DOI:10.19476/j.ysxb.1004.0609.2018.11.08

晶粒尺寸效应对铜极薄带轧制变形机制影响的模拟研究

陈守东1, 2,卢日环2,孙 建1,李 杰1,张 可3

(1. 铜陵学院 机械工程学院,铜陵 244061;

2. 东北大学 轧制技术及连轧自动化国家重点实验室,沈阳 110819;

3. 安徽工业大学 冶金工程学院,马鞍山 243032)

摘 要:采用退火态轧制铜箔为原料,进行晶粒尺寸效应的箔轧实验和晶体塑性有限元模拟。基于率相关晶体塑性理论,开发用户材料子程序(UMAT),建立轧制铜极薄带的晶体塑性有限元模型,改进Voronoi图种子生成的随机性,建立反映晶粒形貌、晶界不规则性的多晶极薄带几何模型,并编写赋予多晶取向的算法,用以控制多晶取向及织构分布,研究晶粒尺寸效应对其变形机制的影响。结果表明:在铜极薄带中尺寸较小晶粒中产生的剪切带相对于尺寸较大晶粒中产生的要均匀,可较好地减小变形局部化;不同晶粒尺寸铜极薄带的滑移系启动和累积滑移存在显著差异,启动的滑移系随晶粒尺寸的减小而增多;表层晶粒和内部晶粒的约束差异导致变形后晶粒取向主要绕横向(TD)进行旋转,旋转角度和极点分散度随晶粒平均尺寸的减小而减小。箔轧实验和模拟得到的轧制力-晶粒尺寸曲线基本一致,即晶粒取向对轧制力的影响随晶粒平均尺寸的减小而减弱。

关键词:极薄带轧制;多晶模型;晶体塑性有限元;晶粒尺寸效应

文章编号:1004-0609(2018)-11-2233-09 中图分类号:TG335.5 文献标志码:A

随着微型化的发展,试样的外观尺寸逐渐达到材料晶粒尺寸相同的等级。工件尺寸减小到某一门槛值后,材料的应力应变关系、组织性能、摩擦因数等在塑性成形过程中呈现出与常规尺寸工件不同的特点,即出现尺寸效应。由于尺寸效应的存在,材料在微成形中表现出各向异性、材料的应力应变分布不均匀、产生应变梯度等现象。材料在微米级以下变形时,变形过程不能直接采用宏观理论的简单缩小来描述,因为变形中出现了尺寸效应等特殊现象,改变了材料在微成形的本构。宏观的J2流变理论已不能用于微成形的变形研究,采用晶体塑性理论可以建立材料在微成形的本构理论。采用实验研究微成形尺寸效应相当困难以及耗费大量的资源,有些实验在现有条件下还是无法完成的。

多晶材料是由大量晶粒组成的,材料的性能和特性受到单个晶粒性质以及各晶粒之间相互作用的影响。准确模拟多晶材料的微成形,关键是建立能够真实反映材料微观结构的有限元模型。近年来,建立了很多种能反映材料微观组织的模型,传统的建立模拟多晶材料的模型主要采用六边形[1-2]或是每个有限元单元[3-5]来代表晶粒,不能反映晶界的不规则性和晶粒形貌的随机性。采用Poisson-Voronoi图生成的多晶模型,每四条边交于一个顶点,每三个面交于一条边,这些和实际材料的晶粒结构很相似[6]。BARBE等[7]基于Voronoi图建立晶体塑性有限元模型,研究了材料变形的局部应力应变。DIARD等[8]基于Voronoi图建立晶体塑性有限元模型模拟密排六方金属的局部力学性能,探究了有限元模型网格划分密度、网格类型对局部应力应变的影响。FAN等[9]基于Voronoi图建立了3种不同的多晶体模型,包括常规多晶模型、表层晶粒细化多晶模型以及表层有钝化层的多晶模型,研究不同多晶模型在变形中的尺寸效应。FRITZEN等[10]建立了一种自动生成三维周期Voronoi图网格的方法,编写相应的算法程序,使生成网格的效率大大提高。WANG等[11]基于Voronoi图建立了考虑微成形中尺寸效应的表面层模型,研究了试样尺寸与晶粒尺寸比值对流动应力的影响,结果表明在微成形中必须同时考虑试样尺寸和晶粒尺寸的共同作用。LI等[12]对厚度为200 μm具有不同晶粒尺寸的纯铜薄带进行杯形件深冲变形实验,指出变形载荷随晶粒尺寸的增大而降低,且表面粗糙度随晶粒尺寸增大而增加。XIE等[13]采用实验和有限元模拟的方法研究了超薄不锈钢304微观轧制的变形过程,指出轧制微观变形模式受到板材厚度变化,即尺寸效应的影响,尺寸效应的作用主要表现对流变应力和摩擦因数的影响。XU等[14]采用实验和模拟相结合的方法,研究了试样外形几何尺寸与晶粒尺寸对纯铜薄板微成形极限的影响规律,发现其微成形极限随着薄板厚度方向上晶粒数量的减少而降低。

以上分析表明,采用Voronoi图建立多晶模型具有合理性。关于拉伸、弯曲的晶体塑性有限元模拟研究较多,很少针对极薄带轧制变形中尺寸效应开展晶体塑性有限元方面的研究。本文作者改进了Voronoi图种子生成的随机性,提出一种新的种子生成算法,建立能反映晶粒形貌、晶界不规则性的多晶几何模型,并编写赋予多晶取向算法,采用晶体塑性有限元模拟的方法研究晶粒尺寸效应对铜极薄带轧制变形机制的影响。

1 晶体塑性理论

采用PEIRCE等[15]提出的率相关晶体塑性本构模型,总的变形梯度F分解为发生滑移的塑性变形(Fp)及晶格畸变和旋转的弹性变形(Fe):

(1)

(1)

(2)

(2)

式中:sα和mα分别为第α滑移系变形前滑移方向和滑移面法向的单位向量;s*α和m*α分别为第α滑移系变形后滑移方向和滑移面法向向量。

变形速度梯度L分解为弹性速度梯度(Le)和塑性速度梯度(Lp)部分:

(3)

(3)

(4)

(4)

式中: 为第α滑移系的剪切应变率,求和表示对所有激活的N1个滑移系进行。

为第α滑移系的剪切应变率,求和表示对所有激活的N1个滑移系进行。

率相关晶体塑性模型采用指数方程描述第α滑移系上滑移剪切率与分切应力之间的关系:

(5)

(5)

式中:如果x≥0,sgn(x)=1;如果x<0,sgn(x)=-1, 为参考剪切应变率;n为率敏感系数;

为参考剪切应变率;n为率敏感系数; 为滑移系上的分剪切应力;

为滑移系上的分剪切应力; 为临界分剪切应力;临界分剪切应力率可表示为

为临界分剪切应力;临界分剪切应力率可表示为

(6)

(6)

采用BASSANI等[16]提出的适合FCC金属的硬化模型,其表达式为

(7)

(7)

式中:hαα为自硬化系数;hαβ为潜硬化系数; 为β滑移系的剪切率;q为潜硬化系数与自硬化系数的比值;γ0为参考剪切应变;γα和γβ分别为α、β滑移系的累积剪切应变;h0为初始硬化率;hs为易滑移阶段硬化模量;τ0为初始临界分剪切应力;τ1为临界分剪切应力饱和值;fαβ表示滑移系α与滑移系β间的相互作用系数,其大小取决于滑移系的几何关系,由5个常数ai来表示。

为β滑移系的剪切率;q为潜硬化系数与自硬化系数的比值;γ0为参考剪切应变;γα和γβ分别为α、β滑移系的累积剪切应变;h0为初始硬化率;hs为易滑移阶段硬化模量;τ0为初始临界分剪切应力;τ1为临界分剪切应力饱和值;fαβ表示滑移系α与滑移系β间的相互作用系数,其大小取决于滑移系的几何关系,由5个常数ai来表示。

数值计算时,采用切线系数法将晶体塑性本构编写成Abaqus/Standard用户子程序UMAT调用。

2 极薄带轧制微观变形数值模拟

2.1 多晶极薄带种子生成

常规Voronoi图是在有限空间内随机播撒种子,每个种子出现在区域内的概率都是一样。该种方法生成种子便于生成,但各种子之间的距离难以控制,会造成Voronoi多边形不均匀性增加。本文作者提出一种更加均匀的Voronoi图种子生成算法,该算法生成Voronoi图的规则性较好且计算效率高。二维修正Voronoi图种子的生成算法流程如下。

1) 设定模拟区域大小,将模拟区域设置为L×W的矩形。给定长宽方向上的晶粒数n1、n2,则整个区域内晶粒总数为n1×n2,晶粒形状控制因子α、β,种子间的最小临界距离δ,将L×W区域分成n1×n2个小矩形,求出各小矩形的中心坐标。

2) 在第一个小矩形内生成种子,根据形状因子α、β及该小矩形中心坐标,在其中播撒种子。

3) 判断种子1与相邻种子间的距离是否大于δ,如果大于δ,表示该种子生成成功,若小于δ,则重新进行第二步,直到找到合适的种子为止。

4) 生成第一个种子成功后,进行重复循环计算其余剩下的n1×(n2-1)个种子。

该算法将模拟区域再分成均匀小的矩形,在小矩形内播撒种子点,种子生成的随机性降低。

2.2 多晶极薄带取向赋予

晶粒取向可通过3个欧拉角按一定转动顺序,使晶体坐标和试样坐标重合,即可用3个欧拉角表示晶粒取向。对于立方晶系,晶体坐标轴分表为[100]、[010]、[001],对应的试样坐标轴为轧制方向RD、横向TD、法向ND。多晶极薄带模型赋予任意或某一特定取向的算法流程如下。

1) 离散欧拉空间,根据ODF取向密度分布设定离散欧拉空间的密度,将欧拉空间3个坐标轴φ1、Ф、φ2按n1、n2、n3分解相应坐标轴,整个欧拉空间被分解成n=n1×n2×n3个子空间。

2) 将第一步中离散的n个欧拉子空间按照φ1、Ф、φ2的顺序排成一列,根据ODF取向密度,按一定顺序在每个子空间内分布一个自然数,该自然数代表取向出现在该子空间的次数。设晶粒取向在这n个子空间中出现的次数依次为自然数a1,a2,a3,···,an,出现总次数为N。

3) 按n个子空间的排列顺序,将n个自然数累积相加,每个累积相加之和除以总次数N,每个子空间可以用一个数值区间表示,如第一个子空间为(0, a1/N),第二个子空间为(a1/N, a1+a2/N)。

4) 为某一晶粒P赋予取向,随机生成一个自然数XP,设定XP位于某一取向区间i,在该区间表示的子空间内生成一取向矩阵gp,设定相邻晶粒取向差Δθ,本文设定取向差Δθ=15°,判断相邻晶粒取向差是否大于Δθ,如果大于15°,则gP就代表该晶粒的取向,否则就重新循环直到满足相邻晶粒取向差Δθ大于15°。

5) 通过第四步生成各晶粒的取向矩阵gP,计算RD和ND在晶粒坐标中所代表的取向。

6) 各晶粒取向矩阵gP确定后,3个欧拉角(φ1,Ф,φ2)分别代表RGB规则中的三原色,根据相应取向赋予各晶粒不同颜色。

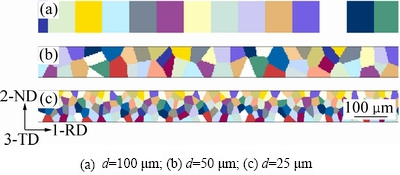

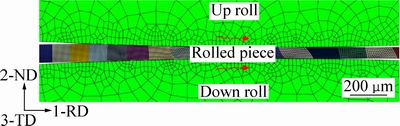

基于上述多晶极薄带种子生成和取向赋予算法,建立的典型轧制极薄带几何模型如图1所示,计算模型尺寸为3 mm×0.1 mm,计算中只改变晶粒尺寸,其中不同颜色代表赋予的不同晶粒取向。

图1 轧制极薄带几何模型

Fig. 1 Polycrystal geometrical model of foil rolling

2.3 轧制极薄带有限元及材料模型

在轧制变形中,有限元网格会发生很大的畸变和扭转以及网格弯曲等,结合轧制变形的特殊性,本文作者基于Abaqus/inp文件方法来建立轧制多晶极薄带的晶体塑性有限元模型。

建立的轧制极薄带晶体塑性有限元模型如图2所示。将极薄带轧制简化为平面应变变形,取轧制方向(1-RD)作为X轴,法向(2-ND)作为Y轴,横向(3-TD)作为Z轴。在模拟过程中,轧辊和铜箔均设置为变形体,采用CPE4R单元离散铜极薄带模型,每个晶粒平均包含100个单元。有限元模型由规则的四边形网格划分而成,这样可以很好地保证计算的收敛性。各晶粒的晶界是由锯齿状的单元组成,锯齿状的晶界结构可以保证计算易收敛性,单元不易畸变。这种单元划分具有很高的质量,可尽量排除单元性质对计算结果的影响。

图2 轧制极薄带晶体塑性有限元模型

Fig. 2 Crystal plasticity finite element model of foil rolling

晶体塑性有限元模拟箔轧工艺参数:上下工作轧辊直径为30 mm,上工作辊转速为1.04 rad/s,上下工作辊异速比为1.1,轧辊与轧件之间接触采用库仑摩擦定律,摩擦因数为0.1,晶粒平均尺寸从100 μm减小到20 μm,即厚度方向上的晶粒个数从1个增加到5个。

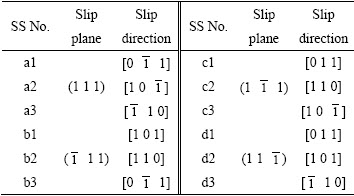

模拟计算所需的材料硬化及滑移系运动参数采用陈守东等的研究成果[17],纯铜为FCC晶体结构,滑移发生在12个滑移系{1 1 1}<1 1 0>上,其滑移面和滑移方向如表1所示。纯铜的弹性模量为C11= 168.4 GPa, C12= 121.4 GPa, C44=75.4 GPa。

表1 晶体塑性模型中所用滑移系定义

Table 1 Definition of slip systems (SS) used in model

3 结果与讨论

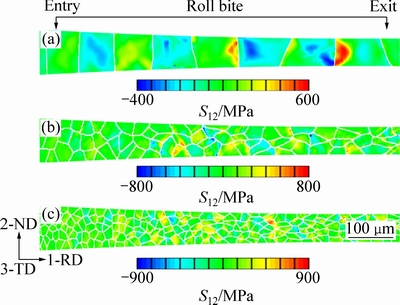

图3所示为晶粒尺寸100、33和20 μm时轧制变形区的切应力分布。由图3可见,轧制变形区的切应力分布不均匀,各晶粒间和晶粒内部均会出现应力梯度现象,但随晶粒尺寸的减小,应力值增大,部分晶粒内部及变形区的应力分布更加均匀。晶粒尺寸较大的晶粒晶界处易出现应力集中现象,随晶粒尺寸的减小,部分晶界特别是三角晶界处也可能是应力最小的地方。晶粒内部也会出现应力集中现象,随着晶粒尺寸的减小,晶界数量增多,为维持协调变形,三角晶界处的应力值增大。应力最大值主要分布在晶界,晶内变形较弱。极薄带轧制变形的不均匀性和应力集中现象是由晶粒几何和取向随机性造成的,晶粒尺寸分布影响更显著。

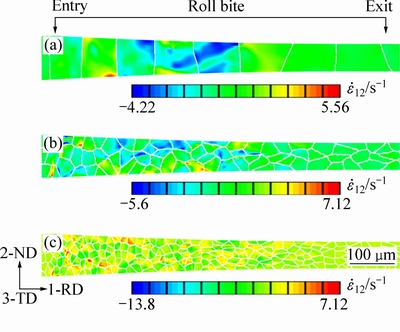

图4所示为晶粒尺寸100、33和20 μm时轧制变形区的切应变率分布。由图4可知,切应变率分布严重不均匀,个别晶粒发生了较大的变形,而有的晶粒几乎没有变形,塑性变形首先在尺寸较大晶粒或取向因子较高的地方发生,随着轧制变形的进行,局部高应变区开始结合形成初始剪切带;随着变形的继续进行,局部剪切带连续产生并逐渐扩展,在尺寸较大的晶粒内部形成了贯穿整个晶粒的局部剪切带;当晶粒尺寸为100 μm时,晶粒内只产生了少量几个剪切带;随着晶粒尺寸的减小,即当晶粒尺寸为33和20 μm时,晶粒内部产生的剪切带数量增多且分布比较均匀。这是由于随着晶粒尺寸的减小,变形分布更加均匀,降低了轧制变形内应力集中的局部性。可见晶粒尺寸较大的极薄带轧制变形时产生的剪切带局部性要高于晶粒尺寸较小的极薄带。因此,在极薄带轧制成形中,通过改变晶粒尺寸是一个改善极薄带轧制成形性能的可行方法。

图3 轧制变形区细观切应力分布

Fig. 3 Contour plots of meso-scale shear stress in roll bite with d=100 μm (a), d=33 μm (b) and d=20 μm (c)

图4 轧制变形区细观切应变率分布

Fig. 4 Contour plots of meso-scale shear strain rate in roll bite with d=100 μm (a), d=33 μm (b) and d=20 μm (c)

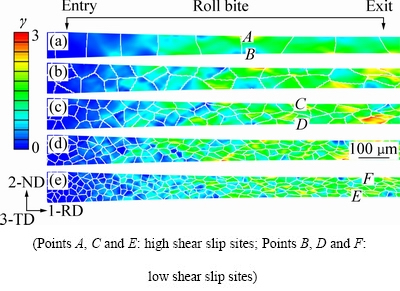

图5 轧制变形区累积塑性滑移分布

Fig. 5 Distribution of accumulated slip in roll bite with d=100 μm (a), d=50 μm (b), d=33 μm (c), d=25 μm (d) and d=20 μm (e)

图5所示为晶粒尺寸100、50、33、25和20 μm时轧制变形区的累积塑性滑移量分布。累积塑性滑移沿铜箔厚度方向和轧制方向的分布状态反映出极薄带轧制微观变形的非均匀性,这与轧制变形区的切应力分布和剪切带形成过程是一致的。晶界处(A、E处)出现滑移集中,但晶界甚至三角晶界处(D、F处)是滑移最小的地方,另外,在晶粒内部(C处)也可能出现滑移集中现象。由于晶粒尺寸及取向差异,出现贯穿整个晶粒的滑移带及局部滑移现象,个别晶粒发生了很大的滑移,而有的晶粒发生滑移较小,如A、C和E处为高滑移区,B、D和F处为低滑移区,这是部分晶粒处于择优取向而首先进行滑移,先滑移晶粒受到晶界阻碍而被减弱,相邻晶粒及晶粒内部受到协调变形作用和较小的应力-应变而进行较小的滑移,导致晶粒间的滑移局部化。随着晶粒尺寸的减小,晶内-晶间的累积塑性滑移量分布更加均匀,可见较小的晶粒尺寸可以减弱滑移的局部化趋势。

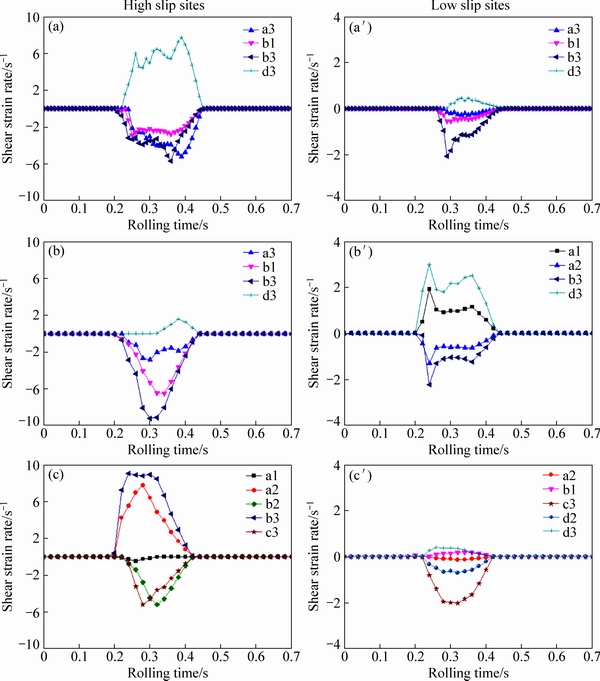

图6 轧制过程中高-底滑移区启动滑移系演化情况

Fig. 6 Activated slip systems at high-low slip sites during cold rolling with d=100 μm (a), d=33 μm (b) and d=20 μm (c)

图6所示为晶粒尺寸为100、33和20 μm时极薄带轧制变形过程中高-低滑移位置处启动滑移系的状态(高滑移区如图5中A、C和E处,低滑移区如图5中B、D和F处),可见轧制变形区内不同位置处的滑移系启动状态和滑移程度有很大差异且受晶粒尺寸的影响较大,高滑移区位置启动滑移系的滑移程度明显大于低滑移区,随着晶粒尺寸的减小,高-低滑移区内启动的滑移系数目增多,滑移运动的波动程度明显减弱。当晶粒尺寸为100 μm时,高-低滑移区开动的滑移系数目和类型都是一样的,4个滑移系被激活运动,滑移系d3沿正方向进行滑移,滑移系a3、b1和b3则沿负方向进行滑移,两处的差别只在于高滑移区的滑移程度明显大于低滑移区;当晶粒尺寸为33 μm时,高-低滑移区开动的滑移系数目都是4个,高滑移区启动滑移系的类型与晶粒尺寸为100 μm时的一样,而滑移系a1代替b1在低滑移区被激活开动,滑移系a1和d3沿正方向滑移,滑移系a3和b3沿负方向滑移,4个滑移系的滑移状态呈对称分布;当晶粒尺寸为20 μm时,高-低滑移区开动的滑移系数目为5个,启动滑移系的类型和滑移程度与晶粒尺寸较大模型有较大差异,呈现多系滑移状态。

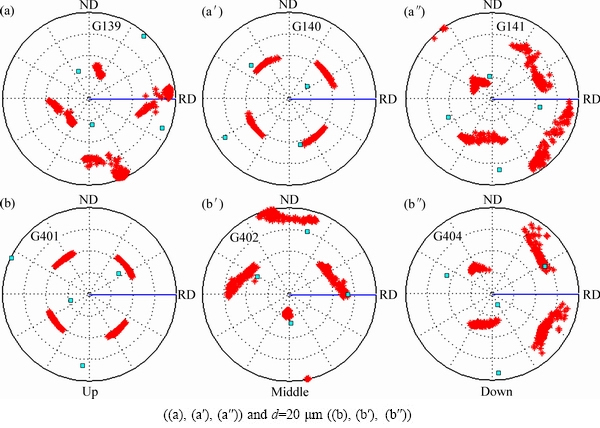

图7所示为晶粒尺寸为33 μm和20 μm时沿铜箔厚度方向上表层-中间-下表层晶粒轧制变形前后{111}极图的对比。其中晶粒平均尺寸d=33 μm时,铜箔厚度方向上有3层晶粒,d=20 μm时,铜箔厚度方向上有5层晶粒,图中青色实体方框表示各晶粒的初始取向。轧制变形后各晶粒绕横向(TD)发生了明显的转动,但各晶粒的具体转动情况不同,晶粒取向的变化不仅与原始晶粒取向有关也与晶粒所处变形区的位置密切相关。当晶粒尺寸为33 μm时,表层晶粒G139和G141的取向极点转动角度和分散度明显大于中间晶粒G140的,中间晶粒G140变形后的取向只是绕TD旋转,极点没有发生扩展,而两个表层晶粒的取向极点除发生转动外,还沿RD和ND发生扩展;当晶粒尺寸为20 μm时,表层晶粒G401和G404的取向旋转角度大于中间晶粒G402的,表层晶粒G401变形后的取向不仅绕TD转动很大角度,而且还沿RD和ND进行偏移;随晶粒尺寸的减小,变形后晶粒取向的转动角度和极点分散程度减小,表层晶粒和内部晶粒取向变化的差异性减弱,表明特定位置处晶粒变形后取向的变化与启动滑移系的滑移状态及晶界-晶内作用特性密切相关。

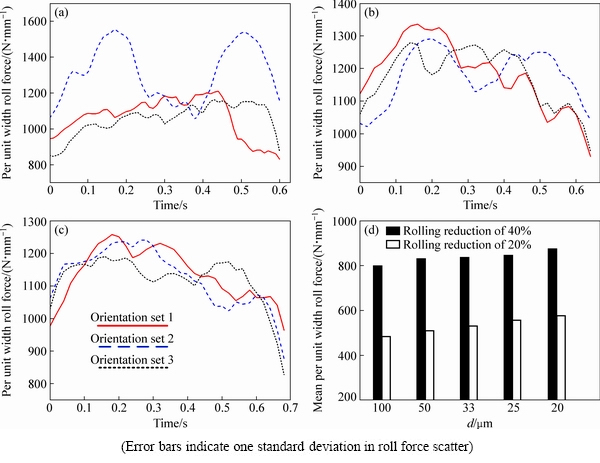

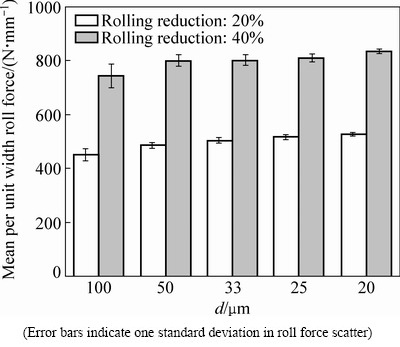

图8所示为3组不同晶粒尺寸与赋予3种不同晶粒取向分布状态下,晶体塑性有限元模拟极薄带轧制过程的轧制力-时间曲线及轧制力统计晶粒尺寸效应。由图8可知,不同晶粒尺寸与取向分布对极薄带轧制的力学性能有显著影响。当晶粒尺寸为100 μm时,模拟得到的3条轧制力曲线偏差很大,其中一条在开始和结束阶段各出现一个峰值,而另外2条曲线则随时间先逐渐增加,中间保持稳定,最后在变形结束时迅速降低;当晶粒尺寸为33 μm和20 μm时,3条轧制曲线之间偏差较小,先随时间增加到最大值后逐渐减小,轧制终了则迅速降低。随晶粒尺寸的减小,不同取向模型轧制力曲线之间的偏差减小,且轧制力的波动明显降低,即晶粒尺寸越小,轧制力对晶粒取向的依赖性越弱。在20%和40%两种轧制压下率情况下,随晶粒尺寸的减小,单位宽度轧制力逐渐增大,且偏差逐渐降低。

图7 轧制变形区上表层、中间、下表层晶粒{111}极图变形前后变化情况

Fig. 7 {111} Pole figures of grains before and after deformation in roll bite with d=33 μm

图8 不同晶粒尺寸下晶粒取向对单位轧制力-时间的影响和轧制力晶粒尺寸效应

Fig. 8 Effect of grain orientation on per unit width roll force during cold rolling with d=100 μm (a), d=33 μm (b), d=20 μm (c) and numerical roll force at two rolling reductions (20%, 40%) with grain size for five grain models (d)

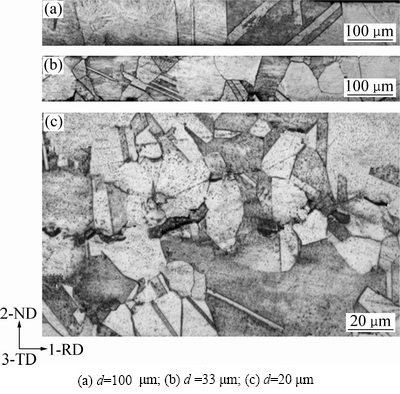

4 箔轧实验

为验证晶体塑性有限元模拟极薄带轧制成形中晶粒尺寸效应的准确性,对同一厚度一系列不同晶粒尺寸的纯铜箔(T2)进行箔轧实验,轧件尺寸:100 mm (长)×20 mm(宽)×0.1 mm(厚),轧前对铜箔进行真空退火处理,退火温度为700~920 ℃,保温时间为5~7 h,退火后经过研磨抛光,用5 g FeCl3+15 mL HCl+85 mL H2O进行腐蚀,腐蚀时间为7 s,退火后典型铜箔的显微组织如图9所示。

图9 退火后不同晶粒尺寸铜箔显微组织

Fig. 9 Microstructure of annealed pure copper foil

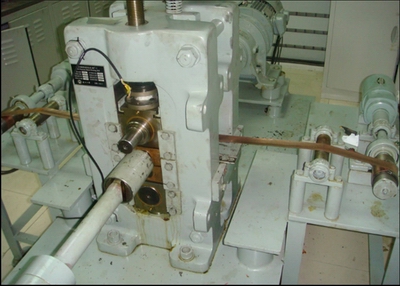

轧制实验使用课题组自主设计研制的四辊多功能微成形轧机,其照片如图10所示,该轧机是二/四辊可逆轧机,辊缝通过压下螺丝控制,轧制线前后各布置一台带张力卷取电机,采用安装在压下螺丝下方的测力传感器测量轧制力,所有信号都通过采样板储存到计算机中,工作辊直径30 mm,辊身长度130 mm,支撑辊直径120 mm,辊身长度120 mm,最大轧制力100 kN,两个工作辊各自采用5.5 kW的电动机传动。

实测轧制压下率为20%和40%时,不同晶粒尺寸箔轧的轧制力与晶粒尺寸关系如图11所示,可见轧制力随晶粒尺寸的减小而逐渐增大,轧制力偏差则减小,实验结果与模拟结果吻合较好。

图10 极薄带制备实验轧机照片

Fig. 10 Photo of experimental rolling mill of foil rolling

图11 不同晶粒尺寸铜箔平均单位宽度轧制力实验结果

Fig. 11 Experimental results of mean per unit width roll force of copper foil with different grain sizes

5 结论

1) 晶粒尺寸影响着极薄带轧制变形机制及滑移特性,在晶内-晶间均出现非均匀变形,并出现剪切带和变形局部化现象,减小晶粒尺寸可降低变形局部化趋势。

2) 不同晶粒尺寸极薄带轧制变形过程中的滑移系启动状态及累积滑移存在显著差异,当晶粒平均尺寸大于33 μm时,在高-低滑移区,滑移系成对开动;当晶粒平均尺寸减小到20 μm时,为多滑移系开动 状态。

3) 表层晶粒和内部晶粒的约束差异引起变形后晶粒取向主要绕TD旋转,取向旋转角度和极点分散度随晶粒平均尺寸的减小而减小。

4) 随晶粒尺寸的减小,晶粒取向对轧制力的影响减弱,箔轧实验与模拟结果吻合较好,即轧制力随晶粒尺寸的减小而增大,波动及偏差减小。

REFERENCES

[1] GROGAN J A, LEEN S B, MCHUGH P E. Influence of statistical size effects on the plastic deformation of coronary stents[J]. Journal of the Mechanical Behavior of Biomedical Materials, 2013, 20: 61-76.

[2] MCGARRY J P, O′DONNELL B P, MCHUGH P E, O'CEARBHAIL E, MCMEEKING R M. Computational examination of the effect of material inhomogeneity on the necking of stent struts under tensile loading[J]. Journal of Applied Mechanics, 2007, 74(5): 978-989.

[3] CHOI Y S, GROEBER M A, TUMER T J, DIMIDUK D M, WOODWARD C, UCHIC M D, PARTHASARATHY T A. A crystal-plasticity FEM study on effects of simplified grain representation and mesh types on mesoscopic plasticity heterogeneities[J]. Materials Science and Engineering A, 2012, 553: 37-44.

[4] LI S Y, DONOHUE B R, KALIDINDI S R. A crystal plasticity finite element analysis of cross-grain deformation heterogeneity in equal channel angular extrusion and its implications for texture evolution[J]. Materials Science and Engineering A, 2008, 480: 17-23.

[5] MOLOTNIKOV A, LAPOVOK R, DAVIES C H J, CAO W, ESTRIN Y. Size effect on the tensile strength of fine-grained copper[J]. Scripta Materialia, 2008, 59(11): 1182-1185.

[6] FAN Z G, WU Y G, ZHAO X H, LU Y Z. Simulation of polycrystalline structure with Voronoi diagram in Laguerre geometry based on random closed packing of spheres[J]. Computational Materials Science, 2004, 29(3): 301-308.

[7] BARBE F, DECKER L, JEULIN D, CAILLETAUD G. Intergranular and intragranular behavior of polycrystalline aggregates. Part 1: F. E. model[J]. International Journal of Plasticity, 2001, 17(4): 513-536.

[8] DIARD O, LECLERCQ S, ROUSSELIER G, CAILLETAUD G. Evaluation of finite element based analysis of 3D multicrystalline aggregates plasticity application to crystal plasticity model identification and the study of stress and strain fields near grain boundaries[J]. International Journal of Plasticity, 2005, 21(4): 691-722.

[9] FAN H D, LI Z H, HUANG M S, ZHANG X. Thickness effects in polycrystalline thin films: Surface constraint versus interior constraint[J]. International Journal of Solids and Structures, 2011, 48(11/12): 1754-1766.

[10] FRITZEN F, BOHLKE T, SCHNACK E. Periodic three-dimensional mesh generation for crystalline aggregates based on Voronoi tessellations[J]. Computational Mechanics, 2008, 43(5): 701-713.

[11] WANG Y, DONG P L, XU Z Y, YAN H, WU J P, WANG J J. A constitutive model for thin sheet metal in micro-forming considering first order size effects[J]. Materials and Design, 2010, 31(2): 1010-1014.

[12] LI W T, FU M W, WANG J L, MENG B. Grain size effect on multi-stage micro deep drawing of micro cup with domed bottom[J]. International Journal of Precision Engineering and Manufacturing, 2016, 17(6): 765-773.

[13] XIE H B, MANABE K, FURUSHIMA T, TADA K. An experimental and numerical investigation on micro rolling for ultra-thin strip[J]. International Journal of Material Forming, 2016, 9(3): 405-412.

[14] XU Z T, PENG L F, FU M W, LAI X M. Size effect affected formability of sheet metals in micro/meso scale plastic deformation: Experiment and modeling[J]. International Journal of Plasticity, 2015, 68(5): 34-54.

[15] PEIRCE D, ASARO R J, NEEDLEMAN A. Material rate dependence and localized deformation in crystalline solids[J]. Acta Metallurgica, 1983, 31(12): 1951-1976.

[16] BASSANI J L, WU T Y. Latent hardening in single crystals II. Analytical characterization and predictions[J]. Proceedings of the Royal Society A, 1991, 435(1893): 21-41.

[17] 陈守东, 刘相华, 刘立忠, 宋孟. Cu极薄带轧制中滑移与变形的晶体塑性有限元模拟[J]. 金属学报, 2016, 52(1): 120-128.

CHEN Shou-dong, LIU Xiang-hua, LIU Li-zhong, SONG Meng. Crystal plasticity finite element simulation of slip and deformation in ultrathin copper strip rolling[J]. Acta Metallurgica Sinica, 2016, 52(1): 120-128.

Simulation of effect of grain size on rolling deformation mechanism of copper ultra-thin strip

CHEN Shou-dong1, 2, LU Ri-huan2, SUN Jian1, LI Jie1, ZHANG Ke3

(1. School of Mechanical Engineering, Tongling University, Tongling 244061, China;

2. State Key Laboratory of Rolling and Automation, Northeastern University, Shenyang 110819, China;

3. School of Metallurgical Engineering, Anhui University of Technology, Maanshan 243032, China)

Abstract: Annealed pure copper foils were taken as raw materials, and after the processes of foil rolling, the grain size effect was studied by foil rolling experiment and crystal plasticity finite element simulation. A user defined material subroutine (UMAT) developed based on the rate-dependent crystal plasticity theory embedded into the finite element software to analyze the grain size effect on micro-scale deformation mechanism of rolling polycrystalline copper ultra-thin strip. The random generating of the Voronoi diagram seeds was improved. The polycrystalline ultra-thin strip geometry model was created by constructing a new seeds generation algorithm, which can express the shape of the grains and the irregular grain boundaries. An algorithm to describe the grain orientation and texture distribution was introduced by adjusting the modeling parameters. The results show that the shear bands in small grain size are more uniform than those in large grain size which could effectively reduce the rolling deformation locality. The activity of slip system and accumulated slip are significant different in the foils with different grain sizes, and the activity of slip systems increases with decreasing grain size. The rotate of crystallographic orientation mainly around the transverse direction attributes to the different constraint of surface grain and internal grain, and the growth of rotation angle and dispersion degree decreases with decreasing grain size. The effect of grain orientation on roll force is weakened with decreasing grain size, and the roll force-grain size curves from the simulation agree well with the rolling experimental results.

Key words: foil rolling; polycrystalline model; crystal plasticity finite element; grain size effect

Foundation item: Project(51804219, 51701144) supported by the National Natural Science Foundation of China; Project (1808085QE161) supported by the Provincial Natural Science Foundation of Anhui Province, China; Project(2016tlxyrc05) supported by the Scientific Research Foundation for Advanced Talents of Tongling University, China

Received date: 2017-09-13; Accepted date: 2018-03-02

Corresponding author: CHEN Shou-dong; Lecturer; Ph.D; Tel: +86-15056817605; E-mail: csdong0910@sina.com

(编辑 龙怀中)

基金项目:国家自然科学基金资助项目(51804219,51701144);安徽省自然科学基金资助项目(1808085QE161);铜陵学院人才科研启动基金资助项目(2016tlxyrc05)

收稿日期:2017-08-13;修订日期:2018-03-02

通信作者:陈守东,讲师,博士;电话:15056817605;E-mail: csdong0910@sina.com