文章编号:1004-0609(2008)08-1498-06

电解铜粉高速压制成形

王建忠,曲选辉,尹海清,周晟宇,易明军

(北京科技大学 材料科学与工程学院 新金属材料国家重点实验室,北京 100083)

摘 要:研究电解铜粉高速压制成形工艺,探讨冲击能量、压制次数对生坯密度、最大冲击力和脱模力的影响。结果表明:当冲击能量为6 076 J时,试样的生坯密度达到最大,为8.42 g/cm3,相对密度约为95%;当冲击能量相同时,采用两次压制制备的试样的生坯密度较单次压制的高且前者的脱模力较低。高速压制过程中,最大冲击力随冲击能量的增加而逐渐增大,而脱模力较低,仅在45~90 kN之间变化。

关键词:电解铜粉;高速压制;生坯密度;冲击力;脱模力

中图分类号:TB 44 文献标识码:A

High velocity compaction of electrolytic copper powder

WANG Jian-zhong, QU Xuan-hui, YIN Hai-qing, ZHOU Sheng-yu, YI Ming-jun

(State Key Laboratory for Advanced Metals and Materials, School of Materials Science and Engineering, University of

Science and Technology Beijing, Beijing 100083, China)

Abstract: The high velocity compacting process of electrolytic copper powder was studied. The effects of impact energy and impact times on the green density, the maximal impact force and the withdraw force of specimen were investigated. The results indicate that the maximum of green density is 8.42 g/cm3 and its relative density is about 95% when the impact energy is 6 076 J. The green density of specimen fabricated by two impacts is better and the withdraw force is lower than that of specimen fabricated by single impact when the whole impact energy is identical. During the compaction the maximal impact force is increased with impact energy increasing, while the withdraw force is lower and changes between 45 kN and 90 kN.

Key words: electrolytic copper powder; high velocity compaction; green density; maximal impact force; withdraw force

制备高密度、高强度和高精度粉末冶金制品是粉末冶金工业的发展方向和研究重点,提高制品致密化程度将大大促进其性能的改进。从传统的致密化途径来看,复压复烧、粉末锻造、热等静压、热压等技术都各有其优缺点[1?2]。而高速压制技术可能是粉末冶金工业寻求低成本高密度材料制备技术的又一次新突破,它突破了目前粉末冶金的局限性,是传统粉末压制成形技术的一种极限式外延的结果[3?4]。

高速压制(High velocity compaction,简称HVC)是瑞典的H?gan?s公司在2001年6月推出的一项新技术。其基本原理[3, 5?9]是通过液压驱动的锤头产生强烈冲击波,在很短时间内(20 ms左右)将冲击能量通过压模传递到粉末上进行致密化。锤头的质量和冲击瞬间的速度决定了冲击能量的大小与材料的致密化程度。液压驱动的锤头质量达5~1 200 kg,压机锤头速度高达2~30 m/s,在20 ms内对粉末进行高能冲击压制,300 ms内可进行第二次压制。锤头冲击行程实现计算机控制,可通过任意选择非常接近的冲击能量来安排冲击次序。

目前,国内对高速压制技术的研究还处于起步阶段,国外虽然对该技术进行了一些研究,但主要集中于铁粉[11?14]、不锈钢粉[15]和聚合物[16?17]等,而对铜粉的研究甚少,尤其是关于成形过程中冲击能量、冲击次数、生坯密度及脱模力等之间的相互关系的研究基本没有相关报道。为此,本文作者采用电解铜粉为原料,拟对其成形过程中的工艺参数进行研究,以期获得它们之间的内在关系,从而为生产实践提供一些理论依据。

1 实验

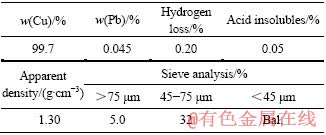

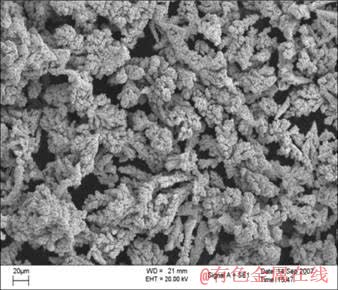

实验原料:有研粉末新材料(北京)有限公司生产的电解铜粉,粒度为<75 μm,粉末特性和显微形貌分别如表1和图1所示。

表1 电解铜粉特性

Table 1 Characteristics of electrolytic copper powder

图1 电解铜粉形貌

Fig.1 Image of electrolytic copper powders

实验设备:南京希顿?东部精密机械有限公司生产的HYP35?7型高速冲击成形压机,如图2所示。

图2 HYP35?7型高速冲击成形压机

Fig.2 Image of machine of HYP35?7

2 结果与讨论

2.1 冲击能量与冲击行程之间的关系

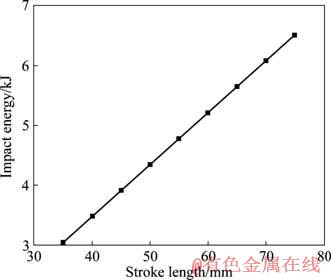

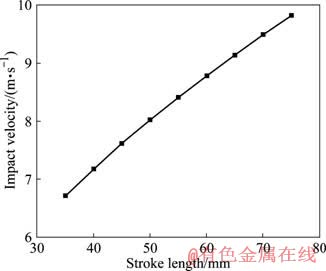

由式(5)可知,冲击能量与冲击行程之间为线性关系,如图3所示。

图3 冲击能量与冲击行程之间的关系

Fig.3 Relationship between impact energy and stroke length

2.2 冲击速度与冲击行程之间的关系

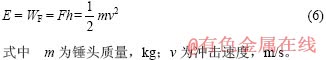

高速压制时的冲击速度是指锤头与上模冲第一次接触时的速度。根据能量守恒定律:

由式(6)可知:v = 。因此,高速压制时的冲击速度与冲击行程之间呈抛物线关系,如图4所示。

。因此,高速压制时的冲击速度与冲击行程之间呈抛物线关系,如图4所示。

图4 冲击速度与冲击行程之间的关系

Fig.4 Relationship between impact velocity and stroke length

2.3 冲击能量对生坯密度的影响

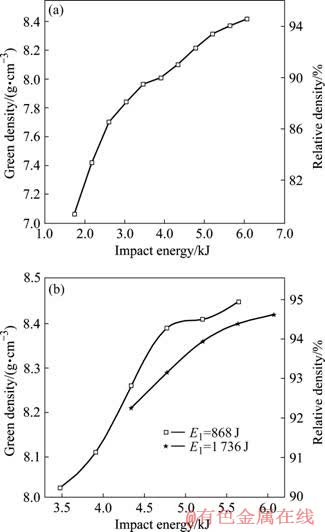

图5(a)所示为单次压制时的生坯密度与冲击能量之间的关系。由图5(a)可知,随着冲击能量的增加,生坯密度逐渐提高。当冲击能量低于3 472 J时,生坯密度增加较快;当冲击能量超过3 906 J时,生坯密度增加较慢;当冲击能量在3 472~3 906 J之间变化时,生坯密度增加幅度较小;当冲击能量增加到6 076 J时,生坯密度达到最大,为8.42 g/cm3,相对密度约为95%。

图5 生坯密度与冲击能量之间的关系

Fig.5 Relationships between green density and impact energy: (a) Single impact; (b) Two impacts

造成上述现象的原因可能是:高速压制在一次压制过程中,锤头要多次撞击上模冲。当冲击波受阻于上模冲时,锤头以一定的速度撞击上模冲后,锤头损失部分能量后继续前进,上模冲获得一个高速度并脱离锤头向下运动。粉末的阻力会消耗上模冲的能量,使其速度下降并与锤头再次接触,再次获得高速度并脱离锤头向下运动,如此反复直至锤头的能量全部被耗尽。在此过程中,电解铜粉受到了多次压制,生坯密度逐次得到提高[17]。

电解铜粉是树枝状粉末(见图1),颗粒之间存在较多孔隙,同时电解铜粉较软,塑性变形较容易。当冲击能量较低(低于3 472 J)时,压制过程中粉末颗粒主要以充填和变形方式进行致密化,这一阶段生坯密度随冲击能量的增加而升高较快。当冲击能量增加到 3 472~3 906 J时,生坯密度增加幅度较小是由于粉末颗粒经过充填、变形后,产生加工硬化现象,进一步变形受到阻碍,而此时的冲击能量又不足以使树枝状粉末发生碎化。但是当冲击能量继续增加时,生坯密度又逐步升高是由于粉末颗粒之间除了充填和变形外,还发生了碎化。同时粉末颗粒之间由于高速碰撞、摩擦形成冷焊,颗粒之间形成波纹状结合。

图5(b)所示为两次压制时的生坯密度与冲击能量之间的关系。由图5(b)可知,随着冲击能量的增加,生坯密度逐渐提高。当总冲击能量相同时,第一次冲击能量为868 J压制的试样的生坯密度高于第一次冲击能量为1 736 J压制的试样。其原因可能是:一方面,当第一次冲击能量较低(868 J)时,粉末颗粒之间的充填和变形进行得较充分,同时粉末颗粒之间的绝大部分气体能够逸出。而当第一次冲击能量为1 736 J时,由于冲击能量高且作用时间短,粉末颗粒之间会残留部分气体。另一方面,当粉末经过第一次冲击能量为1 736 J压制后,已经成为密度为7.06 g/cm3的生坯(见图5(a)),虽然其第二次冲击能量较低,但是冲击波在生坯中的传播速度提高,对生坯的作用时间缩短。同时冲击波与下模冲接触时发生透射而消耗的能量增加,从而使生坯吸收的冲击能量减少,导致其密度 较低。

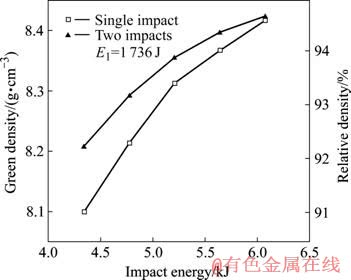

2.4 压制次数对生坯密度的影响

图6所示为不同压制次数制备的试样的生坯密度与冲击能量之间的关系。由图6可知,当总冲击能量相同时,两次压制的生坯密度较单次压制的高。而且随着冲击能量的增加,二者之间的差值逐渐缩小。这是由于单次压制时,冲击能量一次性作用于粉末颗粒上,作用时间短,粉末颗粒之间的气体不能彻底逸出,同时颗粒之间的充填不能充分进行,粉末颗粒之间可能仅仅形成机械结合。而两次压制时,冲击能量分两次作用于粉末颗粒上,第一次压制相当于预压,起到排气、充填等作用,使得粉末颗粒成为具有一定密度的生坯,随后进行的第二次压制使得粉末颗粒之间除了形成机械结合外,还可能形成焊合,从而导致试样的生坯密度进一步提高。

图6 生坯密度与冲击能量之间的关系(不同压制次数)

Fig.6 Relationships between green density and impact energy for single impact and two impacts (E1=1 736 J)

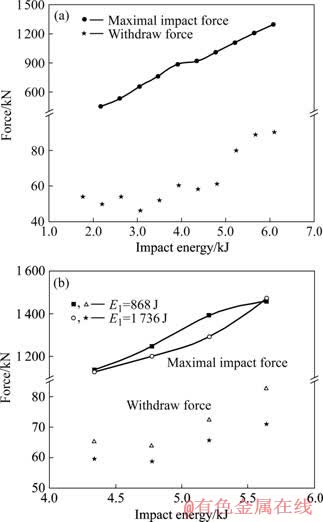

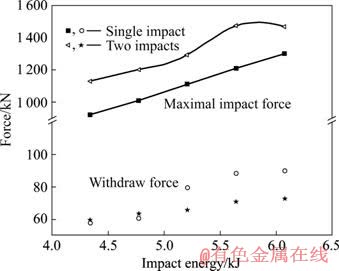

2.5 冲击能量对最大冲击力和脱模力的影响

图7(a)所示为单次压制时的最大冲击力和脱模力与冲击能量之间的关系。由图7(a)可知,高速压制过程中,最大冲击力随着冲击能量的增加而逐渐增大,这是由于冲击波传播速度随着冲击能量的增加而逐渐增大所致。整个压制过程中,脱模力相对较低,仅在45~90 kN之间变化,为最大冲击力的5.24%~ 16.11%,这也充分证明了高速压制技术具有脱模力较低的特 点[18]。

图7 最大冲击力和脱模力与冲击能量之间的关系

Fig.7 Relationships between maximal impact force, withdraw force and impact energy: (a) Single impact; (b) Two impacts, E1= 868 J and E1=1 736 J

图7(b)所示为两次压制时的最大冲击力和脱模力与冲击能量之间的关系。由图7(b)可知,随着冲击能量的增加,最大冲击力逐渐增大。当总冲击能量相同时,第一次冲击能量为868 J压制的试样的最大冲击力较第一次冲击能量为1 736 J时的略高。这是由于第一次冲击能量较低时,其随后的第二次冲击能量较高所致。

从图7(b)中还可以看出,当总冲击能量相同时,第一次冲击能量为868 J压制的试样的脱模力较高一些,这可能是由于其随后的第二次冲击能量较高,使得试样的径向弹性后效增大,从而导致试样与模具模壁之间的摩擦力增大所致。

2.6 压制次数对最大冲击力和脱模力的影响

图8所示为不同压制次数制备的试样的最大冲击力和脱模力与冲击能量之间的关系。由图8可知,随着冲击能量的增加,最大冲击力逐渐增大。当冲击能量相同时,两次压制时的最大冲击力较单次压制的高。这是由于两次压制时,第一次压制使得粉末成为具有一定密度的生坯,随后进行第二次压制时,冲击波受到的阻碍减小,传播速度增大所致。

图8 最大冲击力和脱模力与冲击能量之间的关系(不同压制次数)

Fig.8 Relationships between maximal impact force, withdraw force and impact energy for single impact and two impacts (E1= 1 736 J)

从图8中还可以看出,当冲击能量相同时,单次压制时的脱模力较高。其原因可能是:一方面,单次压制时的生坯密度较两次压制的低,使得单次压制的试样的高度较高;另一方面,单次压制时,冲击波对试样的作用时间较两次压制时的短,使得试样内部产生了较大的内应力,导致试样的径向弹性后效增大,试样与模具模壁之间的摩擦力增大。

3 结论

1) 高速压制过程中,冲击能量与冲击行程之间呈线性关系,而冲击速度与冲击行程之间呈抛物线关系;

2) 当冲击能量为6 076 J时,试样的生坯密度达到最大,为8.42 g/cm3,相对密度约为95%;

3) 两次压制时,第一次冲击能量较低的试样的生坯密度较高,且脱模力也较高;

4) 当冲击能量相同时,两次压制的生坯密度较单次压制的高,但前者的脱模力较低;

5) 最大冲击力随冲击能量的增加而逐渐增大。

REFERENCES

[1] 李元元, 肖志瑜, 陈维平, 倪东惠. 粉末冶金高致密化成形技术的新进展[J]. 粉末冶金材料科学与工程, 2005, 10(1): 1?9.

LI Yuan-yuan, XIAO Zhi-yu, CHEN Wei-ping, NI Dong-hui. Progress in high density powder metallurgy forming technology [J]. Materials Science and Engineering of Powder Metallurgy, 2005, 10(1): 1?9.

[2] 肖志瑜, 陈 平, 李元元. 粉末冶金高致密化的新途径[J]. 材料导报, 2003, 17(11): 5?8.

XIAO Zhi-yu, CHEN Ping, LI Yuan-yuan. New approaches to achieving higher densification of powder[J]. Materials Review, 2003, 17(11): 5?8.

[3] RICHARD F. HVC punches PM to new mass production limits[J]. Metal Powder Report, 2002, 57(9): 26?30.

[4] ORBAN R L. New research directions in powder metallurgy[J]. Romanian Reports in Physics, 2004, 56(3): 505?516.

[5] SKOGLUND P. High density PM components by high velocity compaction[C]// VOLKER A, CHU C L, JANDESKA W F JR, et al. 2001 International conference on Power Transmission Components. Ypsilanti: Metal Powder Industries Federation, 2001: 16?17.

[6] SKOGLUND P. High density PM parts by high velocity compaction[J]. Powder Metallurgy, 2001, 44(3): 199?201.

[7] SKOGLUND P. High-density PM components by high velocity compaction[C]// VOLKER A, CHU C L, JANDESKA W F JR, et al. Advance in Powder Metallurgy & Particulate Materials-2002. New Jersey: Metal Powder Industries Federation, 2002: 1?10.

[8] CAROLINE E. H?gan?s promotes potential of high velocity compaction[J]. Metal Powder Report, 2001, 56(9): 6.

[9] DORE F, LAZZAROTTO L, BOURDIN S. High velocity compaction: overview of materials, applications and potential[J]. Materials Science Forum, 2007, 534/536: 293?296.

[10] TORSTEN E, PPETRI L. Residual stresses in green bodies of steel powder after conventional and high speed compaction[J]. Materials Science Forum, 2002, 407(404): 77?82.

[11] 迟 悦, 果世驹, 孟 飞, 杨 霞, 张 恒, 连玉栋. 粉末冶金高速压制成形技术[J]. 粉末冶金工业, 2005, 15(6): 41?45.

CHI Yue, GUO Shi-ju, MENG Fei, YANG Xia, ZHANG Heng, LIAN Yu-dong. High velocity compaction in powder metallurgy [J]. Powder Metallurgy Industry, 2005, 15(6): 41?45.

[12] BARENDVANDEN B, CHRISTER F, TOMAS L. Industrial implementation of high velocity compaction for improved properties[J]. Powder Metallurgy, 2006, 49(2): 107?109.

[13] JONS?N P, H?GGBLAD H ?, TROIVE L, FURUBERG J, ALLROTH S, SKOGLUND P. Green body behavior of high velocity pressed metal powder[J]. Materials Science Forum, 2007, 534/536: 289?292.

[14] ASLUND C. High velocity compaction (HVC) of stainless steel gas atomized powder[C]// HERBERT D, RAIMUND R. Euro PM 2004 Conference Proceedings. Shrewsbury UK: EPMA, 2004: 533?564.

[15] BRUSKA A, BENGT S, LEIF K. Development of a high-velocity compaction process for polymer powders[J]. Polymer Testing, 2005, 24(4): 909?919.

[16] JAUFFR?S D, LAME O, VIGIER G, DOR? F. Microstructural origin of physical and mechanical properties of ultra high molecular weight polyethylene processed by high velocity compaction[J]. Polymer, 2007, 48(21): 6374?6383.

[17] 陈振华. 现代粉末冶金技术[M]. 北京: 化学工业出版社, 2007: 326.

CHEN Zhen-hua. Modern powder metallurgy technique[M]. Beijing: Chemical Industry Press, 2007: 326.

[18] 沈元勋, 肖志瑜, 温利平, 藩国如, 李元元. 粉末冶金高速压制技术的原理、特点及其研究进展[J]. 粉末冶金工业, 2006, 16(3): 19?23.

SHEN Yuan-xun, XIAO Zhi-yu, WEN Li-ping, PAN Guo-ru, LI Yuan-yuan. Principle, characteristics and status of high velocity compaction in powder metallurgy[J]. Powder Metallurgy Industry, 2006, 16(3): 19?23.

基金项目:国家重点基础研究发展计划资助项目(2006CB605207);国家自然科学基金重点资助项目(50634010);教育部长江学者和创新团队发展计划资助项目(I2P407)

收稿日期:2007-11-20;修订日期:2008-04-06

通讯作者:王建忠,博士研究生;电话:13269187836;E-mail: yun.wang2007@yahoo.com.cn

(编辑 何学锋)