文章编号:1004-0609(2014)04-0950-08

金属型铸造界面换热系数峰值预测模型的建立和验证

徐 戎1, 2,李落星1, 2,张立强1, 2,朱必武1, 2,卜晓兵3

(1. 湖南大学 汽车车身先进设计与制造国家重点实验室,长沙 410082;

2. 湖南大学 机械与运载工程学院,长沙 410082;

3. 湖南大学 材料科学与工程学院,长沙 410082)

摘 要:在改进Hamasaiid模型的基础上提出了新的金属型铸造界面换热系数峰值hmax预测模型,该模型引入表面张力参数,定量研究其对界面换热的影响。采用A356铝合金金属型重力铸造实验对模型进行验证。结果表明:反求计算的hmax约为5944 W/(m2·K),采用Hamasaiid模型计算的hmax约为7987 W/(m2·K),误差约为34%;新模型未考虑表面张力时计算的hmax约为6228 W/(m2·K),误差约为5%,考虑表面张力时计算的hmax约为5992 W/(m2·K),误差约为1%。新模型计算精度有较大提升,计算结果与反求结果具有很好的一致性,表面张力对计算精度有一定影响。

关键词:界面换热系数;金属型重力铸造;表面粗糙度参数;表面张力;接触热阻;反热传导法

中图分类号:TK 124 文献标志码:A

Development and validation of prediction models of heat transfer coefficient peak value during metal casting process

XU Rong1, 2, LI Luo-xing1, 2, ZHANG Li-qiang1, 2, ZHU Bi-wu1, 2, BU Xiao-bing3

(1. State Key Laboratory of Advanced Design and Manufacturing for Vehicle Body, Hunan University,

Changsha 410082, China;

2. College of Mechanical and Vehicle Engineering, Hunan University, Changsha 410082, China;

3. College of Material Science and Engineering, Hunan University, Changsha 410082, China)

Abstract: The new predictive model of metal casting interfacial heat transfer coefficient peak value (hmax) was proposed by improving Hamasaiid’s model. The surface tension was introduced into the model, its impact on the interfacial heat transfer was quantitatively studied. A356 aluminum alloy gravity die casting experiments were performed in order to validate the model. The results show that the hmax value calculated by the inverse heat conduction method is about 5944 W/(m2·K), the result of Hamasaiid’s model is about 7987 W/(m2·K), and the error is about 34%. The hmax value calculated by the new model is about 6228 W/(m2·K), and the error is about 5%, but if the surface tension is considered, the result is about 5992 W/(m2·K), and the error is about 1%. The calculation accuracy of the new model was greatly improved, the calculation results are in good agreement with the inverse results. The surface tension has a certain impact on the calculation accuracy.

Key words: interfacial heat transfer coefficient; metal mold gravity die casting; surface roughness parameters; surface tension; thermal contact resistance; inverse heat conduction method

铸造凝固过程中界面换热系数决定了铸件和铸型之间的换热状况,并进而在很大程度上决定了铸件的组织及性能,而界面换热系数则受到各种因素如浇注温度、压力、铸件和铸型材料、铸型初始温度和界面涂料情况等的影响。铸造中对于一定厚度的铸件和铸型,采用金属型铸造时,由于铸件或铸型的热物性参数很大,界面热阻远大于铸型内部热阻,总热阻近似等于界面热阻;采用砂型铸造时,由于铸件或铸型的热物性参数很小,界面热阻远小于铸型内部热阻,此时可以忽略界面热阻[1-2]。

关于金属型铸造过程界面换热行为的研究,前人已做了大量工作,包括铸件材料及浇注温度[1-7],铸型初始温度及材料[8-9]、铸件的几何形状[10-11]、铸造压力[10, 12-14]、铸型表面涂层的材料及厚度[15]、铸型表面粗糙度[16-17]等。

近年来,采用数值模拟预测各类铸造过程来提高生产效率和质量已经成为一个重要的发展趋势。软件对铸造过程换热的模拟很大程度上取决于输入的边界条件,界面换热系数h就是其中最重要的边界条件之一。然而,由于对固液界面接触机理缺乏深入了解,以前的研究者在模拟时都是假设h为常数,这么做会严重降低模拟的精度,甚至失真[14, 18]。近年来,越来越多的商业软件都要求使用者自己提供h值或者h随时间t变化的情况,因此,了解已知条件下固-液界面接触机理,预测h—t曲线的峰值和形状成为该领域大多数研究者的重要课题。目前,反热传导方法是求解h—t曲线的最常用方法。该方法有精度高且适用各类界面传热情况的优点,但也存在一些应用上的不足,最明显的是该方法目前主要适用于铸件形状简单的一维传热和二维传热过程,对于复杂的三维传热过程的应用有待进一步研究开发。

基于上述的研究成果,本文作者在对Hamasaiid模型[17]进行改进的基础上提出新的金属型铸造hmax预测模型,对铸造过程界面换热行为进行了更深入的分析,意在为进一步理解铸造过程界面换热机理提供新的观点,为复杂传热过程的计算提供新的思路和方法。

1 模型

在固体和液体接触的过程中,由于本身的流动性和填充性,液体能流入固体表面上的几何细节,因此,液体和固体物质之间的接触情况在很大程度上是由固体表面的微观形貌决定的。本文中固体表面形貌模型是在Hamasaiid模型的基础上通过采取不同的固体表面微结构变换方式发展而来的,相关细节请查阅文献[17]。模型采用了几个可测量的参数来描述,这些参数包括:剖面波峰高度偏差绝对值的算术平均值,Ra;峰间距的平均值,Rsm。为了完成建模,还必须做以下假设来简化问题:

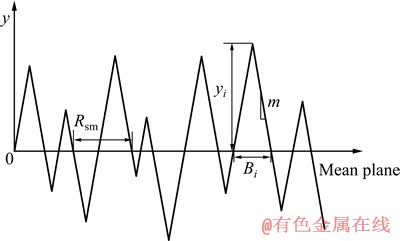

1) 模具表面由连续的波峰和波谷组成,它们的底圆都位于基准面上(y=0),如图1所示;

2) 模具表面所有波峰和波谷均被看成是圆锥体;

3) 模具表面所有波峰和波谷的斜率m的绝对值相同;

4) 模具表面所有波峰和波谷的高度或深度服从高斯分布,函数形式如下:

(1)

(1)

式中:y是任意单个波峰的高度。

图1中的基准面为算术平均基准面,即认为该面上下两端波峰波谷的面积相等。

图1 模具表面形貌纵截面示意图

Fig. 1 Schematic diagram of longitudinal section of die surface

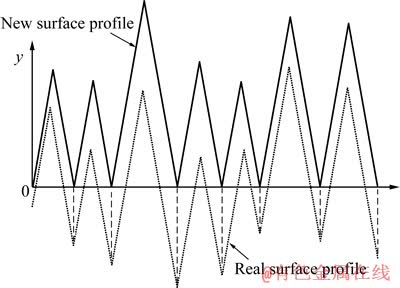

由于当液体和固体接触时,空气会像预期一样被捕获在固体表面微腔的底部,并将固体和液体隔离开,从而实际上决定了接触的质量,进而决定了界面的热传导。因此,当需要定量描述固-液接触界面和该界面上的传热时,被捕获空气的影响是一定要考虑的,所以必须对表面形貌的微结构进行适当的变换。Hamasaiid模型通过扩大微结构的斜率和降低其高度完成了将固体表面所有微结构移到同一平面的变换。因为这种变换改变了微结构的斜率和高度,由于液体表面张力的影响,必然导致固液接触面积的大大增加,从而使模型计算的结果远大于实际,这也是造成Hamasaiid模型的验证中计算结果和实际相差较大的根本原因。

图2 实际模具表面轮廓和转换后模具表面轮廓示意图

Fig. 2 Original topography contours of mold surface (dotted line) and transformed morphology profile (solid line)

为了减少变换过程带来的误差,必须保证微结构斜率不变,因此,本文作者采用平行移动所有微结构到同一平面的变换方法,以保证移动后所有微结构只有高度发生了很小的变化,而斜率和宽度是不变的,如图2所示。变换后表面波峰高度值的分布也将遵循新的分布规律:

(2)

(2)

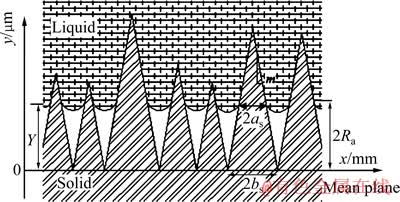

固体表面经过这种等效变换后,固-液接触界面形貌已然变成如图3所示。

图3 变换后的固-液接触纵截面示意图

Fig. 3 Schematic diagram of longitudinal section of solid-liquid interface after transformation

图3中Y是被捕获空气的平均厚度,由于只有高度大于Y的峰能与液体表面接触,故可用Y平面来确定微接触峰的密度ns和平均接触半径as。实际接触峰的密度ns由下面给出:

(3)

(3)

式中:e是空隙因子,近似为1.5;erfc(x)是互补误差函数。平均接触半径可以由下式确定:

(4)

(4)

而底圆的平均半径bs很显然有[17]

(5)

(5)

从以上的分析可以看出,接触峰密度ns和平均接触半径as以及峰底半径平均值bs都是模具表面形貌参数Ra、Rsm和间隙气体平均高度Y的函数。对于已知模具,Ra和Rsm为已知,而Y主要与接触机理(接触压力、表面张力等)有关。假设没有气体逃逸,将被捕获的空气近似看成理想气体,由形貌分析可知,充型前后微腔内空气的平均体积V0和V1可确定如下:

(6)

(6)

(7)

(7)

由式(6)~(7)和理想气体定律,并考虑表面张力的影响,被捕获空气平均厚度的初始值Y0,也是最小值,由下式确定:

(8)

(8)

式中:T1是被捕获空气的温度;P1是浇注完成后铸件高度所产生静压头压力与大气压力P0之和;P(γ)是液态金属的表面张力所产生的背压,可以表示如下:

(9)

(9)

式中: 是液态金属的表面张力;r是附加压力为P(γ)时对应的曲率半径。对于一个已知的铸造过程,式(8)求解的是当铸件为完全液态时的Y值,当液体材料开始凝固或者结晶时,式(8)将不再适用。因此,本研究仅讨论Y0。

是液态金属的表面张力;r是附加压力为P(γ)时对应的曲率半径。对于一个已知的铸造过程,式(8)求解的是当铸件为完全液态时的Y值,当液体材料开始凝固或者结晶时,式(8)将不再适用。因此,本研究仅讨论Y0。

实际中固液接触必然是不完美的,定会在界面处造成收缩而产生传热阻力,即界面热阻。许多文献中提出许多固-固界面接触热阻模型,其中最经典的是热通量管模型[18],而有关固-液界面接触热阻模型的文献非常少[19]。但从LOULOU等[20-21]的研究可以看出,如果将一些附加参数考虑进来,如表面张力和润湿性等,那么热通量管模型也是适用固-液界面的。该模型认为两固体间热流是通过一系列接触半径均为b的微观等温流管来传递的,两固体间的实际接触面是一个半径为c的小圆面,等温流管间的接触热阻可以通过下式来确定[22]:

(10)

(10)

式中:R1和R2是物体1和2在界面的热阻;ψ(ε)是扩散阻力因子,采用最经典的Cooper关系式[18]来表示扩散阻力因子,则固-液界面上单个微观接触点的收缩热阻为

(11)

(11)

(12)

(12)

式中:c是实际接触半径;b是名义接触半径;λ1、λ2是模具和铸件的导热系数。

那么,对于一个给定面积的接触将有大量微接触热阻,它们可以看成是并联连接的,h可以如下表达:

(13)

(13)

式中:bs是微接触点的平均底圆半径;as是平均接触半径。

将式(3)~(5)带入式(13),当Y取到其最小值Y0时,h就变成了hmax且由式(14)确定:

(14)

(14)

2 实验

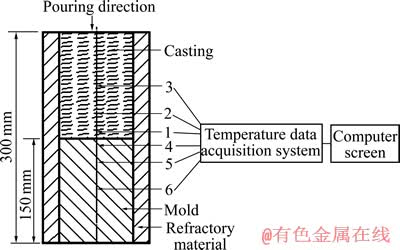

前面已经推导出了固液接触时界面换热系数最大值hmax的预测模型,为验证模型的可行性,本文作者进行金属型重力铸造实验,实验装置和热电偶布置如图4所示。

图4 模具和热电偶布置示意图

Fig. 4 Schematic diagram of mold and thermocouple

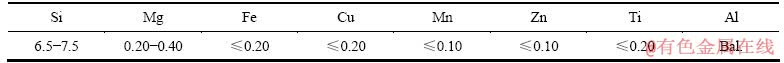

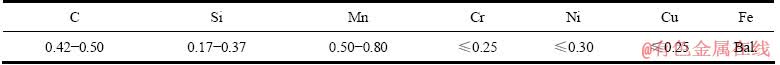

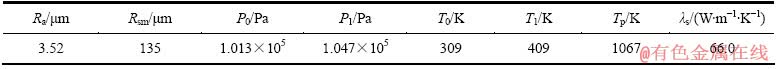

铸件材料为A356铝合金,铸件高度H=150 mm,模具材料为45号钢,两类材料的具体成分如表1和2所列。实验的其它参数,如表面粗糙度、温度、压力等列出如表3所列。

3 结果与分析

3.1 实验测量的温度曲线

表1 A356化学成分

Table 1 Chemical composition (mass fraction, %)

表2 45号钢化学成分

Table 2 45 steel chemical composition (mass fraction, %)

表3 其他实验参数

Table 3 Other experimental parameters

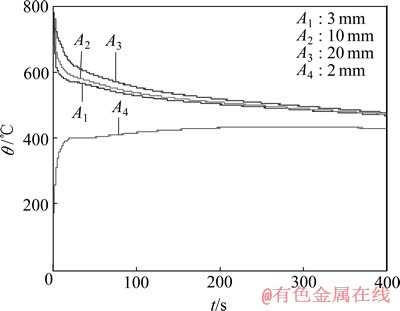

实验测得的铝合金金属型重力铸造过程铸件和模具内部几点的冷却曲线如图5所示,其中A1、A2、A3分别对应的是铸件中心距固液界面3、10和20 mm点测量的冷却曲线,A4是模具中心距固液界面2 mm点测量的冷却曲线。由图5中A1~A3可以看出,初始时铸件各点的温度均急剧下降,且下降的速度从边部到心部逐渐减小,大概从20 s开始3条曲线都陆续出现了转折,首先出现转折的A1甚至出现了一小段平台期,然后才继续下降,但下降的速度逐渐减小;由θ4可以看出,浇注后模具的温度迅速上升,但上升的趋势逐渐减小,也在20 s左右出现了一段平台,然后继续缓慢上升至最大值,随后非常缓慢的下降。

图5 实验测量温度曲线

Fig. 5 Temperature curves measured by thermocouple

3.2 反求的界面换热系数

图6 反求的界面换热系数曲线

Fig. 6 Interface heat transfer coefficient curve calculated by inverse method

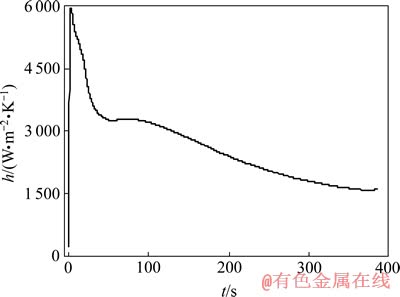

将测量的A1点冷却曲线和相关的参数带入自编的反热传导程序计算所得h—t曲线如图6所示。

由图6可以看出,h—t曲线明显的分为4个阶段。第一阶段大概从开始到约3 s,界面换热系数h急速的增大,在3 s左右达到其最大值hmax,约为5944 W/(m2·K),这个时间几乎与浇注时间差不多,也就是说浇注完成后的一瞬间h就已经达到其最大值;第二阶段约从3 s到50 s左右,h开始迅速下降。从图5可以看出,该阶段初始铸件的温度从底部到心部都在液相线温度(616 ℃)以上,热量仍然大量的从液体金属流向铸型;但随着时间的推移,到该阶段末期,铸件的温度从底部到心部逐渐进入到半固态区,开始凝固收缩,当收缩产生的热应力大于铸件的重力时,便会在界面产生间隙,这使得界面换热效率变得低下;第三阶段约从50 s到100 s左右,由于铸件在不断凝固的过程中,界面间隙的不断扩大使得界面传热的阻力不断增大,传热量不断减小,当铸件凝固释放的相变潜热量与界面传热量相等时就会达到一个动态的热平衡,这就会使得铸件本身的温度变化很小,从而在很大程度上抑制了铸件不断凝固造成的间隙的进一步扩大,并最终使得h在本阶段几乎保持不变,形成了一个平台期;第四阶段从100 s到最后,从本阶段开始,由于铸件几乎完全凝固使得界面的动态热平衡已无法维持,贯穿整个界面的间隙终于形成,铸件和铸型之间的换热方式可能以热辐射和热对流为主,直接接触的热传导换热可能只占整个换热量的很小一部分了。

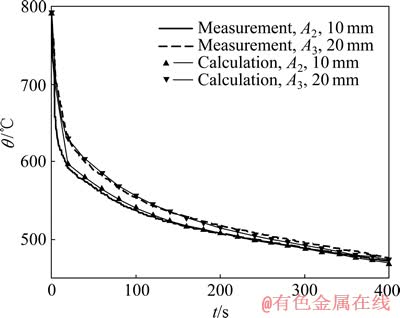

为了证实反热传导程序计算的h—t曲线的准确性,将A2和A3点的程序计算冷却曲线与实验测量冷却曲线同时绘于图7中。由图7可以看出,反求计算值和实验测量值非常的接近,根据计算A2和A3两点的温度绝对误差都在15 ℃以内,90%以上的温度绝对误差在5 ℃以内,由此可见,反热传导程序计算的精度是相当高的,因此程序计算的h—t曲线是非常接近实际的,具有较高的可信度。

图7 反求计算和实验测量的A2和A3点温度曲线

Fig. 7 Temperature curves of A2 by experimental measurements and A3 by inverse heat conduction program calculations

3.3 模型的验证

为验证模型的可行性,必须先将相关实验参数带入模型以计算出hmax。由前面的分析知道,除了P(γ),表3给出了模型计算hmax所需的所有参数。P(γ)是液态金属的表面张力所产生的背压,可以表示如下:

(15)

(15)

式中:γ是液态金属的表面张力;r是附加压力为P(γ)时对应的曲率半径。由式(15)看出,如果知道了液体的表面张力和曲率半径就能求出P(γ)。文献[23-24]给出了纯铝在一定温度范围内的经验公式:

(16)

(16)

文献[25]给出了铝合金在一定温度范围内的经验公式:

(17)

(17)

式中:wSi是硅的质量分数,对于本研究的A356铝合金,wSi取值为7。由式(16)和(17)可推导得本研究铸件所用A356铝合金在一定温度范围内表面张力的经验公式如下:

(18)

(18)

将浇注温度θp带入式(18)得到本次实验A356铝合金表面张力约为0.86 N/m,再由表面形貌分析可得出液体前端的曲率半径与最小平均被捕获空气厚度Y0有如下关系:

(19)

(19)

将式(18)和(19)带入式(15)可得P(γ)是关于Y0的一个函数,在本研究例子中该函数为

(20)

(20)

根据前面的分析,如果考虑液态金属表面张力所产生的背压P(γ)对界面换热的影响,将表3的参数和式(19)带入式(8)求出本例子中的Y0值约为11.26 μm,再将Y0值带入式(3)和(4)得出ns约为6.345×106 m-2,as约为6.193 μm,将它们和所需参数值带入式(14)可求出hmax约为5992 W/(m2·K)。另外,如果不考虑液态金属表面张力所产生的背压P(γ)对界面换热的影响,即认为P(γ)的值为零,则由理论模型计算的hmax约为6228 W/(m2·K)。

由前节分析可知,实验反求的hmax具有相当高的精度,与实际很接近,因此,将模型计算的hmax与之进行对比以验证模型是合理可信的。首先,由图6可知,反热传导程序所得h—t曲线中h只有一个峰值,约为5944 W/(m2·K)。不考虑液态金属表面张力所产生的背压P(γ)时,模型计算的hmax约为6228 W/(m2·K),与实验数据反求的hmax的误差约为5%,精度较高;而考虑液态金属表面张力所产生的背压P(γ)时,模型计算的hmax约为5992 W/(m2·K),与实验数据反求的hmax的误差约为1%,精度很高。另外,采用Hamasaiid模型计算的hmax约为7987 W/(m2·K),误差约为34%。

因此,由上面的分析和比较可知,经本研究改进后,模型的计算精度得到了大幅提升。考虑到计算各个环节带入的舍入误差和一些近似假设带入的误差,模型计算的hmax在未考虑背压P(γ)时仍与实验数据反求的hmax具有较好的一致性,而考虑背压P(γ)时计算精度将得到进一步的提升。此外,未考虑表面张力时(即未考虑背压P(γ)时)模型计算的hmax明显比考虑表面张力时偏大。这是因为当液态金属与模具表面接触时,在外界压力的作用下液态金属有填充到模具表面微腔中的趋势,而表面张力是阻止该趋势发展的一个重要因素,当其被忽略时,液态金属能够填充的实际面积就会增大,也即液态金属与模具表面的接触面积增大,从而使得模型计算的hmax明显偏大。

3.4 Y0对模型计算的影响

由式(14)可知,对于给定的固体表面和液体表面,Ra、Rsm为已知,此时hmax主要取决于被捕获空气平均厚度的最小值Y0,即对模型计算hmax起支配作用的参数是Y0。Y0主要集中体现了浇注温度、铸件高度所产生的静压头压力、表面张力等对模型计算hmax的影响。

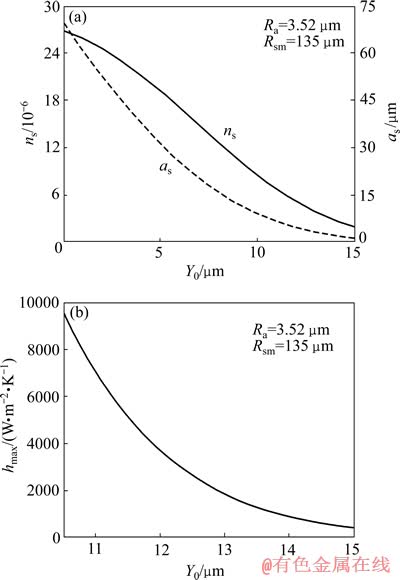

由图8(a)可知,当Y0为0时,ns和as取最大值,而当Y0逐渐增大时,它们都减小并趋近于0。虽然都是随Y0增加而不断减小,但ns和as减小的速度各有不同变化,ns减小的速度经历了一个由慢到快再到慢的过程,而as的减小的速度则是经历了一个由快到慢的过程。由图8(b)可知,hmax随Y0增加而减小,且随着Y0增加,hmax减小的速度也在变小。

图8 Y0对ns、as和hmax的影响

Fig. 8 Effects of Y0 on ns, as (a) and hmax (b)

需要再次强调的是,式(14)只有在模具材料或冷端材料的热物理参数很高,即模具材料或冷端材料的热物理参数远大于被捕获空气的热物性参数时才有意义,因为此时界面热阻远大于物体内部的热阻,是传热的主要阻力,这种情况主要包括金属型铸造等生产过程。如果情况相反,则式(14)计算的hmax将是没有意义的。

3 结论

1) 通过采用新的固体表面微轮廓的变换方式,对Hamasaiid模型进行了改进,提出了新的界面换热系数峰值计算模型。该模型可应用于情况较复杂的界面换热系数峰值的估算。

2) A356铝合金金属型铸造实验验证结果表明,反求计算的hmax约为5944 W/(m2·K),采用Hamasaiid模型计算的hmax约为7987 W/(m2·K),误差约为34%,而改进后模型计算的hmax约为6228 W/(m2·K),误差约为5%,相对于前者,模型的计算精度大幅提升。

3) 通过对液体表面张力的背压P(γ)和曲率半径r的考虑,液体表面张力γ对固-液接触界面换热的影响被定量的引入到预测模型。与反求计算结果的比较表明,考虑了液体表面张力影响的模型计算结果误差约为1%,低于未考虑时的5%,这说明表面张力对固-液界面换热是有一定程度影响的。

4) 对于给定的铸件和模具,被捕获空气平均厚度最小值Y0将对模型计算hmax起决定性作用。

REFERENCES

[1] FERREIRA I L, SPINELLI J E, NESTLER B, GARCIA A. Influences of solute content, melt superheat and growth direction on the transient metal/mold interfacial heat transfer coefficient during solidification of Sn-Pb alloys[J]. Materials Chemistry and Physics, 2008, 111: 444-454.

[2] CHEUNG N, FERREIRA I L, PARIONA M M, QUARESMA J M V, GARCIA A. Melt characteristics and solidification growth direction with respect to gravity affecting the interfacial heat transfer coefficient of chill castings[J]. Materials and Design, 2009, 30: 3592-3601.

[3] 郭志鹏, 熊守美, 曺尚铉, 崔正吉. 合金材料以及工艺参数对压铸过程中铸件/铸型界面换热系数的影响[J]. 金属学报, 2008, 44(4): 433-439.

GUO Zhi-peng, XIONG Shou-mei, CAO Shang-xuan, CUI Zheng-ji. Effects of alloy materials and process parameters on the heat transfer coefficient at metal/die interface in high pressure die casting[J]. Acta Metallurgica Sinica, 2008, 44(4): 443-439.

[4] KIM T G, LEE Z H. Time-varying heat transfer coefficients between tube-shaped casting and metal mold[J]. Heat Mass Transfer, 1997, 40(15): 3513-3525.

[5] SPINELLI J E, CHEUNG N, GOULART P R, QUARESMA J M V, GARCIA A. Design of mechanical properties of Al-alloys chill castings based on the metal/mold interfacial heat transfer coefficient[J]. International Journal of Thermal Sciences, 2012, 51: 145-154.

[6] SILVA J N, MOUTINHO D J, MOREIRA A L, FERREIRA I L, ROCHA O L. Determination of heat transfer coefficients at metal-mold interface during horizontal unsteady-state directional solidification of Sn-Pb alloys[J]. Materials Chemistry and Physics, 2011, 130: 179-185.

[7] SANTOS C A, QUARESMA J M V, GARCIA A. Determination of transient interfacial heat transfer coefficients in chill mold castings[J]. Journal of Alloys and Compounds, 2001, 319: 174-186.

[8] PRABHU K N, KUMAR S T, VENKATARAMAN N. Heat transfer at the metal/substrate interface during solidification of Pb-Sn solder alloys[J]. Journal of Materials Engineering and Performance, 2002, 11(3): 265-273.

[9] 郭志鹏, 熊守美, 曺尚铉, 崔正吉. 铝合金压铸过程铸件/铸型界面换热行为的研究Ⅱ. 工艺参数对界面换热的影响[J]. 金属学报, 2007, 43(11): 1155-1160.

GUO Zhi-peng, XIONG Shou-mei, CAO Shang-xuan, CUI Zheng-ji. Study on heat transfer behavior at metal/die interface in aluminum alloy die casting process Ⅱ. Effect of process parameters on the interfacial heat transfer[J]. Acta Metallurgica Sinica, 2007, 43(11): 1155-1160.

[10] GUO Zhi-peng, XIONG Shou-mei, LIU Bai-cheng, LI Mei, ALLISON J. Determination of the heat transfer coefficient at metal-die interface of high pressure die casting process of AM50 alloy[J]. International Journal of Heat and Mass Transfer, 2008, 51: 6032-6038.

[11] KUMAR T S P, KAMATH H C. Estimation of multiple heat-flux components at the metal/mold interface in bar and plate Aluminum alloy castings[J]. Metallurgical and Materials Transactions B, 2004, 35(B): 575-585.

[12] SUN Zhi-zhong, HU H, NIU Xiao-ping. Determination of heat transfer coefficients by extrapolation and numerical inverse methods in squeeze casting of magnesium alloy AM60[J]. Journal of Materials Processing Technology, 2011, 211: 1432-1440.

[13] AWEDA J O, ADEYEMI M B. Experimental determination of heat transfer coefficients during squeeze casting of aluminium[J]. Journal of Materials Processing Technology, 2009, 209: 1477-1483.

[14] HAMASAIID A, DOUR G, DARGUSCH M S, LOULOU T, DAVIDSON C, SAVAGE G. Heat-transfer coefficient and in-cavity pressure at the casting-die interface during high-pressure die casting of the magnesium alloy AZ91D[J]. Metallurgical and Materials Transactions A, 2008, 39(A): 853-864.

[15] HAMASAIID A, DARGUSCH M S, DAVIDSON C J, TOVAR S, LOULOU T, REZAI-ARIA F, DOUR G. Effect of mold coating materials and thickness on heat transfer in permanent mold casting of aluminum alloys[J]. Metallurgical and Materials Transactions A, 2007, 38(A): 1303-1316.

[16] COATES B, ARGYROPOLULOS S A. The effects of surface roughness and metal temperature on the heat-transfer coefficient at the metal mold interface[J]. Metallurgical and Materials Transactions B, 2007, 38(B): 243-255.

[17] HAMASAIID A, DARGUSCH M S, LOULOU T, DOUR G. A predictive model for the thermal contact resistance at liquid-solid interfaces: Analytical developments and validation[J]. International Journal of Thermal Sciences, 2011, 50: 1445-1459.

[18] COOPER M G, MIKIC B B, YOVANOVICH M M. Thermal contact conductance[J]. International Journal of Heat and Mass Transfer, 1969, 12(3): 279-300.

[19] HEICHAL Y, CHANDRA S. Predicting thermal contact resistance between molten metal droplets and a solid surface[J]. Journal of Heat Transfer, 2005, 127: 1269-1275.

[20] LOULOU T, ARTYUKHIN E A, BARDON J P. Estimation of thermal contract resistance during the first stages of metal solidification process: Ⅱ—Experimental setup and results[J]. International Journal of Heat and Mass Transfer, 1999, 42: 2129-2142.

[21] LOULOU T, ARTYUKHIN E A, BARDON J P. Estimation of thermal contact resistance during the first stages of metal solidification process: Ⅰ—Experiment principle and modelisation[J]. International Journal of Heat and Mass Transfer, 1999, 42: 2119-2127.

[22] BAHRAMI M, CULHAM J R, YOVANOVICH M M, SCHNEIDER G E. Review of thermal joint resistance models for non-conforming rough surfaces in a vacuum[C]// ASME Summer Heat Transfer Conference 2003. Las Vegas, Nevada, USA: American Society of Mechanical Engineers, 2003: 411-431.

[23] DOU Lei, YUAN Zhang-fu, LI Jian-qiang, WANG Xiao-qiang. Surface tension of molten Al-Si alloy at temperatures ranging from 923 to 1123 K[J]. Chinese Science Bulletin, 2008, 53(17): 2593-2598.

[24] KEENE B J. Review of data of surface tension of pure metals[J]. Int Mater Rev, 1993, 38(4): 157-192.

[25] GOICOECHEA J, GARCIA-CORDOVILLA C, LOUIS E, PAMIES A. Surface tension of binary and ternary aluminium alloys of the systems Al-Si-Mg and Al-Zn-Mg[J]. Journal of Materials Science, 1992, 27: 5247-5252.

(编辑 李艳红)

基金项目:国家“十二五”科技支撑计划资助项目(2011BAG03B02);国家自然科学基金面上资助项目(51075132);湖南大学汽车车身先进设计与制造国家重点实验室自主课题资助项目(61075005)

收稿日期:2013-07-11;修订日期:2013-10-13

通信作者:李落星,教授,博士;电话:0731-88821445;E-mail: llxly2000@163.com