DOI: 10.11817/j.ysxb.1004.0609.2021-36585

金川镍渣充填胶凝材料力学性能与水化机理

温震江1, 2,高 谦1,2,杨志强2, 3,杨晓炳1, 2,倪 文1, 2

(1. 北京科技大学 金属矿山高效开采与安全教育部重点实验室,北京 100083;

2. 北京科技大学 土木与资源工程学院,北京 100083;

3. 金川集团股份有限公司,金昌 737100)

摘 要:金川矿山利用镍渣开发新型胶凝材料替代水泥以降低充填成本,为了使镍渣胶凝材料更好地应用于矿山充填,需要对其力学性能与水化机理进行研究。首先对试验材料进行物化分析,然后在此基础上进行强度试验,确定激发剂配比、物料比表面积及料浆质量分数,最后利用XRD分析、红外光谱分析、差热分析、能谱分析以及SEM微观结构分析来探究镍渣胶凝材料水化产物及水化机理,为其在矿山的应用提供理论基础。结果表明:镍渣胶凝材料配比为m(镍渣):m(脱硫石膏):m(电石渣):m(硫酸钠):m(熟料)=85:5:5:3:2;镍渣、脱硫石膏、电石渣和熟料最佳比表面积分别为620、320、320和300 m2/kg;料浆质量分数为81%时不仅满足自流输送,并可按照1:4胶砂比制备充填体,7 d和28 d静态抗压强度分别为3.46 MPa和5.76 MPa,7 d和28 d动载抗压强度分别为5.3 MPa和12.5 MPa,7 d和28 d抗拉强度分别为1.53 MPa和1.79 MPa,7 d和28 d抗剪强度分别为1.19 MPa和4.04 MPa,均满足矿山要求。镍渣在碱和硫酸盐复合激发作用下,结晶态物质和玻璃体不断解聚和溶解,并且发生水化反应,生成大量钙矾石、类钙矾石相;同时,生成不规则的絮状凝胶填充空隙,随着养护龄期不断增长,结构逐渐密实,强度也随之提高。

关键词:充填采矿法;镍渣;复合激发;力学性能;水化机理

文章编号:1004-0609(2021)-04-1074-10 中图分类号:TD853;X751 文献标志码:A

引文格式:温震江, 高 谦, 杨志强, 等. 金川镍渣充填胶凝材料力学性能与水化机理[J]. 中国有色金属学报, 2021, 31(4): 1074-1083. DOI: 10.11817/j.ysxb.1004.0609.2021-36585

WEN Zhen-jiang, GAO Qian, YANG Zhi-qiang, et al. Mechanical properties and hydration mechanism of Jinchuan nickel slag filling cementitious material[J]. The Chinese Journal of Nonferrous Metals, 2021, 31(4): 1074-1083. DOI: 10.11817/j.ysxb.1004.0609.2021-36585

社会的高速速发展对于矿产资源的需求量逐年上升,使得矿产资源开发活动逐渐向深部发展,随之而来的不仅是高应力问题,而且采矿活动所带来的环境压力也越来越大[1-3],尤其是近年来国家对于安全和环保的要求日益提高,越来越多的矿山选择充填法采矿,尤其是胶结充填采矿以其高效安全的特点,被广泛应用[4-5]。但是胶结充填采矿成本较高,尤其是在矿业形势不太景气的情况下,无疑会影响矿山企业的经济效益。研究表明,在胶结充填采矿中充填成本的一半以上为胶凝材料的成本[6]。因此,利用当地固体废弃物资源开发替代水泥的新型胶凝材料,对于降低充填成本至关重要。金川集团公司每年产生熔融二次镍渣约120~130万t,其堆存不仅占用土地,而且会造成环境污染[7],实现镍渣等固废的资源化利用是金川公司面临的重要问题。

国内外专家学者针对镍渣的利用和新型胶凝材料的开发进行了大量的研究,MITRASINOVIC等[8-11]分别研究了利用镍渣提取有用元素、制造微晶玻璃以及作为混凝土骨料和掺合料;杨志强等[6, 13-14]研究利用水淬镍渣开发矿山充填胶凝材料;李保亮等[15-16]研究了不同条件下镍渣水泥的水化机理和力学性能;张立力等[17]采用高镁镍渣制备胶凝材料,并对试块体积稳定性进行了分析,结果表明,高镁镍渣制备的胶凝材料试块体积变化不明显;纪荣健等[18]将高镁镍渣粉掺到磷酸钾镁水泥中以改善浆体流动性和降低其体积收缩率,提高硬化体结构密实性,进而提高强度。基于现有的研究成果,基于机械激发和化学激发利用水淬镍渣开发满足金川矿山要求的新型胶凝材料[12-13],这样不仅可以解决因镍渣堆存造成的环境问题,而且可以降低充填成本[19]。在前期试验的基础上,探究各因素对充填体力学性质的影响,并从微观方面揭示其水化机理,为镍渣胶凝材料在金川矿山的应用提供理论基础。

1 试验材料物化特性分析

1.1 充填骨料

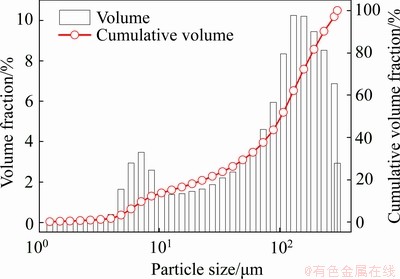

试验采用最大粒径为3 mm的棒磨砂,它是由戈壁集料砂卵石经过“两段一闭路”破碎工艺流程加工成的细砂,其密度为2.67 t/m3,容重为1.49 t/m3,孔隙率为44.99%,含泥量为3.89%,粒径级配分析如图1所示,其平均粒径为0.62 mm,不均匀系数Cu=8.96>5,曲率系数Cc=1.12,满足1<Cc<3,表明棒磨砂属于良好的连续级配。

图1 棒磨砂粒径级配分析

Fig. 1 Analysis of particle size gradation of rod-mill sand

1.2 活性材料

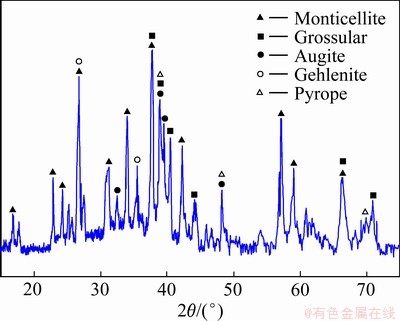

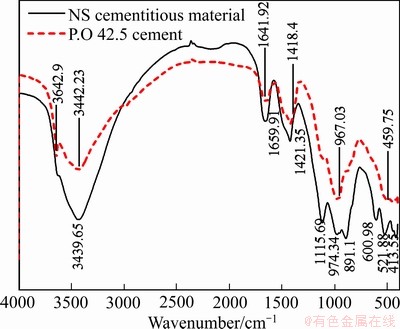

熔融态的镍渣经过水淬之后具有潜在活性,经过粉磨机械激发和化学激发之后具有水硬性。水淬镍渣是由金川公司镍钴研究院提供的闪速炉渣经提铁和水淬处理后的工业产物,对其进行XRD和SEM分析,如图2和3所示。由图3可以看出,镍渣结晶相(区域A)和玻璃相(区域B)相间分布,并且结晶相比较多,包括钙镁橄榄石、普通辉石、铝黄长石及镁(钙)铝榴石等,通过半定量计算结晶相约占79%[13-14]。

图2 金川镍渣XRD谱

Fig. 2 XRD spectrum of nickel slag in Jinchuan

图3 金川镍渣的SEM像

Fig. 3 SEM images of nickel slag in Jinchuan

1.3 激发剂材料

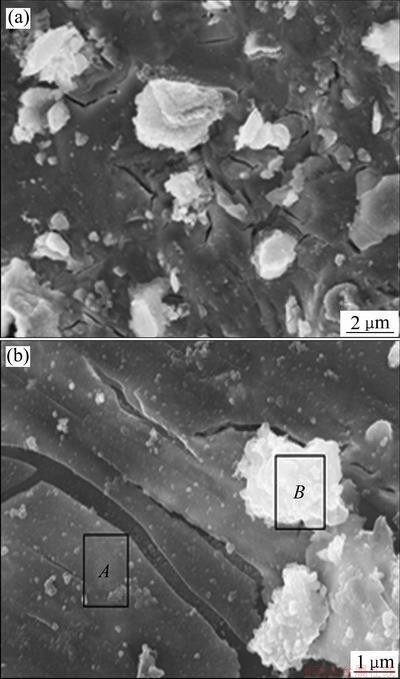

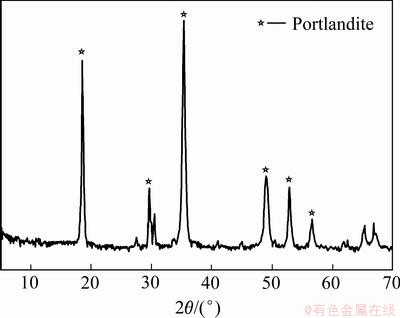

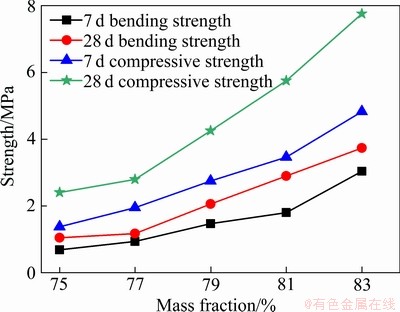

试验采用脱硫石膏、电石渣、熟料和硫酸钠作为激发剂。其中脱硫石膏取自金川热电厂,其主要成分为CaSO4·2H2O;电石渣是电石水解获取乙炔气后的废渣,其XRD分析如图4所示,看出主要成分为羟钙石;熟料是取自金泥集团的普通硅酸盐水泥熟料;硫酸钠采用市场采购的分析纯试剂。本次试验所有材料化学成分如表1所列。

图4 电石渣XRD谱

Fig. 4 XRD pattern of carbide slag

2 试验与结果分析

2.1 试验方法

根据矿用胶凝材料要求和前期试验结果将活性材料和激发剂按照一定比例混合,其中镍渣粉掺量≥85%,脱硫石膏和电石渣混合掺量≤10%,熟料掺量≤2%,硫酸钠掺量≤3%,并且将脱硫石膏和电石渣混合掺量中的脱硫石膏含量按照0~100%分别进行称料充分混合后制成胶凝材料;然后按照胶砂质量比1:4加入棒磨砂骨料,并添加一定量的水搅拌均匀后,分别制备成质量分数75%~83%的料浆,浇筑成40 mm×40 mm×160 mm的标准胶砂试块,拆模后放入标准养护箱,养护7 d和28 d后按照按GB/T 17671—1999要求分别测试其强度。

2.2 结果分析

2.2.1 脱硫石膏掺量对充填体强度的影响

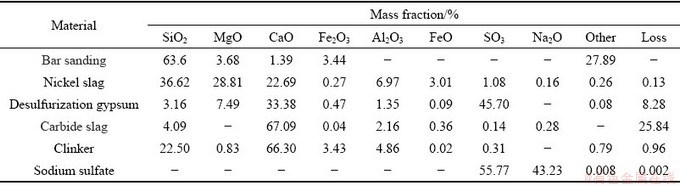

水淬镍渣在激发剂作用下发生水化反应产生强度,试验以脱硫石膏和电石渣为主要激发剂,并且根据前期试验确定胶凝材料配比为镍渣、脱硫石膏和电石渣混合物、硫酸钠和熟料所占比例分别为:85%、10%、3%和2%。为了进一步确定脱硫石膏和电石渣的配比,将混合掺量中的脱硫石膏含量按照0~100%分别进行试验测定其强度,结果如图5所示。由图5可以看出,当脱硫石膏含量小于50%时,随着脱硫石膏含量的增大,强度逐渐增大;当脱硫石膏含量大于50%时,随着脱硫石膏含量的增大,强度逐渐减小;在脱硫石膏含量为50%时,强度达到最大,也就是脱硫石膏与电石渣质量比为5:5时配比最优。

2.2.2 比表面积对充填体强度的影响

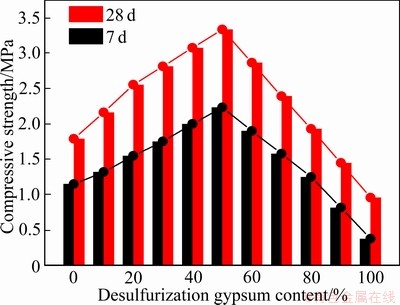

除了化学激发,机械活化对充填体性能影响也很显著。为了提高胶凝材料活性,可以通过控制机械粉磨时间来提高比表面积[6, 13],图6所示为镍渣比表面积对充填体强度的影响。由图6可以看出,随着比表面积的增大,强度也逐渐增大,但当比表面积超过620 m2/kg时强度增长速率减缓,考虑粉磨成本,将620 m2/kg确定为水淬镍渣最优比表面积。同理确定脱硫石膏、电石渣和熟料比表面积分别为:320 m2/kg、320 m2/kg和300 m2/kg。

2.2.3 料浆质量分数对充填体强度的影响

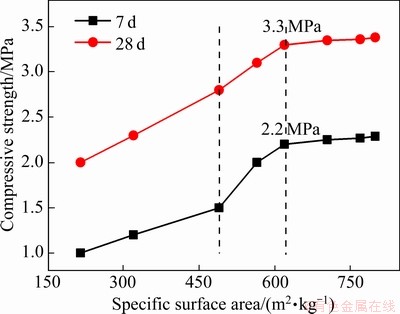

料浆质量分数对充填体强度有显著影响,根据金川矿山高浓度自流输送的要求确定料浆质量分数为75%~83%[20]。根据试验确定的配比和细度制备胶凝材料,然后按照胶砂比1:4加入骨料和水搅拌均匀制成不同质量分数的料浆,料浆质量分数对充填体强度的影响如图7所示。由图7可以看出,各龄期抗折强度和抗压强度均随料浆质量分数增大而增大,随着料浆质量分数从75%增大到83%,7 d和28 d抗折强度分别增大了3.5倍和2.6倍,7 d和28 d抗压强度分别增大了2.52倍和2.24倍。结合料浆自流输送要求,确定料浆质量分数为81%,此时7 d和28 d静态强度分别为3.46 MPa和5.76 MPa。

表1 试验材料化学成分分析

Table 1 Chemical composition analysis of test materials

图5 脱硫石膏含量对充填体强度的影响

Fig. 5 Effect of FGDG content on strength of backfill

图6 镍渣比表面积对充填体强度的影响

Fig. 6 Effect of specific surface area of nickel slag on strength of backfill

2.2.4 动载荷作用下的充填体力学性能

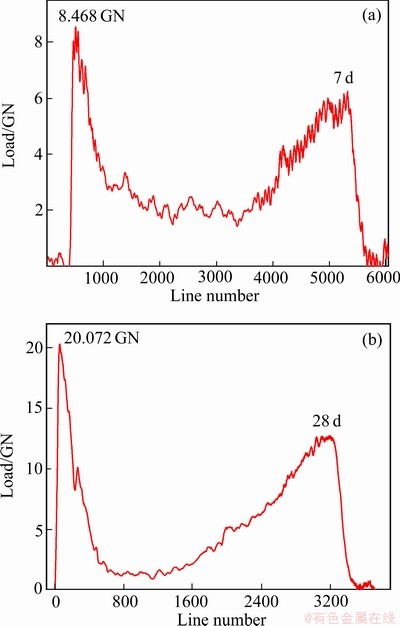

充填体在井下不仅受到静载荷作用,而且还会受到动载荷作用[21]。为了探究动载荷作用下镍渣胶凝材料充填体力学性能,将充填料制备成标准试件,按照GB/T 50081—2002以JSL-3000落锤式示波冲击试验机模拟充填体在冲击载荷下的抗压、抗拉、抗剪强度[21]。以抗压强度为例,其受力情况如图8所示,可以看出,7 d和28 d充填体分别在8468 kN和20072 kN发生破坏,动载抗压强度分别为5.3 MPa和12.5 MPa;同样按照国标测定动载抗拉强度和抗剪强度,动载荷作用下的充填体力学性能结果如表2所示。

图7 料浆质量分数对充填体强度的影响

Fig. 7 Effect of slurry mass fraction on strength of backfill

图8 动载荷下充填体抗压受力图

Fig. 8 Compressive force diagram of backfill under dynamic load

表2 动载荷作用下的充填体力学性能

Table 2 Mechanical properties of backfill under dynamic loading

3 镍渣胶凝材料水化反应机理分析

为了探究镍渣胶凝材料水化产物及机理,分别采用XRD分析水化产物物相、SEM观察水化产物形貌结构、红外光谱仪(FTIR)分析产物组成,并且采用差示扫描量热仪分析水化产物的热性能,以此从微观层面揭示镍渣胶凝材料水化反应过程、产物及其机理。

3.1 水化产物分析

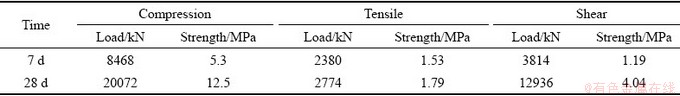

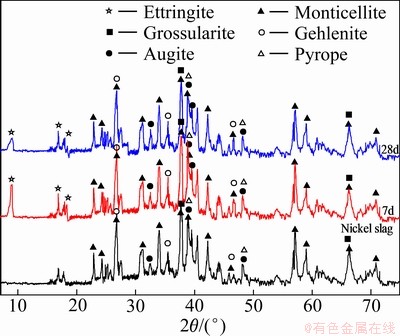

采用X射线衍射仪对镍渣胶凝材料水化产物物相进行分析,结果如图9所示。由图9可以看出,与镍渣原料相比,7 d和28 d水化产物中的大部分钙矾石衍射峰因与其他产物衍射峰重叠,不能被识别,仅有0.47 nm、0.56 nm和 0.96 nm衍射被准确识别,并且水化7 d时衍射峰较28 d时更尖锐[13-14]。为了进一步确定水化产物类型,采用红外光谱、差热与P.O 42.5水泥进行对比分析,其中28 d水化产物红外光谱对比如图10所示。由图10可以看出,波数413.55 cm-1、600.98 cm-1和1115.69 cm-1是钙矾石分子结构中 的吸收带;1641.92 cm-1、3442.23 cm-1和3642.9 cm-1是钙矾石分子结构中结晶水的吸收带;521.88 cm-1、891.1 cm-1是钙矾石分子结构中Al—O键的吸收带;459.75 cm-1、974.34 cm-1是C—S—H中Si—O键的吸收带;1421.35 cm-1左右的振动为

的吸收带;1641.92 cm-1、3442.23 cm-1和3642.9 cm-1是钙矾石分子结构中结晶水的吸收带;521.88 cm-1、891.1 cm-1是钙矾石分子结构中Al—O键的吸收带;459.75 cm-1、974.34 cm-1是C—S—H中Si—O键的吸收带;1421.35 cm-1左右的振动为 造成的[14, 20-23]。由此可见,镍渣胶凝材料水化产物主要为钙矾石和水化硅(铝)酸盐凝胶,与P.O 42.5水泥相似[12-14]。

造成的[14, 20-23]。由此可见,镍渣胶凝材料水化产物主要为钙矾石和水化硅(铝)酸盐凝胶,与P.O 42.5水泥相似[12-14]。

图9 镍渣胶凝材料水化产物XRD谱

Fig. 9 XRD patterns of hydration products of nickel slag cementitious material

图10 镍渣胶凝材料与P.O 42.5水泥水化28 d红外光谱

Fig. 10 IR spectra of 28 d hydration of nickel slag cementitious materials and P.O

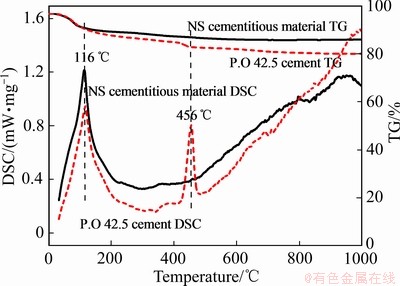

镍渣胶凝材料和P.O 42.5水泥水化28 d热分析结果如图11所示。由图11可以看出,在116 ℃时二者的DSC曲线均存在明显的吸热峰,并且相应的TG曲线存在明显的质量损失,这是由于钙矾石和水化硅酸盐凝胶脱水造成的。在456 ℃时水泥DSC曲线存在吸热峰,且TG曲线存在质量损失,这是Ca(OH)2脱水反应造成的;但是在456 ℃时镍渣胶凝材料DSC曲线不存在吸热峰,这是因为在后期水化反应中,Ca(OH)2已经完全消耗[6, 13-14]。

图11 镍渣胶凝材料和P.O 42.5水泥水化28 d的DSC-TG曲线

Fig. 11 DSC-TG curves of nickel slag cementitious materials and P.O 42.5 cement hydrated for 28 d

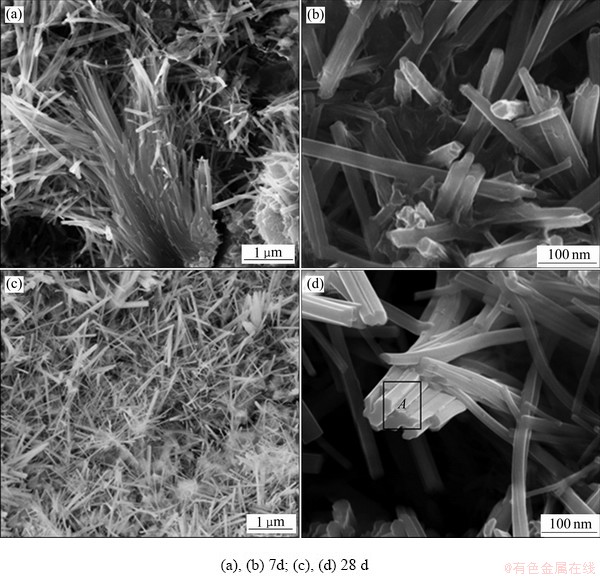

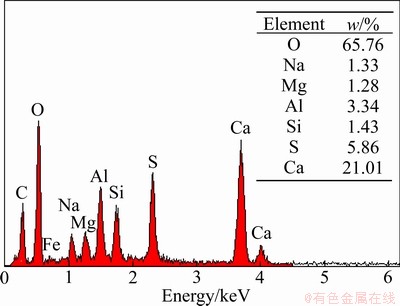

图12所示为镍渣胶凝材料水化产物的SEM像。图12(a)和(b)所示为水化7 d的产物,可以看出,其主要物相是钙矾石,并且伴有凝胶填充空隙;其中钙矾石呈长杆状,其长度约为4~6μm,长径比为20~30左右。图12(c)和(d)所示为水化28 d的产物,可以看出,杆状钙矾石数量显著增加,并且聚集成束径向生长,长径比增大,可以达到100左右[12-13];同时,利用X射线能谱对钙矾石集中的A区域进行半定量分析,结果如图13所示。由图13可以看出,其主要物相为硫铝酸钙,并且包含Na、Mg和Si,对应的含量分别为1.33%、1.28%和1.43%。

3.2 水化反应机理研究

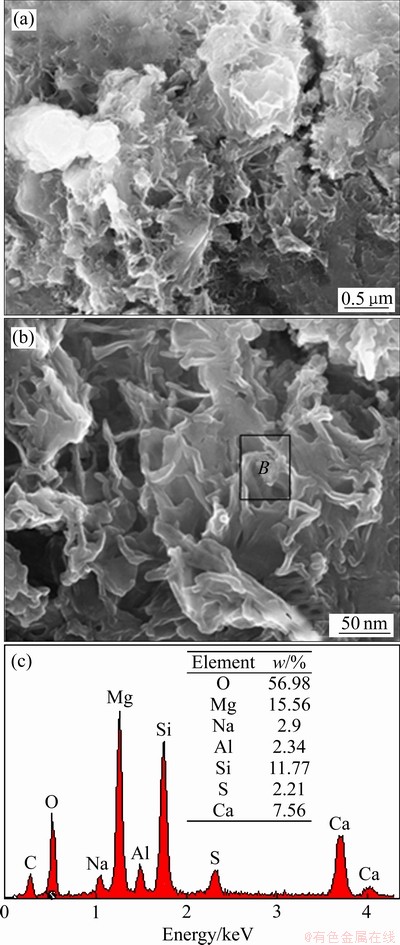

玻璃态和结晶态物质相间分布的水淬镍渣,在激发剂作用下生成无规则的絮状凝胶,其SEM分析如图14(a)和(b)所示,并且进行EDS半定量分析,结果如图14(c)所示。由图14可以看出,其主要物相为硅(铝)酸盐凝胶,并含有Mg2+、Ca2+,其分子式为CaO·(0.9~3.6)MgO·(1.2~3)SiO2·(0.25~0.5) Al2O3·(0.25~0.5)Na2O·nH2O[6, 13-14]。镍渣胶凝材料在早期水化反应时,电石渣水解生成Ca(OH)2,加上脱硫石膏与熟料反应生成的Ca(OH)2作为碱性激发剂,并伴随有少量AFt生成[6, 13-14, 24]。结合硫酸盐激发剂脱硫石膏和Na2SO4共同激发镍渣,其反应过程为:首先,电石渣、熟料水解生成的OH-与镍渣玻璃体表面的Ca2+、Mg2+结合,破坏了镍渣表面结构,接着OH-与玻璃相中的Ca2+、Mg2+发生置换反应,使得以[SiO4]4+四面体和[AlO4]5-四面体为主的镍渣玻璃体结构发生破坏和解聚,并发生复杂的水化反应,最终生成含有Mg2+、Ca2+的水化硅(铝)酸盐絮状凝胶[6, 13-14, 24];其次,玻璃体中Si—O—Al和Al—O—Al在OH-作用下发生解聚,不断释放出Al3+,使得[AlO2]-的浓度逐渐升高,并且与溶液中Ca2+、 反应生成钙矾石,同时溶液中的Na+、Mg2+、Si4+等也参与到水化反应中,生成类钙矾石相[6, 13-14, 24]。总之,在碱和硫酸盐复合作用下,镍渣中的结晶态物质和硅(铝)酸盐玻璃体不断解聚和溶解,发生水化反应,生成大量钙矾石、类钙矾石,并且生成絮状凝胶填充于空隙之中,随着养护时间的增长,结构愈加密实,使得强度逐渐提高[6, 13-14]。

反应生成钙矾石,同时溶液中的Na+、Mg2+、Si4+等也参与到水化反应中,生成类钙矾石相[6, 13-14, 24]。总之,在碱和硫酸盐复合作用下,镍渣中的结晶态物质和硅(铝)酸盐玻璃体不断解聚和溶解,发生水化反应,生成大量钙矾石、类钙矾石,并且生成絮状凝胶填充于空隙之中,随着养护时间的增长,结构愈加密实,使得强度逐渐提高[6, 13-14]。

图12 镍渣胶凝材料水化产物SEM像

Fig. 12 SEM images of hydration products of nickel slag cementitious materials

图13 镍渣胶凝材料水化28 d的EDS谱

Fig. 13 EDS spectrum of 28 d hydration of nickel slag cementitious materials

图14 镍渣胶凝材料水化28 d的SEM像和EDS能谱

Fig. 14 SEM images((a), (b)) and EDS spectrum(c) of 28 d hydration of nickel slag cementitious materials

4 结论

1) 试验对棒磨砂骨料、镍渣和激发剂材料进行物化分析,可知:棒磨砂平均粒径为0.62 mm,且属于良好的连续级配;镍渣结晶相与玻璃相相间分布,结晶度约为79%,活性相对较低;按成分激发剂材料分为碱性和硫酸盐激发剂。

2) 镍渣活性较低,采用化学活化和机械活化以提高镍渣活性,试验以脱硫石膏和电石渣为主要激发剂,并根据试验结果确定镍渣:脱硫石膏:电石渣:熟料:硫酸钠质量比为85:5:5:2:3时充填体活性最高;机械活化分别确定镍渣、脱硫石膏、电石渣和熟料最佳比表面积分别为620、320、320和300 m2/kg。

3) 以胶砂比1:4进行试验,充填料浆质量分数81%时,不仅满足自流输送,并且以此制备充填体,其7 d和28 d静态抗压强度分别为3.46 MPa和 5.76 MPa,7 d和28 d动载抗压强度分别为5.3 MPa和12.5 MPa,7 d和28 d抗拉强度分别为1.53 MPa和1.79 MPa,7 d和28 d抗剪强度分别为1.19 MPa和4.04 MPa,均满足要求。

4) 在碱和硫酸盐复合激发作用下,镍渣中的结晶态物质和硅(铝)酸盐玻璃体不断解聚和溶解,发生水化反应,生成大量钙矾石、类钙矾石,同时生成不规则的絮状凝胶填充空隙;随着养护时间的,结构愈加密实,使得强度逐渐提高。

REFERENCES

[1] 李夕兵, 周 健, 王少锋, 等. 深部固体资源开采评述与探索[J]. 中国有色金属学报, 2017, 27(6): 1236-1262.

LI Xi-bing, ZHOU Jian, WANG Shao-feng, et al. Review and practice of deep mining for solid mineral resources[J]. The Chinese Journal of Nonferrous Metals, 2017, 27(6): 1236-1262

[2] 李新平, 汪 斌, 周桂龙. 我国大陆实测深部地应力分布规律研究[J]. 岩石力学与工程学报, 2012, 31(a01): 2875-2880.

LI Xin-ping, WANG Bin, ZHOU Gui-long. Research on distribution rule of geostress in deep stratum in chinese mainland[J]. Chinese Journal of Rock Mechanics and Engineering, 2012, 31(a01): 2875-2880.

[3] 黄祖绍. 创建绿色环保矿山、实现资源综合利用的探索与实践[J]. 中国矿业, 2015, 24(s2): 76-80.

HUANG Zu-shao. Creating green mining, exploration and practice to achieve comprehensive utilization of resources[J]. China Mining Magazine, 2015, 24(s2): 76-80.

[4] 曹 帅, 薛改利, 宋卫东. 组合胶结充填体力学特性试验与应用研究[J]. 采矿与安全工程学报, 2019, 36(3): 601-608.

CAO Shuai, XUE Gai-li, SONG Wei-dong. Experimental research on mechanical properties of combined cemented tailings backfill and its application[J]. Journal of Mining & Safety Engineering, 2019, 36(3): 601-608.

[5] 姚维信. 矿山粗骨料高浓度充填理论研究与应用[D]. 昆明: 昆明理工大学, 2011.

YAO Wei-xin. Theoretical study and application of high concentration filling of coarse aggregate in mine[D]. Kunming: Kunming University of Science and Technology, 2011.

[6] 李克庆, 冯 琳, 高术杰. 镍渣基矿井充填用胶凝材料的制备[J]. 工程科学学报, 2015, 37(1): 1-6.

LI Ke-qing, FENG Lin, GAO Shu-jie. Preparation of cementitious materials for backfilling by using nickel slag[J]. Chinese Journal of Engineering, 2015, 37(1): 1-6.

[7] 刘家详, 杨 儒, 胡明辉. 高炉水淬渣的利用研究[J]. 矿产综合利用, 2003(3): 40-44.

LIU Jia-xiang, YANG Ru, HU Ming-hui. Utilization of blast furnace slag water quenching[J]. Utilization of Mineral Resources, 2003(3): 40-44.

[8] MITRASINOVIC A M, WOLF A. Separation and recovery of valuable metals from nickel slags disposed in landfills[J]. Sep Sci Technol, 2015, 50: 2553-2558.

[9] WANG Z, NI W, JIA Y, et al. Crystallization behavior of glass ceramics prepared from the mixture of nickel slag, blast furnace slag and quartz sand[J]. J Non-Cryst Solids, 2010, 356: 1554-1558.

[10] CHOI Y C, CHOI S. Alkali-silica reactivity of cementitious materials using ferro-nickel slag fine aggregates produced in different cooling conditions[J]. Constr Build Mater, 2015, 99: 279-287.

[11] KATSIOTIS N S, TSAKIRIDIS P E, VELISSARIOU D, et al. Utilization of ferronickel slag as additive in portland cement: A hydration leaching study[J]. Waste Biomass Valorization, 2015, 6: 177-189.

[12] 温震江, 杨志强, 高 谦, 等. 金川矿山早强充填胶凝材料配比试验与优化[J]. 矿冶工程, 2018, 38(6): 29-32.

WEN Zhen-jiang, YANG Zhi-qiang, GAO Qian, et al. Proportioning and optimization test for backfill cementing material with faster strengthening property in Jinchuan Mine[J]. Mining and Metallurgical Engineering, 2018, 38(6): 29-32.

[13] 杨志强, 高 谦, 王永前, 等. 利用金川水淬镍渣尾砂开发新型充填胶凝剂试验研究[J]. 岩土工程学报, 2014, 36(8): 1498-1506.

YANG Zhi-qiang, GAO Qian, WANG Yong-qian, et al. Experimental study on new filling cementing material using water-hardening nickel slag tailings of Jinchuan Mine[J]. Chinese Journal of Geotechnical Engineering, 2014, 36(8): 1498-1506.

[14] 高术杰, 倪 文, 李克庆, 等. 用水淬二次镍渣制备矿山充填材料及其水化机理[J]. 硅酸盐学报, 2013, 41(5): 612-619.

GAO Shu-jie, NI Wen, LI Ke-qing, et al. Preparation and hydrated mechanism of mine filling material of water-granulated secondary nickel slag[J]. Journal of the Chinese Ceramic Society, 2013, 41(5): 612-619.

[15] 李保亮, 王 申, 潘 东, 等. 蒸养条件下镍渣水泥胶砂的水化产物与力学性能[J]. 硅酸盐学报, 2019, 47(7): 891-899.

LI Bao-liang, WANG Shen, PAN Dong, et al. Hydration products and mechanical properties of ferronickel slag blended cement mortar under steam curing[J]. Journal of the Chinese Ceramic Society, 2019, 47(7): 891-899.

[16] 齐太山. 高炉镍铁渣粉在复合胶凝材料中的水化机理与性能研究[D]. 长沙: 湖南大学, 2017.

QI Tai-shan. Hydration mechanism and performance of blast furnace ferronickel slag power in complex cementitious materials[D]. Changsha: Hunan University, 2017.

[17] 张立力, 李思胜, 高 振, 等. 高镁镍渣-磷石膏基复合胶凝材料的制备与性能评价[J]. 水泥工程, 2020(4): 11-14, 25.

ZHANG Li-li, LI Si-sheng,GAO Zhen, et al. Preparation and performance evaluation of high magnesium nickel slag-phosphogypsum based composite cementitious materials[J]. Cement Engineering, 2020(4): 11-14, 25.

[18] 纪荣健, 王 琪, 盛 敏, 等. 含高镁镍渣粉的磷酸钾镁水泥性能试验研究[J]. 硅酸盐通报, 2020, 39(3): 696-702.

JI Rong-jian, WANG Qi, SHENG Min, et al. Experimental study on properties of magnesium potassium phosphate cement containing high magnesium nickel slag powder[J]. Bulletin of the Chinese Ceramic Society, 2020, 39(3): 696-702.

[19] 周爱民. 矿山废料胶结充填[M]. 2版. 长沙: 冶金工业出版社, 2010: 1-8.

ZHOU Ai-min. Mining waste cemented filling[M]. 2nd ed. Changsha: Metallurgical Industry Press, 2010: 1-8.

[20] 杨志强, 高 谦, 王永前, 等. 金川全尾砂-棒磨砂混合充填料胶砂强度与料浆流变特性研究[J]. 岩石力学与工程报, 2014, 33(S2): 3985-3991.

YANG Zhi-qiang, GAO Qian, WANG Yong-qian, et al. Research on filling body strength and rheological properties of mixed filling mortar with unclassified tailings and rod milling sand in Jinchuan mine[J]. Chinese Journal of Rock Mechanics and Engineering, 2014, 33(S2): 3985-3991.

[21] 张福利, 倪 文, 高术杰, 等. 镍渣胶结充填体动静加载状态下的强度特性[J]. 矿业研究与开发, 2014, 34(5): 19-22, 30.

ZHANG Fu-li, NI Wen, GAO Shu-jie, et al. Strength performance of nickle slag cemented backfill body under dynamic and static loads[J]. Mining Research and Development, 2014, 34(5): 19-22, 30.

[22] 杨南如. 无机非金属材料测试方法[M]. 武汉: 武汉工业大学出版社, 1990: 338-343.

YANG Nan-ru. Inorganic non-metallic material test method[M]. Wuhan: Wuhan Industry University Press, 1990.

[23] ALVAREZ-AYUSO E, NUGTEREN H W. Synthesis of ettringite: away to deal with the acid wastewaters of aluminium anodising industry[J]. Water Res, 2005, 39(1): 65-72.

[24] 王佳佳, 刘广宇, 倪 文, 等. 激发剂对金川水淬二次镍渣胶结料强度的影响[J]. 金属矿山, 2013, 42(4): 159-163.

WANG Jia-jia, LIU Guang-yu, NI Wen, et al. Analysis of the influences of activator on performances of Jinchuan water-granulated secondary Ni slag cemented backfilling materials[J]. Metal Mine, 2013, 42(4): 159-163.

Mechanical properties and hydration mechanism of Jinchuan nickel slag filling cementitious material

WEN Zhen-jiang1, 2, GAO Qian1, 2, YANG Zhi-qiang2, 3, YANG Xiao-bing1, 2, NI Wen1, 2

(1. Key Laboratory of High Efficient Mining and Safety of Metal Mine, Ministry of Education, University of Science and Technology Beijing, Beijing 100083, China;

2. School of Civil and Resource Engineering, University of Science and Technology Beijing, Beijing 100083, China;

3. Jinchuan Group Co., Ltd., Jinchang 737100, China)

Abstract: In Jinchuan Mine, nickel slag was used to develop a new cementing material instead of cement to reduce the filling cost. In order to make nickel slag cementitious material better used in mine filling, it is necessary to study its mechanical properties and hydration mechanism. Firstly, the physicochemical analysis of the test material was carried out, and then the strength test was carried out on the basis of the analysis, the ratio of activator, specific surface area of the material and slurry mass fraction were determined. Finally, the hydration products and hydration mechanism of nickel slag cementitious materials were explored by XRD analysis, infrared spectroscopy analysis, differential thermal analysis, energy spectrum analysis and SEM micro-structure analysis, which provides a theoretical basis for its application in mines. The results show that the proportion of nickel slag cementitious material is m(nickel slag):m(desulfurization gypsum):m(carbide slag):m(sodium sulfate):m(clinker)=85:5:5:3:2; the optimum specific surface areas of nickel slag, desulfurized gypsum, carbide slag and clinker are 620, 320, 320 and 300 m2/kg, respectively; When the slurry mass fraction is 81%, it not only satisfies self-conveying, but also can prepare filling body according to 1:4 cement-sand ratio. The static compressive strengths are 3.46 MPa and 5.76 MPa for 7 d and 28 d, respectively, and the dynamic compressive strengths are 5.3 MPa and 12.5 MPa, tensile strengths are 1.53 MPa and 1.79 MPa, shear strengths are 1.19 MPa and 4.04 MPa, which all meet the requirements of the mine. Under the combined activation of alkali and sulphate, the crystalline material and amorphous of nickel slag are continuously depolymerization and dissolved, and hydration reaction takes place. A large number of ettringite and ettringite phases are formed, while irregular floc gel fills the gap. With the increase of curing age, the structure becomes denser and the strength increases.

Key words: filling mining method; nickel slag; compound excitation; mechanical properties; hydration mechanism

Foundation item: Project(2017YFC0602903) supported by the National Key Research Development Program of China; Project(19073818Z) supported by the Special Project for Transformation of Major Scientific and Technological Achievements in Hebei Province, China

Received date: 2020-06-30; Accepted date: 2020-10-10

Corresponding author: GAO Qian; Tel: +86-18600173341; E-mail: gaoqian@ces.ustb.edu.cn

(编辑 王 超)

基金项目:国家重点研发计划资助项目(2017YFC0602903);河北省重大科技成果转化专项(19073818Z)

收稿日期:2020-06-30;修订日期:2020-10-10

通信作者:高 谦,教授,博士;电话:18600173341;E-mail:gaoqian@ces.ustb.edu.cn