Evaluation of surface roughness and optimization of cutting parameters in turning of AA2024 alloy under different cooling-lubrication conditions using RSM method

来源期刊:中南大学学报(英文版)2020年第6期

论文作者:Seyed Hasan MUSAVI Behnam DAVOODI Behzad ESKANDARI

文章页码:1714 - 1728

Key words:cooling-lubrication methods; surface roughness; minimum quantity lubrication; response surface methodology; AA2024 aluminum alloy

Abstract: In the present study, the effect of reduction of cutting fluid consumption on the surface quality and tool wear was studied. Mathematical models were developed to predict the surface roughness using response surface methodology (RSM). Analysis of variance (ANOVA) was used to investigate the significance of the developed regression models. The results showed that the coefficient of determination values (R2) for the developed models was 97.46% for dry, 89.32% for flood mode (FM), and 99.44% for MQL, showing the high accuracy of fitted models. Also, under the minimum quantity lubrication (MQL) condition, the surface roughness improved by 23%-44% and 19%-41% compared with dry and FM, respectively, and the SEM images of machined surface proved the statement. The prepared SEM images of tool rake face also showed a considerable decrease in adhesion wear. Built-up edge and built-up layer were the two main products of the adhesion wear, and energy-dispersive X-ray spectroscopy (EDX) analysis of specific points on the tool faces helped to discover the chemical compositions of adhered materials. By changing dry and FM to MQL mode, dominant mechanism of tool wear in machining aluminum alloy was significantly decreased. Breakage wear that led to early failure of cutting edge was also controlled by MQL technique.

Cite this article as: Seyed Hasan MUSAVI, Behnam DAVOODI, Behzad ESKANDARI. Evaluation of surface roughness and optimization of cutting parameters in turning of AA2024 alloy under different cooling-lubrication conditions using RSM method [J]. Journal of Central South University, 2020, 27(6): 1714-1728. DOI: https://doi.org/10.1007/s11771-020-4402-2.

J. Cent. South Univ. (2020) 27: 1714-1728

DOI: https://doi.org/10.1007/s11771-020-4402-2

Seyed Hasan MUSAVI1, Behnam DAVOODI2, Behzad ESKANDARI3

1. Department of Mechanical Engineering, Amirkabir University of Technology, Tehran 15875-4413, Iran;

2. School of Mechanical Engineering, Iran University of Science and Technology, Tehran 16846-13114, Iran;

3. Department of Mechanical, Automotive, and Materials Engineering, University of Windsor,Windsor, Canada

Central South University Press and Springer-Verlag GmbH Germany, part of Springer Nature 2020

Central South University Press and Springer-Verlag GmbH Germany, part of Springer Nature 2020

Abstract: In the present study, the effect of reduction of cutting fluid consumption on the surface quality and tool wear was studied. Mathematical models were developed to predict the surface roughness using response surface methodology (RSM). Analysis of variance (ANOVA) was used to investigate the significance of the developed regression models. The results showed that the coefficient of determination values (R2) for the developed models was 97.46% for dry, 89.32% for flood mode (FM), and 99.44% for MQL, showing the high accuracy of fitted models. Also, under the minimum quantity lubrication (MQL) condition, the surface roughness improved by 23%-44% and 19%-41% compared with dry and FM, respectively, and the SEM images of machined surface proved the statement. The prepared SEM images of tool rake face also showed a considerable decrease in adhesion wear. Built-up edge and built-up layer were the two main products of the adhesion wear, and energy-dispersive X-ray spectroscopy (EDX) analysis of specific points on the tool faces helped to discover the chemical compositions of adhered materials. By changing dry and FM to MQL mode, dominant mechanism of tool wear in machining aluminum alloy was significantly decreased. Breakage wear that led to early failure of cutting edge was also controlled by MQL technique.

Key words: cooling-lubrication methods; surface roughness; minimum quantity lubrication; response surface methodology; AA2024 aluminum alloy

Cite this article as: Seyed Hasan MUSAVI, Behnam DAVOODI, Behzad ESKANDARI. Evaluation of surface roughness and optimization of cutting parameters in turning of AA2024 alloy under different cooling-lubrication conditions using RSM method [J]. Journal of Central South University, 2020, 27(6): 1714-1728. DOI: https://doi.org/10.1007/s11771-020-4402-2.

1 Introduction

Modern manufacturing industries thrive for energy-efficient, clean and sustainable machining processes. However, achieving these objectives becomes efficient especially in machining of strategic alloys [1].

The surface quality and tool life of obtained workpiece are two essential factors in machining processes, when the machined products are to be used under dynamic forces [2]. These factors are affected by various parameters, including workpiece material, cutting fluid, geometry of cutting tool, cutting parameters [3], and cooling-lubrication method [4]. Surface roughness is one of the main factors of surface quality [5], having a direct effect on properties such as wear and corrosion resistance as well as fatigue strength [6], which in turn affects performance and service life of the machined components [7]. One of the essential strategies to improve surface roughness is the usage of suitable cutting fluid to lubricate and cool the tool-chip interface [8]. Application of cutting fluids during machining has several advantages including reduction of the friction-generated heat [9], increase in the tool life, improvement in the workpiece surface quality, prevention of the built-up edge and built-up layer formation on the tool rake face and facilitation of the chip transition from the cutting zone [10]. For this purpose, several cutting fluids are used in the machining industry, among which the most common fluids are soluble and pure cutting oils [11, 12].

It is estimated that more than 85% of different cutting fluids used in manufacturing are mineral- based oils, and more than two-third of which are dumped into the environment without any purification and cleaning operations [11]. The International Agency for Research on Cancer has warned that hydrocarbon mineral-based lubricants used in the machining industry are carcinogenic [13, 14]. Therefore, from the cost and safety viewpoint, reduction, and even elimination of the cutting fluid consumption are very important.

In the recent years, some researchers have tried to prove that it is feasible to minimize the consumption of cutting fluid, and at the same time, to achieve acceptable process performance by adjusting appropriate cutting conditions and using new cooling techniques including cryogenic, high- pressure and compressed air/vapor cooling [15, 16]. One of the growing techniques in reducing the amount of cutting fluid consumption is the minimum quantity lubrication (MQL) method [17]. However, in practice, there is still disagreement in the application of cutting fluids during the machining process. Because using cutting fluids generally reduces the cutting temperature and forces, which in turn, increases the tool life and surface quality, many manufacturers still prefer to utilize cutting fluids in the production of parts. Moreover, there is a disagreement between different researchers.

SARTORI et al [18] studied the effect of cooling-lubrication on the machining efficiency of difficult-to-cut alloy in terms of tool nose wear and surface roughness values. According to the results, MQL showed better performance than dry or flood mode (FM). KHAN et al [19] examined the effects of minimum quantity lubrication, flood mode, and dry mode on turning AISI 9310 alloy steel. They stated that lower tool-chip interface temperature and chip reduction coefficient, as well as the average and auxiliary flank wear for MQL machining compared to dry and flooding modes were achieved. Furthermore, obtained surface roughness is much better that under MQL. DHAR et al [20] evaluated the effect of MQL on cutting temperature, chip and dimensional accuracy in turning AISI-1040 steel. The results showed that machining under MQL led to lower cutting temperature, which in turn, results in lower-dimensional inaccuracies in the produced parts when compared with flood and dry machining. TEBALDO et al [21] studied the effect of cooling-lubrication methods on tool life, surface roughness, production cost, cutting force in turning of Inconel 718. Higher tool life and lower time required to cut were obtained as a result of FM machining.

Moreover, surface roughness was lower when using cutting fluid in the process (FM or MQL). However, higher cutting forces were observed in flood mode. JAYAL et al [22] studied the effects of cutting fluid applications on tool wear in machining AISI 1045 steel. Flank wear was lower in flood mode machining compared with dry cutting and MQL. GHANI et al [23] investigated the effect of dry and flood modes on tool life and surface finish in machining of ductile cast iron FCD700. The results showed that dry machining performance is comparable to that of flood mode machining. They found that the performance of FM machining, in terms of tool life, was better than dry machining. However, the surface quality of dry machining was almost similar to that of FM machining. THAKUR et al [24] studied the machinability characteristics (cutting force, tool wear, surface roughness) in turning Incoloy 825. The results showed that although cutting temperature was high for dry machining using a multi-layer PVD coated tool (TiN/TiAlN), and the values of cutting force, surface quality, and tool wear were low in dry machining compared whit MQL and FM. DEVILLEZ et al [25] studied the effect of cooling method (FM and dry modes) on surface integrity. Results showed that acceptable surface quality and residual stress with no severe microstructure alteration were achieved under the optimum cutting condition in dry machining.

According to the literature review, there is no consensus among the researchers on if the cooling-lubrication method should be employed. On the other hand, despite the importance of the aluminum alloys in industrial applications, the effect of different cooling-lubrication methods in the machining of these alloys has been barely studied. In the present study, two environment- friendly methods, i.e., dry machining and minimum quantity lubrication technique, were compared with conventional flood mode. The main objective of this work is to investigate whether or not clean technology could be used to achieve the desired process performance in terms of surface roughness and tool wear, and at the same time, reduce consumption of the cutting fluid. For this purpose, first, the optimum cutting parameters were investigated using response surface methodology (RSM) for the minimum surface roughness. Next, tool wear and surface quality were evaluated by SEM images.

2 Materials and equipment

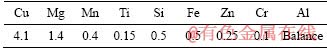

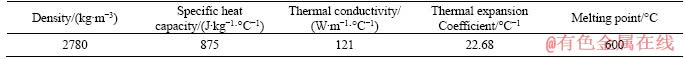

In this study, AA2024 aluminum alloy cylinders with 55 mm diameter were used as the workpiece material. Chemical compositions and physical properties of the aluminum alloy are shown in Tables 1 and 2, respectively.

Table 1 Chemical composition of AA2024 (wt%)

Uncoated cemented carbide manufactured by Sandvik was used as the cutting tool material which had the ISO designation of TCGX16T304 with the manufacturer’s grade code of H13A. This grade of cutting tool has the specifications of high wear resistance and excellent toughness, which is suitable for machining of aluminum alloys [26]. STGCX1616H16 tool holder was utilized for performing the machining process. Uncoated inserts were selected because it has been proved in previous studies that when machining with coated tools, dry and MQL machining outperform the flood mode and in metal cutting by uncoated inserts using a high volume of cutting fluid, the flood cooling is superior. Thus, in this study, the machining process was examined using uncoated tools with a low rate of cutting fluid (2 L/min) in flood mode.

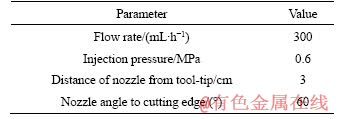

The MQL system was manufactured by the authors in which a compressor was used to produce the compressed air which was mixed with the cutting fluid by a port, and subsequently, the initial spray was generated. The air-fluid spray was made by passing the initial spray through the nozzle. This study was conducted at the optimum parameters of the MQL system, which were obtained in Ref. [27] (Table 3). The precision and accuracy of the presented system were verified through preliminary experimental tests. The image of the MQL system and setup of the experiments are shown in Figure 1.

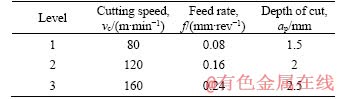

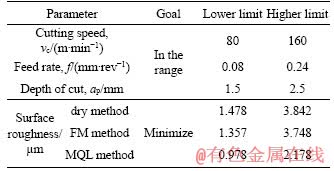

Cutting speed, feed rate, and depth of cut each were selected in three levels as the main variables to evaluate the effect of cutting parameters and cooling-lubrication methods on the cutting conditions (Table 4).

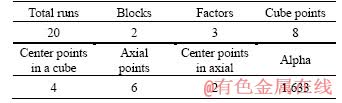

Machining time for each machining process was 20 min. Response surface methodology (RSM) was employed as the design of experiment method. RSM is a group of statistical techniques that establishes a mathematical relationship between input factors and output response parameters [26]. In this study, to investigate the machining process, a standard response surface methodology called Box-Wilson Central Composite Design (CCD) was used. The specifications of the designed RSM is presented in Table 5.

3 Results and discussion

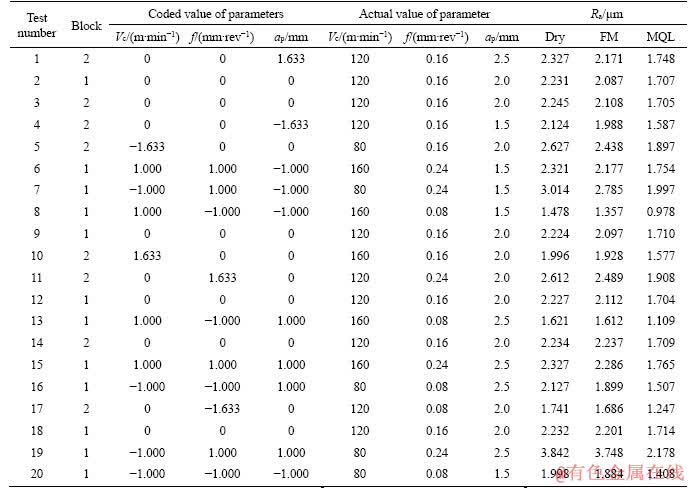

Table 4 presents the arrangement of cutting parameters based on RSM along with the measured values of surface roughness under three cooling- lubrication conditions, i.e., MQL, FM, and dry.

Table 2 Physical properties of AA2024

Table 3 MQL system parameters

Figure 1 Images of MQL system (a) and setup of experiment (b)

Table 4 Cutting parameters and their levels

Table 5 RSM specifications

3.1 Development and analyses of mathematical models

This section aims to determine mathematical models for the surface roughness. In RSM, the relationship between input parameters (Vc, f and ap) and output response (Y) can be expressed with Eq. (1) in which for predicting approximate response values, a second-order polynomial regression model was used (Eq. (2)):

Y=F(vc, f, ap) (1)

(2)

(2)

where B0 is the free term; Bi is a linear coefficient; Bii is the quadratic term; Bij is the interaction factor; xi indicates the input parameters [26]. The values of non-linear coefficients were calculated by regression method according to the experimental data in Table 6, using statistical software package Design-Expert. By replacing the values in Eq. (2), the final surface roughness models in dry machining for coded and actual parameters are presented as Eqs. (3) and (4), respectively.

(3)

(3)

(4)

(4)

Likewise, the final surface roughness models in FM lubrication for coded and actual parameters are written as Eqs. (5) and (6), respectively.

(5)

(5)

(6)

(6)

Also, the final surface roughness models in the MQL technique for coded and actual parameters are Eqs. (7) and (8), respectively.

(7)

(7)

(8)

(8)

Table 6 Matrix L20 of response surface methodology with Ra results

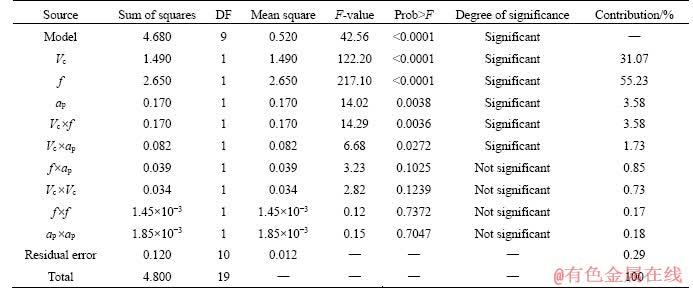

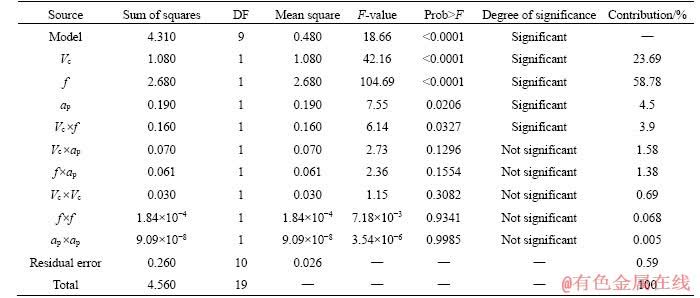

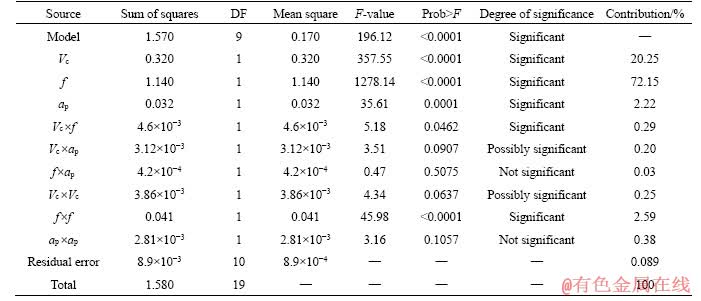

Results of the analyses of variance (ANOVA) for surface roughness in dry, FM, and MQL machining are presented in Tables 7-9, respectively.

Prob>F (Probability>F) and F-values in tables of analysis of variance are evaluated to investigate the suitability of the models and their quality. F-values of the model used in this analysis for dry, FM, and MQL techniques are 42.56, 18.66, and 196.12, respectively. Given the critical F-value of 4.96 for the data, the calculated F-values indicate that the quadratic regression models are suitable for the prediction of surface roughness for each method.Also, Prob>F values for the models are less than 0.0001, which proves that the fitted models are significant. Percentage contribution values are also brought in the ANOVA tables. The feed rate is the most influential factor in surface roughness among three cooling methods. Numerical values of the effect of feed rate on surface roughness using dry, FM, and MQL techniques are 55.23%, 58.78% and 72.15%, respectively. Cutting speed and depth of cut are also two other critical useful parameters on the surface roughness.

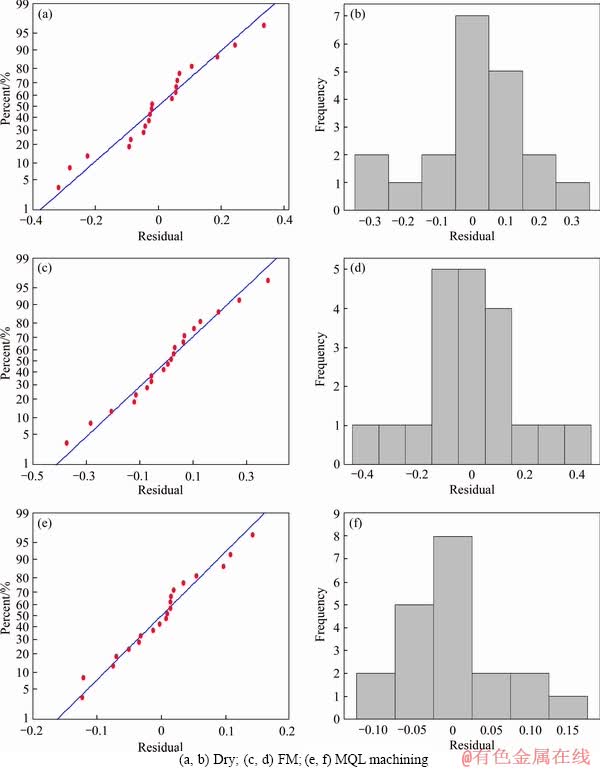

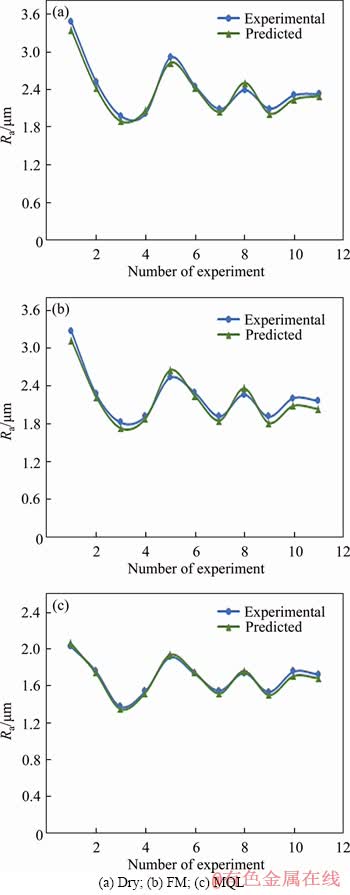

The values of coefficients of determination (R-squared and R-Sq (Adj)) for the developed final models to estimate the amount of surface roughness are obtained as 97.46% and 95.17% for dry, 94.38% and 89.32% for FM, as well as 99.44% and 98.93% for MQL techniques, respectively, showing the high accuracy of fitted models. Therefore, it can be seen in Figure 2 the normal probability plot and distribution histogram of the residuals for surface roughness under dry, FM, and MQL machining conditions. It can be observed that data fall firmly on the straight line, which means that the errors are regularly distributed. Furthermore, the distribution of residual depicts that the residuals are normal and random, showing the strength of the models. Eleven levels of cutting parameters and their results were compared with experimental values to investigate the amount of the accuracy of predicted surface roughness values as shown in Figure 3. The maximum errors between calculated and experimental values in dry, FM and MQL are 4.5%, 5.9%, and 3.9%, respectively. It indicates the acceptable accuracy for predicted values of surface roughness in all three methods.

Table 7 ANOVA for surface roughness in dry machining

Table 8 ANOVA for surface roughness in FM machining

Table 9 ANOVA for surface roughness in MQL machining

Figure 2 Normal probability and histogram of residual distribution for surface roughness under:

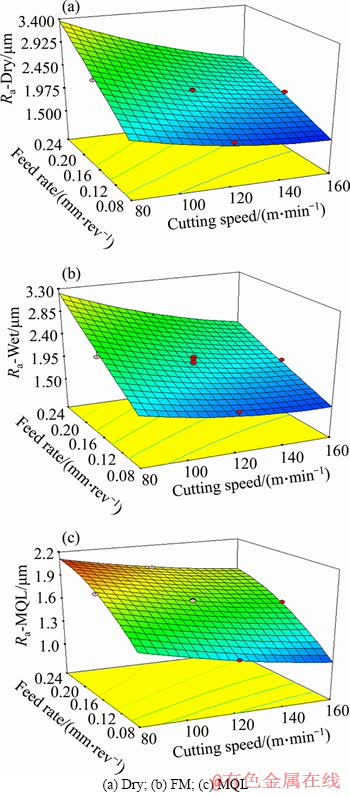

Figure 4 illustrates three-dimensional surface graphs for interaction effects of cutting speed and feed rate on surface roughness. All of the graphs in Figure 4 indicate that the smallest surface roughness is achieved at the highest cutting speeds and the lowest feed rates, i.e., at feed rate of 0.2 mm/rev, and cutting speed of 160 m/min. By decreasing the cutting speed and increasing the feed rate, surface roughness values increased. This confirms the analysis of variance in which feed rate and cutting speed are the most effective parameters.

3.2 Analyses of obtained surface roughness

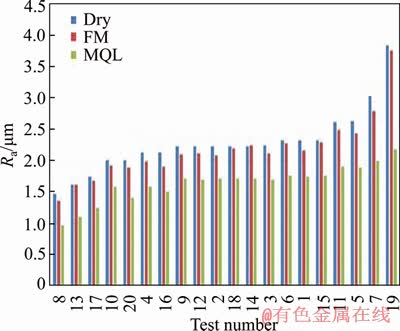

Dry machining is the first choice in the field of environment-friendly machining [28]. In this method, due to the lack of cutting fluid during machining, the environmental hazards of using it are eliminated. The variation of surface roughness values about various cooling- lubrication methods is shown in Figure 5, according to Table 6. As noted by DAVOODI et al [29], the variation is due to the use of cutting fluid and reduction of the adhesion mechanism of tool wear, especially built-up edge formation on the tool rake face. According to Refs. [30, 31], due to the special properties of aluminum edge, the sever adhesion tool wear is not an alloys such as its high tendency to form a built-up unexpected phenomenon in aluminum machining.

Figure 3 Comparison between experimental and predicted values for surface roughness under:

Figure 4 3D graphs of interaction effects of cutting speed and feed rate on surface roughness when using:

Figure 5 Variation of surface roughness at different cutting parameter sets

3.2.1 High ability of aluminum alloys in BUE and BUL formation

In a similar analysis, ATLATI et al [32] stated that this phenomenon could be explained by the following reason: Due to the mechanical properties of the ductile materials (like AA2024), such as softness, low stiffness, and low melting point, the welding conditions of the workpiece material on the tool rake face are increased, and it causes the formation of BUE and BUL, which increases the natural value of Ra.

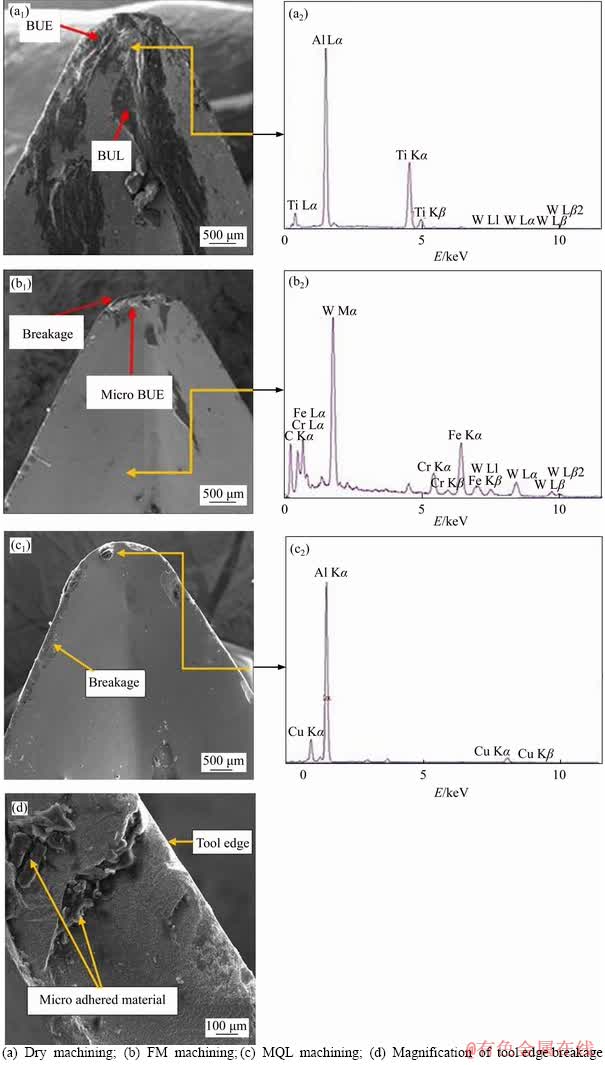

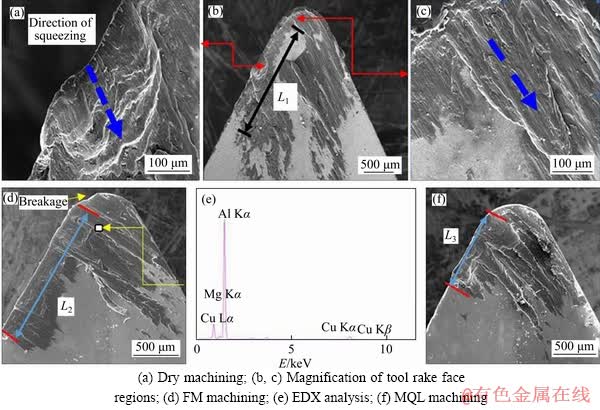

Workpiece material particles stick to the tool rake face after being removed from its surface in the form of chips and subsequently attach to the workpiece machined surface due to the thermal softening phenomenon. This phenomenon increases the amount of surface roughness of the workpiece [33]. The utilization of cutting fluid in FM machining reduces the formation of this type of chips and improves the surface quality slightly [34]. It can be seen in Figure 6 that SEM images of cutting tools at cutting speed of 160 m/min, the feed rate of 0.24 mm/rev and cutting depth of 1.5 mm under various cooling conditions after 90 s, are depicted. It is observable that BUE and BUL are much higher in dry machining. The energy- dispersive X-ray spectroscopy (EDX) analysis of specific points on the tool rake faces is also presented, which helps to discover the chemical compositions of adhered materials. The EDX in Figure 6(a) illustrates that adhered materials near the cutting edge in dry machining are aluminum, copper, and magnesium elements, proving that the workpiece material (AA2024 aluminum alloy) is attached to the rake face. In Figure 6(b), EDX analysis shows the constituents of the tool material without adhered material dominating with tungsten elements. The EDX of Figure 6(a) illustrates that adhered materials near the cutting edge in dry machining are aluminum, copper, and magnesium elements, proving that the workpiece material (AA2024 aluminum alloy) is attached to the rake face. The difference between the materials attached in the dry and flooding modes shows the high capability of cutting fluids in flood cooling to prevent the formation of BUE and BUL on the cutting tool. Due to the application of cutting fluid in the flooding method, BUE formation is reduced, and better surface quality is obtained. The amount of surface roughness improvement in the flooding mode was about 1% to 10% (Figure 5).

3.2.2 High transfer of cutting fluid to cutting zone

On the other hand, MQL machining produces a much better surface finish in comparison to dry and FM machining (Figure 5). This phenomenon can be explained by the following reason.

As noted by SHOKRANI et al [35], using appropriate cooling method (MQL technique), the fluid transfer conditions for cooling the tooltip and lubricating the tool-chip surface improve the penetration of cutting fluid to cutting zone, and more cutting fluid particles are transited to the machining zone due to high-speed injection of cutting fluid. Furthermore, the size of the atomized particles of cutting fluid is reduced because it passes through the MQL nozzle, which leads to better penetration to the machining zone.

In other words, the MQL nozzle acts like a delivery system or a channel that allows the cutting fluid flows to the cutting zone more quickly. Additionally, the lubricating film is formed more efficiently on the tool-chip interface, which improves the condition of chip transfer in the machining zone and reduces the system vibration which leads to a lower amount of tool wear such as adhesion and abrasion wear as it is seen in Figure 6(c). Except for slight breakage and adhesion of the workpiece material (Figure 6(d)), there was no significant tool wear on the rake face. This phenomenon leads to a better surface finish in comparison to other cooling conditions. The surface quality improvements are 23%-44% and 19%-41% when using the MQL technique compared with the dry and FM methods, respectively (Figure 5).

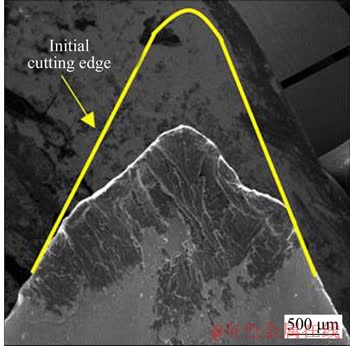

As the cutting process continues, the machining condition gets worse due to higher volumes of tool wear. As noted by OZBEK et al [36], this phenomenon increased the friction in tool-chip interface, and thus the welding conditions exacerbated, and subsequently, the volume of BUE and BUL increased. However, this condition is not very critical for the MQL technique. Figure 7 demonstrates the SEM images of tool rake face after 10 min machining under dry, FM, and MQL at cutting speed of 160 m/min, feed rate of 0.24 mm/rev and depth of cut of 1.5 mm. It is clear that bypassing the machining time, for both cases of dry and FM conditions, the occupied area of the adhered materials on the tool rake face considerably increases. In dry machining, a considerable length of cutting edge (L1) was affected by built-up edge and built-up layer regions (Figure 7(c)). It is also seen that there is a slight breakage on the cutting edge (Figure 7(b)). Although its size is not very large, this leads to complete failure of the cutting tool after 20 min of machining (Figure 8), in flood mode. This phenomenon is due to changing cutting angles of insert, and consequently, increasing interaction at the tool-chip interface and intensifying stresses on tool-tip. All of these factors lead to a significant decrease in cutting fluid penetration into the machining zone. Under such circumstances, the machining operation took place under the dry condition in practice. This resulted in a higher amount of BUL formation on the rake face of the cutting tool in comparison to the beginning of the machining (Figure 7(d)). This makes the length of the affected cutting edge (L2) to be close to that of in dry machining (L1). Under MQL, however, the amount of adhered material is much lower than other cooling methods, and no breakage could be seen on the cutting edge (Figure 7(f)). Moreover, the length of adhesion wear on the cutting edge (L3) is much smaller compared with dry and FM machining. This results in more tool life throughout the machining and lower surface roughness values.

Figure 6 SEM images of tool rake face after 90 s under:

Figure 7 SEM images of tool rake face after 10 min under:

Throughout the machining process, adhered layers of workpiece material on the cutting edge detach from the tool rake face which not only sticks on the machined surface of the workpiece with further machining, producing poor surface quality and higher values of surface roughens [37], but also results in earlier failure of the cutting tool. Successively, it is another reason for high surface roughness values when adhesion wear is high.

Figure 8 SEM image of tool rake face after 20 min under dry machining

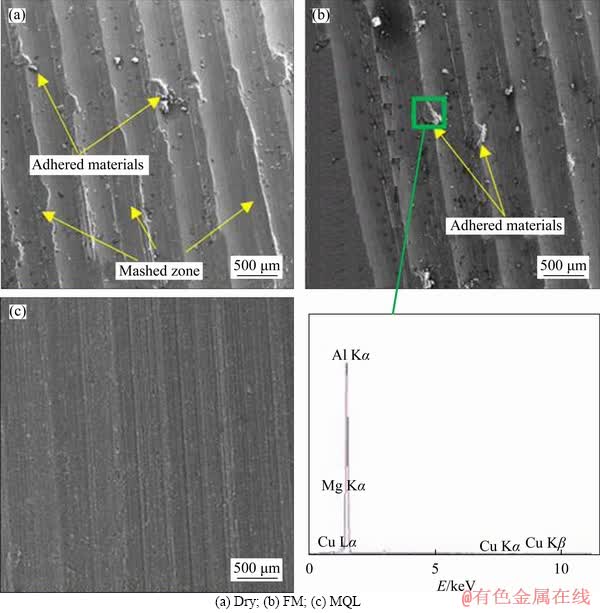

Figure 9 illustrates the machined surfaces under various cooling conditions produced by the tools shown in Figure 7. According to the EDX analysis, the adhered materials are observable in dry and FM machining, which produces higher roughness values (Figure 5).

Figure 9 SEM images of workpiece surface when using cutting tools in Figure 7 under:

MQL also produces a smooth surface without any adhered material. This is mostly because of the lower amount of BUL and no breakage on the cutting tool (Figure 7(e)).

MQL, on the other hand, produces a smooth surface without any adhered material. This is mainly because of the lower amount of BUL and no breakage on the cutting tool (Figure 7(e)).

In Figures 9(a) and (b), which show the surface of the machined workpiece using the dry and FM, the mashed zones as well as the adhered chip material on its surface are observable. The cause of these defects on the workpiece surface can be attributed to the two following reasons:

As noted by ZHANG et al [38], the continuous formation of BUE and consequent removal it on the tool surface result in fracture of the cutting tool edge. As a result, the workpiece material is removed under the squeezing and tension mechanism.

In the second case, as noted by GOMEZ- PARRA et al [39], when the BUE adhered on the rake face is not massive enough to be removed, it temporarily changes the tool edge geometry. By changing the cutting angles, the cutting mechanism is also changed, and the material is not cut, but it is removed by the tension mechanism, and thus its surface will have poor quality.

3.3 Optimization of surface roughness

In this study, the desirability function of RSM was used to find the optimal value of cutting parameters. Three groups of quality criteria can be considered in the analyses: 1) the-higher-the-better; 2) the-lower-the-better; 3) the-nominal-the-better [37]. Since the surface roughness criterion should be decreased, the-lower-the-better was selected to determine the optimum values. In the first step, each response is put into a desirability function that changes over the range from 0 to 1. The amount of 1 means that the response is in the target value and the value of 0 indicates that one or more responses are outside the allowable region. Finally, the individual desirability functions are incorporated to provide a measure of the composite desirability [40, 41].

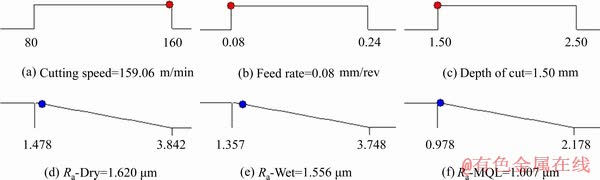

Figure 10 shows the optimization graphs obtained from the RSM method. Table 10 shows the limits for optimization of cutting parameters. The results of the RSM optimization process are reported in Table 11 to reduce the desirability level. Summary of the best values of cutting parameters is as follows: the cutting speed of 160 m/min, the feed rate of 0.08 mm/rev, and the depth of cut of 1.5 mm. The desirability of the optimization was calculated as 0.944, which confirms that all the parameters are in their working range.

Figure 10 Optimized values of cutting parameters

Table 10 Restrictions for optimization of tool life and volume of material removed

4 Conclusions

This research evaluated the improvement of the machining performance in terms of surface quality of 2024 aluminum alloy using different cooling-lubrication methods, namely dry, flood mode (FM), and minimum quantity lubrication (MQL) method.

1) Developed models had a high coefficient of determination (R2): 97.46% for dry, 89.32% for FM, and 99.44% for the minimum quantity lubrication technique, showing the high accuracy of fitted models.

2) Experimental results showed that a significant improvement in finished surface quality could be achieved by the MQL technique. The improvements were 23%-44% and 19%-41% compared with dry and FM methods, respectively.

3) SEM images of the workpiece surface showed better surface quality when the MQL technique was used.

4) MQL technique contributed to a significant decrease in the volume of the mineral-base cutting fluids consumption, which leads to a reduction of the environmental risks as well as the machining costs.

5) Applications of the MQL method resulted in lower adhesion wear on the cutting edge, and consequently, lower surface roughness values.

References

[1] MIA M, GUPTA M, LOZANO J, CAROU D, PIMENOV D, KROLCZYK G, KHAN A, DHAR N. Multi-objective optimization and life cycle assessment of eco-friendly cryogenic N2 assisted turning of Ti-6Al-4V [J]. Journal of Cleaner Production, 2019, 210: 121-133.

[2] LI L, LI C, TANG Y, YI Q. Influence factors and operational strategies for energy efficiency improvement of CNC machining [J]. Journal of Cleaner Production, 2017, 161: 220-238.

[3] DEHGHAN G A, VAHDATI M. Experimental study on the effect of finishing parameters on surface roughness in magneto-rheological abrasive flow finishing process [J]. Proceedings of the Institution of Mechanical Engineers, Part B: Journal of Engineering Manufacture, 2015, 229(9): 1517-1524.

[4] ESKANDARI B, DAVOODI B, GHORBANI H. Multi-objective optimization of parameters in turning of N-155 iron-nickel-base superalloy using gray relational analysis [J]. Journal of the Brazilian Society of Mechanical Sciences and Engineering, 2018, 40(4): 233-244.

[5] MARUDA R, KROLCZYK G, MICHALSKI M, NIESLONY P, WOJCIECHOWSKI S. Structural and microhardness changes after turning of the AISI 1045 steel for minimum quantity cooling lubrication [J]. Journal of Materials Engineering and Performance, 2017, 26: 431-438.

[6] NIKNAM S A, BALAZINSKI M, SONGMENE V. To characterize and optimize the surface quality attributes in slot milling operation [J]. The International Journal of Advanced Manufacturing Technology, 2017, 93(1-4): 727-746.

[7] HAGHSHENAS A, KHONSARI M. Damage accumulation and crack initiation detection based on the evolution of surface roughness parameters [J]. International Journal of Fatigue, 2018, 107: 130-144.

[8] NIKNAM S A, SONGMENE V, AU Y J. The use of acoustic emission information to distinguish between dry and lubricated rolling element bearings in low-speed rotating machines [J]. The International Journal of Advanced Manufacturing Technology, 2013, 69(9-12): 2679-2689.

[9] KADAM G S, PAWADE R S. Surface integrity and sustainability assessment in high-speed machining of Inconel 718–An eco-friendly green approach [J]. Journal of Cleaner Production, 2017, 147: 273-283.

[10] VICENTIN G, SANCHEZ L, SCALON V, ABREU G. A sustainable alternative for cooling the machining processes using a refrigerant fluid in recirculation inside the tool holder [J]. Clean Technologies and Environmental Policy, 2011, 13(6): 831-840.

[11] GHOSH S, RAO P V. Application of sustainable techniques in metal cutting for enhanced machinability: A review [J]. Journal of Cleaner Production, 2015, 100: 17-34.

[12] MUSAVI S H, DAVOODI B, NIKNAM S A. Effects of reinforced nanoparticles with surfactant on surface quality and chip formation morphology in MQL-turning of superalloys [J]. Journal of Manufacturing Processes, 2019, 40: 128-139.

[13] LI K, AGHAZADEH F, HATIPKARASULU S, RAY T G. Health risks from exposure to metal-working fluids in machining and grinding operations [J]. International Journal of Occupational Safety and Ergonomics, 2003, 9 (1): 75-95.

[14] CANCER IAFRO. Polynuclear aromatic hydrocarbons, part 2: carbon blacks, mineral oils (lubricant base oils and derived products), and some nitroarenes [J]. IARC Monogr Eval Carcinog Risk Chem Hum, 1987, 33: 1-245.

[15] GHOREISHI R, ROOHI A H, GHADIKOLAEI A D. Analysis of the influence of cutting parameters on surface roughness and cutting forces in high speed face milling of Al/SiC MMC [J]. Materials Research Express, 2018, 5(8): 1-18.

[16] SHARMA A K, TIWARI A K, DIXIT A R. Effects of minimum quantity lubrication (MQL) in machining processes using conventional and nanofluid based cutting fluids: A comprehensive review [J]. Journal of Cleaner Production, 2016, 127: 1-18.

[17] KROLCZYK G M, MARUDA R, KROLCZYK J, WOJCIECHOWSKI S, MIA M, NIESLONY P, BUDZIK G. Ecological trends in machining as a key factor in sustainable production-A review [J]. Journal of Cleaner Production, 2019, 218: 601-615.

[18] SARTORI S, GHIOTTI A, BRUSCHI S. Solid lubricant- assisted minimum quantity lubrication and cooling strategies to improve Ti6Al4V machinability in finishing turning [J]. Tribology International, 2018, 118: 287-294.

[19] KHAN M, MITHU M, DHAR N R. Effects of minimum quantity lubrication on turning AISI 9310 alloy steel using vegetable oil-based cutting fluid [J]. Journal of Materials Processing Technology, 2009, 209(15, 16): 5573-5583.

[20] DHAR N, ISLAM M, ISLAM S, MITHU M. The influence of minimum quantity of lubrication (MQL) on cutting temperature, chip and dimensional accuracy in turning AISI-1040 steel [J]. Journal of Materials Processing Technology, 2006, 171(1): 93-99.

[21] TEBALDO V, DI CONFIENGO G G, FAGA M G. Sustainability in machining: “Eco-friendly” turning of Inconel 718. Surface characterisation and economic analysis [J]. Journal of Cleaner Production, 2017, 140: 1567-1577.

[22] JAYAL A D, BALAJI A. Effects of cutting fluid application on tool wear in machining: Interactions with tool-coatings and tool surface features [J]. Wear, 2009, 267(9, 10): 1723-1730.

[23] GHANI J A, RIZAL M, HARON C H C. Performance of green machining: A comparative study of turning ductile cast iron FCD700 [J]. Journal of Cleaner Production, 2014, 85: 289-292.

[24] THAKUR A, GANGOPADHYAY S. Dry machining of nickel-based super alloy as a sustainable alternative using TiN/TiAlN coated tool [J]. Journal of Cleaner Production, 2016, 129: 256-268.

[25] DEVILLEZ A, LE COZ G, DOMINIAK S, DUDZINSKI D. Dry machining of Inconel 718, workpiece surface integrity [J]. Journal of Materials Processing Technology, 2011, 211(10): 1590-1598.

[26] DAVOODI B, ESKANDARI B. Tool wear mechanisms and multi-response optimization of tool life and volume of material removed in turning of N-155 iron–nickel-base superalloy using RSM [J]. Measurement, 2015, 68: 286-294.

[27] BARARI N, NIKNAM S A, MEHMANPARAST H. Tool wear morphology and life under various lubrication modes in turning stainless steel 316L [J]. Transactions of the Canadian Society for Mechanical Engineering, 2019, 51: 1-10. DOI: 10.1139/tcsme-2019-0051.

[28] HONG SY, BROOMER M. Economical and ecological cryogenic machining of AISI 304 austenitic stainless steel [J]. Clean Products and Processes, 2000, 2(3): 157-166.

[29] DAVOODI B, TAZEHKANDI A H. Experimental investigation and optimization of cutting parameters in dry and wet machining of aluminum alloy 5083 in order to remove cutting fluid [J]. Journal of Cleaner Production, 2014, 68: 234-242.

[30] DAVOODI B, MUSAVI S H, NANKALI M. Development a new cutting tool by changing the surface texture for increasing the machining performance [J]. Modares Mechanical Engineering, 2017, 17(7): 441-450.

[31] MUSAVI S H, DAVOODI B, NANKALI M. Creating the micro-grooves on tool rake face for improving the anti-wear properties [J]. Modares Mechanical Engineering, 2018, 18: 1-10.

[32] ATLATI S, HADDAG B, NOUARI M, MOUFKI A. Effect of the local friction and contact nature on the Built-Up Edge formation process in machining ductile metals [J]. Tribology International, 2015, 90: 217-227.

[33] MUSAVI S H, DAVOODI B, NIKNAM S A. Effects of reinforced nanofluid with nanoparticles on cutting tool wear morphology [J]. Journal of Central South University, 2019, 26(5): 1050-1064.

[34] MUSAVI S H, DAVOODI B, NIKNAM S A. Environmental-friendly turning of A286 superalloy [J]. Journal of Manufacturing Processes, 2018, 32: 734-743.

[35] SHOKRANI A, AL-SAMARRAI I, NEWMAN S. Hybrid cryogenic MQL for improving tool life in machining of Ti-6Al-4V titanium alloy [J]. Journal of Manufacturing Processes, 2019, 43: 229-243.

[36] OZBEK O, SARUHAN H. The effect of vibration and cutting zone temperature on surface roughness and tool wear in eco-friendly MQL turning of AISI D2 [J]. J Mater Res Technol, 2020. DOI: 10.1016/j.jmrt.2020.01.010.

[37] TAZEHKANDI A H, PILEHVARIAN F, DAVOODI B. Experimental investigation on removing cutting fluid from turning of Inconel 725 with coated carbide tools [J]. Journal of Cleaner Production, 2014, 80: 271-281.

[38] ZHANG K, DENG J, XING Y, LI SH, GAO H. Effect of micro scale texture on cutting performance of WC/Co-based TiAlN coated tools under different lubrication conditions [J]. Applied Surface Science, 2015, 326: 107-118.

[39] GOMEZ-PARRA A, ALVAREZ-ALCO M, SALGUERO J, BATISTA M, MARCOS M. Analysis of the evolution of the built-up edge and built-up layer formationmechanisms in the dry turning of aeronautical aluminum alloys [J]. Wear, 2013, 302: 1209-1218.

[40] DAVOODI B, MUSAVI S H. An experimental investigation of the effect of lubrication method on surface roughness and cutting fluid consumption in machining of super alloys [J]. Modares Mechanical Engineering, 2016, 16: 343-352.

[41] MUSAVI S H, DAVOODI B, ESKANDARI B. Pre-cooling intensity effects on cooling efficiencyin cryogenic turning [J]. The Arabian Journal for Science and Engineering, 2019, 44: 10389-10396. DOI: 10.1007/s13369-019-04056-6.

(Edited by ZHENG Yu-tong)

中文导读

RSM方法对不同冷润滑条件下的AA2024合金车削加工进行参数优化及表面粗糙度评价

摘要:本文研究了减少切削液消耗对刀具表面质量和刀具磨损的影响。利用响应面方法(RSM)建立了预测表面粗糙度的数学模型,使用方差分析(ANOVA)来研究所建立回归模型的有效性。结果表明,拟合模型的R2分别为dry型的97.46%、FM型的89.32%、MQL型的99.44%,具有较高的拟合精度。在MQL型条件下,表面粗糙度较dry型和FM型分别提高了23%~44%和19%~41%,加工表面的SEM图像证明了这一说法。刀具前端面扫描电镜图像表明粘着磨损明显减少。粘着磨损的主要产物是粘着边和粘着层,利用X射线能谱分析刀具表面特定点,确定粘着材料的化学成分。将dry工艺和FM工艺改为MQL工艺,显著降低了铝合金加工过程中刀具磨损的程度。导致切削刀具早期失效的断裂磨损通过MQL技术得到了控制。

关键词:冷却润滑法;表面粗糙度;最小润滑量;响应面法;AA2024

Received date: 2019-09-24; Accepted date: 2020-03-16

Corresponding author: Behnam DAVOODI, PhD, Associate Professor; Tel: +98-21-73228911; E-mail: bdavoodi@iust.ac.ir; ORCID: 0000-0001-7102-3291