快速凝固Cu-Sn合金的组织形态及相结构

翟秋亚, 杨 扬, 徐锦锋, 郭学锋

(西安理工大学 材料科学与工程学院, 西安 710048)

摘 要: 研究快速凝固Cu-20%Sn亚包晶合金的相结构、 晶体生长行为和组织特征, 分析冷却速率与组织形成之间的相关规律。 结果表明: 在急冷快速凝固条件下, 合金的包晶转变和共析转变均受到抑制, 形成了以亚稳的Cu5.6Sn金属间化合物为主相的快速凝固组织; 随着冷却速率的增大, α-Cu相含量减少, Cu5.6Sn相数量显著增多; 晶体生长的方向性增强; Cu5.6Sn 生长方式由小平面向非小平面生长转变, 组织形态由粗大板条状向细密柱状转变。 TEM分析表明: 在Cu5.6Sn晶内存在大量的位错塞积及孪晶; 孪晶之间相互平行, 间距约25~80nm; 随冷却速率的增大, 位错密度增大, 孪晶数量增多。

关键词: Cu-Sn合金; 快速凝固; 晶体生长; 相结构; 位错 中图分类号: TG457.13

文献标识码: A

Microstructural morphology and phase structure of rapidly solidified Cu-Sn alloy

ZHAI Qiu-ya, YANG Yang, XU Jin-feng, GUO Xue-feng

(School of Materials Science and Engineering,Xi’an University of Technology, Xi’an 710048, China)

Abstract: The phase structure, crystal growth behavior and microstructural characteristics of rapidly solidified Cu-20%Sn alloy were investigated and the relationships between the microstructure formation and the cooling rate were analyzed theoretically. The results show that under rapid solidification condition, the peritectic transition and eutectoid transitions of the alloy are all suppressed, which results in the formation of microstructures characterized mainly by metastable Cu5.6Sn metallic compound. With increasing cooling rate, the amount of α-Cu phase decreases, while that of Cu5.6Sn phase increases. Meanwhile, the growth form transforms from faced to non-faced growth and the microstructure exhibits apparent growth orientation. TEM reveals that there exists large quantity of dislocation pile-up and twins in Cu5.6Sn grains. Those twins are parallel to each other with the interspacing about 25~80nm, and extend to the boundary of Cu5.6Sn branches. The increase of cooling rate results in the increase of dislocation density and twin quantity.

Key words: Cu-Sn alloy; rapid solidification; crystal growth; phase structure; dislocation

Cu-Sn包晶合金以低的电阻率、 高的电迁移寿命和连接可靠性等优点, 在大规模集成电路和芯片的互连接领域有着极大的应用潜力[1-8]。 然而, 由于用常规凝固方法所获得的合金材料中, 合金相的固溶度低, 晶界偏析严重, 对合金的强度和耐磨性能造成不利的影响, 从而严重地制约了其在微电子领域的应用[9, 10]。 合金的凝固行为、 相结构及组织形态、 晶体缺陷等对材料物化性能和力学性能有着显著的影响, 对此方面的研究一直是材料科学领域的重要研究课题[11, 12]。 快速凝固可显著地细化组织、 最大限度的扩展合金相的固溶度及形成亚稳相结构, 从而大幅度提高和改善合金的性能。 因此, 有关Cu-Sn合金快速凝固行为的研究具有一定理论意义和工程应用价值。 本文作者采用XRD、 TEM和SEM显微分析技术研究快速凝固Cu-Sn包晶合金的组织形态和相结构特征, 分析冷却速率与合金微结构之间的内在联系, 探讨合金的快速凝固机制及其组织形成规律。

1 实验

1.1 快速凝固合金的显微分析

Cu-20%Sn(质量分数, %)母合金系用高纯Cu(99.99%)和Sn(99.999%)在超高真空电弧炉中熔配而成。 样品质量约为1.2~1.8g, 采用单辊法实现快速凝固。 合金薄带的尺寸为: 厚20~40μm, 宽5mm。 实验过程中辊面线速度控制在13~40m/s范围。

合金薄带经镶嵌和抛光之后, 选用“5g FeCl3+15mL HCl+100mL C2H5OH”溶液进行浸蚀。 使用ARMRAY-1000B型扫描电镜分析合金的组织形态, 用D/MAX-1200 型X射线衍射仪(XRD)分析合金的相结构, 并用JEM2010型透射电子显微镜分析合金的微结构。

1.2 冷却速率的理论计算

为了揭示冷却速率与合金微结构之间的内在联系, 将热传导方程、 Navier-Stokes方程和连续方程相耦合, 对液态合金的温度场和冷却速率( =-dT/dt)进行了理论计算。 动量传输和热量传输主控方程表达如下[13]:

=-dT/dt)进行了理论计算。 动量传输和热量传输主控方程表达如下[13]:

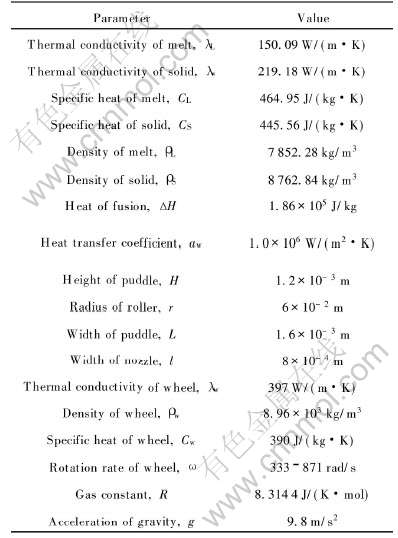

具体计算方法和过程及方程说明详见文献[13]。 合金的物性参数由纯Cu和Sn的物性参数[14]拟合而成。 理论计算用物性参数列入表1。 计算结果表明, 随着辊速的增大, 冷却速率增大。 计算获得的冷却速率在(1.34~2.65)×106 K/S范围。算获得的冷却速率在(1.34~2.65)×106 K/S范围。

表1 理论计算所用物性参数

Table 1 Physical parameters used in calculation

2 结果及讨论

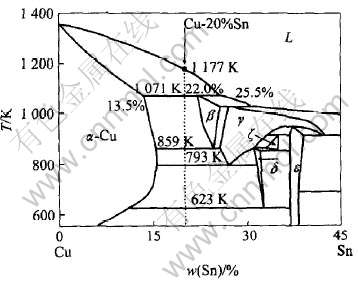

Cu-Sn包晶合金二元平衡相图[15]的左侧部分如图1所示, 实验用合金成分用箭头标于图中。 在平衡凝固条件下, 当合金温度降至1177K时, 首先从液相中析出初生α-Cu枝晶。 当温度降低到包晶转变温度1071K时, α-Cu枝晶与剩余液体发生包晶转变L+α-Cu→β, 生成((Cu5Sn)相。 随着温度的进一步降低, 将依次发生下列共析转变: 859K时的β→α-Cu+γ, 793K时的γ→α-Cu+δ和623K时的δ→α-Cu+ε。 由于原子半径差异较大, Sn在Cu中的扩散速度较慢, 623K下的共析转变往往难以进行, 室温组织通常由α-Cu枝晶和分布其间的δ(Cu31Sn8)两相组成。

图1 合金成分在Cu-Sn相图中的位置

Fig.1 Selection of alloy composition in Cu-Sn phase diagram

在急冷快速凝固条件下, 大的冷却速率使晶体的形核与生长行为发生了较大的变化, 势必形成与平衡条件不同的相结构和组织形态。

2.1 快速凝固过程的相选择

2.1.1 XRD分析

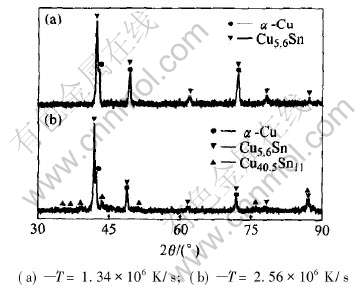

不同冷速下快速凝固Cu-20%Sn合金的XRD谱如图2所示。 由图可见, 面心立方的α-Cu相和亚稳的具有简单四方结构的Cu5.6Sn及面心立方结构的Cu40.5Sn11金属间化合物相的衍射峰均有显示。

图2 快速凝固合金的X射线衍射谱

Fig.2 X-ray diffraction patterns of rapidly solidified alloys at different cooling rates

低冷速( =1.34×106 K/s)条件下, Cu5.6Sn 和α-Cu的衍射强度均较高, Cu40.5Sn11相的衍射强度相对较弱。 随着冷速的增大, Cu5.6Sn和Cu40.5-Sn11的衍射强度进一步增强, 而α-Cu的衍射强度则有所减弱。 这说明在急冷快速凝固条件下, 合金的快速凝固组织主要由α-Cu 、 Cu5.6Sn和少量Cu40.5-Sn11相组成, 而且随着冷速的增大, α-Cu相含量减少, 亚稳的Cu5.6Sn和Cu40.5Sn11相的含量趋于增多。

=1.34×106 K/s)条件下, Cu5.6Sn 和α-Cu的衍射强度均较高, Cu40.5Sn11相的衍射强度相对较弱。 随着冷速的增大, Cu5.6Sn和Cu40.5-Sn11的衍射强度进一步增强, 而α-Cu的衍射强度则有所减弱。 这说明在急冷快速凝固条件下, 合金的快速凝固组织主要由α-Cu 、 Cu5.6Sn和少量Cu40.5-Sn11相组成, 而且随着冷速的增大, α-Cu相含量减少, 亚稳的Cu5.6Sn和Cu40.5Sn11相的含量趋于增多。

一般认为, 冷速的增大会使α-Cu中的过饱和度增大, α-Cu相区扩大, 化合物相含量减小。 然而, 在高冷速条件下, 初生相和包晶相可能发生竞争形核与生长, 两相溶质浓度与平衡浓度均发生较大的偏离, 相区变化具有一定的不确定性, 受到溶质截留效应和溶质扩散速度等因素的制约, 从而造成相含量的显著变化。

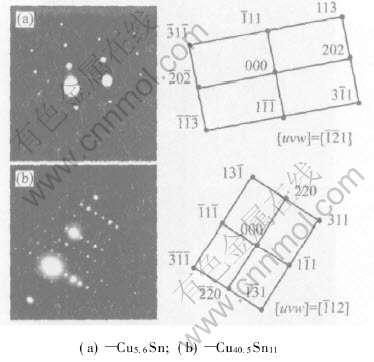

2.1.2 快速凝固合金的TEM分析

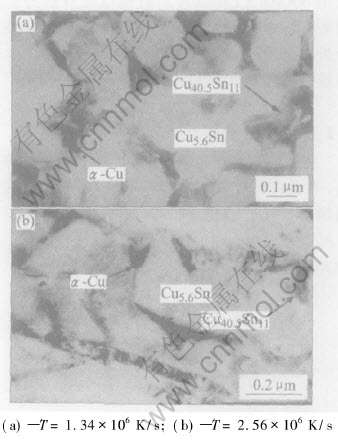

为了进一步确定快速凝固合金的相结构, 对合金薄带做了TEM分析。 低冷速条件下获得的合金薄带的TEM形貌如图3所示。 由图可见, 存在三种物相: 呈块状的亮白色相、 分布于亮白色相之间的深色相、 以及含量极少的带有灰色斑纹的第三相。 亮色选区和灰色斑纹选区的透射斑点分别如图4(a)和图4(b)所示。 经计算和标定可知, 亮白相为Cu5.6Sn, 灰色斑纹区为Cu40.5Sn11相, 而深色区域则为α-Cu相。 可见, 低冷速条件下的合金薄带由α-Cu, Cu5.6Sn和少量Cu40.5Sn11相组成。

图3 快速凝固合金的TEM像

Fig.3 TEM morphologies of rapidly solidified alloys at different cooling rates

高冷速( =2.56×106 K/s)条件下获得的合金薄带的TEM形貌如图3(b)所示。 从中可以看出, 合金由Cu5.6Sn、 少量α-Cu和Cu40.5Sn11相组成。 Cu5.6Sn相呈板条形态, 具有明显的方向性。

=2.56×106 K/s)条件下获得的合金薄带的TEM形貌如图3(b)所示。 从中可以看出, 合金由Cu5.6Sn、 少量α-Cu和Cu40.5Sn11相组成。 Cu5.6Sn相呈板条形态, 具有明显的方向性。

图4 选区TEM衍射斑点及其标定图

Fig.4 Selected area electron patterns and its diffraction labeled graphs

XRD和TEM分析结果表明, 在急冷快速凝固条件下, Cu-20%Sn合金形成了以Cu5.6Sn为主相的快速凝固组织, 而且随着冷速的增大, Cu5.6Sn的含量显著增多, 生长方向性增强。

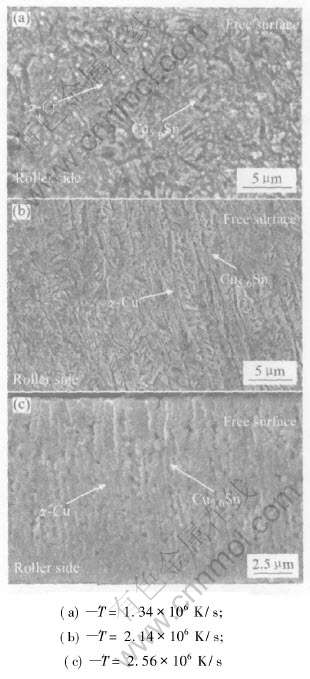

2.2 快速凝固组织特征

快速凝固Cu-20%Sn合金的组织形态如图5所示。 图5(a)所示为低冷速条件下的凝固组织。 图中, α-Cu按枝晶方式生长, Cu5.6Sn相分布其间。 晶体形态以粗大的等轴晶为特征。 近辊面组织细小, 晶区厚度约5~8μm, Cu5.6Sn晶粒直径约30~500nm, 而自由面组织相对较粗大, 晶区厚度约32~35μm, Cu5.6Sn晶粒尺寸约0.5~10μm。 在粗晶区中, 白色的条状Cu5.6Sn相与深色的α-Cu相具有类层片状的结构特征, 层片间距约50~500nm。 两相体积分数之比约φ(Cu5.6Sn)∶φ(α-Cu)=5∶2。

随着冷速的增大, Cu5.6Sn相数量增多, 生长方向性增强, 凝固组织显著细化。 因而形成了大量的板条状Cu5.6Sn类马氏体组织。 板条平直规则, 长度约2~3μm, 长宽比为4∶1~5∶1。 板条之间相互平行, 与生长主轴构成约45°夹角, 如图5(b)所示。

图5(c)所示为高冷速( =2.56×106 K/s)下获得的快速凝固组织。 其主要由主轴垂直于辊面且相互平行的细密的Cu5.6Sn柱状晶组成。 柱状晶的形成主要与冷却速率大, 液池低部温度梯度高有关。 由于冷却速率大, 合金于近辊面区快速形核之后, 固/液界面原子层变厚, 粗糙度增加, Cu5.6Sn相由小平面生长转变为非小平面生长, 在高的温度梯度驱动下, 沿垂直于辊面方向快速定向生长, 形成细密的柱状晶组织。 柱状晶在由辊面向自由面生长进程中, 随着冷却速率的减小, 其间距有所增大, 形态变得粗壮。

=2.56×106 K/s)下获得的快速凝固组织。 其主要由主轴垂直于辊面且相互平行的细密的Cu5.6Sn柱状晶组成。 柱状晶的形成主要与冷却速率大, 液池低部温度梯度高有关。 由于冷却速率大, 合金于近辊面区快速形核之后, 固/液界面原子层变厚, 粗糙度增加, Cu5.6Sn相由小平面生长转变为非小平面生长, 在高的温度梯度驱动下, 沿垂直于辊面方向快速定向生长, 形成细密的柱状晶组织。 柱状晶在由辊面向自由面生长进程中, 随着冷却速率的减小, 其间距有所增大, 形态变得粗壮。

图5 Cu-20%Sn合金快速凝固组织

Fig.5 Rapid solidification microstructures of Cu-20%Sn alloy at different cooling rates

2.3 快速凝固合金相中的位错及孪晶

2.3.1 位错

在低冷速( =1.34×106 K/s)条件下, Cu5.6-Sn晶内存在着稀疏的位错线, 如图6(a)所示。 随着冷速的增大, 晶内和晶界上位错密度增加, 出现了数量较多的位错塞积, 如图6(b)中的剪头所示(对应的冷却速率

=1.34×106 K/s)条件下, Cu5.6-Sn晶内存在着稀疏的位错线, 如图6(a)所示。 随着冷速的增大, 晶内和晶界上位错密度增加, 出现了数量较多的位错塞积, 如图6(b)中的剪头所示(对应的冷却速率 =2.56×106 K/s)。 位错的产生与合金的快速凝固过程密切相关: 一方面, 熔体快淬使合金中的空位浓度显著增加, 大量空位的存在是位错产生的发源地; 另一方面, 合金内部的热应力、 相变应力及辊轮驱动的切应力不仅诱发位错的形成, 而且在促使空位聚集、 崩塌的同时还会引起位错的运动和增殖。 因而, 辊速愈大, 冷速愈大, 位错密度越高。 另外, 凝固过程中溶质截留效应使Sn在α-Cu与Cu5.6Sn相中的固溶度增大, 并由此引起较大的晶格畸变也是位错产生的原因之一。

=2.56×106 K/s)。 位错的产生与合金的快速凝固过程密切相关: 一方面, 熔体快淬使合金中的空位浓度显著增加, 大量空位的存在是位错产生的发源地; 另一方面, 合金内部的热应力、 相变应力及辊轮驱动的切应力不仅诱发位错的形成, 而且在促使空位聚集、 崩塌的同时还会引起位错的运动和增殖。 因而, 辊速愈大, 冷速愈大, 位错密度越高。 另外, 凝固过程中溶质截留效应使Sn在α-Cu与Cu5.6Sn相中的固溶度增大, 并由此引起较大的晶格畸变也是位错产生的原因之一。

图6 Cu5.6Sn晶粒中位错线及位错堆积

Fig.6 Dislocations and dislocation pile-up in Cu5.6Sn grain

2.3.2 孪晶

TEM观察发现, 快速凝固Cu-20%Sn合金中除存在位错塞积之外, 在Cu5.6Sn相中还存在着大量的孪晶。 孪晶之间相互平行, 间距很小, 约25~80nm。 众多的孪晶形成孪晶带。 在孪晶内部还存在着一些相互平行的二次孪晶, 如图7(a)所示。 图7(b)为图7(a)选区所对应的电子衍射图。 从图中可以看出, 至少存在着3套Cu5.6Sn相的衍射斑点, 而且具有明显的镜面对称性。 形成孪晶的主要原因是, 条带在快速凝固及急冷过程中, 各微区收缩应力不均衡; 受辊轮驱动的剪切应力较大; 以及β相在切变型相变过程中的晶界运动等。

2.4 快速凝固组织的形成机制

图7 Cu5.6Sn中的孪晶及其电子衍射图

Fig.7 Twins in Cu5.6Sn compounds (a) and its electron diffraction pattern (b)

Cu-20%Sn合金快速凝固组织的形成与冷却速率密切相关。 在快速凝固条件下, Sn原子扩散困难, 包晶转变α-Cu+L→β进行得十分有限。 当冷速较小时, 剩余液相在与先析α-Cu相接触界面处发生包晶反应的同时, 往往直接析出β相。 最终形成看似被β相包围着的外形不甚规则的板条状金属间化合物β(Cu5Sn)相。 高温β相在急冷过程中, 发生类马氏体相变, 形成亚稳的β′(Cu5.6Sn)相, 承袭了原β相的形貌特征。

随着冷速的增大, 包晶转变进一步受到抑制, 在过冷熔体中发生α与β相的竞争形核与快速生长。 相比较而言, β相的溶质浓度与合金的原始成分更为接近, 较小的溶质扩散即可满足β相形成的成分条件, 有利于β相的快速形核和生长。 反映在合金的组织上, β相含量明显增多, α相含量大幅度降低。 而且, 随冷速的增大, β相生长方式由小平面生长向非小平面生长过渡(按小平面生长, 形成板条状组织; 以非小平面方式生长, 则形成细密的柱状晶组织)。 在随后的急冷过程中, 发生β→β′切变型相变, 形成Cu5.6Sn相。 少量Cu40.5Sn11的形成是切变型相变过程中β相与α-Cu相在两相界面处发生了局部原子互扩散的产物。 这即为图3中少量灰色斑纹状的Cu40.5Sn11分布于α-Cu相附近的原因所在。 较低温度下通常发生的各种共析反应受到抑制, 因而形成以Cu5.6-Sn为主相的快速凝固组织。

3 结论

1) 在快速凝固条件下, Cu-20%Sn合金的包晶转变L+α-Cu→β在很大程度上受到抑制, β相可从过冷液体中独立形核析出。 较低温度下的共析转变则被完全抑制, 形成以亚稳的Cu5.6Sn为主相的快速凝固组织。

2) 随着冷速的增大, α-Cu相含量减少, Cu5.6-Sn相大幅度增多; Cu5.6Sn相从小平面生长向非小平面生长转变, 其组织形态由粗大板条状向细密的柱状过渡。

3) TEM分析表明, 在Cu5.6Sn晶内存在大量的位错塞积和孪晶。 孪晶之间相互平行, 间距约25~80nm。 冷却速率的增大使位错密度增大, 孪晶数量增多。

致谢

作者感谢西北工业大学应用物理系魏炳波教授和空间材料科学与技术实验室提供的实验支持。

REFERENCES

[1]Huang J S, Zhang J, Cuevas A, et al. Recrystallization and grain growth in bulk Cu and Cu(Sn) alloy[J]. Mater Chem Phys, 1997, 49: 33-41.

[2]Lee K L, Hu C K. In situ scanning electron microscope comparison studies on electromigration of Cu and Cu(Sn) alloys for advanced chip interconnects[J]. J Appl Phys, 1995, 7(78): 4428-4437.

[3]Liu C Y, Chen C, Tu K N. Electromigration in Sn-Pb solder strips as a function of alloy composition[J]. J Appl Phys, 2000, 10(88): 5703-5709.

[4]Tu K N, Lee T Y, Jang J W. Wetting reaction versus solid state aging of eutectic SnPb on Cu[J]. J Appl Phys, 2001, 9(89): 4843-4849.

[5]Hu C K, Luther B, Kaufman F B, et al. Copper interconnection integration and reliability[J]. Thin Solid Films, 1995, 262(1-2): 84-92.

[6]Kim H K, Tu K N. Rate of consumption of Cu in soldering accompanied by ripening[J]. Appl Phys Lett, 1995, 14(67): 2002-2004.

[7]Kim H K, Liou H K, Tu K N. Three-dimensional morphology of a very rough interface formed in the soldering reaction between eutectic SnPb and Cu[J]. Appl Phys Lett, 1995, 18(66): 2337-2339.

[8]Clevenger L A, Arcot B, Ziegler W, et al. Interdiffusion and phase formation in Cu (Sn) alloy films[J]. J Appl Phys, 1998, 1(83): 90-99.

[9]Al-Ganainy G S, Fawzy A, Ei-Salam F A. Transient and steady-state creep characteristics of Cu-2%Sn alloy in the solid solution region[J]. Physica B, 2004, 344: 443-450.

[10]Liu X Y, Kane W, McMahon C J Jr. On the suppression of dynamic embrittlement in Cu-8%Sn by an addition of zirconium[J]. Scripta Materialia, 2004, 50: 673-677.

[11]XU Jin-feng, WANG Nan, WEI Bing-bo. Microstructural characteristics and electrical resistivity of rapidly solidified Co-Sn alloys[J]. Chinese Science Bulletin, 2004, 49(21): 2242-2246.

[12]徐锦锋, 翟秋亚, 袁森. AZ91D镁合金的快速凝固特征[J]. 中国有色金属学报, 2004, 6(14): 939-944.

XU Jin-feng, ZHAI Qiu-ya, YUAN Sen. Rapid solidification characteristics of melt-spun AZ91D magnesium alloy[J]. The Chinese Journal of Nonferrous Metals, 2004, 6(14): 939-944.

[13]徐锦锋, 魏炳波. 急冷快速凝固过程中液相流动与组织形成的相关规律[J]. 物理学报, 2004, 53(6): 160-166.

XU Jin-feng, WEI Bin-bo. Liquid phase flow and microstructure formation during rapid solidification[J]. Acta Physica Sinica, 2004, 53(6): 160-166.

[14]Brandes E A. Smithells Metals Reference Book[M]. 6th ed. London: Butterworth & Co (Publishers) Ltd, 1983. 14-6-9.

[15]Massalski T B, Murray J L, Bennett L H, et al. Binary Alloy Phase Diagrams[M]. ASM International, 1986, 2: 1481-1482.

(编辑何学锋)

基金项目: 陕西省教育厅科学研究项目(06JK220)

收稿日期: 2005-11-02; 修订日期: 2006-02-21

通讯作者: 翟秋亚, 副教授; 电话: 029-82310856; 传真: 029-82310856; E-mail: qiuyazhai@xaut.edu.cn