J. Cent. South Univ. Technol. (2008) 15: 411-417

DOI: 10.1007/s11771-008-0077-9

Passive smart self-repairing concrete beams by using shape memory alloy wires and fibers containing adhesives

KUANG Ya-chuan(匡亚川)1, 2, OU Jin-ping(欧进萍)2, 3

(1. School of Civil and Architectural Engineering, Central South University, Changsha 410075, China;

2. School of Civil and Hydraulic Engineering, Dalian University of Technology, Dalian 116024, China;

3. School of Civil Engineering, Harbin Institute of Technology, Harbin 150090, China)

Abstract: An innovative approach to increase structural survivability of concrete and maintain structural durability of concrete was developed in case of earthquakes and typhoons. This approach takes advantage of the superelastic effect of shape memory alloy(SMA) and the cohering characteristic of repairing adhesive. These SMA wires and brittle fibers containing adhesives were embedded into concrete beams during concrete casting to form smart reinforced concrete beams. The self-repairing capacity of smart concrete beams was investigated by three-point bending tests. The experimental results show that SMA wires add self-restoration capacity, the concrete beams recover almost completely after incurring an extremely large deflection and the cracks are closed almost completely by the recovery forces of SMA wires. The number or areas of SMA wires has no influence on the tendency of deformation during loading and the tendency of reversion by the superelasticity. The adhesives released from the broken-open fibers fill voids and cracks. The repaired damage enables continued function and prevents further degradation.

Key words: self-repairing concrete; shape memory alloy; superelasticity; repairing fiber; repairing adhesive

1 Introduction

Due to the demand of repairing damage and cracks in real time, ensuring the safety and reliability of concrete structures, self-repairing concrete has become a very important research topic and has been developed rapidly in recent years. Self-repairing concretes are embedded adhesives that are released from hollow fibers inside the concrete when cracking of the matrix and the fibers occurs[1-7]. It has been shown that the adhesive effectively improves the strength of cracked portions of the concrete and increases its ability to deflect in a ductile manner under loading. However, the width of the tensile cracks in such materials cannot be easily tuned. Localized fracture leads to continuous increases in crack width under decreasing tensile loading, and rapidly exhausts the amount of chemicals available for crack sealing and concrete re-healing[8]. Thus, in order to make the proposed self-repairing concept work, it is critical to control the tensile crack width; otherwise, large hollow fibers will be needed, which will in turn negatively modify the mechanical properties of the concrete.

Shape memory alloy(SMA) exhibits stable superelasticity above a reverse transformation finish temperature. Therefore, it can sufficiently work as a superelastic material to handle macro-size cracks for structural use in building[9-12]. This motivates us to develop a type of passive smart self-repairing concrete to increase the survivability in case of earthquakes and typhoons, and maintain structural durability by regaining mechanical properties (repairing) and water tightness (sealing) of concrete structures, and by combining with the deflection self-restoration characteristics of the SMA wires and the adhesive due to the cohering characteristic. It is done in response to the superelasticity and no external power supply, and is, therefore, a passive mode repairing.

In this work, the capacity of self-restoration of simple concrete beam driven by the superelasticity of SMA wires was investigated experimentally and experiment results were systemically analyzed. Next, the concept of a passive smart self-repairing concrete was described. Finally, experimental confirmation of the passive smart self-repairing concrete was presented.

2 Superelasticity of SMA and SMA concrete

2.1 Characteristics of materials

SMA is a smart material with two useful forms: the shape memory form which enables a prescribed shape change upon heating and the superelastic form. In recent years, increasing research effort has been made in using shape memory alloy materials for civil structures to survive extreme events such as earthquakes[13-17]. The most widely used alloy is an alloy of nickel and titanium, namely Nitinol. This particular alloy is of very good electrical and mechanical properties, long fatigue life, and high corrosion resistance[18-20].

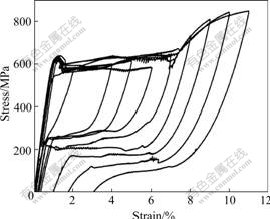

The transformation temperature is set for SMA to exhibit superelasticity at room temperature. The SMA wire used in this work is a Ni-50.8%Ti (mass fraction) wire made in China. The differential scanning calorimetry(DSC) tests result shows that the martensite start temperature of the alloy is -56.1 ℃, the martensite finish temperature is -84.6 ℃, the reverse transforma- tion start temperature is -15.5 ℃, and the reverse trans- formation finish temperature is 12.1 ℃. The ultimate tensile strength is about 920 MPa and the ultimate strain is about 19%. Fig.1 shows the measured stress—strain relationship of the SMA wire, indicating that the SMA wire exhibits good superelasticity.

Fig.1 Stress—strain curves of SMA wire

2.2 SMA concrete

Nitinol SMA wires are embedded into a concrete during fabrication to form a SMA concrete by taking advantage of the superelastic effect of SMA. During the loading, the embedded SMA wires deform together with the concrete members. In the presence of damage and cracks due to earthquake and typhoons, SMA wires incur great deformation. Once these mobile loads are removed, SMA wires will exert large forces to cause deflection reverse and cracks close by the superelasticity of SMA wires. Therefore, the concrete becomes intelligent since it has the ability of self-restoration.

2.2.1 Experimental design and method

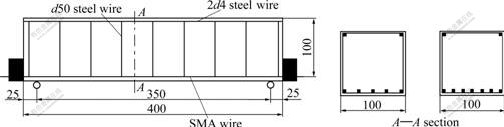

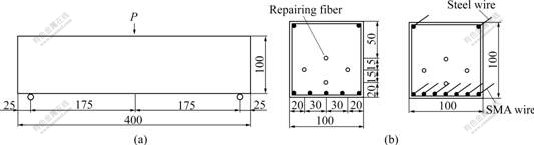

The specimens used in this experiment were the reinforced normal concrete beams (100 mm sides in cross-section and 400 mm in length). The maximum aggregate size was 6 mm for all the specimens. Fig.2 shows the details and dimensions of the specimen. To obtain a reliable anchorage for the end of SMA wires, steel blocks were attached on both ends of the beam and the SMA wires were fixed in holes of the steel blocks through the frictional forces generated between screws and the SMA wires. The main reinforcements were SMA wires (500 mm in length and 2.0 mm in diameter) in tensile area. The diameter of the hoops was 3 mm and their pitch was 50 mm. Three specimens were tested: a concrete beam reinforced with 5 main bars of SMA evenly arranged at the bottom of the section along the longitudinal axis (specimen L1), a control concrete beam with 2 main bars of steel wires of 4.0mm in diameter arranged at the bottom of the section (specimen L2), and a similar beam to L1 with 7 main bars of SMA (specimen L3). The concrete cover thickness of the wires was 9 mm.

The specimens were tested at the age of 28 d. Bending tests were conducted with an MTS apparatus. A concentrated load was applied to the center of the beam with a static deformation rate, in the orthogonal direction to the beam’s axis. The span of the beam was 350 mm by placing the center of the bottom supports 25 mm away from the edges. The external load and the deflection at the center of the specimen orthogonal to its axis were recorded automatically by a data acquisition system. A crack scale was used to measure the crack widths at each peak loading and unloading points under loading cycles.

2.2.2 Capacity of self-restoration

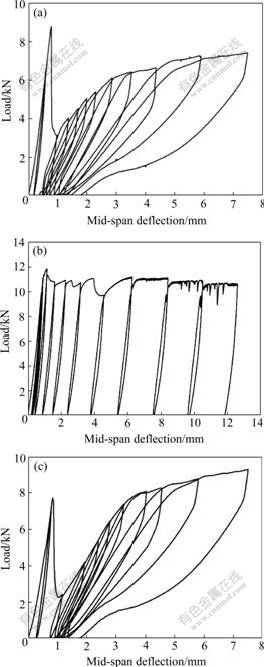

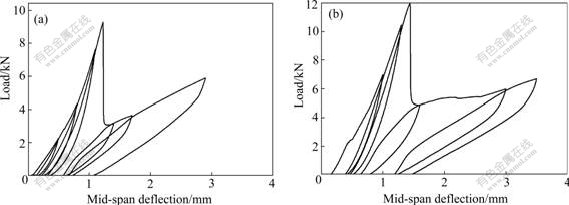

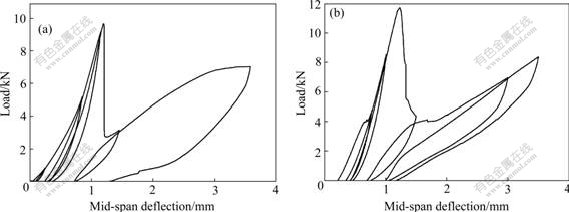

Figs.3(a)-(c) show the relationship between load and mid-span deflection of specimens L1, L2 and L3, respectively. In the beam reinforced by SMA wires, an abrupt decrease of load is observed immediately after a crack is generated, because the concrete has no more resistance to tensile stress. The load then constantly

Fig.2 Dimensions and SMA wires details of specimen (unit: mm)

Fig.3 Curves of load vs mid-span deflection: (a) Specimen L1; (b) Specimen L2; (c) Specimen L3

increases until load removal. When the beam with SMA is unloaded after it incurs an extremely large deflection, the deflection recovers almost completely by the superelasticity of the SMA wires, as shown in Figs.3(a) and (c).

For specimen L2 reinforced by steel wires, when the mid-span deflection exceeds 2 mm, the load is relatively constant, as shown in Fig.3(b). After the mid-span defection exceeds 8 mm, the load decreases and the main reinforcements finally fail. When specimen L2 is unloaded after it incurs an extremely large deflection, the deflection recovers hardly, compared with specimens L1 and L3 reinforced by SMA wires.

For specimen L3, the curve of load vs mid-span deflection is similar to that of specimen L1. In other words, both the deformation tendencies of specimens L1 and L3 during loading and unloading are similar. The residual crack width after unloading is almost the same for specimens L1 and L3, and does not relate to the number of SMA bars. But specimen L3 can carry more loads than specimen L1 at identical deflection because there are more main bars of SMA in specimen L3 than in specimen L1. This indicates that increasing the number or areas of SMA wires can effectively increase the bearing capacity and stiffness of concrete beam.

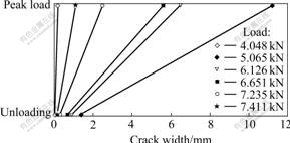

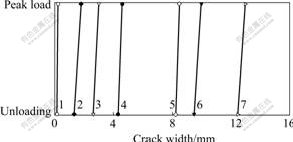

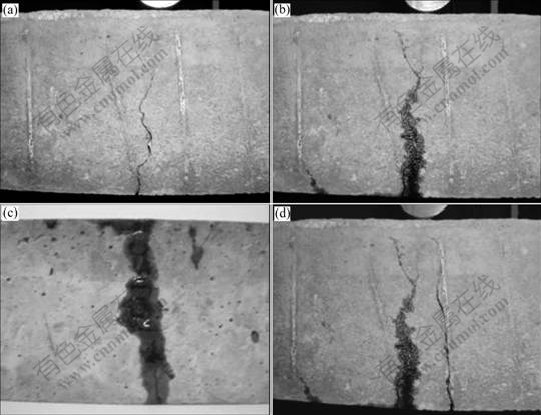

Figs.4(a) and (b) show crack behavior of specimen L1 at the maximum deflection and after unloading, respectively. These figures clearly show that the crack under maximum deflection almost closes after unloading. Figs.5 and 6 show the variation in crack width for specimens L1 and L2, respectively, at peak load and unloading on several cycles after the crack is generated. After unloading, the residual crack width of specimen L1 is almost equal, but that of specimen L2 tends to rapidly increase with crack width increasing at hysteresis peaks.

Fig.4 Crack behavior of specimen L1: (a) At maximum deflection; (b) After unloading

3 Passive smart self-repairing concrete

3.1 Passive self-repairing concrete concept

In all of the SMA-reinforced beams, it can be

Fig.5 Crack width at center of specimen L1

Fig.6 Crack width at center of specimen L2: 1—11.346 kN; 2—10.713 kN; 3—10.938 kN; 4—11.159 kN; 5—11.212 kN; 6—11.104 kN; 7—10.919 kN

observed that the deformation and the width of the crack or gap of the beams increase during loading, but the deflection recovers almost completely and the crack almost closes after unloading. This clearly indicates that using SMA as main bars of the concrete beams can increase the self-restoration capacity to concrete beams. Unfortunately, the cracked concrete itself is not indeed repaired in SMA self-repairing concrete. Therefore, the cracks experience reopening during reloading.

The passive smart self-repairing concrete can maintain material and structural durability by regaining mechanical properties (repairing) and water tightness (sealing) in concrete structures, and increase concrete structural survivability in the case of being damaged due to overloading. The passive smart self-repairing concept becomes feasible by taking advantages of the deflection self-restoration characteristics of the SMA self-repairing

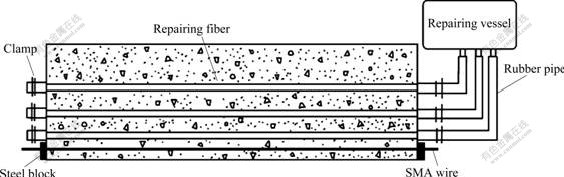

concrete and the repairing adhesives due to the cohering and sealing properties. The superelastic SMA wires and brittle fibers containing adhesives are placed in tension areas of structural members caused by loading before fabricating. To obtain enough adhesive for repairing cracks, the fibers are connected with outer vessel containing repairing adhesive by rubber pipes. The adhesive in vessel can be supplied and regained. In the presence of damage and cracks due to overloading, such as earthquakes and typhoons, fibers around the cracked areas rupture. Once these mobile loads are removed, the superelasticity of SMA wires will recover the deflections and deformation of structural members. At the same time, the switch of the repairing vessel containing adhesives is turned on and repairing adhesives flow out from the broken-open fibers to fill/repair the crack. Fig.7 shows the sketch map of the passive smart self-repair concrete.

3.2 Experimental confirmation

To demonstrate the feasibility of the concept of passive smart self-repairing concrete, two specimens containing SMA wires reinforced bars and adhesive-filled brittle fibers were designed and conducted. Fig.8 shows the details and dimensions of the specimen. Four adhesive-filled glass fibers (6.0 mm in diameter and 0.6 mm in thickness) were distributed along the longitudinal axis below the neutral axis of the beam. A low viscosity epoxy adhesive was served as the sealing/repairing chemicals. To obtain enough adhesive for repairing cracks, the fibers were connected with outer vessel containing repairing adhesive by rubber pipes. The main SMA wires and hoops in specimens L4 and L5 were identical to those in specimens L1 and L3, respectively.

The specimens were subjected to a three-point bending test at the age of 28 d. The specimens were first loaded to a certain deformation until an obvious crack appeared near the mid-span of specimens and the repairing fibers in the cracked areas ruptured. Subsequently, the loading was removed and the SMA

Fig.7 Sketch map of passive smart self-repairing concrete

wires returned the deflections of specimens. Meanwhile, the clamp was opened and the adhesive flowed out from the broken-open fibers to fill/repair the crack. Then the test stopped and 10 d was allotted between the first and the second tests. During the period of time, the adhesive was allowed to set-up. After the predetermined time, testing resumed on the specimens, and all information was recorded.

3.3 Experimental results and analysis

Figs.9 and 10 show the relationship between load and mid-span deflection of specimens L4 and L5 in the first and the second test, respectively. Compared Figs.9(a) and 10(a) with Figs.9(b) and 10(b), respectively, it can be observed that the second testing is similar to the previous re-loading. This indicates that the strength of cracked section is repaired and improved by the release of adhesive from the broken-open fibers into the crack, and the cracking loads of specimens L4 and L5 in the second test are increased by 28.6% and 21.2%, respectively. While in general, that is reverse for normal concrete beam reinforced by steel bars.

Fig.11 shows the crack pattern of specimen L4. Visual observations show that after the release of adhesive into the crack from the first loading, stress is redistributed to the un-cracked section where new crack was formed, while the sealed crack remained closed. Therefore, the specimen repaired is able to derive reserve

Fig.8 Experimentation of passive smart self-repairing concrete (unit: mm): (a) Experimental setup sketch; (b) Distribution of SMA wires and fibers

Fig.9 Load vs mid-span deflection curve of specimen L4: (a) First test; (b) Second test

Fig.10 Load vs mid-span deflection curve of specimen L5: (a) First test; (b) Second test

Fig.11 Crack patterns of specimen L4: (a) Crack near mid-span of specimen; (b) Repaired crack by adhesives from broken-open fibers; (c) Repaired crack at bottom of specimen; (d) Original crack from the first loading without reopening and new cracks newly formed

strength from the un-cracked sections. 4 Conclusions

1) The self-restoration capacity of concrete beams reinforced with SMA as main bars is increased, and the deflection of the beams reverses and the crack almost closes completely after the beams incur an extremely large deformation.

2) Increasing the numbers or areas of SMA wires can effectively increase the bearing capacity and stiffness of concrete beams, whereas the tendency of deformation during loading and that of reversion by the superelasticity are identical.

3) Compared with the concrete beams reinforced with SMA wires, the passive smart beam performs better in repairing concrete after damage occurs. The strength of cracked section is repaired and improved by the release of adhesive from the broken-open fibers into the crack. During reloading, the sealed cracks by adhesives remain closed and new cracks are formed near the sealed cracks in the smart concrete beams, while the original cracks experience reopening in the concrete beams reinforced with SMA wires.

References

[1] DRY C. Matrix cracking repair and filling using active and passive modes for smart timed release of chemicals from fibers into cement matrices [J]. Smart Materials and Structures, 1994, 3(2): 118-123.

[2] DRY C. Smart earthquake-resistant materials: Using time-released adhesives for damping, stiffening, and deflection control [C]//SPIE. Proceedings of SPIE. Lyon, France: SPIE, 1996: 958-967.

[3] DRY C. Three designs for the internal release of sealants, adhesive, and waterproofing chemicals into concrete to reduce permeability [J]. Cement and Concrete Research, 2000, 30(2): 1969-1977.

[4] VICTOR C L, YUM M L, CHAN Y W. Feasibility study of a passive smart self-healing cementitious composite [J]. Composites (Part B), 1998, 29(6): 819-827.

[5] OU Jin-ping, KUANG Ya-chuan. Experiments and analysis of concrete material with crack self-repairing performance using embedded capsules filled with adhesive [J]. Acta Mechanical Solida Sinica, 2004, 25(3): 320-324. ( in Chinese)

[6] KUANG Ya-chuan, OU Jin-ping. Experiments and analyses of the self-healing of cracks in reinforced concrete beams with embedded fibers filled with adhesive [J]. China Civil Engineering Journal, 2005, 38(4): 53-59.

[7] KUANG Ya-chuan, OU Jin-ping, LI Dong-sheng. Experimental research on concrete material with crack self-repairing performance using embedded fibers filled with adhesive [J]. Journal of Building Structures, 2006, 27(S): 107-112. ( in Chinese)

[8] KUANG Ya-chuan, OU Jin-ping. Research and progress of concrete materials with crack self-repairing ability as biomaterials [J]. Advances in Mechanics, 2006, 36(3): 406-414. (in Chinese)

[9] YUJI S, YOSHIKAZU K, TOSSHIBUMI F, MASANORI I. Experimental study on enhancement of self-restoration of concrete beams using SMA wire [C]// SPIE. Proceedings of SPIE. Bellingham, USA: SPIE, 2003:178-186.

[10] MA Huai-zhong. Application of shape memory alloy to the structural deformation and control of the crevice [J]. Journal of Northwest Institute of Light Industry, 1998, 16(3): 120-125. ( in Chinese)

[11] SUN G J, SUN S S, XU X D, WU J S. A study on the thermomechanical deformation of elastic beam with embedded shape memory alloy wires [J]. Materials and Deign, 2000, 21(6): 525-528.

[12] SUP C, JUNG J L. The shape control of a composite beam with embedded shape memory alloy ire actuators [J]. Smart Materials and Structures, 1998, 7(5): 759-770.

[13] ARUP K M, IHOSVANY N. Smart prestressing with shape-memory alloy [J]. Journal of Engineering Mechanics, 1998, 124(10): 1121-1128.

[14] LI Hui, LIU Zhi-qiang, OU Jin-ping. Study on damage emergency repair performance of a simple beam embedded with shape memory alloys [J]. Advances in Structural Engineering, 2004, 7(6): 495-502.

[15] WILDE K, GARDONI P, FUJINO Y. Base isolation system with shape memory alloy device for highway bridges [J]. Engineering Structures, 2000, 22(1): 222-229.

[16] DESROCHES R, DELEMONT M. Seismic retrofit of simply supported bridges using shape memory alloys [J]. Engineering Structures, 2002, 24(3): 325-332.

[17] SHIBA K, MASE S, YABE Y, KAZUO T. Active/passive vibration control systems tall building [J]. Smart Materials and Structures, 1998, 7(5): 588-598.

[18] CHEN Gui-jun, ZHU Wei-jun, QIANG Shi-kun. Microstructure and super-elasticity behavior of NiTi alloy [J]. Steel Wire Products, 2003, 29(3): 2-5. (in Chinese)

[19] CUI Li-shan, QI Min, SHI Ping, CHEN Fei-xia, YANG Da-zhi. Output of stress and strain for NiTi shape memory alloy wires [J]. Journal of Functional Materials and Devices, 1996, 2(2): 78-82. (in Chinese)

[20] PLIETSCH R, EHRLICH K. Strength differential effect in pseudoelastic NiTi shape memory alloys [J]. Acta Materialia, 1997, 45(6): 2417-2424.

(Edited by CHEN Wei-ping)

Foundation item: Project(50538020) supported by the National Natural Science Foundation of China; Project(20070421050) supported by China Postdoctoral Science Foundation

Received date: 2007-07-19; Accepted date: 2007-08-30

Corresponding author: KUANG Ya-chuan, PhD; Tel: +86-731-2656540; E-mail: kuangyachuan@mail.csu.edu.cn