdew-Burke-Ernzerhof functionals[J]. Phys Rev B, 1999, 59(11): 7413-7421.

[20] FRANSCIS G P,PAYNE M C. Finite basis set corrections to total energy pseudopotential calculations[J]. J Phys (Condens Matter), 1990, 19(2): 4395-4404.

[21] MONKHORST H J, PACK J D. Special points for Brillouin-zone integrations[J]. Phys Rev B, 1976, 13(12): 5188-5192.

[22] FU C L, YOO M H. Deformation behavior of B2 type aluminides: FeAl and NiAl[J]. Acta Metallurgica et Materialia, 1992, 40(4): 703-711.

[23] PUGH S F. Relations between the elastic moduli and the plastic properties of polycrystalline pure metals[J]. Philosophical Magazine, 1954, 45: 823-843.

[24] YU W Y, WANG N, XIAO X B, TANG B Y, PENG L M, DING W J. Firstprinciples investigation of the binary AB2 type Laves phase in Mg-Al-Ca alloy: Electronic structure and elastic properties[J]. Solid State Science, 2009, 11(8): 1400-1407.

Microstructure and mechanical properties of laser welding joint with aluminum/steel surface preset filler powder addition

ZHOU Dian-wu,JIANG De-fu, LIU Jin-shui, ZHOU Lai-qin, PAN Jing-chun

(State Key Laboratory of Advanced Design and Manufacturing for Vehicle Body, Hunan University, Changsha 410082, China)

Abstract: In view of the technical difficulties of aluminum/steel welding, the 1.2 mm-thick 6016 aluminum alloy and 1.4 mm-thick DP590 dual phase steel was laser welded by adding AlSi12Mg1.5 powder to aluminum surface and Sn powder to aluminum/steel interlayer layer with lap joint applied with aluminum sheet on the top and steel sheet at the bottom. The weld appearance, microstructure and mechanical properties of welding joint were studied. The temperature field distribution of aluminum/steel joints was calculated by establishing the transient finite element model of aluminum/steel laser welding based on ANSYS finite element software. The modulus and thermodynamic properties of compounds such as FeSn, Fe3Sn, FeAl3 and Fe2Al5, were calculated by using first–principles method based on density functional theory. The results indicate that 6016 aluminum alloy and DP590 double phase steel can be effectively connected with preset filler powder to aluminum/steel surface, no obvious porosity, cracks, and other defects are seen when the welding power is 2750 W, welding speed is 32 mm/s, the defocus distance is -2.0 mm, Ar gas acts as the protection gas with flow rate 20 L/min, and laser deflection is along welding direction 10°. The average linear load of the welding sample with aluminum/steel surface preset filler powder reaches 54.16 N/mm. Compared to that without aluminum/steel interlayer powder addition, the average shear strength of weld joint increases by 1.6 times. The relative intensity of spectra and electron density of plasma increases, which shows that the laser energy absorption rate increases by adding AlSi12Mg1.5 powder to the aluminum surface. Thus, the surface of the weld is improved. When Sn powder is added to aluminum/steel interlayer layer, the aluminum and steel are both melted, the fusion width of the upper aluminum and the lower steel increases, the combined area of aluminum/steel increases, and the welding rate is improved. In addition, grain size of weld zone is fine, Fe-Al compound layer thickness decreases. FeSn and Fe3Sn compounds has better ductility and is more stable than that of Fe-Al compounds at high temperature, which can improve the mechanical properties of weld joint.

Key words: laser welding; aluminum/steel; preset filler powder; Fe-Al compounds

Foundation item: Projects(51674112, 51774125) supported by the National Natural Science Foundation of China; Project(2018YFB1107905) supported by the National Key Research and Development Program of China

Received date: 2018-01-10; Accepted date: 2019-03-20

Corresponding author: ZHOU Dian-wu, Professor, Doctor; Tel: +86-13017297124; E-mail: ZDWe_mail@126.com

(编辑 龙怀中)

基金项目:国家自然科学基金资助项目(51674112, 51774125);国家重点研发计划课题资助项目(2018YFB1107905)

收稿日期:2018-01-10;修订日期:2019-03-20

通信作者:周惦武,教授,博士;Tel: +86-13017297124; E-mail: ZDWe_mail@126.com