稠油水平井平行双管注汽井筒参数计算模型

东晓虎1,刘慧卿1,庞占喜1,张传新2,易勇刚2,秦耘3

(1. 中国石油大学 石油工程教育部重点实验室,北京,102249;

2. 中石油新疆油田分公司工程技术研究院,新疆 克拉玛依,834000;

3. 四川石油学校,四川 成都,610213)

摘要:考虑到传统单管蒸汽注入模型的局限性,利用热传递理论,建立平行双管稠油水平井的井筒参数计算模型以及蒸汽回流模型,并采用节点分析方法进行求解。采用蒸汽回流模型对水平段封隔器的封隔情况进行了模拟,从而对稠油双管注汽水平井的实际验封过程进行分析。结果表明:与传统的单管蒸汽注入方式相比,平行双管注汽具有明显的优势,与单管注蒸汽过程相比,双管注汽可以提高注汽井井底蒸汽干度0.1以上。平行双管注汽的井筒沿程蒸汽参数与双注汽管的注汽方式、注汽参数以及管柱尺寸等有较大关系,井口蒸汽干度与注汽速率对井筒热损失程度影响较大;双管注汽的井筒蒸汽干度主要损失于水平段,主注汽管水平段管柱的尺寸应尽可能的小。

关键词:稠油油藏;水平井;平行双管;热损失;压力验封

中图分类号:TE319.1 文献标志码:A 文章编号:1672-7207(2014)03-0939-07

Model for steam properties in parallel-tubing horizontal wells of heavy oil reservoir

DONG Xiaohu1, LIU Huiqing1, PANG Zhanxi1, ZHANG Chuanxin2, YI Yonggang2, QIN Yun3

(1. MOE Key Laboratory of Petroleum Engineering, China University of Petroleum, Beijing 102249, China;

2. Engineering and Technology Research Institute of Xinjiang Oilfield, CNPC, Karamay 834000, China;

3. Sichuan Petroleum School, Chengdu 610213, China)

Abstract: Based on the heat conduction theory, momentum conservation and energy conservation law, the computation model of steam properties of parallel-tubing in the thermal horizontal wells is established. Also the model of sealed checking of packer in horizontal segment is proposed. The models are solved with the method of node analysis. Through the flow computation of steam at the conditions of valid and invalid sealing states, the sealed checking process of packer in the parallel-tubing horizontal well is analyzed. The results indicate that the influences of steam injection method and injection parameters are significant, especially the well-head steam quality and the steam injection rate. Compared with single-tube, the steam quality of well-bottom of the parallel-tubing injection could be improved by above 0.1.

Key words: heavy oil reservoir; horizontal wells; parallel tubing; heat loss; sealed checking of packer

采用水平井开发稠油油藏不但可以提高油层的吸汽能力,而且还可以加速井筒到油藏之间的热传递,提高波及系数,增加原油的生产能力[1-2]。但由于水平段油层非均质与水平井筒变质量流的存在,注汽过程中若采用笼统方式注汽,往往会造成注入蒸汽的局部突进,导致水平段动用不均[3-4]。为了改善这种沿程吸汽不均现象,急需采用一种新的完井管柱与注汽方式,平行双管注汽在一定程度上改善了直井或水平井吸汽不均、动用程度差的问题[5-6]。平行双管注汽方式是为实现多段注汽而提出来的,是在注汽井井筒内下入平行的两跟注汽管柱,分别用于对油层的不同部位进行注汽。与单一注汽管的单点注汽方式相比,这种方式可以实现主、副双管的双点注汽。对于水平井平行双管注汽方式而言,主管下至水平井趾端,副管下至水平井跟端,可以实现对水平井跟端与趾端的同时注汽,并根据具体吸汽状况在井口对两端的注汽参数进行调整,提高水平段的均匀吸汽程度。关于直井及水平井注汽条件下的井筒沿程蒸汽参数,Ramey率先提出并建立了注蒸汽井的井筒传热模型,在此基础上,国内外出现了许多该模型的改进形式。Satter[7]考虑了井筒蒸汽冷凝对井筒热损失的影响;Meyer[8]研究了双重孔隙介质的热传导与热扩散规律;Hasan等[9]考虑了注汽时间对井筒传热的影响;Gao等[10]通过引入适当假设,建立了水平井的径向井筒传热模型,该模型可以用于计算和预测水平段方向上的井筒传热规律和油藏温度分布规律。但总的来说,大都是基于单管注汽方式[11-13]。对于平行双管热采井的蒸汽注入井筒沿程参数计算,传统的单管蒸汽注入模型已不再适用,此时需要充分考虑两注汽管之间的温度场耦合效应。本文作者在热传递理论与能量守恒原理的基础上,建立了水平井平行双管注入的蒸汽参数计算模型,以此为基础,提出了水平段封隔器的压力验封流程模型(也称蒸汽回流模型),并进行了求解。

1 模型建立

1.1 基本假设

(1) 注汽过程中,井筒内主、副管位置上下一致,未发生管柱扭曲;

(2) 蒸汽流动是等质量流,井口注汽参数(注汽速率、压力、温度及干度)保持不变;

(3) 注汽管到水泥环外缘为一维稳定传热,水泥环外缘到地层为非稳态传热,不考虑沿井身方向的纵向传热;

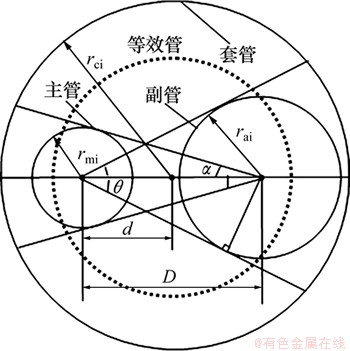

(4) 管柱采用热采封隔器作封,环空充满空气。注汽管柱结构如图1所示。

1.2 沿程压力梯度模型

饱和蒸汽注入到井筒之后成为水汽两相流动,因此需要采用汽液两相流的方法来计算压力变化。根据压力平衡方程,其压力梯度方程主要包括摩擦损失压

图1 稠油水平井平行双管注汽管柱结构示意图

Fig. 1 Schematic diagram of dual-string structure in thermal horizontal wells

力梯度、位能压力梯度和动能压力梯度模型。根据质量守恒与动量守恒,

(1)

(1)

(2)

(2)

式中: 为截面1处饱和水蒸汽密度,kg/m3;

为截面1处饱和水蒸汽密度,kg/m3; 为截面2处饱和水蒸汽密度,kg/m3;

为截面2处饱和水蒸汽密度,kg/m3; 为截面1处饱和水蒸汽流速,m/s;

为截面1处饱和水蒸汽流速,m/s; 为截面2处饱和水蒸汽流速,m/s;A为注汽管柱截面积,m2;

为截面2处饱和水蒸汽流速,m/s;A为注汽管柱截面积,m2; 为饱和水蒸汽质量流量,g/s;p为蒸汽压力,Pa;

为饱和水蒸汽质量流量,g/s;p为蒸汽压力,Pa; 为微元段水蒸汽平均密度,kg/m3;

为微元段水蒸汽平均密度,kg/m3; 为微元段井斜角,(°);

为微元段井斜角,(°); 为微元段水蒸汽所受摩擦力。

为微元段水蒸汽所受摩擦力。

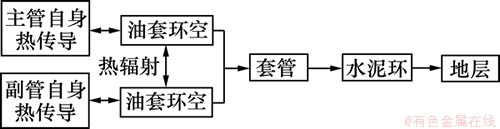

1.3 井筒沿程热损失模型

注汽过程中,各注汽管之间的蒸汽传热主要通过热传导、热对流与热辐射3种形式进行,其中热辐射部分体现了2支注汽管间的热流交换。对于双管注入来说,总的传热过程由以下几个部分组成:主(副)管自身的热传递,主(副)管到副(主)管的热辐射,主(副)管到套管内壁的热辐射,套管与水泥环及水泥环与地层之间的热传递。井筒内部的传热关系如下图2所示, 主、副管间为并联关系,二者经过自身的热传导,一同向环空进行辐射传热,之后经套管、水泥环到达地层。

图2 双管注热井筒传热过程

Fig. 2 Heat conduction process of dual-string steam injection

针对双管的偏心注入问题,引入等效管柱的概念,该管柱的传热过程等效于主、副管传热的综合效应,等效管的几何参数与主、副管尺寸有关。按照等热量传递原则,等效管柱的内、外径尺寸定义如下:

(3)

(3)

式中:rei为等效管内半径,m;rmi为主管内半径,m;rai为副管内半径,m;reo为等效管外半径,m;rmo为主管外半径,m;rao为副管外半径,m。

等效管的传热系数(考虑传热至套管内壁),如下所示:

(4)

(4)

(5)

(5)

(6)

(6)

式中:Ue为等效管传热系数,W/(m2·℃);Um为主注汽管传热系数,W/(m2·℃);Ua为副注汽管传热系数,W/(m2·℃);hmm为主管内壁强迫对流换热系数,W/(m2·℃);hma为副管内壁强迫对流换热系数,W/(m2·℃); 为主/副管导热系数,W/(m·℃);

为主/副管导热系数,W/(m·℃); 为主管对副管的辐射角系数为

为主管对副管的辐射角系数为 ;

; 为主管对套管内壁的辐射角系数,

为主管对套管内壁的辐射角系数, ;

; 为主管对环空的辐射换热系数,W/(m2·℃);hcmc为主管对环空的对流换热系数,W/(m2·℃);hrma为主管对副管的辐射换热系数,W/(m2·℃);hcma为主管对副管的对流换热系数,W/(m2·℃);

为主管对环空的辐射换热系数,W/(m2·℃);hcmc为主管对环空的对流换热系数,W/(m2·℃);hrma为主管对副管的辐射换热系数,W/(m2·℃);hcma为主管对副管的对流换热系数,W/(m2·℃); 为副管对主管的辐射角系数,

为副管对主管的辐射角系数, ;

; 为副管对套管内壁的辐射角系数,

为副管对套管内壁的辐射角系数, ;

; 为副管对环空的辐射换热系数,W/(m2·℃);hcac为副管对环空的对流换热系数,W/(m2·℃);hram为副管对主管的辐射换热系数,W/(m2·℃);hcam为副管对主管的对流换热系数,W/(m2·℃)。

为副管对环空的辐射换热系数,W/(m2·℃);hcac为副管对环空的对流换热系数,W/(m2·℃);hram为副管对主管的辐射换热系数,W/(m2·℃);hcam为副管对主管的对流换热系数,W/(m2·℃)。

按照等效管与套管、水泥环之间的串联关系,进而得到总传热系数:

(7)

(7)

因此,注汽管到水泥环外缘的总传热量(热损失)dQ为:

(8)

(8)

式中:hc为等效管对环空的对流换热系数,W/(m2·℃);hr为等效管对环空的辐射换热系数,W/(m2·℃); 为套管导热系数,W/(m·℃);

为套管导热系数,W/(m·℃); 为水泥环导热系数,W/(m·℃);

为水泥环导热系数,W/(m·℃); 为水泥环外缘半径,m;

为水泥环外缘半径,m; 为套管内缘半径,m;

为套管内缘半径,m; 为套管外缘半径,m;ts为蒸汽温度,℃;tw为水泥环外缘温度,℃。

为套管外缘半径,m;ts为蒸汽温度,℃;tw为水泥环外缘温度,℃。

水泥环到地层间的不稳定导热可以表示为

(9)

(9)

无因次地层导热时间函数f(t)采用修正的Ramey公式[9]为

式中:te为地层温度,℃; 为地层导热系数,W/(m·℃);

为地层导热系数,W/(m·℃); 为无因次时间,

为无因次时间, ;α为地层热扩散系数,m2/h;

;α为地层热扩散系数,m2/h; 为蒸汽注入时间,h。

为蒸汽注入时间,h。

1.4 井筒沿程蒸汽干度模型

考虑摩擦损失对微元体蒸汽干度的影响,即微元体向井筒传递的热量与摩擦损失之和等于微元体在单位长度上单位时间内内能的变化和机械能变化[14-15],建立的能量守恒方程如下:

(10)

(10)

式中:

.

.

.

.

.

.

式中:dQ为微元段总传热量,W;dW为微元段水蒸汽摩擦力做功,W;Hm为水蒸汽热焓,kJ/kg,vm为水蒸汽流速,m/s;Lv为汽化潜热,kJ/kg;x为微元段水蒸汽干度。

结合上述方程,即可以得到双管注蒸汽条件下的井筒不同位置处的蒸汽参数。

2 模型求解

2.1 未知参量处理

(1) 摩擦力的求取。此处选用文献[14]中关于摩擦力的计算公式:

(11)

(11)

(2) 两相阻力系数的求取。根据Beggs-Brill方法,计算过程中采用两相雷诺数,

,阻力系数的计算采用文献[16]中所用方法。

,阻力系数的计算采用文献[16]中所用方法。

(3) 饱和水蒸汽状态方程。饱和水蒸汽的饱和温度与饱和压力关系如下式所示:

(12)

(12)

(4) 环空压力降。计算环空气液两相流动时,仍采用上述圆管流动方程,此时需要引入环空水力当量直径与环空当量粗糙度的概念:

(13)

(13)

(14)

(14)

式中:D1和D2分别为内管外径与外管内径,m;ε1和ε2分别为内管外壁粗糙度与外管内壁粗糙度。

2.2 模型求解步骤

将水平井井筒自井口到井底分为N段,每段长度为△z,压力增量为△p,蒸汽干度变化为△x;从井口(i=1)开始计算:

(1) 计算微元段内饱和水蒸汽的物性参数与运动参数,进而根据方程(1)和(2)分别计算出主、副管微元段的水蒸汽井筒压力损失dp。

(2) 假设微元段的总传热系数为U=0.50,由步骤(1)中所得到的压力增量dp计算微元段水蒸汽物性参数,并根据方程(4)~(9)求取总传热系数Ut。判断|Ut-U|<ε是否成立,若成立则分别计算主、副管热损失转向下一步,若不成立则令U=Ut继续迭代。

(3) 按照方程(10)求取微元段蒸汽干度损失dx;判断微元段内|dp-△p|<ε与|dx-△x|<ε是否成立,若成立转向下一步,若不成立则令△p=dp,△x=dx,转向步骤(1)。

(4) 令i=i+1,以上一节点为起点,进行下一节点求解,重复步骤(1)~(3),直到到达井底为止。

3 实例计算

3.1 井筒蒸汽参数计算

由于采用平行双管完井的水平井垂直段井筒半径都较大,因此该方式目前主要用于较浅层的稠油油藏,国内的辽河、胜利与新疆油田均有应用。以新疆重32井区的某一热采双管水平井为例,计算平行双管完井条件下的井筒热损失程度,基础数据如表1所示。分别研究注汽方式与注汽参数对井筒热损失程度和沿程压力梯度的影响。

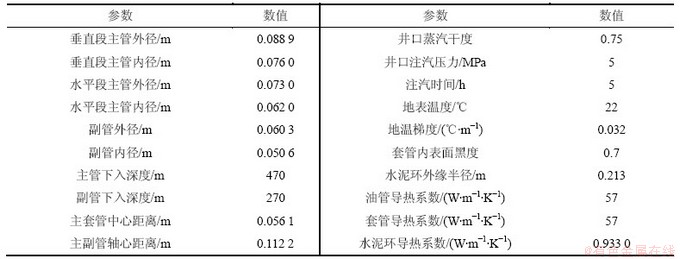

表1 井身结构基础数据

Table 1 Basic data of wellbore structure

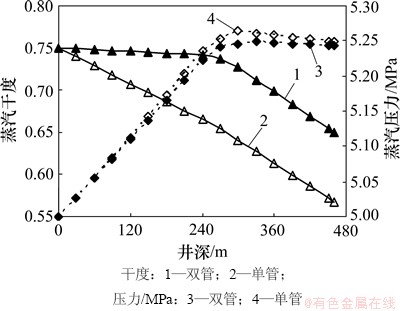

3.1.1 不同的注汽方式

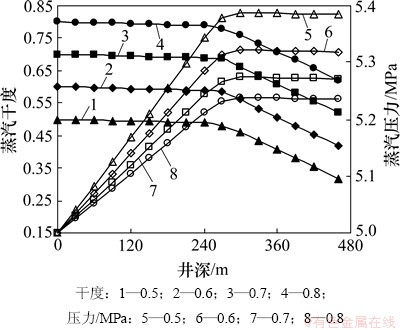

现场实际注汽过程中,为了减小双管注汽水平井前后两段吸汽剖面的差异,会采用不同的注汽方式,主要有双管同注方式与单管注入方式2种,单管注入即仅单一的主管注汽方式。以表1中的基础数据为依据,2种方式下的注汽速率均为8 t/h,分别计算该双管水平井在不同注汽方式下的热损失程度以及井筒的蒸汽沿程压力梯度,结果如图3所示。由于井筒热损失的存在,导致随着井深的增大,井筒蒸汽干度逐渐降低。而且由于两注汽管热流交换与热量补充的原因,采用双管同注方式下的井底蒸汽干度更大,且井筒蒸汽干度主要损失于水平段,这主要是由于水平方向上仅有单管注汽的缘故。此外对于垂直段井筒来说,由于重力势能的原因,井筒蒸汽压力随着深度的增大而增大,对于水平段井筒,随着深度的增大,井筒蒸汽压力呈降低趋势,并且采用单管注入方式时,蒸汽压力降低的趋势更加明显。

图3 不同注汽方式下的井筒蒸汽干度与蒸汽压力

Fig. 3 Steam quality and steam pressure of different steam injection methods

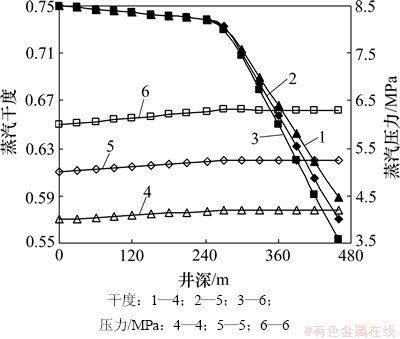

3.1.2 不同的注汽参数

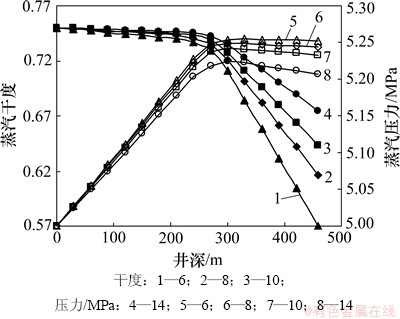

(1) 注汽压力的影响。注汽压力对井筒蒸汽热损失程度的影响如图4所示。蒸汽注入方式采用双管同注方式,注汽速率为7 t/h。结果可见井口注汽压力对垂直段蒸汽干度影响较小,对水平段蒸汽干度影响较大,这是由于模型考虑了水平段井筒摩阻对热损失的影响。井口注入压力越大,井筒摩擦损失越大,从而热损失增大,导致井底蒸汽干度减小。

(2) 蒸汽干度的影响。井口蒸汽干度对井筒沿程蒸汽参数的影响如图5所示。蒸汽注入方式采用双管同注方式,注汽速率为7 t/h。井口注入蒸汽干度对井筒蒸汽压力影响较大,干度越大,则位能损失越小,从而导致压力增幅减小,即高干度下的井底蒸汽压力较低干度下的小。此外,蒸汽干度从0.8变化至0.7的井筒压力变化幅度比蒸汽干度从0.6变化至0.5的井筒压力变化幅度要小,可见:干度对井筒蒸汽压力的影响不是线性的,此外,注入蒸汽干度主要损失于水平段,对垂直段井筒热损失影响较小。

图4 不同注汽压力下的井筒蒸汽干度与蒸汽压力

Fig. 4 Steam quality and steam pressure of different steam injection pressure

图5 不同井口蒸汽干度下的井筒干度与蒸汽压力

Fig. 5 Steam quality and steam pressure of different well-head steam qualities

(3) 注汽速率的影响。注汽速率对井筒沿程蒸汽参数的影响如图6所示。注入方式采用双管同注方式,蒸汽干度与注汽压力不变。结果显示注汽速率对井筒蒸汽干度与蒸汽压力均有不同程度的影响。注汽速率越大,井筒摩擦损失越大,从而蒸汽压力也就越小;注汽速率越大,热能补充越充足,蒸汽热能损失也就越小,从而井筒蒸汽干度越大。

图6 不同注汽速率下的井筒蒸汽干度与蒸汽压力

Fig. 6 Steam quality and steam pressure of different steam injection rates

3.1.3 不同的管柱尺寸

考虑到地面蒸汽锅炉与注汽管线的限制,在矿场实际注汽过程中,各注汽井的井口注汽参数一般难以有太大的调整,为此计算了不同管柱尺寸组合下的注汽管井筒沿程蒸汽参数。结果显示在双管注汽条件下,对于井筒沿程的蒸汽干度,注汽管柱尺寸越小,相应管柱的热损失程度越小,蒸汽干度越高。而且由于双管注汽过程的井筒热损失主要存在于水平段,因此在注汽过程中,为了使得井底获得更高干度的蒸汽,主注汽管水平段管柱的尺寸应尽可能的小。

3.2 压力验封过程

3.2.1 验封过程分析

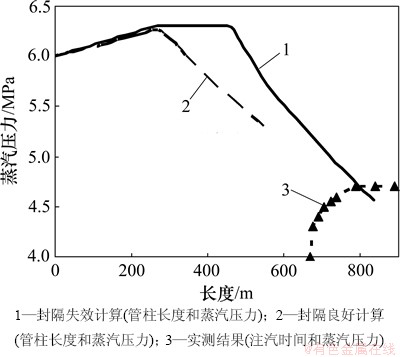

实际矿场中,为了检验水平段封隔器的坐封状态,需要进行验封作业。验封时,从主管或者副管注入饱和蒸汽,若封隔器坐封失效,则注入的蒸汽会通过油套环空从副管与环空回流至井口,进而通过测取井口环空或者副管处的蒸汽状态可反推出封隔器的实际坐封状态;相反若封隔器坐封良好,则主管注入的蒸汽不会回流至井口,仅有副管注入的蒸汽回流至井口。

对于封隔失效的情况,在进行验封计算时,可以将蒸汽在井筒内的流动分为以下4个过程:(1) 主管饱和蒸汽下降流;(2) 水平段注汽管柱气液两相流;(3) 水平段环形空间气液两相流;(4) 环空/副管上升流。对于封隔良好的情况,蒸汽在井筒内的流动主要包括以下2个过程:(1) 副管饱和蒸汽下降流;(2) 环空上升流。通过对封隔器封隔失效与封隔良好2种情况下的蒸汽流动过程进行计算,在获得了井口蒸汽参数的基础上,对比实测的井口蒸汽压力,便可得到井底封隔器状态。

3.2.2 验封计算

以表1中的双管热采水平井为基础,分别对水平段封隔器封隔失效与封隔良好2种情况进行计算,计算结果与实测的井口环空压力变化曲线如图7所示。在进行变压力验封作业时,主、副管先同时注汽4 h(注汽压力6 MPa,干度0.8),接着主副管同时关闭2 h,观察主管与环空压力变化,之后打开主管,注汽2~3 h,再观察环空压力变化。计算得到的封隔失效与封隔良好2种情况下的井口环空压力分别为4.56和5.30 MPa,实测的稳定后的井口环空压力为4.70 MPa,与封隔失效时的计算结果相差2.98%,因此可以得到该水平井水平段封隔器封隔失效的结论。

图7 双管热采水平井水平段封隔器验封曲线

Fig. 7 Checking curves of sealed state of packer in the horizontal segment

4 结论

(1) 考虑到传统注汽井筒参数计算模型的局限性,本文在充分考虑各注汽管间热场耦合的基础上,建立了平行双管注汽井筒的蒸汽参数预测模型与蒸汽回流模型,该模型稳定可靠,易于求解。

(2) 通过引入实际的双管注汽实例,采用节点分析方法计算平行双管注汽过程中的井筒沿程蒸汽参数,并分析了注汽方式、注汽参数以及注汽管尺寸等参数对平行双管注汽过程中井筒沿程蒸汽参数的影响。

(3) 平行双管同注蒸汽可以充分提高热采注汽井的井底蒸汽质量约0.1以上;井口注入压力对注蒸汽热损失影响不大,井口蒸汽干度越大,井底压力越小,蒸汽干度也越大;注入速率越大,热能补充越快,井筒热损失减小,井底蒸汽干度越大;在矿场实际注汽过程中,为了使得井底获得更高干度的蒸汽,主注汽管水平段管柱的尺寸应尽可能的小。

(4) 采用蒸汽回流模型,对封隔器封隔失效与封隔良好2种条件下的蒸汽流动状况进行了计算,对比分析了计算结果与实测结果误差情况,结果发现文中所举的热采双管水平井封隔器封隔失效。

参考文献:

[1] 王家宏. 中国水平井应用实例分析[M]. 北京: 石油工业出版社, 2003: 86-92.

WANG Jiahong. Application analysis of China horizontal well[M]. Beijing: Petroleum Industry Press, 2003: 86-92.

[2] Florez A A, Araujo P Y, Uzcategui R M, et al. Improved heavy oil recovery by drilling horizontal wells in Rubiales field, colombia[R]. Mexico City: Society of Petroleum Engineers, 2012: 1-14.

[3] 黄学军, 崔桂香, 张兆顺. 变质量管内流动与油藏耦合的数值模拟[J]. 重庆大学学报(自然科学版), 2000, 23(S0): 80-82.

HUANG Xuejun, CUI Guixiang, ZHANG Zhaoshun. Numerical simulation of the coupling flow between the wellbore and oil reservoir[J]. Journal of Chongqing University (Natural Science Edition), 2000, 23(S0): 80-82.

[4] 苏玉亮, 张东, 李明忠. 油藏中渗流与水平井筒内流动的耦合数学模型[J]. 中国矿业大学学报, 2007, 36(6): 752-758.

SU Yuliang, ZHANG Dong, LI Mingzhong. Mathematical model coupling seepage in the reservoir with flow in the horizontal wellbore[J]. Journal of China University of Mining & Technology, 2007, 36(6): 752-758.

[5] ZHONG Liguo, ZHANG Shoujun, WU Fei, et al. Improved heavy-oil recovery by separated-zones horizontal-well steam stimulation[J]. Journal of Canadian Petroleum Technology, 2012, 51(2): 106-114.

[6] Hlght M A, Redus C L, Lehrmann J K. Evaluation of dual-injection methods for multiple-zone steamflooding[J]. SPE Reservoir Engineering, 1992, 7(1): 45-51.

[7] Satter A. Heat losses during flow of steam down a wellbore[J]. Journal of Petroleum Technology, 1965, 17(7): 845-851.

[8] Meyer B R. Heat transfer in hydraulic fracturing[J]. SPE Production Engineering, 1989, 4(4): 423-429.

[9] Hasan A R, Kabir C S. Heat transfer during two-phase flow in wellbores: part I—Formation temperature[R]. Dallas: Society of Petroleum Engineers, 1991: 469-478.

[10] Gao G H, Jalali Y. Prediction of temperature propagation along a horizontal well during injection period[J]. SPE Reservoir Evaluation & Engineering, 2008, 11(1): 131-140.

[11] 杨德伟, 黄善波, 马冬岚, 等. 注蒸汽井井筒两相流流动模型的选择[J]. 石油大学学报(自然科学版), 1999, 23(2): 44-46.

YANG Dewei, HUANG Shanbo, MA Weilan, et al. Selection of models for two phase flow in the steam injection well[J]. Journal of University of Petroleum, China, 1999, 23(2): 44-46.

[12] 王利群, 周惠忠. 水平井沿井管射孔蒸汽出流分布的计算模型[J]. 清华大学学报(自然科学版), 1996, 36(4): 76-81.

WANG Liquan, ZHOU Huizhong. Model for steam mass flow rate distribution from the holes along horizontal well[J]. Journal of Tsinghua University (Sci & Tech), 1996, 36 (4): 76-81.

[13] 宋永臣, 王志国, 杨文哲, 等. 注蒸汽井筒热损模拟实验及改进设计研究[J]. 工程热物理学报, 2010, 31(10): 1731-1734.

SONG Yongchen, WANG Zhiguo, YANG Wenzhe, et al. Heat loss experiment of steam injection wellbore and its improved design[J]. Journal of Engineering Thermophysics, 2010, 31(10): 1731-1734.

[14] 倪学锋, 程林松, 李春兰, 等. 注蒸汽井井筒内参数计算新模型[J]. 计算物理. 2005, 22 (3): 251-255.

NI Xuefeng, CHENG Linsong, LI Chuanlan, et al. A new model for the steam properties in steam injection wells[J]. Chinese Journal Computation of Physics, 2005, 22(3): 251-255.

[15] 刘慧卿, 范玉平, 赵东伟, 等. 热力采油技术原理与方法[M]. 东营: 石油大学出版社, 2000: 30-34.

LIU Huiqing, FAN Yuping, ZHAO Dongwei, et al. Theory and method of thermal recovery[M]. Dongying: University of Petroleum Press, 2000: 30-34.

[16] 张琪. 采油工程原理与设计[M]. 东营: 石油大学出版社, 2006: 33-49.

ZHANG Qi. Theory and design of production engineering[M]. Dongying: University of Petroleum Press, 2006: 33-49.

(编辑 陈爱华)

收稿日期:2013-03-26;修回日期:2013-05-15

基金项目:国家自然科学基金资助项目(51274212)

通信作者:东晓虎(1986-),男,陕西西安人,博士研究生,从事油藏工程与提高采收率方面的研究;电话:010-89731163;E-mail: dongxh0578@gmail.com