隐晶质石墨提纯工艺中硅的焙烧动力学研究

张清岑,刘建平,肖 奇

(中南大学 资源加工与生物工程学院, 湖南 长沙 410083)

摘要: 研究了隐晶质石墨的提纯工艺中焙烧动力学方程。分析了焙烧时间、焙烧温度及矿样原始尺寸对焙烧过程中脱硅效果的影响。研究结果表明:硅是最难脱除的杂质,其主要赋存物相为高岭石、石英和云母;采用碱焙烧法以及氢氟酸法相结合的工艺可以使脱硅率达到80%以上;采用酸浸加压等强化措施后,最终得到的石墨纯度可达99.56%;碱焙烧过程的活化能为40.694kJ/mol;降低了原矿平均粒度,提高了焙烧温度;添加矿化剂有助于提高脱硅效率。

关键词: 隐晶质石墨;脱硅作用;物相分析;动力学

中图分类号:TB 321 文献标识码:A 文章编号: 1672-7207(2005)01-0029-05

Baking Kinetics for Silicic Impurity in

Purification Process of Aphanitic Graphite

ZHANG Qing-cen, LIU Jian-ping, XIAO Qi

(School of Minerals Processing and Bioengineering, Central South University, Changsha 410083, China)

Abstract:Kinetic equation in the baking process of purifying aphanitic graphite were researched. Influence of the diameter of raw ore, alkali baking time and baking temperature on desilication was discussed. Phase analysis results show that it is difficult to eliminate silicic impurity. Kaoline, silicon dioxide and mica are the most familiar silicic impurity in the raw ore. A high silicic transform rate over 80% can be obtained by a special technology combining alkali leaching and hydrofluoric acid soaking. The purity of the graphite reaches 99.56% by high-pressure acid leaching method. Kinetic results show that the activation energy is 40.964 kJ/mol in the alkali leaching process. Reducing average grain size of raw ore, prolonging aikali baking time and addingmineralizer are all helpful to increasing the silicic transform rate.

Key words: aphanitic graphite; desilication ; phase analysis; kinetics

我国石墨矿资源丰富,石墨产量和出口量居世界前列[1]。出售和出口的石墨产品以原矿及初级加工产品为主,杂质含量高,成分复杂,应用范围窄,销售价格低。采用传统石墨提纯工艺如浮选提纯法对于微晶石墨提纯的效果不理想。自20世纪90年代以来,人们针对石墨化学性质稳定,一般条件下不与各种强酸、碱、强氧化剂及还原剂、各种有机和无机溶剂发生作用的特征,相继开发出了高温碱法、酸洗法、氯化焙烧法[2,4]、氢氟酸法等化学提纯工艺,不仅使石墨产品成本降低,而且提高了产品质量[5-7]。然而,在提纯时,由于针对性不强,造成的药剂消耗量大,能耗大,设备腐蚀严重及污染严重等问题,运用这些提纯工艺无法实现大规模工业化生产。某些已应用于生产的工艺则存在产品中硅、氯杂质含量超标、产品质量不稳定等问题。

针对这些情况,作者以氢氟酸法结合高温碱焙烧法的两步法处理工艺对产出高纯微晶石墨产品的工艺路线及硅元素在各工序中的行为进行研究,以脱硅率为指标,对各阶段硅杂质的物相进行分析,结合试验建立硅在焙烧阶段反应的动力学模型。

1 试验方法及原料

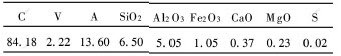

以湖南郴州隐晶质石墨为原料,其化学成分如表1所示。

表 1 隐晶质石墨样品中杂质含量

Table 1 Content of impurity in

aphanitic graphitew/%

硅的存在物相中,硅酸盐的含量达到石墨总质量的4.17%,石英含量则为2.33%。原矿的X射线衍射图谱如图1所示。可以看出,石墨中的硅杂质成分种类较少,石英、高岭石和云母是主要成分,但这些化合物的化学活性都不高,云母由于层内各原子间结合紧密,尽管层间结合力很弱(云母是完全解离型晶体),其硬度反而比石墨的高(云母莫氏硬度为3),化学提纯时反应很难进行[2],溶出相对困难。此外,X射线衍射图谱中未能检测到游离石英,而化学分析出的石英含量却相当高,表明游离石英结晶较差,晶体颗粒上嵌布大量缺陷,化学活性较高,在进行化学处理时易于和氢氧化钠等化学试剂作用生成相应的硅酸盐而被除去[3,4]。

—云母; ■—高岭石; □—石墨; ○—水碳酸钠

1—原矿; 2—碱焙烧样(未水洗); 3—碱焙烧样(已水洗);

4—盐酸浸出矿; 5—氢氟酸酸浸(混盐酸)

图 1 石墨原矿的X射线衍射图

Fig. 1 X-ray diffraction patterns of raw graphite

石墨提纯试验流程如图2所示。其中,烧碱和混合酸使用量按照化学计算量的130%计。

图 2 石墨提纯试验流程图

Fig. 2 Flow chart of graphite

purifying experiment

2 试验结果及分析

2.1 物相

由图1可见,石墨原矿中硅的主要存在物相为高岭石、石英和云母,经加碱焙烧,绝大部分石英和所有高岭石转化为可溶性硅酸盐,经水洗,可溶性硅酸盐中有少许水解成为硅胶而残留于石墨中,其余都溶解于水而与石墨分离;在以上过程中,以云母形式存在的硅基本上没有参与反应,因此,经焙烧、水洗后,石墨中仍存在的硅主要为云母、石英和硅胶细粒。采用氢氟酸酸浸可以有效地消除这些杂质,使其转化为水溶性的氟硅酸盐。因此,经氢氟酸浸和水洗后,石墨的纯度明显提高,采用酸浸过程加压等强化除杂措施后,石墨的固定碳含量可达99.56%。此时,脱硅率为98.16%,与采用提纯效果最好的高温提纯法所达到的脱硅率99.5%相近[8]。

2.2 碱焙烧过程动力学研究

2.2.1 焙烧过程控制机制

不可逆过程控制机制一般通过活化能来判定。活化能处于40~300 kJ/mol范围时,反应处于低温区,过程为动力学所控制;活化能在8~20 kJ/mol时,反应为扩散过程所控制[9]。反应

SiO2(s)+2NaOH(l)=Na2SiO3(l)+H2O(g)

的产物浓度对于反应速率的影响忽略不计。因发生如下反应:

Na2SiO3(l)+ SiO2(s)= Na2O·2SiO2(l)

考虑到熔碱的共同影响,反应产物对于反应速率的影响可忽略不计,因此,硅的碱焙烧过程可认为是一级的不可逆反应。

对于不可逆反应,确定活化能的方法一般是在温度以外其他参数保持恒定时,对反应时间-转化率曲线使用阿累尼乌斯公式进行处理。

设反应温度为T1和T2时,其反应速率常数K1和K2分别为

其中: K0为常数;E为反应活化能;R为摩尔气体常数,R=8.314 J/(mol·K)。

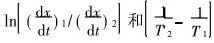

在对不同温度的动力学曲线进行研究时,可认为在微小时间段Δt内反应速率为常数,在T1和T2温度下达到相同转化率后某一特定时间段Δt内的反应速率分别为 ,则有

,则有

对不同温度下的动力学曲线进行处理,将所得 数据进行线性回归,所得直线的斜率即为

数据进行线性回归,所得直线的斜率即为 的值。

的值。

在温度为350,450,550和650℃时焙烧时间与浸出率的关系如图3所示。

图 3 不同温度下除杂时间与硅杂质的浸出率ηsi的关系

Fig. 3 Relationship between time and leachingrate at different temperature

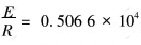

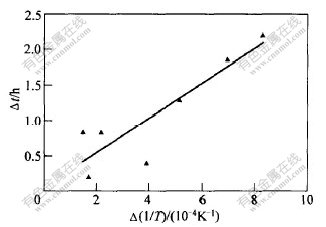

Δt和Δ(1/T)的关系如图4所示。所得直线的斜率为0.506 6,即 ,故E=40.694 kJ/mol。因此,可以确定反应为动力学所控制。

,故E=40.694 kJ/mol。因此,可以确定反应为动力学所控制。

2.2.2 焙烧过程的动力学方程

假定杂质成分在石墨中均匀分布,石墨在粉磨后呈球状。浸出时(包括碱焙烧和酸浸),浸出剂呈液态紧密包裹在硅矿物的周围,此时,反应方程式为:

SiO2(s)+2NaOH(l)=Na2SiO3(l)+H2O(g)。

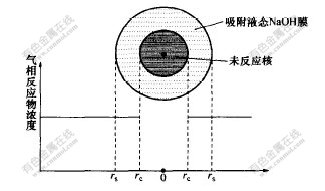

抽象为:A(l)+bB(s)=C(l)+D(g)。其中,b为反应的化学计量系数[8,9]。反应进行到某时刻t时的动力学模型如图5所示。

图 4 针对图3得到的参数Δt与Δ(1/T)的关系

Fig. 4 Relationship between Δt and Δ(1/T)

图 5 碱熔出硅的动力学模型

Fig. 5 Dynamic model in alkali leaching

图5中,rs和rc分别为某时刻杂质颗粒吸附溶出介质(主要是生成物的溶液)后颗粒的粒径及未反应部分的粒径。未反应核内的液相反应物浓度为零。

碱焙烧过程中,由于硅氧键具有很高的键能,反应体系温度固定在450℃时,氢氧化钠刚好融熔,而硅氧键基本上没有因为升温而遭到破坏,因此,氢氧化钠与二氧化硅的反应速度并不快,整个反应过程为化学反应所控制,也就是说,硅的溶出反应符合化学反应控制的未反应收缩核模型。此时,矿粒外表面与吸附流体膜内各处氢氧化钠的浓度处处相等,设该浓度为Cc,硅杂质颗粒的初始粒径为r0,某时刻t时颗粒的粒径为rc,则Cs=Cc;于是t时刻颗粒与碱熔体反应的速率表达式为:

其中: GA为体系在该时刻的反应物A的自由能;S为解除面积;K为反应速率常数。而对于反应物A和B,有

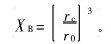

由几何知识知,球形固体颗粒反应物B的转化率XB为:

结合式(5)可以得出:

对于云母类硅酸盐,由于矿物颗粒具有圆板状的形状,其圆板面的化学稳定性良好[10],能较好地抵御烧碱的侵蚀,反应主要发生在结构缺陷较多的边缘区域,因此,该类杂质矿物的溶出反应应采用圆柱体模型,即转化率符合如下表达式:

相应地,杂质云母碱溶时的转化率表达式为:

由阿累尼乌斯公式,温度为T时反应速率常数应为:

2.2.3 反应时间对脱硅的影响

式(7)中,如果反应物A即氢氧化钠保持过量,氢氧化钠的浓度视为常数,r0用硅颗粒的平均粒径代替,那么物理量 可视为常数,设该常数为P,P的大小受反应速率常数K(由式(9)可知,反应活化能对K的影响最大,且K随温度增加而升高)、杂质成分的粒径及密度、溶出剂浓度共同影响,于是,式(7)可以简化为:

可视为常数,设该常数为P,P的大小受反应速率常数K(由式(9)可知,反应活化能对K的影响最大,且K随温度增加而升高)、杂质成分的粒径及密度、溶出剂浓度共同影响,于是,式(7)可以简化为:

展开得: XB=P3t3-3P2t2+3Pt。 (11)

其中:0≤Pt≤1。由于 中各参数已确定,可得P=0.312 s-1,将不同时间点代入上式,求出相应的XB,即可估算出反应完全时(XB=1)所需时间约为3.115 h,这里取3.2 h。

中各参数已确定,可得P=0.312 s-1,将不同时间点代入上式,求出相应的XB,即可估算出反应完全时(XB=1)所需时间约为3.115 h,这里取3.2 h。

根据式(11)的计算结果与实验结果的对比结果如图6所示。可见,计算结果与实验反应进程非常接近,2条曲线不完全吻合的原因是焙烧温度太低,时间太短,云母化学性质不活泼。

反应条件:每100 g石墨加碱30 g,焙烧温度450℃;

用足量盐酸进行酸处理,体系总体积600 mL,酸浸温度80℃,

酸浸时间3 h,依据为石墨中硅杂质残留量

图 6 反应物B的转化率XB的计算结果

与实验结果比较

Fig. 6 Comparison of calculated results and

testing results of XB

2.2.4 焙烧温度对脱硅的影响

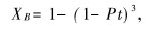

焙烧温度对脱硅效果的影响如图7所示。

图 7 焙烧温度对提纯效果的影响

Fig. 7 Effect of baking temperature

on leaching rate

由阿累尼乌斯公式可知,反应速率常数随温度的升高迅速提高(速率常数随-1/T的增大呈指数升高),因此,可以预料,在不产生副反应的前提下,适当升温可以提高反应的效率,提高产品的纯度。由图7可知,反应温度低于450℃时,升温使硅的脱除率急剧升高,产品中硅含量随之下降;温度高于450℃后,继续升温,硅的脱除率只是缓慢提高。

由式(7)和式(8)可知反应物B的转化率受几个因素的共同影响:反应物A浓度不变时(如模型中架设),反应物B初始粒径r0越小,反应物B的密度越小,摩尔质量越大,反应时间越长,则B的转化率越大;由(9)式可知,反应时间一定时,提高温度导致速率常数K迅速提高,因此,可以预料,高温对于反应的快速发生有利;另外,添加适当的矿化剂以降低反应的活化能,能大幅度提高反应的速率。由于反应的不可逆性,虽然反应属于放热反应,温度的升高不会导致反应平衡往逆方向移动,因此,可以适当升温以提高反应速率,降低原料的初始粒径,达到提高除硅效率的目的[9]。

3 结 论

a.石墨提纯过程各阶段的X射线衍射图谱表明,微晶石墨中的硅杂质主要是高岭石、云母和游离石英。

b.焙烧过程的活化能为40.694 kJ/mol,焙烧过程为化学反应控制过程。

c.以化学反应控制为基础建立了石墨中杂质焙烧过程的动力学模型,推导出了该种情况下的动力学方程。

d. 降低原矿平均粒度,提高烧结温度,添加矿化剂,均有助于提高脱硅效率。

参考文献:

[1] LU Xian-jun, FORSSBERG E. Preparation of High-purity and Low-sulphur Graphite from Woxna Fine Graphite Concentrate by Alkali Roasting[J]. Materials Engineering, 2002,15(10):755-757.

[2]BONNISSEL M, LUO L, TONDER D. Compacted Exfoliated Natural Graphite as Heat Conduction Medium[J]. Carbon, 2001,39(1):2151-2161.

[3]王光民.高纯石墨生产工艺探讨[J].非金属矿,2001,24(4):30-31

WANG Guang-min. Discussion in the Super-pure Graphite Production Technics[J]. Non-metals Mine, 2001,24(4):30-31.

[4]周永兴,赵秀如. 土状石墨提纯[J].岩矿测试,2001,20(1):283-284.

ZHOU Yong-xing, ZHAO Xiu-ru. Purifying of Clay-liked Graphite[J].Rock and Mineral Analysis, 2001,20(1): 283-284.

[5]李常清,韦永德.液相化学法制取高纯石墨研究[J].非金属矿,2002,25(2):35-37.

LI Chang-qing, WEI Yong-de. A Study on Purifying Graphite by Fluid-chemical Method[J]. Non-metals Mines, 2002, 25(2):35-37.

[6]刘槐清,谢有赞.隐晶质石墨的高温碱煅烧法提纯工艺研究[J].碳素技术,2000, (1):12-14.

LIU Huai-qing, XIE You-zan. Study on Purification Technology of Aphanitic Graphite by Calcining Under High Temperature and Alkali[J]. Carbon Technologies, 2000,(1):12-14.

[7]张向军,陈斌.高温石墨化提纯晶质(鳞片)石墨[J].碳素技术,2001,(2):39-40.

ZHANG Xiang-jun, CHEN Bin. Depuration of Scaly Graphite by High Temperature Graphitization[J]. Carbon Technologies, 2001,(2): 39-40.

[8]杨华明.搅拌磨超细粉碎及机械化学的研究[D].长沙:中南工业大学矿物工程系,1998.

YANG Hua-ming. A Detailed Study on Ultrafine Grinding and Mechano-chemistry of Stirred Mill[D]. Changsha: Department of Mineral Engineering, Central South University of Technology, 1998.

[9]莫鼎成.冶金动力学[M].长沙:中南工业大学出版社,1987.

MO Ding-cheng. Metallurgic Dynamics[M]. Changsha: Press of Central South University of Technology, 1987.

[10]刘建平.隐晶石墨纯化研究[D] .长沙:中南大学资源与生物工程学院,2004.

LIU Jian-ping. Research in the Purification of Aphanitic Graphite[D]. Changsha: School of Minerals Processing & Bioengineering, Central South University, 2004.

收稿日期:2004-06-04

基金项目:国家自然科学基金资助项目(50374083)

作者简介:张清岑(1945-),男,河南南阳人,教授,从事超细粉体分散、磁性材料等研究

论文联系人: 刘建平,男,硕士;电话:0731-8830543(O);E-mail: Qingcen@mail.csu.edu.cn