采用新型发泡剂制备泡沫铝

周向阳, 刘希泉, 李 劼, 刘宏专

(中南大学 冶金科学与工程学院, 长沙 410083)

摘 要: 研究了一种在泡沫铝制备过程中可替代TiH2及ZrH2类发泡剂的新型发泡粉末的热分解行为, 探讨该新型发泡剂加入量及发泡温度等因素对泡沫铝孔隙率的影响。 研究表明: 该新型发泡材料具有分解温度范围宽及分解过程缓慢的特点。 当采用该发泡剂时, 泡沫铝制备过程无需额外加入金属Ca类增粘剂; 随发泡温度的升高, 泡沫铝的孔隙率先升高后下降; 随发泡剂量的增多, 发泡体中的无泡层逐渐减少, 当发泡剂的加入量在1.40%以上时, 发泡体中的无泡层消失; 在发泡温度740℃、 发泡剂加入量1.40%~2.20%、 搅拌时间3min、 保温发泡时间5min的条件下, 可以制备出孔径2~5mm, 孔隙率60%~80%, 孔隙基本均匀且无实心体的泡沫铝。

关键词: 泡沫铝; 发泡剂; 热分解行为; 无泡层; 孔隙率 中图分类号: TG146.2

文献标识码: A

Preparation of aluminum foam using novel foaming agent

ZHOU Xiang-yang, LIU Xi-quan, LI Jie, LIU Hong-zhuan

(School of Metallurgical Science and Engineering, Central South University,Changsha 410083, China)

Abstract: The thermal decomposition behavior of a novel foaming agent substituting for TiH2 and ZrH2 during the preparation process of aluminum foam was investigated. The effects of the foaming agent content and foaming temperature on the porosity of aluminum foam were also discussed. The experimental results show that the novel foaming agent has a wide decomposition temperature range and a slow decomposed rate; the extra viscosifier such as Ca is unnecessary while using this foaming agent; the porosity firstly increases and then decreases with foaming temperature rising; the free-bubble layer in material decreases with foaming agent addition increasing, and the free-bubble layer disappears while foaming agent addtion is more than 1.4%; an aluminum foam product characterized by no free-bubble layer, uniform bubble distribution, pore sizes of 2-5mm and porosity of 60%-80% can be obtained under the conditions the foaming temperature 740℃, foaming agent addition 1.40%-2.20%, stirring time 3min and foaming time 5min.

Key words: aluminum foam; foaming agent; thermal decomposition behavior; free-bubble layer; porosity

泡沫铝所具有的低密度、 高刚度、 冲击吸能性、 低导热率、 低磁导率和良好阻尼性等特性, 使得其在许多高科技领域及一般工业领域的应用受到了越来越广泛的重视。 泡沫铝的制备方法有熔体吹气发泡法、 熔体发泡剂发泡法、 渗流铸造法、 粉末冶金法等, 其中熔体发泡法为最容易实现连续化大规模生产的方法之一[1-5]。

常规的熔体发泡法包括熔体熔化、 增粘、 快速搅拌、 加入发泡剂(TiH2和ZrH2等)保温发泡及冷却等工序。 但这种常规熔体发泡法仍然存在不少缺陷。 主要表现在: 1) 所采用TiH2及ZrH2类发泡剂的价格昂贵; 且其分解温度范围为380~820℃, 600℃时分解速率相当快, 从其加入熔体、 并形成气泡的时间相当短暂, 这使得气泡在熔体中的分布和长大相当难控制, 也使得泡沫铝制备过程中的控制条件(包括发泡温度、 时间及搅拌强度等)相当苛刻, 还使得它们只适用于制备某些低熔点的铝合金泡沫[6-8]; 2) 该工艺通常需要一个增粘过程, 增粘温度范围通常在800~900℃之间, 并且所用的增粘材料通常是价格比较贵的金属钙或者是氧化铝、 碳化硅等陶瓷颗粒[7, 9-11], 这会增加泡沫铝的生产能耗及成本; 3) 这类发泡剂制备泡沫铝时, 粘度控制不当会产生实心体, 降低生产效率和成品率[12]; 4) 加入金属钙作为增粘剂时, 热处理对泡沫铝的硬度不会提高[13]; 5) 发泡剂TiH2及ZrH2往往需要预处理[14-15]。 正是由于这些缺陷, 导致了泡沫铝的生产成本居高不下, 也限制了泡沫铝的大规模商业化应用。 因此, 研制新型发泡剂及研究泡沫铝的低成本制备工艺意义相当重大。 本文作者研究了一种新型发泡剂的热分解行为, 以及使用该发泡剂的泡沫铝制备工艺。

1 实验

1.1 泡沫铝样品的制备

泡沫铝样品的制备步骤包括: 1) 将铝锭在坩埚中熔化并升温到700~780℃后进行保温(该温度即为发泡温度); 2) 在1000r/min的搅拌速度下, 均匀地将计量好的新型发泡剂加入铝熔体中, 发泡剂加完后再继续搅拌3min, 提起搅拌桨, 然后在该温度下保温5min, 最后将坩埚提出熔炼电炉, 空冷即制得泡沫铝样品。

1.2 性能测试与表征

采用DSC-DTA测试技术分析所合成发泡剂的热分解行为。 所用设备为美国TA公司生产的SDT Q600型测试仪。 将少量的发泡剂样品置于样品皿中, 在100mL/min的空气流量下升温至800℃, 升温速度为5K/min。

采用高像素数码相机(SONY, DSC-P10)对切割后试样的宏观断面形貌拍照, 并观测孔径的大致范围。

采用文献[16]报道的方法测试泡沫铝的孔隙率。

铝熔体发泡效率η计算式为

2 结果与讨论

2.1 发泡剂热分解行为分析

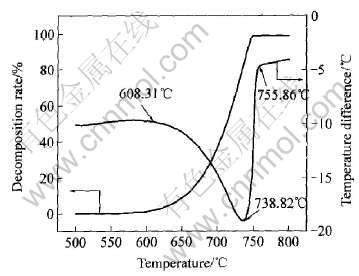

图1所示为所研制新型发泡剂在500~800℃温度段的分解速率曲线与DTA曲线。 显然, 该发泡剂在608.31℃才开始分解; 随着温度的升高, 分解速率缓慢上升; 650℃以上分解速率才开始快速增大, 700~750℃之间的分解速率上升较快; 最大吸热峰的位置在738.82℃处, 当温度达755.86℃时反应基本结束。 在本研究的升温速率下(5K/min), 整个分解反应过程持续长达29.5min。

图1 发泡剂的分解速率和温差—温度曲线

Fig.1 Decomposition rate and DTA curves of foaming agent

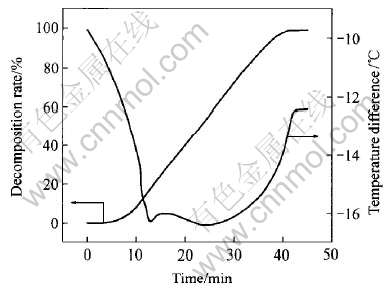

图2所示为所研制发泡剂在680℃恒温条件下的分解速率及DTA曲线。 由图可知, 在680℃恒温条件下的分解速率变化曲线接近一条直线, 并且在680℃下分解完全的时间长达40min。 这说明该发泡剂在680℃是一个缓慢均速分解的过程。 因为泡沫纯铝的一般发泡温度在680~740℃之间, 从以上分析可知, 所研制的发泡剂完全可以代替TiH2制备泡沫纯铝及泡沫铝合金; 并且因为该发泡剂的分解时间长, 从而使得泡沫铝制备过程中的各种条件(包括温度、 时间及搅拌强度等)没有使用TiH2作发泡剂时的苛刻, 可以很从容地通过调整发泡剂的搅拌和保温发泡时间来达到控制最终泡沫铝孔隙率的目的。

图2 680℃恒温时发泡剂的分解速率和温差—时间曲线

Fig.2 Decomposition rate and DTA-temperature curves of foaming agent at 680℃

另外, 所合成新型发泡剂在600~700℃分解缓慢的特点, 为两步法制备各种异型的泡沫铝或泡沫铝合金型材提供了可能。 两步法是指首先在较低的温度下(600~700℃), 将发泡剂加入并搅拌均匀 后铸成含未分解或只有少量分解发泡剂的铸锭, 然后将铸锭通过挤压或锻造等方式变形成所需形状的前驱体, 最后将此前驱体加热至发泡温度保温发泡一段时间, 从而制得泡沫铝型材。

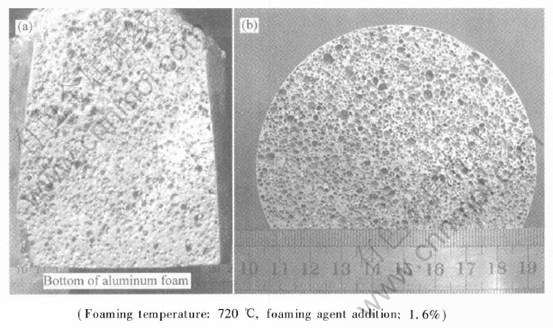

图3所示为采用所合成发泡剂、 在720℃发泡所制备泡沫铝试样的整体和局部形貌照片。 可以看出, 所制备泡沫铝试样底部无实心体, 泡沫铝中各孔洞分布基本均匀, 并且各孔的孔径在2~5mm之间, 测试结果还表明该泡沫铝的孔隙率达到了70%。 2.2 发泡温度的确定及对泡沫铝孔隙率的影响

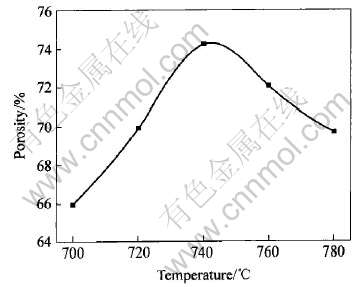

纯铝的熔点为660℃。 在发泡阶段, 由于发泡剂在分解过程中吸收热量, 会使得熔体温度有较大下降[17]。 因此, 分别选取700、 720、 740、 760、 780℃ 5个温度点来考察发泡温度对泡沫孔隙率的影响。 所用新型发泡剂的加入量为1.60%。

不同发泡温度下泡沫铝孔隙率的变化如图4所示。 可以看出, 发泡温度低于740℃时, 随着温度的升高, 孔隙率逐渐增大; 发泡温度为740℃时, 孔隙率达到最大值, 为74.25%; 当发泡温度超过740℃时, 孔隙率反而逐渐下降。 出现这种现象的原因可能是: 在发泡时间、 保温时间及搅拌强度一定的情况下, 发泡温度影响熔体的粘度和发泡剂分解产生的气体量。 如果发泡温度过低, 发泡剂分解速率相对缓慢, 产生的气体量和压力就小, 从而会使得熔体中的气泡量少; 另外, 低温下熔体的粘度较大, 气泡所受的粘滞力阻止气泡的长大, 也会抑制发泡剂的进一步分解, 从而会使得泡沫体中的气泡量少且气泡较小, 最终的结果是使得泡沫体的孔隙率低下。 随发泡温度的升高, 发泡剂分解速率加快, 气体膨胀加快, 泡沫铝样品的孔隙率和孔径也相应地增大; 但如果发泡温度太高, 熔体的粘度将变小, 此时发泡气体的急剧增多会引起试样体积的急剧膨胀, 气泡间液膜变薄导致大气泡互相并聚连通, 部分气泡还会逸出熔体外, 导致泡沫体孔隙率降低[16]。

图3 用新型发泡剂制备的泡沫铝试样的剖面形貌照片

Fig.3 Macro-shape section photograph of aluminum foam sample prepared with novel foaming agent

图4 发泡温度对孔隙率的影响

Fig.4 Effect of foaming temperature on porosity

2.3 发泡剂加入量对泡沫铝孔隙率的影响

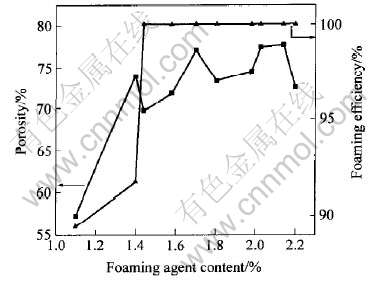

所采取的发泡温度为740℃, 所选择的发泡剂加入量在1.10%~2.20%之间。 发泡剂加入量与泡沫铝孔隙率和发泡效率的关系如图5所示。 可以看出, 发泡剂加入量为1.10%时, 发泡效率为89.41%, 孔隙率为57.27%; 当发泡剂的量增加到1.40%, 发泡效率为91.73%, 孔隙率上升到74.00%; 当发泡剂的量进一步增加, 超过1.40%时, 发泡效率上升到100%, 即完全没有实心体存在; 发泡剂加入量为2.00%和2.15%时, 孔隙率分别达到77.47%和77.75%。 但当发泡剂的加入量大于2.20%时, 实验发现, 熔体的粘度太大, 发泡剂的加入、 搅拌、 分散均匀存在一定的困难。 也就是说, 当本新型发泡剂在1.40%~2.20%范围内变化时, 可实现100%的发泡效率。

图5 发泡剂的加入量对孔隙率和发泡效率的影响

Fig.5 Effects of foaming agent content on porosity and foaming efficiency

3 结论

1) 所研制的新型发泡剂具有分解温度宽(608.31~755.86℃), 分解速率平缓(680℃恒温条件下近40min才完全分解)的特点, 可以代替TiH2来制备泡沫铝。

2) 随发泡温度的升高, 泡沫铝的孔隙率先提高后下降; 随发泡剂量的增多, 发泡体中的实心部分逐渐减少, 当发泡剂的加入量在1.40%以上时, 可实现无实心体泡沫铝的制备。

3) 用该发泡剂制备泡沫铝时, 制备过程无需增粘。

4) 在发泡温度740℃左右、 发泡剂加入量1.40%~2.20%、 搅拌时间3min、 保温发泡时间5min条件下, 可以制备出孔径2~5mm、 孔隙率60%~80%、 孔隙基本均匀且无实心体的泡沫铝。

REFERENCES

[1]Degischer H P, Kriszt B. 多孔泡沫金属[M]. 左孝青, 周芸, 译. 北京: 化学工业出版社, 2005: 1-16.

Degischer H P, Kriszt B. Handbook of Cellular Metal: Production, Processing, Applications[M]. ZUO Xiao-qing, ZHOU Yun, transl. Beijing: Chemical Industry Press, 2005: 1-16.

[2]周向阳, 龙波, 刘红专, 等. 轻合金泡沫材料制备技术研究进展[J]. 材料导报, 2005, 19(9): 61-63.

ZHOU Xiang-yang, LONG Bo, LIU Hong-zhuan, et al. Development of light alloy foam materials preparation technology[J]. Materials Review, 2005, 19(9): 61-63.

[3]Asholt P. Aluminium foam produced by the melt foaming route process, properties and applications[A]. Proceedings of Metal Foams and Porous Metal Structures[C]. Bremen: MIT Press-verlag, 1999: 133-138.

[4]Gaillard C, Despois J F, Mortensen A. Processing of NaCl powders of controlled size and shape for the microstructural tailoring of aluminium foams[J]. Mater Sci Eng A, 2004, 374: 250-262.

[5]Kanahashi H, Mukai T, Yamada Y, et al. Experimental study for the improvement of crashworthiness in AZ91 magnesium foam controlling its microstructure[J]. Mater Sci Eng A, 2001, 308 : 283-287.

[6]吴照金, 王艳明, 何德坪. 铝熔体泡沫化制备胞状铝的研究进展[J]. 铸造, 1999(4): 1-5.

WU Zhao-jin, WANG Yan-ming, HE De-ping. Research advances in the foamed process of cellular aluminum[J]. Foundry, 1999(4): 1-5.

[7]王政红, 陈派明. 发泡法制备泡沫铝[J]. 材料开发与应用, 1998, 13(3): 30-32.

WANG Zheng-hong, CHEN Pai-ming. Fabrication of foamed aluminum by foaming Technique[J]. Development and Application of Materials, 1998, 13(3): 30-32.

[8]戴戈, 何德坪, 尚金堂. 铝合金泡沫化过程中粘度的变化[J]. 材料研究学报, 2005, 19(1): 35-41.

DAI Ge, HE De-ping, SHANG Jin-tang. Change of viscosity in the foamed process of Al alloy metal[J]. Chinese Journal of Material Research, 2005, 19(1): 35-41.

[9]罗洪杰, 姚广春, 张晓明, 等. 闭孔泡沫铝材料制备过程中气泡的形成与演化[J]. 中国有色金属学报, 2004, 14(8): 1377-1381.

LUO Hong-jie, YAO Guang-chun, ZHANG Xiao-ming, et al. Formation and evolution of bubble in fabricating closed-cell aluminum foam[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(8): 1377-1381.

[10]左孝青, 周芸, 赵国宾, 等. CaCO3发泡剂制备泡沫铝工艺研究[J]. 稀有金属, 2004, 28(1): 195-198.

ZUO Xiao-qing, ZHOU Yun, ZHAO Guo-bin, et al. Preparation of aluminum foam by CaCO3 foaming agent[J]. Chinese Journal of Rare Metals, 2004, 28(1): 195-198.

[11]刘荣佩, 田鹏, 吴新光, 等. SiCp增强泡沫铝基复合材料制备工艺及润湿性研究[J]. 稀有金属, 2004, 28(1): 21-24.

LIU Rong-pei, TIAN Peng, WU Xin-guang, et al. Fabricating process of SiC particle-reinforced aluminum foam matrix composite and its wettability[J]. Chinese Journal of Rare Metals, 2004, 28(1): 21-24.

[12]罗洪杰, 姚广春, 刘宜汉, 等. 粉煤灰增黏制备泡沫铝材料的研究[J]. 东北大学学报(自然科学版), 2005, 26(3): 274-277.

LUO Hong-jie, YAO Guang-chun, LIU Yi-han, et al. Fabrication of aluminum foam with fly ash as viscosifier[J]. Journal of Northeastern University (Natural Science), 2005, 26(3): 274-277.

[13]李杰锋, 余焜, 何德坪. 钙的添加对铝合金热处理性能的影响[J]. 东南大学学报(自然科学版), 2003, 33(2): 153-155.

LI Jie-feng, YU Kun, HE De-ping. Effect of calcium additions on the heat treatment properties of aluminum alloy[J]. Journal of Southeast University (Natural Science Edition), 2003, 33(2): 153-155.

[14]方吉祥, 赵康, 谷臣清. 化学法制备Al2O3包覆TiH2颗粒发泡剂[J]. 中国有色金属学报, 2002, 12(6): 1205 -1209.

FANG Ji-xiang, ZHAO Kang, GU Chen-qing. Pre-paration of Al2O3-coated TiH2 foaming reagent by chemical method[J]. The Chinese Journal of Nonferrous Metals, 2002, 12 (6): 1205 -1209.

[15]王红怡, 赵军, 宋苇, 等. TiH2的SiO2凝胶包裹对其释氢的影响[J]. 东南大学学报(自然科学版), 1999, 29(6): 145-148.

WANG Hong-yi, ZHAO Jun, SONG Wei, et al. Effect of SiO2 gel coating of TiH2 on its hydrogen liberation[J]. Journal of Southeast University (Natural Sicence Edition), 1999, 29(6): 145-148.

[16]王芳, 王录才. 发泡温度对泡沫铝孔结构的影响及机理分析[J]. 太原重型机械学院学报, 2003, 24(1): 70-72.

WANG Fang, WANG Lu-cai. Influence of foaming temperature on the pore structure of aluminum foam and analysis of its mechanism[J]. Journal of Taiyuan Heavy Machinery Institute, 2003, 24(1): 70-72.

[17]储少军, 吴铿, 牛强, 等. 铝合金熔体发泡过程的工艺参数控制[J]. 化工冶金, 1998, 19(3): 260-265.

CHU Shao-jun, WU Keng, NIU Qiang, et al. Control of foaming of Al alloy melt[J]. Engineering Chemistry & Metallurgy, 1998, 19(3): 260-265.

(编辑陈爱华)

收稿日期: 2006-06-04; 修订日期: 2006-09-21

通讯作者: 周向阳, 博士; 电话: 0731-8836329; E-mail: 13908482918@hnmcc.com