文章编号:1004-0609(2011)02-0430-06

烧结助剂对高气孔率SiC陶瓷结构和性能的影响

王少锋1, 2,汪长安2,孙加林1,周立忠2, 刘伟渊2,黄 勇2

(1. 北京科技大学 材料学院,北京 100083;

2. 清华大学 材料科学与工程系 新型陶瓷与精细工艺国家重点实验室,北京 100084)

摘 要:由叔丁醇、丙烯酰胺和SiC粉及烧结助剂组成固相含量为10%(体积分数)的陶瓷浆料,采用凝胶注模成型和无压烧结工艺制备多孔SiC陶瓷,研究Al2O3和Al2O3+SiO2这两种烧结助剂体系对多孔SiC陶瓷的气孔率、显微结构和力学性能的影响。结果表明:Al2O3+SiO2复合烧结助剂明显改善SiC陶瓷的烧结性能,与采用单一的Al2O3烧结助剂相比,SiC样品的烧结温度和莫来石的生成温度均降低50 ℃左右;两种不同的烧结助剂制成的试样中的气孔均呈很窄的单峰分布,中位孔径为2 μm左右;随烧结温度的升高压缩强度增大,而气孔率变化不大;以Al2O3+SiO2为烧结助剂、在1 400 ℃烧结的试样的气孔率和强度分别达到70.57%和17. 74 MPa。

关键词:多孔陶瓷;SiC;烧结助剂;烧结性能;凝胶注模;叔丁醇

中图分类号:TQ174 文献标志码:A

Effects of sintering additives on microstructure and properties of porous SiC ceramics with high porosity

WANG Shao-feng1, 2, WANG Chang-an2, SUN Jia-lin1, ZHOU Li-zhong2, LIU Wei-yuan2, HUANG Yong2

( 1. School of Materials Science and Engineering, University of Science and Technology Beijing, Beijing 100083, China;

2. State Key Laboratory of New Ceramics and Fine Processing, Department of Materials Science and Engineering,

Tsinghua University, Beijing 100084, China)

Abstract: The porous SiC ceramics were fabricated by gel-casting and pressureless sintering process in air atmosphere with a solid loading of 10% slurry constituting of tert-butyl alcohol, acrylamide, SiC powder and sintering additives. The effects of two kinds of sintering additives, Al2O3 and Al2O3+SiO2, on the porosity, microstructure and mechanical properties of the porous SiC ceramics were studied. The results show that the sintering additive of Al2O3+SiO2 obviously improves the sinterability of SiC ceramics, and compared with that only using Al2O3 as sintering additive, both sintering temperature of SiC specimen and formation temperature of mullite phase are decreased by about 50 ℃. The median pore diameter of the porous SiC ceramics is about 2 μm and presents single peak distribution. The compressive strength of the porous SiC ceramics increases with increasing the sintering temperature, whereas the porosity has little change. Using Al2O3+SiO2 as sintering additive, the porosity and compressive strength of SiC porous ceramics sintered at 1 400 ℃ reach 70.57% and 17.74 MPa, respectively.

Key words: porous ceramics; SiC; sintering additive; sintering properties; gel-casting; tert-butyl alcohol

多孔SiC陶瓷具有低热膨胀系数、高热传导率、良好的力学性能和化学稳定性,广泛应用于熔融金属过滤器、高温气体过滤器、催化剂载体、热绝缘体等领域[1-3]。

SiC具有强的共价键[4],其烧结机制为蒸发-凝聚,没有液相产生,烧结温度高达2 200 ℃[5]。为了降低烧结温度及在常压无保护气氛下对SiC进行烧结,通常采用加入Al2O3、MgO、Y2O3、稀土氧化物及堇青石等作为烧结助剂[6-8],目的是反应生成高温性能良好的莫来石和玻璃相等,对SiC颗粒进行更好的烧结。制备多孔SiC陶瓷的方法很多,如有机泡沫浸渍法[9-10]、加入造孔剂法[11-12]及直接发泡法等,这些方法制备的多孔SiC陶瓷的气孔尺寸较大,孔径分布不均匀,造成材料强度低,影响其实际应用。近年来,凝胶注模成型工艺也被用来制备多孔陶瓷,这种方法制备的多孔陶瓷具有气孔率高、孔径分布均匀以及强度高等优 点[13-14],可以较好地解决以上问题。

本文作者采用凝胶注模成型工艺和氧化粘结法制备多孔SiC陶瓷,研究在不同的烧结温度下多孔SiC陶瓷的制备、总气孔率、开口气孔率、孔径尺寸及分布、压缩强度等规律。

1 实验

1.1 原材料

本实验中所使用的原料如下:SiC粉(潍坊精细粉公司生产),平均粒径D50=3.23 μm,纯度不低于99.95%;α-Al2O3(CT-3000,青岛美铝公司)生产,平均粒径D50=0.80 μm,纯度不低于99.89%;非晶SiO2粉(洛阳耐火材料研究院生产),平均粒径D50=0.40 μm,纯度95.66%。使用的试剂包括丙烯酰胺单体(AM);N,N′-亚甲基双丙烯酰胺(MBAM)交联剂;叔丁醇(tert-butyl alcohol,TBA),以上3种试剂均为分析纯,北京化学试剂公司生产。

1.2 坯体的制备

在该成型工艺中,以叔丁醇为溶剂、丙烯酰胺为单体。与传统的水基凝胶注模成型相比,由于叔丁醇具有较高的冰点、较高的饱和蒸汽压及较小的表面张力,可以制备高气孔率、特别是高开口气孔率、高强度的多孔陶瓷[15]。以α-Al2O3粉和非晶α-SiO2粉作为助烧剂,利用SiC颗粒表面氧化形成的SiO2与α-Al2O3原位合成的莫来石进行粘结。实验采用两种配方:一种是只加α-Al2O3粉做助烧剂;另一种是同时添加α-Al2O3和非晶SiO2微粉作为烧结助剂,具体配料组成见表1。

将TBA、AM和MBAM按一定的质量比配制成预混夜,将SiC粉、α-Al2O3粉和非晶的SiO2粉按表1中的配比与以上预混夜配成浆料,固相含量控制为10%,放入以玛瑙球为球磨介质的球磨罐中,球磨4 h。然后依次在分散良好的SiC陶瓷浆料中加入适量的催化剂N,N,N′,N′-四甲基乙二胺(TEMED)溶液和引发剂过硫酸铵(APS)溶液,边加入边搅拌,混合均匀后立即倒入模具中,放入80 ℃烘箱中干燥。随着叔丁醇的挥发,丙烯酰胺在引发剂、交联剂和催化剂的作用下迅速聚合成三维网络的聚丙烯酰胺,粉体颗粒被均匀地结合在有机网络中,因而脱模的坯体具有很高的强度。

表1 试样A和B的配料组成

Table 1 Compositions of samples A and B

1.3 性能表征

将烧结后的SiC陶瓷加工成d 20 mm×20 mm的标准试样。采用阿基米德排水法测定样品密度和开气孔率。通过测定SiC在不同烧成温度下的氧化程度计算材料的相对密度,并得到材料的总气孔率。用WDW3020万能试验机上测定材料的压缩强度。以上性能的每组试样测试3~4个样品为一组。用AutoPore VI 9500型全自动压汞仪测定样品孔径的大小及分布。采用岛津Shinadzu SSX-550型SEM扫描电镜观察样品的微观结构。物相采用岛津公司XRD-7000,maxima-x进行分析。

2 结果与分析

2.1 多孔SiC陶瓷的烧成

SiC坯体的TG-DSC曲线如图1所示。由图1可知,在360 ℃和600 ℃处有2个明显的放热峰。360 ℃的放热峰对应结合力较弱的交联点及主链末梢部分的分解。600 ℃放热峰为聚丙烯酰胺主链的分解。根据这个热分析结果,将坯体的烧成划分为两个阶段:低于800 ℃为低温阶段,高于800 ℃为高温阶段。在低温阶段升温速率为1 ℃/min,在360 ℃和600 ℃各保温2h,主要是去除有机物。在高温阶段升温速率为5 ℃/min,烧成温度分别为1 300、1 350、1 400、1 450和1 500 ℃,保温1 h。烧成是在无压无保护气氛的箱式炉中进行。

图1 SiC坯体的TG-DSC曲线

Fig.1 TG-DSC curves of SiC green body

2.2 多孔SiC陶瓷的氧化程度和物相组成

从图1所示的DSC-TG曲线可以看出,SiC在750 ℃左右与空气中的氧发生氧化反应,生成SiO2及 CO和CO2,1 mol SiC氧化为SiO2,试样质量增加20 g。通过称量不同烧结温度下试样(排胶以后的试样)氧化前后的质量,可以算出SiC的氧化程度,如图2所示。由图2可看出,随着烧结温度的增加,SiC的氧化程度是加速的,试样A的氧化程度略高于试样B的,这可能是由于试样A中单位体积SiC颗粒接触空气表面积大的缘故。试样A在1 500 ℃下SiC的氧化程度为21.08%。

图2 试样A和B的氧化程度

Fig.2 Oxidation degree of samples A and B after being sintered at different temperatures

试样A和B的相组成如图3所示。由图3可看出,随着烧结温度的增加,试样A和B中SiC相和刚玉相逐渐减少,方石英相逐渐增多。试样A在1 500 ℃、试样B在1 400 ℃均可见莫来石的衍射峰。SiC先氧化为无定形的SiO2,大约在1 100 ℃转变为方石英。方石英与α-Al2O3反应生成莫来石与温度有直接的关系,理论上在1 300 ℃可以生成莫来石,但这时生成的莫来石晶粒非常细小,XRD谱中显示不出来。试样B在1 400 ℃可见莫来石的衍射峰,说明生成较多的莫来石,在1 450 ℃,莫来石的衍射峰非常明显。主要原因是加入纯度为95.66%的非晶SiO2带来了较多的杂质,在高温下,这些杂质呈现为液态的玻璃相,有利于Al3+和Si4+的相互扩散,促进莫来石的生长,符合莫来石生长的溶解-沉析机制[16]。所以,从XRD谱上可以看出试样B生成莫来石的温度比试样A的低近100 ℃。另外,非晶SiO2表面缺陷多,表面积大,反应活性高,能够降低生成莫来石的活化能。

图3 试样A和B在不同的烧结温度的XRD谱

Fig.3 XRD patterns of samples A and B after being sintered at different temperatures

2.3 多孔SiC陶瓷孔径尺寸分布和气孔率

2.3.1 孔径尺寸分布

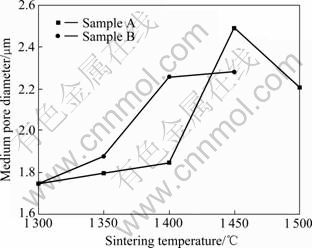

图4和5所示分别为不同烧结温度下试样A和B的气孔尺寸分布曲线以及中间孔径。从图4和5可看出:试样A和B的中间孔径基本上是随着烧结温度的升高而增大;在1 300 ℃,试样A的中间孔径为1.75 μm,到1 450 ℃其中间孔径增大到2.49 μm,到1 500 ℃稍有降低,中间孔径为2.21 μm;在1 300 ℃时,试样B的中间孔径为1.75 μm,到1 450 ℃时中间孔径增大到2.28 μm;两种试样孔径都呈单峰分布,且分布在一个较窄的范围。这说明试样随着烧结温度的增加,由于SiC颗粒的氧化,氧化的SiO2及莫来石化产生较大的体积膨胀,弥补颗粒烧结而产生的收缩,试样中小的气孔随着烧结温度的增加逐渐合并成大的气孔,总的趋势表现为颗粒间中间孔径是增大的。

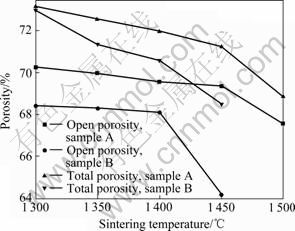

2.3.2 总气孔率和开口气孔率

图6和表2所示分别为不同烧结温度下试样A和B的气孔率以及陶瓷性能。由图6可知,对于试样A,随着烧结温度的增加,从1 300 ℃升高到1 450 ℃时,开口气孔率和总气孔率变化不大,从1 450 ℃升高到 1 500 ℃时,气孔率明显降低,总口气孔率从71.21%降低到68.90%。对于试样B,当烧结温度从1 300 ℃升高到1 400 ℃时,开口气孔率变化不大,总气孔率略有降低,从1 400 ℃升高到1 450 ℃时,开口气孔率和总气孔率明显降低,开口气孔率从68.10%降低到64.20%,体密度略微增加。

图4 不同烧结温度下试样A和B的气孔尺寸分布曲线

Fig.4 Pore size distribution of samples A and B after being sintered at different temperatures

图5 不同的烧结温度下试样A和B的中间孔径

Fig.5 Medium pore diameter of samples A and B after being sintered at different temperature

图6 不同烧结温度下试样A和B的气孔率

Fig.6 Porosity of samples A and B after being sintered at different temperatures

表2 不同烧结温度下试样A和B陶瓷的性能

Table 2 Properties of samples A and B after being sintered at different temperatures

试样A和B总的气孔率变化不大的主要原因如下:SiC的氧化及氧化生成的熔融石英方石英化产生大的体积膨胀,理论计算体积膨胀约为108.2%,另外,SiC氧化的SiO2与Al2O3生成莫来石,也会产生较大的体积膨胀,这些体积膨胀弥补了坯体随着烧结温度的提高颗粒烧结而带来的体积收缩。与试样A相比,试样B的开口气孔率较低,主要原因是因为引入了纯度为96.66%的非晶SiO2,带入3.33%的杂质,高温时生成了较多的玻璃相,堵塞了部分气孔。

2.4 对多孔SiC陶瓷性能的影响

从表2可看出,随着烧结温度从1 300 ℃升高到 1 450 ℃,试样A的开口气孔率和总气孔率变化不大,压缩强度增加从3.45 MPa增加到12.14 MPa;烧结温度大于1 450 ℃时,气孔率和压缩强度明显降低。烧结温度从1 300 ℃升高到1 400 ℃时,试样B的开口气孔率变化不大,总气孔率略有降低,压缩强度从10.28 MPa增加17.74 MPa;烧结温度高于1 400 ℃时,气孔率和压缩强度都降低。

在高气孔率的条件下,试样A和B均具有较高的强度,这主要是生成较多的连接SiC颗粒的熔融方石英玻璃、莫来石及反应剩余长大的致密方石英颗粒[17]和α-Al2O3颗粒,这均加强了制品的强度。试样B的显微照片如图7(a),(b),(c),(d)所示,随着温度的提高,被熔融方石英玻璃和莫来石连接的SiC颗粒变得致密,SiC颗粒的棱角变得圆滑,颗粒之间的气孔呈球形。当烧结温度高于1 400 ℃时,玻璃相逐渐增多,玻璃相脆性强,强度低。另外,SiC随着温度的升高,氧化生成大量的方石英,而方石英非常大的热膨胀系数(在20~700 ℃,方石英的热膨胀系数为17.5×10-6 K-1,而SiC的热膨胀系数为4.7×10-6 K-1)对样品的高温性能是有害的,加热和冷却过程中容易产生微裂纹。所以,当烧结温度为1 450 ℃时,虽然试样B的气孔率降低,压缩强度并没有增加,而是下降;对于试样A,当烧结温度大于1 450 ℃时,其压缩强度也下降。

图7 不同烧结温度下试样A和B的SEM像

Fig.7 SEM images of samples A and B after being sintered at different temperatures for 1 h in air: (a) Sample B, 1 350 ℃; (b) Sample B, 1 400 ℃; (c) Sample B, 1 450 ℃; (d) Sample B, 1 500 ℃; (e) Sample A, 1 400 ℃

在1 400 ℃时,试样B与试样A相比,总气孔率差不多,压缩强度从7.39 MPa升高到17.74 MPa,开口气孔率由69.55%下降到68.10%。

由于试样B中加入了8%的非晶SiO2,带来了部分杂质,且非晶的SiO2反应活性高,所以,与试样A相比,可以在较低的温度烧结,如图7(b)所示,对于1 400 ℃烧成的B试样,由于生成了较多的玻璃相,SiC颗粒较小,边角圆滑,结合非常紧密,小颗粒的α-Al2O3粉和SiO2相互反应生成了较多的莫来石。在试样B的XRD谱(见图3)上,在1 400 ℃可见莫来石的衍射峰,说明生成较多的莫来石。与试样B相比,试样A(见图7(e))颗粒之间的结合明显疏松,SiC颗粒棱角分明,产生的玻璃相非常少。由图3试样A的XRD谱上可知,在1 400 ℃,看不见莫来石的衍射峰,说明α-Al2O3与方石英生成的莫来石的量非常少,且α-Al2O3颗粒之间的烧结也不明显,所以,在1 400 ℃,试样B的压缩强度高,开口气孔率略有下降。加入非晶SiO2助烧剂的试样B明显改善了其烧结性能,与试样A相比,烧结温度和生成莫来石的温度均降低了50 ℃左右。

3 结论

1) 采用凝胶注模工艺,以叔丁醇为溶剂,加入Al2O3和Al2O3+SiO2这两种助烧剂可以制备高气孔率、高强度的多孔SiC陶瓷。

2) 以Al2O3为助烧剂,在1 450 ℃下烧结的SiC陶瓷的总气孔率为71.21%,压缩强度为12.14 MPa。以Al2O3+SiO2为助烧剂的试样在1 400 ℃气孔率和压缩强度分别为70.57%(开口气孔率占总气孔率的90%以上)和17.74 MPa,与单纯采用Al2O3为助烧剂相比,陶瓷的总气孔率差不多,但其压缩强度却高出10.35 MPa。由于非晶SiO2助烧剂的加入,明显地改善了SiC陶瓷的烧结性能,烧结温度和生成莫来石的温度比单纯采用Al2O3为助烧剂的样品均降低50 ℃左右。

(3) 实验中制备的多孔SiC陶瓷的中间孔径基本上是随着烧结温度的增加而增大,且呈单峰分布,平均中间孔径2 μm。

REFERENCES

[1] SUWANMETHANOND V, GOO E, LIU P K T, JOHNSTON G, SAHIMI M, TSOTSIS T. Porous silicon carbide sintered substrates for high-temperature membranes[J]. Ind Eng Chem Res, 2000, 39: 3264-3271.

[2] KITAOKA S, MATSUSHIMA Y, CHEN C, AWAJI H. Thermal cyclic fatigue behavior of porous ceramics for gas cleaning[J]. J Am Ceram Soc, 2004, 87(5): 906-913.

[3] FUKUSHIMA M, ZHOU Y, MIYAZAKI H, YOSHIZAWA Y, HIRAO K. Microstructural characterization of porous silicon carbide membrane support with and without alumina additive[J]. J Am Ceram Soc, 2006, 89(5): 1523-1529.

[4] RIEDEL R, PASSING G, SCHONFELDER H, BROOK J R. Synthesis of dense silicon-based ceramics at low temperatures[J]. Nature, 1992, 355(6362): 714-717.

[5] JIHLE J, HERRMANN M, ADLER J. Phase formation in porous liquid phase sintered silicon carbide: Part Ⅰ: Interaction between Al2O3 and SiC[J]. Journal of the European Ceramic Society, 2005. 25(7): 987-995.

[6] DING Shu-qiang, ZHU Su-min, ZENG Yu-ping, JIANG Dong-liang. Effect of Y2O3 addition on the properties of reaction-boned porous SiC ceramics[J]. Ceramics International, 2006, 32(4): 461-466.

[7] ZHU Su-min, DING Shu-qiang, XI Hong-an, LI Qin, WANG Ruo-ding. Preparation and characterization of SiC/cordierite composite porous ceramics[J]. Ceramics International, 2007, 33(1): 115-118,

[8] DING Shu-qiang, ZENG Yu-ping, JIANG Dong-liang. In-situ reaction bonding of porous SiC ceramics[J]. Materials Characterization, 2008, 59(2): 140-143.

[9] PU Xi-peng, LIU Xue-jian, QIU Fa-gui, HUANG Li-ping. Novel method to optimize the structure of reticulated porous ceramic[J]. J Am Ceram Soc, 2004, 87(7): 1392-1394.

[10] ZHU Xin-wen, JIANG Dong-liang, TAN Shou-hong, ZHANG Zhao-quan. Improvement in the strut thickness of reticulated porous ceramics[J]. J Am Ceram Soc, 2001, 84(7): 1654-1656.

[11] KIM Y W, KIM S H, SONG I H, KIM H D. Fabrication of open-cell, microcellular silicon carbide ceramics by carbothermal reduction[J]. J Am Ceram Soc, 2005, 88(10): 2949-2951.

[12] WANG Hao, SUNG In-kyung, LI Xiao-dong, KIM Dong-pyo. Fabrication of porous SiC ceramics with special morphologies by sacrificing template method[J]. J Porous Mater, 2004, 11(4): 265-271.

[13] MENG Guang-yao, WANG Huan-ting, ZHENG Wen-jun, LIU Xing-qin. Preparation of porous ceramics by gelcasting approach[J]. Mater Lett, 2000, 45(5): 224-227.

[14] MECHNICH P, SCHNEIDER H, SCHM?CKER M, SARUHAN B. Accelerated reaction bonding of mullite[J]. J Am Ceram Soc, 1998, 81(7): 1931-1937.

[15] CHEN Rui-feng, HUANG Yong, WANG Chang-an, QI Jian-qiang. Ceramics with ultra-low density fabricated by gelcasting: An unconventional view[J]. J Am Ceram Soc, 2007, 90(11): 3424-3429.

[16] SARUHAN B, ALBERS W, SCHNEIDER H. Reaction and sintering mechanisms of mullite in the systems cristobalite/ α-Al2O3 and amorphous SiO2/α-Al2O3[J]. J Eur Ceram Soc, 1996, 16(10): 1075-1081.

[17] DAS D, FARJAS J, ROURA P. Passive-oxidation kinetics of SiC microparticles[J]. J Am Ceram Soc, 2004, 87(7): 1301-1313.

(编辑 龙怀中)

基金项目:国家重点基础研究发展计划资助项目(2006CB605207-2);国家高技术研究发展计划资助项目(2007AA03Z435);国家自然科学基金重点资助项目(90816019)

收稿日期:2009-11-29;修订日期:2010-03-03

通信作者:汪长安,博士,教授;电话:010-62785488;E-mail: wangca@tsinghua.edu.cn