DOI:10.19476/j.ysxb.1004.0609.2017.11.21

稀土矿络合浸出废液合成的冰晶石脱硅

张晓伟,李 梅,胡家利,柳召刚,王觅堂,胡艳宏

(内蒙古科技大学 材料与冶金学院,包头 014010)

摘 要:包头混合稀土精矿络合浸出分离稀土后的废液中含有大量的铝离子,经过特殊的工艺技术能够将废水中大量的铝合成冰晶石,但该冰晶石中的硅含量超标,发现采用硫酸-氢氟酸-盐酸的混酸可以有效地脱除冰晶石中硅的化合物。确定以下优化的脱硅条件:硫酸浓度0.4 mol/L、氢氟酸浓度0.8 mol/L、盐酸浓度0.4 mol/L、反应时间90 min、反应温度80 ℃、液固比5:1;在该条件下硅的脱除率达到74.24%,除硅后冰晶石中硅的含量为0.23%,达到冰晶石国家标准要求。XRD分析结果表明大部分硅和杂质已经被脱除;SEM测试结果表明混酸法脱除冰晶石中硅的过程中使冰晶石分散性变好,而冰晶石本身的化学结构并没有被破坏。

关键词:络合浸出;废液;冰晶石;脱硅

文章编号:1004-0609(2017)-11-2349-07 中图分类号:TF803 文献标志码:A

稀土作为一种重要的战略资源已经受到了国内外科研与应用领域的广泛关注,而稀土资源的开采与冶炼同时也成为有色金属领域的焦点,随着环保要求的不断提高和环保制度的不断完善,对稀土冶炼工业也提出了更高的要求[1]。我国是稀土生产的大国,为了响应党和国家的号召,达到新的环保要求,我国的稀土企业以及科研院所在稀土冶炼设备的升级改造以及新工艺开发[2-5]方面做了较多的工作。

李梅课组近年来在包头稀土精矿络合浸出工艺理论研究方面做了深入的研究[6-7],不仅采用酸铝络合体系有效地分离了氟碳铈矿与独居石,探究了相关的反应动力学与热力学[8-10],而且将稀土分离后废液中的铝有效地合成了冰晶石。冰晶石也可称为氟化铝钠或者六氟铝酸钠,分子式为Na3AlF6,白色细小的结晶体;在电解铝行业有着广泛的应用,起到了助熔剂的作用;在研磨的过程中,冰晶石作为研磨添加剂,能够提高研磨性能,延长研磨工具的使用时间;冰晶石作为一种熔剂和脱氧剂,对金属有着很大的影响;在其他领域,冰晶石可以作为涂层、乳化剂、乳白剂、填充剂以及除虫剂等添加剂为材料的性能带来改善[11]。

由于天然的冰晶石特别少,所以目前,工业上所用冰晶石皆为人工制造[12]。其中萤石法合成冰晶石被广泛应用,但随着萤石资源的枯竭,很多其他生产冰晶石的方法如雨后春笋般陆续出现,而再生冰晶石法正被越来越多人接受[13]。李梅课题组对包头稀土精矿络合法浸出废液的成分进行综合分析后,采用特殊的工艺有效合成了冰晶石,不仅处理了废水,还合成了有价值的冰晶石资源,实现了新工艺全流程的清洁与高效化循环。

使用这种废水合成的冰晶石中含有少量含硅化合物,硅含量超过国家标准,导致该类冰晶石无法进行工业使用。匡家灵[14]研究发现硅在冰晶石中主要以氟硅酸钠和二氧化硅的形式存在。本文作者采用H2SO4-HF-HCl的混酸对冰晶石中的硅进行脱除,分别考察了酸的浓度、反应时间、反应温度和液固比对冰晶石中硅的脱除率的影响,分析了冰晶石脱硅后的物相变化及表面形态,对冰晶石的提纯提纯和应用具有重要的科学意义。

1 实验

1.1 原料

实验用到的冰晶石样品为包头稀土精矿络合浸出后废液所合成的冰晶石,化学成分别采用ICP仪器分析和化学分析按照氧化物或元素计算列于表1。实验中所用到的氢氟酸、硫酸及盐酸均为天津风船化学试剂公司生产的分析纯试剂。

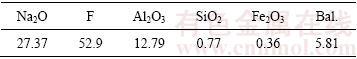

表1 冰晶石样品化学成分含量

Table 1 Contents of cryolite (mass fraction, %)

1.2 实验方法和步骤

本实验主要采用条件实验的方法,通过改变酸浓度、反应时间、反应温度和液固比等,对硅的浸出率和冰晶石的回收率进行研究。实验中称取10g冰晶石样品置于500 mL烧杯中,加入一定比例的HF-H2SO4-HCl混合酸,将烧杯放入DZKW-D-4恒温水浴锅中并控制到预定温度,使用JJ-1精密增力电动搅拌器对搅拌速度进行控制,反应到预定时间后取出过滤烘干,称取冰晶石剩余冰晶石的质量,采用钼蓝分光光度法测定脱硅后冰晶石中硅的含量。

冰晶石中硅的脱除率S计算方法如下:

(1)

(1)

式中:S为硅的脱除率,%;W为浸出渣质量,g;ρ为浸出液硅的浓度,g/L;V为浸出液体积,L;Q为浸出渣中硅的质量分数,%。

冰晶石的回收率为冰晶石脱硅后的质量与脱硅前的质量的比值。

主要反应方程如下:

SiO2+4HF→SiF4+2H2O (2)

Na2SiF6+2HCl→SiF4+2NaCl+2HF (3)

Na2SiF6+2H2SO4→SiF4+Na2SO4+2HF (4)

SiF4+3H2O→H2SiO3+4HF (5)

2 结果与讨论

2.1 盐酸浓度对硅浸出和冰晶石回收的影响

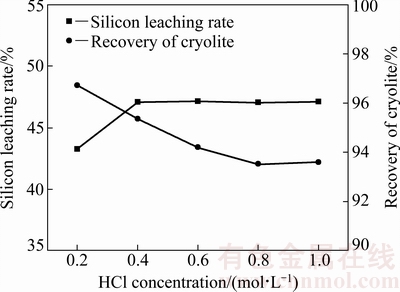

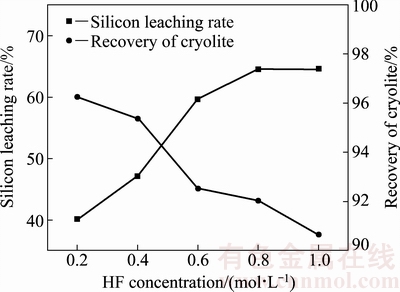

实验首先研究了硅的浸出率和冰晶石回收率受盐酸浓度变化的影响,选取实验条件硫酸浓度为0.6 mol/L,氢氟酸浓度为0.6 mol/L,反应时间为30 min,反应温度为60 ℃,液固比为5:1 (mL:g,下同),得到硅的浸出率和冰晶石回收率随盐酸浓度变化的曲线(见图1)。

由图1可知,盐酸浓度的变化对硅的浸出率和冰晶石回收率都有一定的影响,由0.2 mol/L升高至0.4 mol/L时,硅的浸出率有一个大的变化,超过0.4 mol/L后,随着盐酸浓度的增加硅的浸出率基本保持不变,这说明盐酸浓度超过0.4 mol/L对含硅化合物的分解几乎没有影响。随着盐酸浓度的升高,冰晶石回收逐渐下降,这是因为随着盐酸浓度的升高,冰晶石样品中的杂质分解以及微量冰晶石的分解导致的,盐酸浓度越高,杂质和冰晶石的分解都会加剧,当盐酸浓度超过0.8 mol/L时,盐酸会阻碍其他两种酸参与反应,造成冰晶石回收率回升的现象。所以盐酸对硅的浸出以及冰晶石回收率会有一定的影响,但不是主要因素,并且大量盐酸的进入会阻碍其他两种酸对冰晶石中硅的脱除,故选取盐酸浓度为0.4 mol/L进行后续研究。

图1 盐酸浓度对硅的浸出率和冰晶石回收率的影响

Fig. 1 Effect of HCl concentration on leaching rate of silicon and recovery of cryolite

2.2 硫酸浓度对硅浸出和冰晶石回收的影响

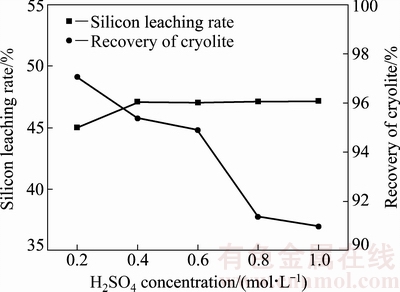

为了研究硅的浸出率和冰晶石回收率受硫酸浓度变化的影响,选取实验条件盐酸浓度为0.4 mol/L,氢氟酸浓度为0.6 mol/L,反应时间为30 min,反应温度为60 ℃,液固比为5:1,得到硅的浸出率和冰晶石回收率随硫酸浓度变化的曲线图(见图2)。

由图2可知,硫酸的浓度对硅的浸出率和冰晶石回收率都有一定的影响,硅的浸出率随着硫酸浓度的升高而增加,由0.2 mol/L升高至0.4 mol/L时,硅的浸出率明显增大,超过0.4 mol/L后,随着硫酸浓度的增加硅的浸出率略有增长,这是因为由0.2 mol/L升高至0.4 mol/L时,硫酸浓度的升高促进了冰晶石中氟硅酸钠的分解,但由于氟硅酸钠在冰晶石中的含量不及二氧化硅高,所以硫酸浓度增加到0.4 mol/L时,反应达到平衡,硅的浸出率不再发生变化。冰晶石回收率随着硫酸浓度的增加大幅降低,硫酸浓度由0.2 mol/L升高到1.0 mol/L时,冰晶石回收率降低了6.08%,这是因为随着硫酸浓度的升高,冰晶石样品中不仅含有硅的氟硅酸钠被硫酸分解,其他杂质受到硫酸的影响也逐渐增加,同时冰晶石也发生了部分分解,从而导致冰晶石回收率持续下降。所以在保证有效脱除冰晶石中硅的同时又要确保冰晶石的回收率,选取硫酸浓度为0.4 mol/L进行后续研究。

图2 硫酸浓度对硅的浸出率和冰晶石回收率与的关系

Fig. 2 Effect of H2SO4 concentration on leaching rate of silicon and recovery of cryolite

2.3 氢氟酸浓度对硅浸出和冰晶石回收的影响

为了研究硅的浸出率和冰晶石回收率受氢氟酸浓度变化的影响,选取实验条件盐酸浓度为0.4 mol/L,硫酸浓度为0.4 mol/L,反应时间为30 min,反应温度为60 ℃,液固比为5:1,得到硅的浸出率和冰晶石回收率随氢氟酸浓度变化的曲线图(见图3)。

由图3可知,氢氟酸浓度的变化对硅的浸出和冰晶石回收率都有很大的影响,随着氢氟酸浓度的增大,当氢氟酸浓度由0.2 mol/L增大到0.8 mol/L时,硅的浸出率有了较大的增长,超过0.8 mol/L后,随着氢氟酸浓度的增加,硅的浸出率只有微小变化,其主要原因在于固液反应受反应物浓度的影响较大,在混酸脱除硅的过程中,氢氟酸主要与二氧化硅发生反应,氢氟酸浓度的增加促进了反应向正方向移动,反应速率也会大大加快,而反应达到平衡后,继续增加氢氟酸浓度,几乎对反应没有影响。冰晶石收率随着氢氟酸浓度的增加大幅降低,且下降程度很大,氢氟酸浓度由0.2 mol/L升高到1.0 mol/L时,冰晶石回收率持续降低,这是因为随着氢氟酸浓度的升高,冰晶石样品中不仅二氧化硅与氢氟酸发生反应,其他杂质和部分冰晶石也同时会与氢氟酸发生反应,而这些反应则会造成冰晶石回收率持续下降。经综合分析,选取氢氟酸浓度为0.8 mol/L进行后续研究。

图3 氢氟酸浓度对硅的浸出率和冰晶石回收率的影响

Fig. 3 Effect of HF concentration on leaching rate of silicon and recovery of cryolite

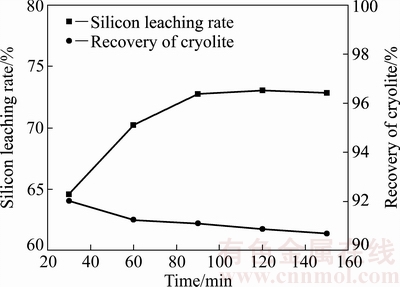

2.4 反应时间对硅浸出和冰晶石回收率的影响

为了研究硅的浸出率和冰晶石回收率受反应时间变化的影响,选取实验条件盐酸浓度为0.4 mol/L,硫酸浓度为0.4 mol/L,氢氟酸浓度为0.8 mol/L,反应温度为60 ℃,液固比为5:1,得到硅的浸出率和冰晶石回收率随反应时间变化的曲线图(见图4)。

图4 反应时间对硅的浸出率和冰晶石回收率的影响

Fig. 4 Effect of reaction time on leaching rate of silicon and recovery of cryolite

由图4可知,随着反应时间的增加,硅的浸出率逐渐增大,当反应时间从30 min升高至90 min时,矿物浸出率明显增大,超过90 min后,硅的浸出率基本不变;这是因为在90 min以前在混酸的作用下,冰晶石表面的硅化合物几乎全部分解,反应达到平衡,所以反应时间的延长并不会继续促进硅的浸出。冰晶石的回收率随着反应时间的延长而逐渐下降,当反应时间从30 min升高至90 min时,冰晶石回收率下降较明显;超过90 min后,冰晶石回收率下降趋势变缓;这是因为在90 min之前是硅化合物和部分冰晶石同时分解,90 min后裸露的硅化合物几乎反应完全,所以冰晶石的回收率下降变缓,选取90 min作为后续研究的时间条件。

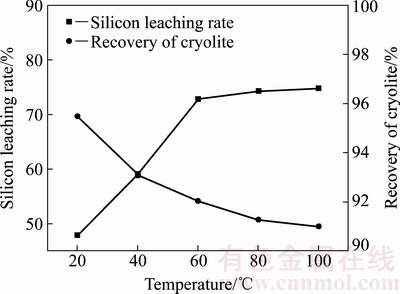

2.5 反应温度对硅浸出和冰晶石回收的影响

为了研究硅的浸出率和冰晶石回收率受反应温度变化的影响,选取实验条件盐酸浓度为0.4 mol/L,硫酸浓度为0.4 mol/L,氢氟酸浓度为0.8 mol/L,反应时间为90 min,液固比为5:1,得到随反应温度变化的曲线图(见图5)。

图5 反应温度对硅的浸出率和冰晶石回收率的影响

Fig. 5 Effect of reaction temperature on leaching rate of silicon and recovery of cryolite

由图5可知,在脱除硅的过程中,反应温度对硅的浸出率和冰晶石回收率都有较大的影响,当反应温度由20 ℃上升至600 ℃时,硅的浸出率明显增加,当反应温度大于60 ℃之后,硅的浸出率随着反应温度的升高稍有增加,主要原因是在固液反应中,温度对于固液反应的体系有着很大的影响,不论是硅化合物的分解还是冰晶石的分解,温度升高能够使溶液中的反应物活化分子数量增加,促使反应向正方向移动,加快反应速度。冰晶石回收率随着反应温度的增大而逐渐降低,且下降幅度逐渐减小,反应温度由20 ℃上升至100 ℃时,冰晶石回收率持续降低,这是因为随着反应温度的升高,硅化合物和冰晶石的分解反应会同时加剧,硅化合物分解结束后冰晶石仍在继续分解,因此在保证有效脱除冰晶石中硅的前提下,使操作和温度控制更为容易,选取反应温度为80 ℃进行后续研究。

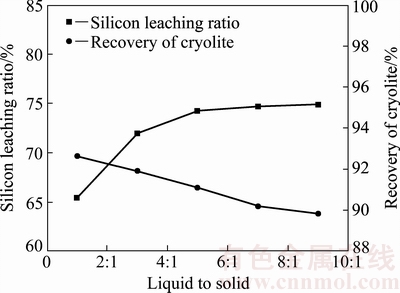

2.6 液固比对硅浸出和冰晶石回收的影响

为了研究硅的浸出率和冰晶石回收率受液固比变化的影响,选取实验条件盐酸浓度为0.4 mol/L,硫酸浓度为0.4 mol/L,氢氟酸浓度为0.8 mol/L,反应时间为90 min,反应温度为80 ℃,得到硅的浸出率和冰晶石回收率随液固比变化的曲线图(见图6)。

图6 硅的浸出率和冰晶石回收率与液固比的关系

Fig. 6 Effect of liquid-solid ratio on leaching ratio of silicon and recovery rate of cryolite

由图6可知,液固比的改变对硅的浸出率和冰晶石回收率都有一定的影响,随着液固比的增大,当液固比由1:1 增大到5:1 时,矿物浸出率有了较大的增加,超过5:1后,随着液固比的增加,硅的浸出率变化不大,其主要原因在于固液反应受液固比的影响较大,在液体反应物浓度和质量足够充足的条件下,液固比的改变对反应速度的影响较大,在液固比为5:1时,反应已经基本达到平衡,所以当液固比超过5:1时,对硅的浸出率已经影响不大。冰晶石回收率随着液固比的增大而持续降低,这是因为随着液固比的增大,硅化合物分解虽然基本分解完全,但是冰晶石在不断的被破坏,所以在保证有效脱除冰晶石中硅的前提下,减小冰晶石的损耗,选取液固比5:1。

对优化条件下脱硅后得到冰晶石进行硅含量检测发现,该冰晶石中的硅含量为0.23%,国家标准中对工业冰晶石的要求是硅含量不大于0.25%,所以该冰晶石硅含量达到了国标要求。

2.7 XRD及SEM分析

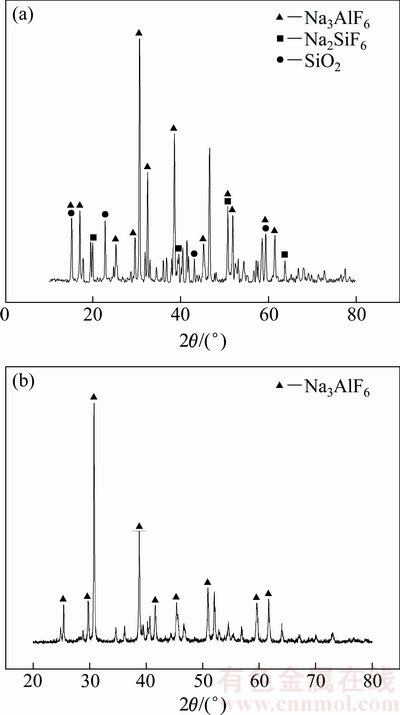

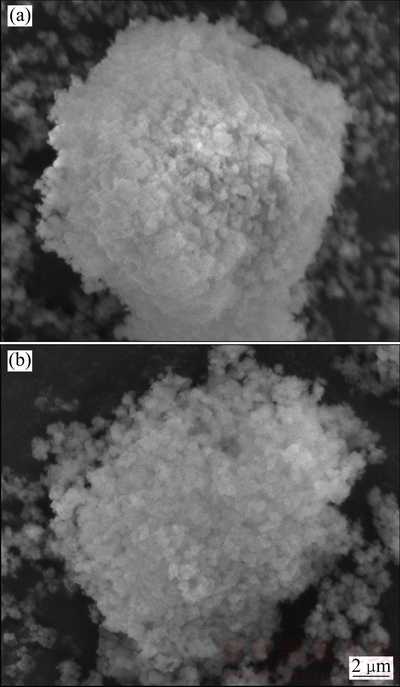

冰晶石脱硅前的XRD物相分析和SEM检测结果如图7(a)和图8(a)所示,在优化条件:盐酸浓度为0.4 mol/L,硫酸浓度为0.4 mol/L,氢氟酸浓度为0.8 mol/L,反应时间为90 min,反应温度为80 ℃,液固比5:1的反应条件下脱硅后得到的冰晶石的XRD物相分析和SEM检测结果分别如图7(b)和图8(b)所示。

图7 冰晶石脱硅前后XRD谱

Fig. 7 XRD patterns of cryolite before (a) and after (b) desilication

通过图7可知,在冰晶石脱硅以前,该冰晶石样品中有氟硅酸钠和二氧化硅的峰出现,样品经H2SO4-HF-HCl的混合酸脱硅处理后,整个体系的峰相变得清晰,杂峰已经明显减少,其中含硅化合物的峰完全消失,只有冰晶石峰的出现,这说明通过混酸脱硅法有效脱除了冰晶石样品中的硅和其他杂质。

通过对脱硅前后后冰晶石进行SEM检测可知,H2SO4-HF-HCl的混合酸处理前冰晶石是由微小颗粒组成的紧密团聚球体,经过混酸脱硅处理以后,冰晶石仍然是由小颗粒组成的团聚体,但表面结构变得松散,形貌结构基本没有发生变化,这说明混酸法脱除冰晶石中硅的过程中使冰晶石分散性变好,而冰晶石本身的化学结构并没有被破坏。

3 结论

图8 冰晶石脱硅前后SEM像

Fig. 8 SEM images of cryolite before (a) and after (b) desilication

1) 采用HF-H2SO4-HCl的混酸对包头稀土精矿络合浸出废液合成的冰晶石进行脱硅,效果明显,确定了一组优化的脱硅条件:H2SO4 0.4 mol/L,HCl 0.4 mol/L,HF 0.8 mol/L,反应时间90 min,反应温度85 ℃,液固比5:1;在该反应条件下脱硅率为74.24%,处理后冰晶石中硅的含量为0.23%,国家标准中硅的含量要求是不大于0.25%,所以该冰晶石达到了国标要求。

2) 对浸出前后的冰晶石样品进行XRD和SEM分析,XRD分析结果表明冰晶石样品中的硅化合物的峰已经全部消失,冰晶石的峰清晰可见,大部分硅和杂质已经被脱除;SEM测试结果表明混酸法脱除冰晶石中硅的过程中使冰晶石分散性变好,而冰晶石本身的化学结构并没有被破坏。

REFERENCES

[1] 王 珍. 中国稀土资源开发和环境保护问题研究[J]. 浙江工业大学学报(社会科学版), 2015, 14(1): 13-17.

WANG Zhen. On the development of Chinese rare earth resources and environment protection[J]. Journal of Zhejiang University of Technology (Social Science), 2015, 14(1): 13-17.

[2] TIAN Jun, CHI Ru-an, YIN Jing-qun. Leaching process of rare earths from weathered crust elution-deposited rare earth ore[J]. Transactions of Nonferrous Metals Society of China, 2010, 20(5): 28: 892-896.

[3] BIAN Xue, CHEN Jian-li, ZHAO Zhi-hua, YI Shao-hua, LUO Yao, ZHANG Feng-yun, WU Wen-yuan. Kinetics of mixed rare earths minerals decomposed by CaO with NaCl-CaCl2 melting salt[J]. Journal of Rare Earths, 2010, 28(S1): 86-90.

[4] XU Yan-hui, LIU Hai-jiao, MENG Zhi-jun, CUI Jian-guo, ZHAO Wen-yi, LI Liang-cai. Decomposition of bastnasite and monazite mixed rare earth mineral calcined by alkali liquid[J]. Journal of Rare Earths, 2012, 30(2): 155-158.

[5] 冯宗玉, 黄小卫, 王 猛, 张国成. 典型稀土资源提取分离过程的绿色化学进展及趋势[J]. 稀有金属, 2017, 41(5): 604-612.

FENG Zong-yu, HUANG Xiao-wei, WANG Meng, ZHANG Guo-cheng. Progress and trend of green chemistry in extraction and separation of typical rare earth resources[J]. Chinese Journal of Rare Metals, 2017, 41(5): 604-612.

[6] 张晓伟, 李 梅, 柳召刚, 胡艳宏, 刘 佳, 阳建平. HNO3-Al(NO3)3溶液分离包头混合稀土精矿的研究[J].中国稀土学报, 2013, 31(5): 588-595.

ZHANG Xiao-wei, LI Mei, LIU Zhao-gang, HU Yan-hong, LIU Jia, YANG Jian-ping. Separation of Baotou mixed rare earth concentrate by HNO3-Al(NO3)3 solution[J]. Journal of Rare Earths, 2013, 31(5): 588-595.

[7] LI Mei, ZHANG Xiao-wei, LIU Zhao-gang, WANG Mi-tang, LIU Jia, YANG Jian-ping. Mixed rare earth concentrate leaching with HCl-AlCl3 solution[J]. Rare Metals, 2013, 32(3): 312-317.

[8] 李 梅, 张晓伟, 阳建平, 柳召刚, 刘 佳. 采用盐浸法从包头稀土精矿中提取稀土的研究[J]. 中南大学学报(自然科学版), 2014, 45(6): 1759-1765.

LI Mei, ZHANG Xiao-wei, YANG Jian-ping, LIU Zhao-gang, LIU Jia. Extracting rare earth from Baotou rare earth concentrate with salt leaching method[J]. Journal of Central South University (Science and Technology), 2014, 45(6): 1759-1765.

[9] LI Mei, ZHANG Xiao-wei, LIU Zhao-gang, HU Yan-hong, LIU Jia, YANG Jian-ping. Kinetics on leaching fluorine from mixed rare earth concentrate with hydrochloric acid and aluminium chloride[J]. Hydrometallurgy, 2013, 140: 71-76.

[10] 张晓伟, 李 梅, 柳召刚, 胡艳宏, 王觅堂, 刘 佳, 阳建平. 包头稀土精矿的配合浸出及动力学研究[J]. 中国有色金属学报, 2014, 24(8): 2137-2143.

ZHANG Xiao-wei, LI Mei, LIU Zhao-gang, HU Yan-hong, WANG Mi-tang, LIU Jia, YANG Jian-ping. Complex leaching and kinetics of Baotou mixed rare earth concentrate[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(8): 2137-2143.

[11] 丁慧萍. 冰晶石产品的生产技术及市场状况[J]. 云南冶金, 2004, 33(3): 64-69.

DING Hui-ping. Production technology and market situation of cryolite products[J]. Yunnan Metallurgy, 2004, 33(3): 64-69.

[12] 刘海霞, 韩建军, 杨水艳, 王建萍. 冰晶石生产工艺现状及发展方向[J]. 无机盐工业, 2009, 41(11): 8-10.

LIU Hai-xia, HAN Jian-jun, YANG Shui-yan, WANG Jian-ping. Current status and development direction of cryolite production technology[J]. Inorganic Chemicals Industry, 2009, 41(11): 8-10.

[13] WANG Liang-shi, WANG Chun-mei, YU Ying, HUANG Xiao-wei, LONG Zhi-qi, HOU Yong-ke, CUI Da-li. Recovery of fluorine from bastnasite as synthetic cryolite by-product[J]. Journal of Hazardous Materials, 2012, 209/210: 77-83.

[14] 匡家灵. 湿法磷酸副产氟硅酸制备冰晶石的降硅试验探讨[J]. 化肥工业, 2013, 40(6): 13-16.

KUANG Jia-ling.Discussion and exploration on silicon reduction experiment of using fluosilicic acid from wet process phosphoric acid to produce cryolite[J]. Chemical Fertilizer Industry, 2013, 40(6): 13-16.

Desilication for cryolite synthesized by rare earth ore complexing leaching waste liquid

ZHANG Xiao-wei, LI Mei, HU Jia-li, LIU Zhao-gang, WANG Mi-tang, HU Yan-hong

(School of Material and Metallurgy, Inner Mongolia University of Science and Technology, Baotou 014010, China)

Abstract: After rare earth separation by complexation extraction from Baotou mixed rare earth concentrate, the obtained waste liquid contains a large number of aluminum ions. The aluminum ions in waste liquid can be transformed into cryolite through a special processing technology, but the content of silicon in cryolite exceeds the content required in Chinese national standard. The compounds of silicon could be removed by the mixture of H2SO4-HF-HCl. The optimized conditions for removing silicon are obtained as follows: 0.4 mol/L HCl, 0.8 mol/L H2SO4, and 0.4 mol/L HCl for 90 min reaction at 85 ℃ under the liquid-solid ratio of 5:1. The removal rate of silicon reaches 74.24% under the optimized conditions. The content of silicon in the cryolite after desilication is 0.23%, which meets the requirement of the content of silicon in cryolite in Chinese national standard. XRD results indicate that most of the silicon and impurities is removed. SEM images show that, during the process of desilication, the dispersity of cryolite is enhanced while the chemical structure of cryolite is maintained.

Key words: complexation extraction; waste liquid; cryolite; removing silicon

Foundation item: Project(51564042) supported by the National Natural Science Foundation of China; Project (2014ZD04) supported by the Inner Mongolia Natural Science Foundation, China; Project(2017MS0531) supported by the Inner Mongolia Science and Technology University Scientific Research Foundation, China; Projects(2016YQL07, 2015QDL24) supported by the Inner Mongolia Science and Technology University Scientific Research Foundation, China

Received date: 2017-03-06; Accepted date: 2017-06-09

Corresponding author: LI Mei; Tel: +86-472-5954390; E-mail: limei@imust.cn

(编辑 王 超)

基金项目:国家自然科学基金资助项目(51564042);内蒙古自然科学基金重大资助项目(2014ZD04);内蒙古自然科学基金资助项目(2017MS0531);内蒙古科技大学创新基金资助项目(2016YQL07,2015QDL24)

收稿日期:2017-03-06;修订日期:2017-06-09

通信作者:李 梅,教授,博士;电话:0472-5954390;E-mail:limei@imust.cn