文章编号:1004-0609(2008)02-0288-06

LY12铝合金摩擦点焊接头组织及性能

刘克文1, 2,邢 丽1,柯黎明1

(1. 南昌航空大学 材料科学与工程学院,南昌 330063;

2. 江铃汽车股份有限公司 车架厂,南昌 330001)

摘 要:采用摩擦点焊对厚度为2 mm的LY12铝合金进行焊接实验,分析接头的显微组织及力学性能。根据焊点接头的组织特征可将其分为塑性区、动态静止层、热影响区和母材。结果表明:塑性区和动态静止层的晶粒在热和力作用下发生动态再结晶形成细小的等轴晶,热影响区的晶粒在摩擦热作用下长大变粗;搅拌头旋转速度为2 500 r/min,焊接时间为12 s时,可以获得力学性能较好的焊点,焊点的剪切强度达到9.24 kN;焊点的剪切强度随搅拌头旋转速度的增大而增大,随焊接时间的延长先增大后减小;塑性区的显微硬度较高,但略小于母材,接头显微硬度的最小值分布在热影响区;焊点热输入量较多时,接头为Ⅰ型断裂,焊点的剪切强度较高;焊点热输入量较少时,接头为Ⅱ型断裂,焊点的强度较低。

关键词:LY12铝合金;摩擦点焊;显微组织;力学性能

中图分类号:TG 456.9 文献标识码:A

Microstructures and properties of friction stir spot welding joints for LY12 aluminum alloy

LIU Ke-wen1, 2, XING Li1, KE Li-ming1

(1. School of Materials Science and Engineering, Nanchang Hangkong University, Nanchang 330063, China;

2. JMC Frame Plant, Jiang Ling Motors Corporation Ltd., Nanchang 330001, China)

Abstract: Friction stir spot welding(FSSW) of LY12 aluminum sheet with thickness of 2 mm were investigated, the joint microstructures and mechanical properties were analyzed. Based on the structure character of the joint, the microstructure of the joint can be divided into plasticity zone, dynamically quiescent layer, heat affected zone and base metal. The results show that the plasticity zone and dynamically quiescent layer become fine equiaxed recrystallisation under the thermo-mechanical effect, the grains in the heat-affected zone grow up because of the effect of friction heat. When the rotation speed is 2 500 r/min and the welding time is 12 s, good joint is achieved, and the tensile shear strength of the joint reaches 9.24 kN. The tensile shear strength of spot increases with increasing tool rotation speed, with increasing welding time, the strength increases first, while then reduces. The microhardness of plasticity zone is high, but is slightly lower than that of the base metal, the minimum value of microhardness is in the heat affected zone. When the energy input of joint is high, the fracture type of spot is mode Ⅰ, and the tensile shear strength is high; on the contrary, when the energy input of joint is less the fracture type of spot is mode Ⅱ, and the strength is low.

Key words: LY12 aluminum alloy; friction stir spot welding(FSSW); microstructure; mechanical properties

铝合金具有高比强度、断裂韧度、疲劳强度和耐腐蚀稳定性,是制造航空、航天、汽车和船舶等构件的理想材料之一。目前,铝合金板的连接方法主要有铆接、电阻焊和钎焊。但是,铆接存在制造工艺复杂、水密性差、浪费材料等缺点[1]。电阻焊需要较大的功率,工件的变形较大,且电极的磨损严重,焊接质量随电极磨损而下降[2];钎焊时,焊后工件变形较大,容易产生未焊透、熔蚀等缺陷[3]。

摩擦点焊(FSSW)是由SAKANO等[4]在搅拌摩擦焊(FSW)基础上开发的一种新型固态连接技术。它利用带有轴肩和搅拌针的搅拌头一边高速旋转,一边缓慢地插入被焊工件,直到搅拌头的轴肩与工件表面紧密接触。在轴肩压力的作用下,搅拌针在工件内部进行摩擦和搅拌,产生的摩擦热使搅拌针周围被焊材料达到塑性状态,形成点焊接头,焊接结束后将搅拌头拔出,从而完成整个焊接过程。国内外学者研究了铝合金[5-8]、铜合金[9]和镁合金[10]搅拌摩擦焊接头的显微组织和性能。NORTH等[11-13]研究了Al 6111合金、Al 2024合金、AZ91合金和异种材料Al 6111合金与AZ91合金摩擦点焊时搅拌头的温度循环曲线,分析点焊时焊点的热输入量和塑性环宽度。刘克文等[14-15]研究LY12铝合金摩擦点焊时工艺参数的优化及焊点的表面成型。但对铝合金摩擦点焊接头的显微组织、力学性能及焊点的断裂方式的研究还不多。本文作者针对飞机制造中常用的LY12铝合金进行摩擦点焊实验,对接头的显微组织、力学性能及焊点断裂方式进行分析。

1 实验

焊接实验材料为LY12铝合金,经过淬火+自然时效处理,表1所列为材料的化学成分。焊件尺寸为300 mm×100 mm×2 mm。实验采用的搅拌头用高温合金制成,搅拌头轴肩直径为16 mm,搅拌针直径为4 mm、长度为3 mm。摩擦点焊实验用自制的焊接夹具在XKA714数控铣床上进行,图1所示为摩擦点焊示意图。焊接前,将两工件搭接放置于刚性垫板上并用压板压紧。焊接时,工件及垫板固定不动,搅拌头高速旋转,并在压力作用下垂直插入工件,控制轴肩压入工件的深度为0.5 mm。搅拌头的旋转速度为1 000~2 500 r/min,焊接时间选用4~16 s,焊接时间是指搅拌头搅拌针完全插入工件,轴肩与工件表面开始接触到离开工件的时间。焊接完后,沿焊点中心截取制备金相试样,用1% HF酸进行腐蚀,用LEICA图像分析仪观察焊点的横截面形貌和显微组织。用WT-401MVD型显微硬度计测量焊点横截面的显微硬度分布。按国标GB2651-89加工焊点的剪切试样,在WE-10A型液压式万能材料实验机上进行剪切性能测试,并对剪切断口进行观察分析。

表1 铝合金LY12的化学成分

Table 1 Chemical composition of LY12(mass fraction, %)

图1 摩擦点焊示意图

Fig.1 Schematic illustration of FSSW

2 结果与分析

2.1 接头组织分析

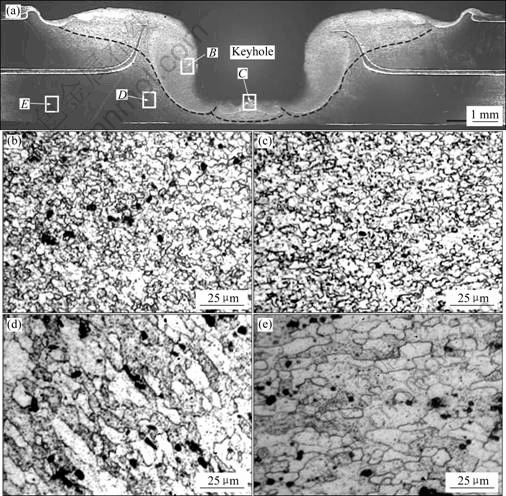

在搅拌头旋转速度为2 500 r/min、焊接时间为12 s时,焊点横截面的组织形态如图2所示。图2(a)所示为焊点横截面的宏观形貌,根据横截面形貌的特征,可将摩擦点焊焊点的横截面分为4个区域,即塑性区、动态静止层、热影响区和母材,分别对应图2(a)中的B、C、D、E这4个区。由图可知,塑性区B是指匙孔两侧直接受轴肩及搅拌针作用的区域,实验中将塑性区中只受搅拌针作用的区域称之为塑性环;动态静止层C是指匙孔底部材料受搅拌针挤压,在点焊过程中运动速度很慢的区域;热影响区D是指塑性区与母材的过渡区,母材E是指远离匙孔中心的区域。图2(b)~(e)所示分别为接头塑性区、动态静止层、HAZ和母材的显微组织。由图可见,塑性区和动态静止层的晶粒为均匀、细小的再结晶等轴晶粒;热影响区的晶粒与母材相似,但尺寸比母材稍大;母材区的晶粒较粗大。

图2 摩擦点焊接头的组织形态

Fig.2 Structure morphologies of FSSW joint: (a) Macrosection morphology of FSSW joint; (b) Plasticity zone; (c) Dynamically quiescent layer; (d) HAZ; (e) Base metal

焊点接头各区域组织不同的原因是,塑性区在轴肩及搅拌针热、力作用下发生较大的塑性挤压变形,产生动态再结晶;动态静止层在点焊时运动速度较慢,但也受到搅拌针的挤压作用,经历的塑性变形较大,在热和力的作用下也产生动态再结晶;热影响区离搅拌头较远,没有受到搅拌头的挤压,而只受到搅拌头的摩擦热作用,晶粒长大变粗;母材区的晶粒既没有受到搅拌头的挤压也没有受到摩擦热作用,因此为原始的淬火+自然时效组织。以上结果表明,点焊接头各区域的组织显著不同,塑性区的组织是在摩擦热和力的作用下发生动态再结晶后形成的细小的等轴晶,晶粒尺寸远小于母材,动态静止层的组织也是产生塑性变形后形成的等轴晶,热影响区的晶粒在摩擦热的作用下发生长大。

2.2 搅拌头旋转速度对焊点剪切强度的影响

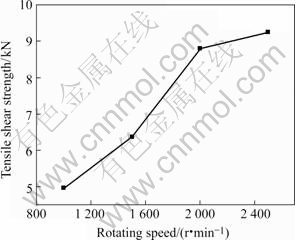

摩擦点焊过程中的热量主要来源于搅拌头轴肩和搅拌针与工件的摩擦热。实验中取焊接时间为12 s,搅拌头旋转速度为1 000~2 500 r/min,考察搅拌头旋转速度对接头剪切强度的影响。

图3所示为焊点剪切强度与搅拌头旋转速度的关系。由图可知,当焊接时间一定时,焊点的剪切强度随搅拌头旋转速度的增大而增大,当旋转速度为2 500 r/min时,焊点的剪切强度达到最大值,为9.24 kN。焊点剪切强度的这种分布原因是,当搅拌头旋转速度过低时,轴肩和搅拌针与工件摩擦产生的热量少,接头的温度较低,塑化金属的变形抗力较大,界面在轴肩压力作用下形成结合的长度较小,因此接头的剪切强度较小。随着搅拌头旋转速度的增加,焊接时摩擦产生的热量增多,搅拌针附近塑化金属的温度升高变形抗力减小,在轴肩压力作用下,界面形成结合的长度增加,因此接头的剪切强度较大。

图3 焊点剪切强度与搅拌头旋转速度的关系

Fig.3 Relationship between tensile shear strength and rotation speed of tool for joints

2.3 焊接时间对焊点剪切强度的影响

在搅拌头旋转速度为2 500 r/min,焊接时间为4~ 16 s时,焊点剪切强度与焊接时间的关系如图4所示。焊接时,保证轴肩对各焊点的压入深度均为0.5 mm,调整搅拌头插入工件的速度,控制焊接时间。由图可知,当焊接时间为4 s时,焊点的剪切强度较小,焊点的剪切强度随焊接时间的延长而增大,焊接时间为12 s时,焊点的剪切强度达到最大值,为9.24 kN。当焊接时间继续增加时,剪切强度随焊接时间的延长而减小。

图4 焊点剪切强度与焊接时间的关系

Fig.4 Relationship between tensile shear strength and welding time for joints

焊接时间较短时,轴肩和搅拌针与工件接触时间短,产生的热量较少,塑性金属的变形抗力较大,界面形成结合的长度较短,焊点的剪切强度较低。随焊接时间的增长,搅拌头与工件摩擦的时间增长,接头的热输入量增多,塑化金属的温度增加,变形抗力减小,在搅拌头作用下充分流动,界面形成结合的长度增加,且接头处的金属混合较均匀,出现缺陷的趋势减小,接头的剪切强度较高。因此焊点的剪切强度较高。当焊接时间继续增加时,点焊时热输入较大,热循环峰值温度较高,LY12(CZ)铝合金是淬火+自然时效铝合金,其强化作用主要是合金析出相,而当温度过高时,合金析出相发生过时效长大,使材料软化,因此剪切强度降低。

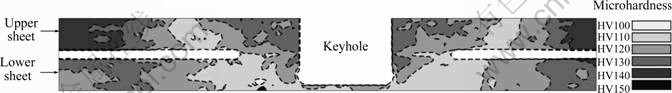

2.4 接头硬度分布

图5所示为搅拌头旋转速度为2 500 r/min、焊接时间为12 s时,点焊接头横截面显微硬度的分布云图。此云图是根据接头横截面上沿横向和纵向每隔0.25 mm进行硬度测试的结果,用surfer软件绘成。

图5 焊点的显微硬度分布

Fig.5 Microhardness distribution of FSSW joint

从图中可以看出,匙孔两侧的硬度呈对称分布,母材的显微硬度值最高,塑性区的显微硬度其次,动态静止层的硬度低于塑性区,接头显微硬度的最小值在热影响区。在点焊过程中,塑性区在搅拌头轴肩和搅拌针的直接作用下发生了较大的塑性变形,产生了动态再结晶,晶粒为细小的等轴晶,因此硬度较高。随着距塑性区距离的增大,被焊材料受搅拌头的热作用减小,焊接热循环峰值温度较低,固溶析出相发生了丛聚,导致其密度降低,因此硬度逐渐减小。在HAZ处,晶粒在摩擦热的作用下发生长大,且固溶析出相全部过时效长大,因此硬度最低。随着距塑性区距离的继续增加,热循环峰值温度降低,合金析出相过时效长大倾向降低,硬度随之增加。母材没有受到搅拌头热、力作用,为固溶时效处理状态,硬度最高。

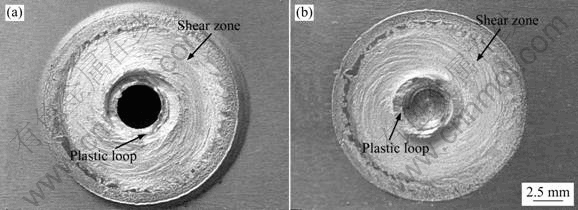

2.5 接头断口分析

图6和7所示分别为LY12铝合金摩擦点焊接头典型的剪切试样断口形貌。根据其形貌特征基本可以分为两类:一类为Ⅰ型断裂,另一类为Ⅱ型断裂。Ⅰ型断裂是指焊点处不仅形成了塑性环,在塑性环外部区域有较多材料形成了结合,在外载荷作用下,材料受剪形成撕裂的痕迹,文中将此区域称为剪切区,如图6所示。Ⅱ型断裂是指焊点处只形成塑性环,在塑性环外部区域只有局部材料实现连接,没有形成剪切区,如图7所示。

图6 剪切试样Ⅰ型断裂的断口形貌

Fig.6 Fracture morphologies of mode Ⅰ for shear sample: (a) Upper sheet; (b) Bottom sheet

图7 剪切试样Ⅱ型断裂的断口形貌

Fig.7 Fracture morphologies of mode Ⅱ for shear sample: (a) Upper sheet; (b) Bottom sheet

图6所示为搅拌头旋转速度为2 500 r/min、焊接时间为12 s时焊点的剪切断口形貌,图6(a)和(b)所示分别为剪切断裂试样上、下板材的宏观形貌。从图中可以看出,在剪切载荷作用下,上板材沿匙孔周围与下板材脱离时,在上板材上留下小孔,如图6(a)所示;在下板材表面形成“钮扣”状塑性环,塑性环外部区域有较多材料形成了结合,在外载荷作用下形成剪切区,如图6(b)所示。图7所示为搅拌头旋转速度为2 500r/min、焊接时间为4 s时焊点的剪切断口形貌,图7(a)和(b)所示分别为剪切断裂试样上、下板材的宏观形貌。由图可见,上、下两板材受剪切载荷沿匙孔周围分离时在上板形成小孔,如图7(a);在下板形成“钮扣”状塑性环,在塑性环外部区域只有局部材料实现了连接,没有形成剪切区,如图7(b)。

形成两种不同类型的焊点断口形貌的原因是,在焊接过程中,搅拌针周围材料在搅拌头摩擦热和力的作用下形成塑性环。当焊接时间较长时,焊接过程中的热输入量较多,焊点处除形成塑性环外,其外部区域大部分材料形成结合,在外载作用下形成剪切区。焊点受剪切载荷时,裂纹由两板材的交界面先扩展到剪切区,然后延伸到塑性环,剪切载荷由塑性环和剪切区共同承受,因此焊点的剪切强度较高。当焊接时间较短时,焊接过程中的热输入量较少,焊点处只有塑性环,其外部区域只有局部材料形成结合,在外载作用下没有形成剪切区。焊点受剪切载荷时,裂纹由上、下板材的交界面直接扩展到塑性环,剪切载荷由塑性区承受,焊点的剪切强度较低。

3 结论

1) 焊点接头根据组织特征可分为塑性区、动态静止层、热影响区和母材。塑性区晶粒在热和力的作用下发生动态再结晶成为细小的等轴晶,晶粒尺寸远小于母材,动态静止层产生塑性变形后也变成细小的等轴晶,热影响区晶粒在摩擦热的作用下长大。

2) 摩擦点焊焊点的剪切强度随搅拌头旋转速度的增加而增大,随焊接时间的增加先增大后减小,当焊接时间为12 s时达到最大值,为9.24 kN。

3) 塑性区的显微硬度较高,但略小于母材,动态静止层的硬度低于塑性区,接头显微硬度的最小值出现在热影响区。

4)Ⅰ型断裂和Ⅱ型断裂为铝合金LY12摩擦点焊接头典型的断裂方式,焊点热输入量较多时,接头为Ⅰ型断裂,焊点的剪切强度较高;焊点热输入量较少时,接头为Ⅱ型断裂,焊点的剪切强度较低。

REFERENCES

[1] 吴淑霞, 张世伟. 常见铆接缺陷及起因探析[J]. 机械工程师, 2001(12): 54-56.

WU Shu-xia, ZHANG Shi-wei. Common rivet joint shortcoming and the cause[J]. Mechanical Engineer, 2001(12): 54-56.

[2] Spinella D J, Brockenbrough J R, Fridy J M. Trends in aluminum resistance spot welding for the automotive industry[J]. Welding Journal, 2005, 84(1): 34-40.

[3] 胡 刚, 康 慧. 铝合金真空钎焊的发展[J]. 焊接技术, 2001, 30(2): 1-3.

HU Gang, KANG Hui. Development of Vacuum brazing in aluminum[J]. Welding Technology, 2001, 30(2): 1-3.

[4] Sakano R, Murakami K, Yamashita K, et al. Development of spot FSW robot system for automobile body members[C]//Proceedings of the 3rd International Symposium of Friction Stir Welding. Japan, 2001: 645-650.

[5] 邢 丽, 柯黎明, 刘鸽平, 黄奉安. 铝合金LD10的搅拌摩擦焊组织及性能分析[J]. 焊接学报, 2002, 23(6): 55-58.

XING Li, KE Li-ming, LIU Ge-ping, HUANG Feng-an. Microstructure and mechanical properties of a friction stir welded LD10 aluminum[J]. Transactions of the China Welding Institution, 2002, 23(6): 55-58.

[6] 邢 丽, 柯黎明, 周细应, 刘鸽平. 防锈铝LF6的固态塑性连接工艺[J]. 中国有色金属学报, 2002, 12(6): 1162-1165.

XING Li, KE Li-ming, ZHOU Xi-ying, LIU Ge-ping. Solid-state plasticized joining for aluminum alloy LF6[J]. The Chinese Journal of Nonferrous Metals, 2002, 12(6): 1162-1166.

[7] Sutton M A, Yang B, Reynolds A P. Microstructural studies of friction stir welds in 2024-T3 aluminum[J]. Mater Sci Eng A, 2002, 323: 160-166.

[8] 刘小文, 鄢君辉, 杜随更. LY12搅拌摩擦焊接技术[J]. 焊接学报, 2001, 22(4): 55-58.

LlU Xiao-wen, YAN Jun-hui, DU Sui-geng. Friction stir welding of LY12 alloys[J]. Transactions of the China Welding Institution, 2001, 22(4): 55-58.

[9] 邢 丽, 孙德超, 柯黎明, 张彦富. 紫铜搅拌摩擦焊接工艺研究及接头组织分析[J]. 机械科学与技术, 2003, 22(6): 986-988.

XING Li, SUN De-chao, KE Li-ming, ZHANG Yan-fu. Study of the copper friction stir welding process and analysis of its weld microstructure[J]. Mechanical Science and Technology, 2003, 22(6): 986-988.

[10] 邢 丽, 柯黎明, 孙德超, 周细应. 镁合金薄板的搅拌摩擦焊工艺[J]. 焊接学报, 2001, 22(6): l8-20.

XING Li, KE Li-ming, SUN De-chao, ZHOU Xi-ying. Friction stir welding of MB8 magnesium alloy sheet[J]. Transactions of the China Welding Institution, 2001, 22(6): l8-20.

[11] Gerlich A, Su P, North T H. Peak temperatures and microstructures in aluminum and magnesium alloy friction stir spot welds[J]. Science and Technology of Welding and Joining, 2005, 6(10): 647-653.

[12] Gerlich A, Avramovic-Cingara G, North T H. Stir zone microstructure and strain rate during Al 7075-T6 friction stir spot welding[J]. Metall Mater Trans A, 2006, 37(9): 2773-2886.

[13] Gerlich A, Su P, North T H. Friction stir spot welding of aluminum and magnesium alloys[J]. Materials Forum, 2005, 29: 290-294.

[14] 刘克文, 邢 丽, 柯黎明. LY12铝合金摩擦点焊工艺及力学性能[J]. 焊接学报, 2007, 28(9): l7-21.

LIU Ke-wen, XING Li, KE Li-ming. The process and mechanical properties of friction stir spot welding for LY12 aluminum alloy[J]. Transactions of the China Welding Institution, 2007, 28(9): l7-21.

[15] 刘克文, 邢 丽, 柯黎明. 铝合金摩擦点焊工艺参数的优化[J]. 新技术新工艺, 2007(6): 69-71.

LIU Ke-wen, XING Li, KE Li-ming. Optimization of friction stir spot welding parameters for LY12 Al alloy[J]. New Technology & New Process, 2007(6): 69-71.

基金项目:航空科学基金资助项目(05H56015)

收稿日期:2007-03-29;修订日期:2007-10-22

通讯作者:邢 丽,教授;电话:13755672074; E-mail:xingli_59@126.com

(编辑 龙怀中)