2124铝合金热轧厚板的热处理制度

王昌臻1,潘清林1,何运斌1,邹 亮1,尹志民1,聂 波2,何振波2

(1. 中南大学 材料科学与工程学院,湖南 长沙,410083;

2. 东北轻合金有限责任公司,黑龙江 哈尔滨,150060)

摘 要:通过室温拉伸性能测试和DSC,OM,TEM分析,研究了不同固溶处理和时效处理对2124铝合金40 mm厚板组织与性能的影响。结果表明:合金适宜的固溶温度为495~500 ℃,固溶时间为80~100 min;适当提高固溶温度或延长固溶时间,合金中过剩相的溶解程度增大,合金的固溶程度增大,因而合金强度提高,但过高的固溶温度或固溶时间使合金的伸长率降低;当淬火水温度在16~35 ℃范围内时,合金性能变化不大,但稍高水温淬火有利于提高合金的伸长率;随淬火转移时间的延长,合金的强度有所上升,但伸长率下降,为了提高合金的塑韧性,淬火转移时间应尽可能短;合金适宜的时效温度为185 ℃,时效时间为12 h,合金主要强化作用来源于S′和θ′过渡相的析出强化。

关键词:2124铝合金;热处理;组织;力学性能

中图分类号:TG146.2 文献标识码:A 文章编号:1672-7207(2007)03-0386-08

WANG Chang-zhen1, PAN Qing-lin1, HE Yun-bin1, ZOU Liang1, YIN Zhi-min1, NIE Bo2, HE Zhen-bo2

(1. School of Materials Science and Engineering, Central South University, Changsha 410083, China;

2. Northeast Light Alloy Co. Ltd., Harbin 150060, China)

Abstract: The microstructures and properties of 2124 alloy in different solutions and aging treatments were studied by tensile test, DSC, OM and TEM analysis. The results show that the suitable solution temperature and time of alloy are 495-500 ℃ and 80-100 min, respectively. Increasing the temperature or extending the time of solution properly can accelerate the solution of excess phase, which can raise the degree of solution of alloy and improve the strength of alloy, but the excessive temperature or time of solution reduces the elongation of alloy. The properties change little when the temperature of quench ranges in 16-35 ℃, but increasing temperature improves the elongation. The strength increases and elongation decreases with prolonging transfer time, and in order to improve the strength and elongation, the transfer time should be deduced as far as possible. The suitable aging temperature and time are 185 ℃ and 12 h respectively, S′ and θ′ phase are the main strengthening phases of alloy.

Key words: 2124 aluminum alloy; heat treatment; microstructure; mechanical properties

2124铝合金是20世纪70年代美国在传统2024铝合金的基础上,通过降低铁、硅等杂质含量而发展起来的航空用Al-Cu-Mg系高纯高强高韧铝合金[1],通常以厚板T851状态使用,美国在1台F-16战斗机上使用约99个加工件,质量达1 t左右[2]。通过调整成分、提高纯度和采用新的热处理工艺,2124合金不仅保持2024合金的强度,而且具有较好的断裂韧性和疲劳性能,其厚板的伸长率和韧性比2024合金的高,尤其是短横向性能更为突出,是一种应用前景广阔的新型铝合金材料。近年来,国内外主要研究了2124合金的断裂行为和析出相,但对其厚板热处理制度的研究较少[3-5]。在此,本文作者研究2124铝合金热轧厚板固溶处理制度与时效处理制度,并对其组织性能与热处理工艺参数的关系进行分析。

1 实 验

本实验研究使用的2124铝合金40 mm热轧厚板和2%预拉伸厚板由东北轻合金有限责任公司提供,采用半连续铸造技术制备的铸锭(厚度为440 mm)经均匀化处理后热轧至40 mm厚板材。沿长横向截取试样进行组织观察和拉伸性能测试。试样在箱式电阻炉中进行固溶处理,在电热鼓风干燥箱中进行时效。合金的室温拉伸力学性能测试在CSS–44100电子万能材料实验机上进行,拉伸速度为1 mm/min。热分析在Universal V4.10 TA Instruments热分析仪上进行。金相显微分析在POLYVER–MET金相显微镜上进行,样品采用Keller试剂腐蚀。透射电镜样品经机械预减薄后双喷穿孔而成,电解液为硝酸与甲醇混合液(体积比为1?3),温度约-20 ℃。TEM组织观察在TECNAI G2 20电镜上进行,加速电压为200 kV。

2 实验结果

2.1 固溶处理制度对合金热轧厚板组织与性能的 影响

2.1.1 固溶温度对合金组织性能的影响

合金热轧板在不同固溶温度(470~520 ℃)下固溶80 min,冷水淬火后于185 ℃时效12 h的拉伸力学性能见图1。可见,合金的抗拉强度和屈服强度随着固溶温度的升高逐渐增加,而伸长率在470~510 ℃不断增加,在510 ℃后达到最大值后随固溶温度的升高又开始呈现出显著下降的趋势。从固溶前合金的DSC曲线可以看出,合金的过烧温度为509 ℃(图2),由文献[1]可知,固溶温度应该低于过烧温度10~15 ℃,又考虑到实际生产中的各种影响因素,在满足力学性能要求的前提下,热轧板适宜的固溶处理温度应控制在495~500 ℃范围内为宜。

图1 合金固溶温度与力学性能的关系

Fig.1 Relationship between solution temperature and mechanical properties of alloy

图2 热轧态合金的DSC曲线

Fig.2 DSC curve of hot-rolled plates

图3所示为合金不同固溶温度处理下金相显微组织。由图3可知,经不同固溶温度处理后,合金中还存在少量残留的未溶第二相。随着固溶温度的升高(图3(a)~(c)),合金中未溶的第二相数量逐渐减少,晶粒呈长大倾向;温度升至520 ℃ 时,晶界出现粗化现象,另外还可见少量的复熔共晶球,表明已发生轻微过烧(图3(c))。

(a) 480 ℃, 80 min; (b) 498 ℃, 80 min; (c) 520 ℃, 80 min

图3 不同固溶温度处理后合金的金相组织

Fig.3 Optical micrographs of alloy under different temperatures of solution treatment

2.1.2 固溶时间对合金组织性能的影响

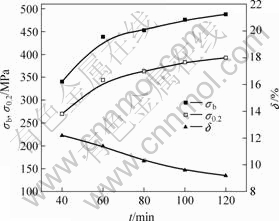

合金热轧板在498 ℃分别固溶40,60,80,100和120 min冷水淬火后于185 ℃时效12 h的拉伸力学性能见图4。可以看出,随着固溶时间的延长,合金的抗拉强度和屈服强度都不断增加,并且在开始阶段增加较快,后来趋于缓慢,而伸长率则一直缓慢下降。综合考虑合金的强度和塑性,固溶时间在80~100 min为宜。

图4 合金固溶时间与力学性能的关系

Fig.4 Relationship between solution time and mechanical properties of alloy

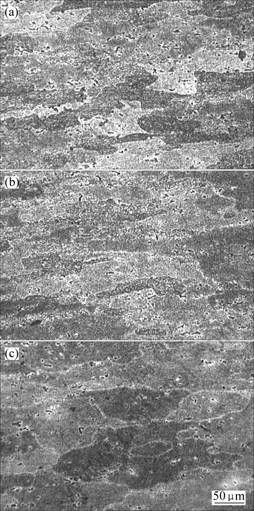

图5所示为合金经不同固溶时间处理后的金相显微组织。由图5可知,经不同固溶时间处理后,合金中还存在少量残留的未溶第二相,随着固溶时间的增加(图5(a)~(c)),合金中未溶的第二相数量逐渐减少,晶粒出现长大倾向。

(a) 498 ℃, 40 min; (b) 498 ℃, 80 min; (c) 498 ℃, 120 min

图5 不同固溶时间处理后合金的金相组织

Fig.5 Optical micrographs of alloy under different time of solution treatment

2.1.3 淬火水温对合金热轧板组织性能的影响

图6所示为热轧板经498 ℃固溶80 min后,在不同的淬火水温(16,20,25和35 ℃)淬火后于185 ℃时效的拉伸力学性能。

图6 合金淬火水温与力学性能的关系

Fig.6 Relationship between water temperature of quench and mechanical properties of alloy

从图6可以看出,淬火水温对合金的性能影响不明显,水温较低(16 ℃)时,有利于合金的抗拉强度和屈服强度,而随着淬火水温从16 ℃升高到35 ℃,伸长率增大约1%,说明水温的升高有助于提高合金的塑性。

图7所示为40 mm热轧板经498 ℃固溶80 min,分别在20,25和35 ℃的水中淬火后于185 ℃时效12 h的金相组织。可以看出,淬火水温分别为20,25和35 ℃ 时,合金的晶粒大小没有明显变化,晶内都存在一定的过剩相,可见淬火水温在16~35 ℃范围内变化时对合金的组织没有明显影响。

(a) 20 ℃; (b) 25 ℃; (c) 35 ℃

图7 不同淬火水温处理后合金的金相组织

Fig.7 Optical micrographs of alloy under different temperatures of water quench

2.1.4 淬火转移时间对合金热轧板组织性能的影响

图8所示为热轧板经498 ℃固溶80 min,在16 ℃ 的淬火介质中进行淬火,淬火转移时间分别为1,5,15和30 s, 再经185 ℃时效12 h后的拉伸力学性能图。可以看出,随着淬火转移时间的延长,合金的抗拉强度和屈服强度缓慢升高,而合金的伸长率逐渐下降。从合金强度方面考虑,转移时间在1~35 s范围内,延长淬火转移时间可以提高合金的强度,但使合金的塑性降低2%。为了提高合金的塑韧性,建议淬火转移时间应尽可能短。

图8 合金淬火转移时间与力学性能的关系

Fig.8 Relationship between transfer time of quench and mechanical properties of alloy

图9所示为热轧板经498 ℃固溶80 min,在16 ℃ 的淬火介质中进行淬火,淬火转移时间分别为5,15和30 s,再经185 ℃时效12 h后不同的金相组织。由图9可以看出,转移时间为5 s时,第二相粒子最少,随着淬火转移时间的延长,可略见未固溶的第二相粒子增多。因此,淬火转移时间应尽可能短。

(a) 5 s; (b) 15 s; (c) 30 s

图9 不同淬火转移时间后合金的金相组织

Fig.9 Optical micrographs of alloy under different transfer time of water quench

2.2 时效制度对合金预拉伸板组织与性能的影响

2.2.1 时效制度对合金拉伸性能的影响

图10所示为合金经498 ℃固溶处理80 min,冷水淬火,2%预拉伸后,分别在170,185和200 ℃时效不同时间的拉伸力学性能曲线。可以看出,合金在170,185和200 ℃时效均具有显著的时效强化特性。170 ℃时效时,时效初期合金的抗拉强度出现下降过程,然后逐渐升高,屈服强度则一直缓慢上升,继续增加时效时间,强度在16 h达到峰值,随后下降;185 ℃时效时,抗拉强度在8 h前逐渐升高,屈服强度在 8 h前急剧增加,在8~16 h强度达到峰值,随后缓慢下降;200 ℃时效时,抗拉强度在时效初期有一个下降过程,随后变化不明显,屈服强度在4 h前急剧升高,在8~12 h达到强度峰值后缓慢下降。伸长率在170 ℃时效一直缓慢下降;在185 ℃和200 ℃时效初期急剧下降,随后变化不大。对比不同温度下的时效曲线可看出,随着时效温度的升高,合金达到强度峰值的时间缩短,强化速度加快,且峰值强度较低。因此,适宜的峰值时效制度为185 ℃,12 h。在此条件下,合金的抗拉强度(σb)、屈服强度(σ0.2)和伸长率(δ)分别为483 MPa,454 MPa和7.4%。

(a) 170 ℃; (b) 185 ℃; (c) 200 ℃

图10 时效处理对合金力学性能的影响

Fig.10 Effect of ageing processes on mechanical properties of alloy

2.2.2 时效制度对合金TEM显微组织的影响

图11所示为合金经498 ℃,80 min固溶、冷水淬火及2%预拉伸后,于不同时效制度时效后的TEM显微组织。从图11可以看出,合金经170 ℃时效12 h时有少量针状S′ (Al2CuMg)相析出,尺寸细小,还有部分预拉伸处理后形成的位错缠结(图11(a)),表明在较低温时效条件下,沉淀相析出长大速度较慢;合金在185 ℃时效12 h时,位错缠结基本消失,晶内除了在一定的惯习面上析出大量针状的S′相外,还有少量细小的θ′ (CuAl2)相开始析出,呈弥散分布(图11(c)),当合金在200 ℃时效12 h时,细小针状的S′相长大为粗大的S平衡相,θ′长大为θ相,呈大量弥散分布(图11(e)),且在高放大倍数下可见θ相周围出现一个位错绕过时形成的位错环(图11(f)),表明高温下平衡相析出长大速度加快。比较图11(c)和图11(d)可知,合金在185 ℃时效4 h时,晶内有少量细小的S′相(图11(b));延长时效时间至24 h时,S′相明显粗化长大,且有部分转变为S平衡相,表明已经进入过时效阶段(图11(d))。

(a) 170 ℃,12 h; (b) 185 ℃,4 h; (c) 185 ℃,12 h; (d) 185 ℃,24 h; (e), (f) 200 ℃,12 h

图11 不同时效处理后合金的TEM显微组织

Fig.11 TEM microstructure of alloy under different ageing processes

3 讨 论

3.1 固溶处理制度对合金组织与性能的影响

研究表明,合金中的过剩相主要是热加工过程中形成的S(Al2CuMg)和θ(CuAl2)等第二相[1]。合金的力学性能与其固溶程度密切相关。通过确定合理的固溶制度,使合金中粗大的第二相尽可能地溶入基体中,提高溶质原子在基体中的固溶度,进而增加时效过程中的相变驱动力,即可使主要强化相S′的形核率提高,从而使析出物数量增加,尺寸减小,合金强度提高[5]。

当合金的固溶温度在500 ℃以下或固溶时间少于80 min时,各合金元素未充分固溶到基体中,合金组织中仍存在较多的过剩相,使合金的固溶强化和随后的沉淀强化效果减小,此合金强度较低;温度上升到500 ℃以上或时效时间大于80 min时,过剩相减少到一定程度后,而此时溶质原子的溶入增量有限,固溶原子的固溶强化和随后的沉淀强化效果增加趋势已不大,所以,当温度超过500 ℃以后或时效时间大于80 min时合金的强度上升缓慢。值得注意的是, 温度在520 ℃时已经达到合金的过烧温度,但强度还未出现下降的趋势,由文献[6]可知,主要是因为轻微过烧对拉伸时的力学性能没有明显的影响,但金属中存在的这种过烧组织会使冲击载荷下的强度大大降低。因此,固溶温度应该根据具体情况确定。

合金的伸长率随着固溶温度的升高呈先上升后下降的趋势,合金中的过剩相是影响合金塑性的主要因素。金属的塑性变形主要通过位错运动来实现,合金中存在硬而脆的过剩相,阻碍了位错运动,对塑性产生不利影响。固溶温度低(480 ℃),合金中未溶解的过剩相较多,导致合金塑性较低,提高固溶温度,合金中过剩相充分溶解,使合金塑性提高。但固溶温度过高(520 ℃)时,合金发生轻微过烧,出现复熔共晶球和局部晶界宽化现象,使合金的伸长率迅速降低[7]。

3.2 时效处理制度对合金组织与性能的影响

透射电镜观察分析表明,2124合金中主要强化相为S′相和少量θ′相。平衡相S和θ的强化作用较小。合金在时效过程中强度的变化主要由GP区、过渡相和平衡相的大小、数量和分布决定[8-13]。

时效初期合金组织的变化主要是GP区的回溶和过渡相的析出长大,对于本实验预拉伸厚板,由于自然时效时形成的大部分GP区小于临界尺寸,在时效过程中,大量GP区回溶,而少量大于临界尺寸的GP区转变成过渡相,进而转变成平衡相,这些相的尺寸较粗大,含量较少,对位错运动的阻碍作用较小,合金强度较低,导致时效初期出现软化回归现象,表现为170 ℃和200 ℃时效初期抗拉强度出现一个降低的 过程。

随着时效时间的延长,过渡相进一步长大,呈大量弥散分布。由于过渡相与基体保持半共格关系,它造成的晶格畸变比GP区的大,内应变场阻碍位错运动的作用也增大,另外,由于过渡相具有独立的面心立方正交结构,它不同于基体的晶体结构,所以,位错切割时还要消耗能量,位错线切割析出相颗粒时,不仅需要克服析出相颗粒所造成的应力场,还由于析出相颗粒被切成2部分,因而表面能增加,并改变了析出相内部原子之间的邻近关系,使能量升高,引起强 化[14]。所以,均匀分布的GP区加上均匀弥散的过渡相能使合金获得最佳的强化效果,合金出现强度峰值。

继续增加时效温度或延长时效时间,过渡相慢慢长大粗化,随后转变为平衡相,并与基体失去共格关系,成为一种独立的相结构。当析出相长大到一定尺寸时,位错遇到第二相时,由切割机制转变为绕过机制,在第二相周围连续地产生位错环(图11(e),(f)),形成位错塞积。由Orowan机制[15]可知,屈服强度与第二相属性无关,只取决于第二相的尺寸及分布,屈服应力反比于第二相粒子间距,因此,屈服应力降低,合金达到过时效状态。

4 结 论

a. 固溶温度和固溶时间对2124铝合金热轧厚板的拉伸力学性能影响较大,合金适宜的固溶温度为495~500 ℃,固溶时间为80~100 min。

b. 适当提高固溶温度或延长固溶时间,合金中过剩相的溶解程度增大,提高了合金的固溶程度,从而提高合金的强度,但过高固溶温度或固溶时间使合金的伸长率降低。

c. 淬火水温度在16~35 ℃范围内,合金性能变化不大,但稍高水温淬火有利于提高合金的伸长率。

d. 随着淬火转移时间的延长,合金的强度有所上升,但伸长率下降。为了提高合金的塑韧性,淬火转移时间尽可能短。

e. 2124合金在170,185和200 ℃时效均具有显著的时效强化特性,合金适宜的时效温度为185 ℃,时效时间为12 h。

f. 2124合金主要强化作用来源于S′和θ′过渡相的析出强化。

参考文献:

[1] 王祝堂, 田荣璋. 铝合金及其加工手册[M]. 长沙: 中南大学出版社, 2000.

WANG Zhu-tang, TIAN Rong-zhang. Manual for aluminium alloy and its processing[M]. Changsha: Central South University Press, 2000.

[2] 郑玉珍, 刘存玉, 刘金凤. 影响2124铝合金断裂韧性的因素[J]. 航空材料, 1989, 9(4): 16-23.

ZHENG Yu-zhen, LIU Cun-yu, LIU Jin-feng. Influence of some factors on fracture toughness of 2124 aluminium alloy[J]. Aeronautical Materials, 1989, 9(4): 16-23.

[3] 梁忠华. 2124铝合金铸态及厚板的组织分析[J]. 黑龙江大学自然科学学报, 1996, 12(2): 72-76.

LIANG Zhong-hua. Microscopical structures analysis of cast constitution and plant in 2124 aluminium alloy[J]. Journal of Natural Science of Heilongjiang University, 1996, 12(2): 72-76.

[4] 李满良, 初春溪, 许晨玲. 组元含量和T851参数对2124合金厚板组织和性能的影响[J]. 轻合金加工技术, 1991, 19(1): 20-25.

LI Man-liang, CHU Chun-xi, XU Chen-ling. Effect of component content and parameter of T851 on microstructure and tensile properties of the thick hot-rolled plate of 2124 alloy[J]. Light Alloy Fabrication Technology, 1991, 19(1): 20-25.

[5] 宁爱林. 固溶处理对高纯高强铝合金组织和性能的影响[J]. 金属热处理, 2004, 29(4): 13-16.

NING Ai-lin. Effect of solution treatment on microstructure and properties of high-purity and high-strength aluminum alloy[J]. Heat Treatment of Metals, 2004, 29(4): 13-16.

[6] 高树增,侯振庆. 2A12-T81 铝合金板材热处理工艺研究[J]. 轻合金加工技术, 1998, 2(9): 39-42.

GAO Shu-zeng, HOU Zhen-qing. Research on heat treatment process for aluminum alloy 2A12-T81 sheet[J]. Light Alloy Fabrication Technology, 1998, 2(9): 39-42.

[7] 胡赓祥. 金属学[M]. 上海: 上海科技出版社, 1980.

HU Geng-xiang. Metallic theory[M]. Shanghai: Shanghai Science and Technology Press, 1980.

[8] YAN Jin. A precipitate phase in AA2124[J]. Journal of Materials Science, 1991, 26: 3244-3248.

[9] Smith G W. Precipitation kinetics in solutionized aluminum alloy 2124 determination by scanning and isothermal calorimetry[J]. Thermochimica Acta, 1998, 317: 7-23.

[10] Wang S C. Precipitation hardening in Al-Cu-Mg alloys revisited[J]. Scripta Materialaia, 2006, 54: 287-291.

[11] Srivatsan T S. Microstructure, tensile properties and fracture behaviour of an Al-Cu-Mg alloy 2124[J]. Journal of Materials Science, 1993, 28: 3205-3212.

[12] 王莉梅. Al-Cu-Mg系合金时效过程的电镜观察[J]. 轻合金加工技术, 1995, 23(26): 15-19.

WANG Li-mei. TEM observation during aging prosess of Al-Cu-Mg alloy[J]. Light Alloy Fabrication Technology, 1995, 23(26): 15-19.

[13] Sivakumar K. Microstructural characteristics of shock consolidated 2124 Al alloycompacts[J]. Journal of Materials Science, 1997, 32: 5271-5278.

[14] 徐 洲, 赵连城. 金属相变原理[M]. 北京: 科学出版社, 2004.

XU Zhou, ZHAO Lian-cheng. Principle of metallic phase transition[M]. Beijing: Science Press, 2004.

[15] Honycomber W K. The plastic deformation of metals[R]. Edwad Arnold Ltd, 1984: 18.

收稿日期:2006-09-28

基金项目:湖南省杰出青年科学基金资助项目(06JJ10007); 国家高技术研究发展计划资助项目(2006AA03Z560)

作者简介:肖 鹏(1971-),男,湖南涟源人,博士,从事高性能陶瓷基复合材料制备及应用研究

通讯作者:肖 鹏,教授;电话:0731-8830131;E-mail:xiaopeng@mail.csu.edu.cn